Abstract

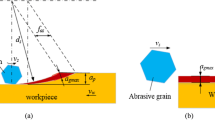

This study introduces a pioneering three-dimensional simulation model for Abaqus multi-grit grinding, developed via Python’s secondary capabilities. The model generates random 48-sided abrasive grains arranged on a cylinder following a characteristic distribution pattern, thus emulating a 200-grit micro-abrasive rod. The model considers varying spindle speeds, grinding depths, and feed rates to investigate the influence of multi-grit on the surface profiles of chips and workpieces for the nickel-based single-crystal Superalloy DD5. The multi-grain simulation reveals that grain 1 produces serrated chips at 60 kr/min in 46% of the global process, increasing to 60% at 80 kr/min. Abrasive generation and grinding initiation occur 10% and 12% earlier, respectively, at 100 kr/min compared to 80 kr/min Additionally, peak grinding forces rise with displacement as spindle speed increases. With a feed rate of 2 m/s, serrated chips constitute 36% of the global process in grain 1, increasing to 50% at 3 m/s. At a peak feed rate of 4 m/s, grinding force decreases as displacement increases. The normal distribution of abrasive particles causes an increase in the number of particles involved in grinding as grinding depth grows. This innovative model contributes valuable insights into the complex dynamics of multi-grit grinding processes and optimization strategies.

Similar content being viewed by others

Data availability

All data and materials used to produce the results in this article can be obtained upon request from the corresponding authors.

Code availability

Not applicable.

References

Miao Q, Ding WF, Kuang WJ, Xu JH (2020) Tool wear behavior of vitrified microcrystalline alumina wheels in creep feed profile grinding of turbine blade root of nickel-based superalloy. Tribol Int 145:0301-679X. https://doi.org/10.1016/j.triboint.2019.106144

Li Q, Gou CG, Ding GS, Leng YF, Yue HT (2020) Research on milling subsurface layer damages of DD5 Ni-based superalloy. China Mech Eng 31:2638–2645. https://doi.org/10.3969/j.issn.1004-132X.2020.21.015

Cui RJ, Huang ZH (2016) Microstructual evolution and stability of second generation nickel-based superalloy DD5. Nonferrous Met Soc China Trans 26:2079–2085. https://doi.org/10.1016/S1003-6326(16)64323-6

Zhang H, Gong YD, Liang CY, Sun Y, Zhao JB (2023) Study on milling material removal mechanism and surface integrity of nickel-based single crystal superalloy DD5. Int J Adv Manuf Technol 125:2323–2338. https://doi.org/10.1007/s00170-022-10448-0

Sun Y, Su ZP, Gong YD, Ba DC, Yin GQ, Zhang H, Zhou LH (2021) Analytical and experimental study on micro-grinding surface-generated mechanism of DD5 single-crystal superalloy using micro-diamond pencil grinding tool. Archiv Civ Mech Eng 21:1644–9665. https://doi.org/10.1007/s43452-020-00163-6

Doman DA, Warkentin A, Bauer R (2009) Finite element modeling approaches in grinding. Int J Mach Tools Manuf 49:0890–6955. https://doi.org/10.1016/j.ijmachtools.2008.10.002

Li C, Li XL, Wu YQ, Zhang FH, Huang H (2019) Deformation mechanism and force modelling of the grinding of YAG single crystals. Int J Mach Tool Manuf 143:0890–6955. https://doi.org/10.1016/j.ijmachtools.2019.05.003

Ding ZS, Sun GX, Guo MX, Jiang XH, Li BZ, Liang SY (2020) Effect of phase transition on micro-grinding induced residual stress. J Mater Process Technol 281:0924–136. https://doi.org/10.1016/j.jmatprotec.2020.116647

Cheng J, Gong YD (2014) Experimental study of surface generation and force modeling in micro-grinding of nickel-based silicon considering crystallographic effects. Int J Mach Tools Manuf 77:0890–6955. https://doi.org/10.1016/j.ijmachtools.2013.10.003

Magomedov IA, Sebaeva ZS (2020) Comparative study of finite element analysis software packages. J Phys Conf Ser 1515:1742–6596. https://doi.org/10.1088/1742-6596/1515/3/032073

Chen X, Öpöz TT, Oluwajobi A (2017) Analysis of grinding surface creation by single-grit approach. J Manuf Sci Eng 139:1087–1357. https://doi.org/10.1115/1.4037992

Flavia F, Erica L, Enrico L, Alessandro F (2022) Real single grain grinding finite element method simulation for case-hardened steel based on equivalent contact area analysis. J Manuf Sci Eng 144:1087–1357. https://doi.org/10.1115/1.4051536

Chaudhari A, Sharma A, Awale AS, Yusufzai MZK, Vashista M (2022) Modeling and simulation study of dry ultrasonic vibration-assisted grinding of tool steel with single alumina abrasive grit. J Manuf Sci Eng 144:1037–1857. https://doi.org/10.1115/1.4054602

Kadivar M, Shamray S, Soltani B, Daneshi A, Azarhoushang B (2019) Laser-assisted micro-grinding of Si3N4. Precis Eng 60:0141–6359. https://doi.org/10.1016/j.precisioneng.2019.09.004

Zhu T, Cai M, Gong YD, Gao XJ, Yu N, Li X (2022) Study on chip formation in grinding of nickel-based polycrystalline superalloy GH4169. Int J Adv Manuf Technol 121:1135–1148. https://doi.org/10.1007/s00170-022-09386-8

Yang M, Li CH, Zhang YB, Jia DZ, Li RZ, Hou YL, Cao HJ, Wang J (2019) Predictive model for minimum chip thickness and size effect in single diamond grain grinding of zirconia ceramics under different lubricating conditions. Ceram Int 45:0272–8842. https://doi.org/10.1016/j.ceramint.2019.04.226

Sopeltzev A, Dyakonov A, Patra K (2015) Dynamic model of material deforming under micro-grinding. Procedia Eng 129:1877–7058. https://doi.org/10.1016/j.proeng.2015.12.020

Johannes R, Thomas F, Waimer Matthias W, Anoush P, Heinz V, Rrza V (2021) Axial crush simulation of composites using continuum damage mechanics: FE software and material model independent considerations. Compos Part B-Eng 225:1359–8368. https://doi.org/10.1016/j.compositesb.2021.109284

Karkalos NE, Markopoulos AP, Kundrák J (2017) Molecular dynamics model of nano-metric peripheral grinding. Procedia CIRP 58:2212–8271. https://doi.org/10.1016/j.procir.2017.03.189

Zhou P, Zhu NN, Xu CY, Niu FL, Li J, Zhu YW (2021) Mechanical removal of SiC by multi-abrasive particles in fixed abrasive polishing using molecular dynamics simulation. Comput Mater Sci 191:0927–251. https://doi.org/10.1016/j.commatsci.2021.110311

Fan WG, Zhang S, Wang JD, Wang XH, Wang WX (2020) Temperature field of open-structured abrasive belt rail grinding using FEM. Int J Simul Model 19:1726–4529. https://doi.org/10.2507/IJSIMM19-2-CO10

Gong YD, Wang B, Wang WS (2002) The simulation of grinding wheels and ground surface roughness based on virtual reality technology. J Mater Process Technol 129:0924–136. https://doi.org/10.1016/S0924-0136(02)00589-7

Sirigiri VKR, Gudiga VY, Gattu US, Suneesh G, Buddaraju KM (2022) A review on Johnson Cook material model. Mater Today Proc 62:3450–3456. https://doi.org/10.1016/j.matpr.2022.04.279

Yıldız A, Kurt A, Yağmur S (2020) Finite element simulation of drilling operation and theoretical analysis of drill stresses with the deform-3D. Simul Model Pract Th 104:1569–2190. https://doi.org/10.1016/j.simpat.2020.102153

Zhang XL, Yao B, Feng W, Sheng ZH (2014) Modeling of virtual grinding wheel based on random distribution of multi-abrasive grains and prediction of grinding force. Acta Aeronaut Astronaut Sin 35:3489–3498. https://doi.org/10.7527/S1000-6893.2014.0065

Wang B, Wang H, Zhang ZQ, Zhou MJ (2018) Study on mesoscopic modeling method for three-dimensional random concave-convex concrete aggregate. Chin J Appl Mech 35:1072–1076. https://doi.org/10.11776/cjam35.05.B062

Setti D, Arrabiyeh PA, Kirsch B, Heintz M, Aurich JC (2020) Analytical and experimental investigations on the mechanisms of surface generation in micro grinding. Int J Mach Tool Manuf 149:0890–6955. https://doi.org/10.1016/j.ijmachtools.2019.103489

Zhang Y, Wu T, Li C, Wang YF, Geng YQ, Dong GJ (2019) Numerical simulations of grinding force and surface morphology during precision grinding of leucite glass. Int J Mech Sci 231:0020–7403. https://doi.org/10.1016/j.ijmecsci.2022.107562

Yang ZC, Zhu LD, Lin B, Zhang GX, Ni CB, Sui TY (2019) The grinding force modeling and experimental study of ZrO2 ceramic materials in ultrasonic vibration assisted grinding. Ceram Int 45:8873–8889. https://doi.org/10.1016/j.ceramint.2019.01.216

Na Y, Lee US, Kim BH (2021) Experimental study on micro-grinding of ceramics for micro-structuring. Appl Sci 11:2076–3417. https://doi.org/10.3390/app11178119

Park HW, Liang SY (2008) Force modeling of micro-grinding incorporating crystallo-graphic effects. Int J Mach Tool Manuf 48:1658–1667. https://doi.org/10.1016/j.ijmachtools.2008.07.004

Philip AM, Chakraborty K (2023) The Johnson Cook model for the machinability study. Mater Today Proc 80:2214–7853. https://doi.org/10.1016/j.matpr.2023.02.371

Zhang JH, Ge PQ, Zhang L (2007) Research on the grinding force based on the probability statistics. China Mech Eng 18:2399–2402. https://doi.org/10.3321/j.issn:1004-132x.2007.20.002

Takahashi Y, Kobayashi D, Fujii S, Takuma M, Saitoh K, Sato T (2022) Time-dependent crack growth mechanism in Ni-based single crystal superalloys at high-temperature. Mater Sci Eng A 859:0921–5093. https://doi.org/10.1016/j.msea.2022.144179

Gong SQ, Sun Y, Jin LY, Su ZP (2020) Experimental study on fabricating micro-holes in DD5 single-crystal nickel-based superalloy using electrical discharge drilling. Archiv Civ Mech Eng 20:1644–9665. https://doi.org/10.1007/s43452-020-00089-z

Qiu J, Yang T, Zhang ZY, Li Q, Yan ZX, Wang LB (2022) On the anisotropic milling machinability of DD407 single crystal nickel-based superalloy. Materials (Basel) 15:1996–1944. https://doi.org/10.3390/ma15082723

Zhang H, Gong YD, Liang CY, Su Y, Zhao JB, He ZF (2023) Effect of thermal exposure on subsurface microstructure evolution of nickel-based single crystal superalloy DD5 after milling. J Manuf Process 97:1526–6125. https://doi.org/10.1016/j.jmapro.2023.05.010

Li SC, Xiao GJ, Zhuo XQ, Chen BQ, Zhao ZY, Huang Y (2023) Fatigue performance and failure mechanism of ultrasonic-assisted abrasive-belt-ground Inconel 718. Int J Fatigue 168:0142–1123. https://doi.org/10.1016/j.ijfatigue.2022.107406

Gong YD, Zhou YG, Wen XL, Cheng J, Sun Y, Ma LJ (2017) Experimental study on micro-grinding force and subsurface microstructure of nickel-based single crystal superalloy in micro grinding. J Mech Sci Technol 31:3397–3410. https://doi.org/10.1007/s12206-017-0629-8

Cai M, Zhu T, Gao XJ, Yan YF, Yu N, Zeng L (2022) Study on machining performance in grinding of Ni-based single crystal superalloy DD5. Int J Adv Manuf Technol 120:7657–7671. https://doi.org/10.1007/s00170-022-09256-3

Cheng TW, Wang Y, Zhao YX, Lv LX, Hu Q, Ma DX (2016) Effect of remelting solution heat treatment on microstructure evolution of nickel-based single crystal superalloy DD5. Mater Charact 192:1044–5803. https://doi.org/10.1016/j.matchar.2022.112186

Li P, Jiang W, Rui SS, Yao WX, Shi HJ, Han QN, Huang J (2021) Effect of misorientation on the fatigue life of nickel-base single crystal superalloy DD5 at 980 °C. Int J Fatigue 153:0142–1123. https://doi.org/10.1016/j.ijfatigue.2021.106479

Funding

This work was supported by the National Natural Science Foundation of China (NO. U1908230), the Natural Science Foundation of Liaoning Province (NO. 2023-BS-185), the Science and Technology Research Project of the Educational Department of Liaoning Province (NO. LJKZ0384), the Talent Scientific Research Fund of LNPU (NO. 2021XJJL-007).

Author information

Authors and Affiliations

Contributions

Minghui Chen: writing — original draft, software, investigation, visualization. Ming Cai: writing — original draft, review and editing, conceptualization, funding, visualization. Yadong Gong: supervision, investigation, methodology. Tao Zhu: data curation, formal analysis. Qiang Gong: data curation, formal analysis. Yu Liu: data curation, formal analysis.

Corresponding author

Ethics declarations

Ethical approval

The authors declare that there is no ethical issue applied to this article.

Consent to participate

The authors declare that all authors have read and approved to submit this manuscript to IJAMT.

Consent for publication

The authors declare that all authors agree to sign the transfer of copyright for the publisher to publish this article upon on acceptance.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chen, M., Cai, M., Gong, Y. et al. Study on the removal mechanism in multi-abrasive micro-grinding of nickel-based superalloy. Int J Adv Manuf Technol 128, 2199–2220 (2023). https://doi.org/10.1007/s00170-023-12040-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12040-6