Abstract

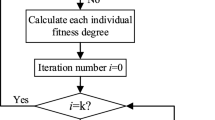

In the milling process of thin-walled parts, chatter is very easy to occur, which has a very adverse impact on the surface quality and machining efficiency of the workpiece. In order to solve the problem of low accuracy of milling state identification caused by few initial samples and dynamic changes in the milling process, a hybrid online evolutionary chatter identification model combining unsupervised learning and supervised learning was proposed. First of all, aiming at the problem that traditional K-means algorithm is difficult to adapt to online dynamic clustering of milling chatter, an online incremental-sparse K-means algorithm (ISK-Means) was proposed, and the dynamic incremental-sparse strategy of K-means was designed. Second, aiming at the problem that the online sequential extreme learning machine (OS-ELM) algorithm directly adds its predicted samples to the training sample set during the incremental learning process, and the pseudo-samples in the training sample set would lead to the degradation of the OS-ELM model, a hybrid online evolutionary chatter identification model combining the ISK-means and the OS-ELM was proposed, and the online identification and evolution strategy was designed. Finally, the experimental results show that the ISK-means algorithm can greatly improve the clustering efficiency and is suitable for milling chatter online dynamic clustering. Meanwhile, compared with the existing model, the recognition accuracy of the hybrid online evolutionary chatter recognition model combined with ISK-means algorithm and OS-ELM algorithm is improved by 1.31%. This is of great significance for the online control of subsequent chatter.

Similar content being viewed by others

Data availability

The raw/processed data required to reproduce these findings cannot be shared for the time being. Data will be made available upon request.

References

Wang ZX, Liu XL, Li MY, Wang LH, Liang SY, Yu FH (2022) Multi-point contact stability prediction considering force-induced deformation effect in milling thin-walled parts. J Mech Eng 58(17):309–320. https://doi.org/10.3901/JME.2022.17.309

Quintana G, Ciurana J (2011) Chatter in machining processes: a review. Int J Mach Tools Manuf 51(5):363–376. https://doi.org/10.1016/j.ijmachtools.2011.01.001

Lamraoui M, Barakat M, Thomas M, Badaoui ME (2015) Chatter detection in milling machines by neural network classification and feature selection. J Vib Control 21(7):1251–1266. https://doi.org/10.1177/1077546313493919

Wang L, Pan J, Shao Y, Zeng Q, Ding X (2021) Two new kurtosis-based similarity evaluation indicators for grinding chatter diagnosis under non-stationary working conditions. Measurement 176(2):109215. https://doi.org/10.1016/j.measurement.2021.109215

Wang C, Zhang X, Chen X (2022) Real time FFT identification based time-varying chatter frequency mitigation in thin-wall workpiece milling. Int J Adv Manuf Technol 119(11–12):7403–7413. https://doi.org/10.1007/s00170-022-08755-7

Perrelli M, Cosco F, Gagliardi F, Mundo D (2022) In-process chatter detection using signal analysis in frequency and time-frequency domain. Machines 10(1):24. https://doi.org/10.3390/machines10010024

Wang Y, Zhang M, Tang X, Peng F, Yan R (2021) A kmap optimized VMD-SVM model for milling chatter detection with an industrial robot. J Intell Manuf 33(5):1483–1502. https://doi.org/10.1007/s10845-021-01736-9

Yang K, Wang GF, Dong Y, Zhang QB, Sang LL (2019) Early chatter identification based on an optimized variational mode decomposition. Mech Syst Signal Process 115:238–254. https://doi.org/10.1016/j.ymssp.2018.05.052

Liu XL, Wang ZX, Li MY, Yue CX, Liang SY, Wang LH (2021) Feature extraction of milling chatter based on optimized variational mode decomposition and multi-scale permutation entropy. Int J Adv Manuf Technol 114:2849–2862. https://doi.org/10.1007/s00170-021-07027-0

Wang YQ, Bo QL, Liu HB, Hu L, Zhang H (2018) Mirror milling chatter identification using Q-factor and SVM. Int J Adv Manuf Technol 98(5–8):1163–1177. https://doi.org/10.1007/s00170-018-2318-x

Zheng QZ, Chen GS, Jiao AL (2022) Chatter detection in milling process based on the combination of wavelet packet transform and PSO-SVM. Int J Adv Manuf Technol 120(1):1237–1251. https://doi.org/10.1007/s00170-022-08856-3

Krishnan PS, Rameshkumar K, Krishnakumar P (2020) Hidden Markov modelling of high-speed milling (Hsm) process using acoustic emission (Ae) signature for predicting tool conditions. Advances in Materials and Manufacturing Engineering. Lecture Notes in Mechanical Engineering, Springer, Singapore, pp 5731–580. https://doi.org/10.1007/978-981-15-1307-7_65

Han ZY, Jin HY, Fu HY (2016) Modeling of chatter recognition system in CNC milling based on ESPRIT and hidden Markov model. Comput Integr Manuf Syst 22(8):1938–1944. https://doi.org/10.13196/j.cims.2016.08.012

Shrivastava Y, Singh B (2018) Possible way to diminish the effect of chatter in CNC turning based on EMD and ANN approaches. Arab J Sci Eng 43:4571–4591. https://doi.org/10.1007/s13369-017-2993-1

Lamraoui M, Barakat M, Thomasm BME (2015) Chatter detection in milling machines by neural network classification and feature selection. J Vib Control 21(7):1251–1266. https://doi.org/10.1177/1077546313493919

Jeong K, Seong Y, Jeon J, Moon S, Park J (2022) Chatter monitoring of machining center using head stock structural vibration analyzed with a 1D convolutional neural network. Sensors 22(14):5432. https://doi.org/10.3390/s22145432

Liu YM, Ye GW, Zhao ZZ, Zhang Z (2023) Diagnosis model of RV reducer based on EEMD-PSO-ELM. Comput Integr Manuf Syst 29(01):224–235. https://doi.org/10.13196/j.cims.2023.01.019

Ma J, Liang S, Du Z, Chen M (2021) Compound fault diagnosis of rolling bearing based on ALIF-KELM. Math Probl Eng. https://doi.org/10.1155/2021/2636302

Dong W, Zhang S, Hu M, Zhang L, Liu H (2022) Intelligent fault diagnosis of wind turbine gearboxes based on refined generalized multi-scale state joint entropy and robust spectral feature selection. Nonlinear Dyn 107(3):2485–2517. https://doi.org/10.1007/s11071-021-07032-8

Yang Y, Liao QF, Wang J, Wang Y (2022) Application of multi-objective particle swarm optimization based on short-term memory and K-means clustering in multi-modal multi-objective optimization. Eng Appl Artif Intell: Int J Intell Real-Time Autom 112:104866. https://doi.org/10.1016/j.engappai.2022.104866

Bigdeli M, Abu-Siada A (2022) Clustering of transformer condition using frequency response analysis based on K-means and GOA. Electr Power Syst Res 202:107619. https://doi.org/10.1016/j.epsr.2021.107619

Feng C, Xu WQ, Chen LW, Hu Y, Gao S (2015) Turbine blade fault detection based on feature extraction. 12th IEEE International Conference on Electronic Measurement & Instruments (ICEMI),. IEEE, Qingdao, pp 146–152. https://doi.org/10.1109/ICEMI.2015.7494240

Peng Y, Wu T, Cao G, Huang S, Wu H, Kwok N, Peng Z (2017) A hybrid search-tree discriminant technique for multivariate wear debris classification. Wear 392–393:152–158. https://doi.org/10.1016/j.wear.2017.09.022

Arthur D , Vassilvitskii S (2007) K-means++: the advantages of careful seeding. In Proceedings of the Eighteenth Annual ACM-SIAM Symposium on Discrete Algorithms , New Orleans, Louisiana. Society for Industrial and Applied Mathematics. ACM, USA, pp 1027–1035. https://doi.org/10.1145/1283383.1283494

Dong Z, Men Y, Li Z (2021) Chilling injury segmentation of tomato leaves based on fluorescence images and improved K-means++ clustering. Trans ASABE 64(1):13–22. https://doi.org/10.13031/trans.13212

Mehdizadeh M, Macnish C, Khan RN, Bennamoun M (2011) Semi-supervised neighborhood preserving discriminate embedding: a semi-supervised subspace learning algorithm. Lect Notes Comput Sci 6494:199–212. https://doi.org/10.1007/978-3-642-19318-7_16

Liang NY, Huang GB, Saratchandran P, Sundararajan N (2006) A fast and accurate online sequential learning algorithm for feedforward networks. Trans Neural Netw IEEE 17(6):1411–1423. https://doi.org/10.1109/TNN.2006.880583

Yin G, Zhang YT, Li Z, Cheng LJ (2013) Fault diagnosis based on online sequential extreme learning machine. J Vib Meas Diagn 33(2):325–329. https://doi.org/10.16450/j.cnki.issn.1004-6801.2013.02.015

Xiao SZ, Zhang F, Huang XZ (2022) Online thickness prediction of hot-rolled strip based on ISSA-OSELM. Int J Interact Des Manuf 16(3):1089–1098. https://doi.org/10.1007/s12008-021-00833-6

Ma YP, Niu PF, Yan SS, Li GQ (2018) A modified online sequential extreme learning machine for building circulation fluidized bed boiler’s NOx emission model. Appl Math Comput 334:214–226. https://doi.org/10.1016/j.amc.2018.03.010

Gu ZY, Pang SW, Zhou WX, Li YC, Li QH (2022) An online data-driven LPV modeling method for turbo-shaft engines. Energies 15(4):1255. https://doi.org/10.3390/en15041255

Huang GB, Zhu QY, Siew CK (2006) Extreme learning machine: theory and applications. Neurocomputing 70(1–3):489–501. https://doi.org/10.1016/j.neucom.2005.12.126

Funding

This work was financially supported by (1) International (regional) cooperation and exchange program of national Natural Science Foundation of China under Grant No. 51720105009, (2) National Natural Science Foundation of China under Grant No. 52175393, and (3) China Postdoctoral Science Foundation under Grant No. 2023MD734168.

Author information

Authors and Affiliations

Contributions

Zhixue Wang has designed the experiments, analyzed and arranged data, and written the manuscript; Caixu Yue has conducted the experiments, analyzed and arranged data, and written the manuscript; Xianli Liu has organized the project and collected and analyzed data; Maoyue Li has conducted the experiments and collected and analyzed data; Boyang Meng and Liying Yong have reviewed the manuscript.

Corresponding author

Ethics declarations

Ethical approval

The research does not involve human participants or animals and the authors warrant that the paper fulfills the ethical standards of the journal.

Consent to participate

It is confirmed that all the authors are aware and satisfied of the authorship order and correspondence of the paper.

Consent for publication

All the authors are satisfied that the last revised version of the paper is published without any change.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, Z., Yue, C., Liu, X. et al. On-line evolutionary identification technology for milling chatter of thin walled parts based on the incremental-sparse K-means and the online sequential extreme learning machine. Int J Adv Manuf Technol 128, 2001–2011 (2023). https://doi.org/10.1007/s00170-023-12030-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12030-8