Abstract

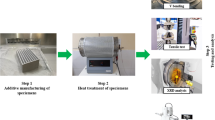

In this study, we have investigated the microstructural changes during deformation of the SLM samples printed Inconel 718 using hot torsion tests. Prior to thermomechanical testing, the as-built samples are homogenized at 850 °C for 2 h in Ar atmosphere followed by air cooling. Hot torsion tests are performed at temperatures of 800, 1000 and 1100 °C, and at strain rates of 0.01, 0.1 and 1 s−1. It is observed that the dynamic recrystallization mechanism progresses with the evolution of annealing twins which is quantified by the increase in % of annealing twins during thermomechanical deformation. It is observed that samples deformed at 850 °C for strain rates of 0.01 and 0.1 s−1 shows brittle like fracture and no dynamic recrystallization. However, the samples deformed at 1000 and 1100 °C for strain rates of 0.01, 0.1 and 1 s−1 shows typical stress strain curves obtained for dynamic recrystallization. It is noted that the peak stress decreases with an increase in the temperature and increases with an increase in the strain rate. Alongside, an activation energy (Q) of 379.62 kJ/mol for SLMed Inconel 718 samples is calculated which agrees with the reported values in the literature for Hot compression tests.

Similar content being viewed by others

References

Nowotnik A, Pędrak P, Sieniawski J, Góral M (2012) Mechanical properties of hot deformed Inconel 718 and X750. J Achiev Mater Manuf Eng 50(2):74–80

Yuan H, Liu WC (2005) Effect of the δ phase on the hot deformation behavior of Inconel 718. Mater Sci Eng A 408(1–2):281–289

Loria EA (1992) Recent developments in the progress of superalloy 718. JOM 44(6):33–36

Trosch T, Strößner J, Völkl R, Glatzel U (2016) Microstructure and mechanical properties of selective laser melted Inconel 718 compared to forging and casting. Mater Lett 164:428–431

Zhou LX, Baker TN (1995) Effects on dynamic and metadynamic recrystallization on microstructures of wrought IN-718 due to hot deformation. Mater Sci Eng A 196(1–2):89–95

Wang Y, Shao WZ, Zhen L, Zhang XM (2008) Microstructure evolution during dynamic recrystallization of hot deformed superalloy 718. Mater Sci Eng A 486(1–2):321–332

Garcia CI, Camus DE, Loria EA, DeArdo AJ (1991) Microstructural refinement of as-cast alloy 718 via thermomechanical processing. Superalloys 718(625):925–941

Thomas A, El-Wahabi M, Cabrera JM, Prado JM (2006) High temperature deformation of Inconel 718. J Mater Process Technol 177(1–3):469–472

Weis MJ, Mataya MC, Thompson SW, Matlock DK (1989) The hot deformation behavior of an as-cast alloy 718 ingot. Rockwell International Corp., Golden, CO (USA). Rocky Flats Plant

Mostafa A, Shahriari D, Rubio IP, Brailovski V, Jahazi M, Medraj M (2018) Hot compression behavior and microstructure of selectively laser-melted IN718 alloy. Int J Adv Manuf Technol 96:371–385

Li LX, Lou Y, Yang LB, Peng DS, Rao KP (2002) Flow stress behavior and deformation characteristics of Ti-3Al-5V-5Mo compressed at elevated temperatures. Mater Des 23(5):451–457

Zrnik J, Dobatkin SV, Mamuzić I (2008) Processing of metals by severe plastic deformation (SPD)–structure and mechanical properties respond. Metalurgija 47(3):211–216

Iturbe A et al (2017) Mechanical characterization and modelling of Inconel 718 material behavior for machining process assessment. Mater Sci Eng A 682:441–453. https://doi.org/10.1016/j.msea.2016.11.054

Zouari M, Logé R, Bozzolo N (2017) In situ characterization of Inconel 718 post-dynamic recrystallization within a scanning electron microscope. Metals 7(11):476. https://doi.org/10.3390/met7110476

Guo-Zheng Q (2013) Characterization for dynamic recrystallization kinetics based on stress-strain curves. Recent Dev Study Recryst: 61–64

Chen K et al (2015) Transition of deformation behavior and its related microstructure evolution in Nimonic 80A under hot-to-warm working. Mater Charact 106:175–184

Fatemi-Varzaneh SM, Zarei-Hanzaki A, Beladi H (2007) Dynamic recrystallization in AZ31 magnesium alloy. Mater Sci Eng A 456(1–2):52–57

Ferdowsi MRG, Mazinani M, Ebrahimi GR (2014) Effects of hot rolling and inter-stage annealing on the microstructure and texture evolution in a partially homogenized AZ91 magnesium alloy. Mater Sci Eng A 606:214–227

Kabir ASH, Sanjari M, Su J, Jung I-H, Yue S (2014) Effect of strain-induced precipitation on dynamic recrystallization in Mg–Al–Sn alloys. Mater Sci Eng A 616:252–259

Yang Y et al (2013) Influence of extrusion on the microstructure and mechanical behavior of Mg-9Li-3Al-x Sr alloys. Metall Mater Trans A 44(2):1101–1113

Lin YC et al (2015) EBSD study of a hot deformed nickel-based superalloy. J Alloys Compd 640:101–113

Zhang H, Zhang K, Zhou H, Lu Z, Zhao C, Yang X (2015) Effect of strain rate on microstructure evolution of a nickel-based superalloy during hot deformation. Mater Des 80:51–62

Gottstein G, Frommert M, Goerdeler M, Schäfer N (2004) Prediction of the critical conditions for dynamic recrystallization in the austenitic steel 800H. Mater Sci Eng A 387:604–608

Shaban M, Eghbali B (2010) Determination of critical conditions for dynamic recrystallization of a microalloyed steel. Mater Sci Eng A 527(16–17):4320–4325

Baochun Z, Guiyan L, Fenglian L, Xinming H, Lei H, Qingyun S (2015) Determination of critical conditions for initiation of dynamic recrystallization by new method. Mater Manuf Process 30(10):1235–1239

Poliak EI, Jonas JJ (1996) A one-parameter approach to determining the critical conditions for the initiation of dynamic recrystallization. Acta Mater 44(1):127–136

Mirzadeh H, Najafizadeh A (2010) Prediction of the critical conditions for initiation of dynamic recrystallization. Mater Des 31(3):1174–1179

Chen F, Feng G, Cui Z (2014) Mathematical modeling of critical condition for dynamic recrystallization. Procedia Eng 81:486–491

Cram DG, Zurob HS, Brechet YJM, Hutchinson CR (2009) Modelling discontinuous dynamic recrystallization using a physically based model for nucleation. Acta Mater 57(17):5218–5228

Senkov ON, Miracle DB, Firstov SA (2006) Metallic materials with high structural efficiency, vol 146. Springer Science & Business Media

Fatemi-Varzaneh SM, Zarei-Hanzaki A, Cabrera JM, Calvillo PR (2015) EBSD characterization of repetitive grain refinement in AZ31 magnesium alloy. Mater Chem Phys 149:339–343

Yanushkevich Z, Belyakov A, Kaibyshev R (2015) Microstructural evolution of a 304-type austenitic stainless steel during rolling at temperatures of 773–1273 K. Acta Mater 82:244–254

Jiang MG, Yan H, Chen RS (2015) Twinning, recrystallization and texture development during multi-directional impact forging in an AZ61 Mg alloy. J Alloys Compd 650:399–409

Azarbarmas M, Aghaie-Khafri M, Cabrera JM, Calvo J (2016) Dynamic recrystallization mechanisms and twining evolution during hot deformation of Inconel 718. Mater Sci Eng A 678:137–152

ASM International, Ed. (1990) ASM handbook, 10th editon. Materials Park, Ohio: ASM International

Puchi-Cabrera ES, Staia MH, Guérin J-D, Lesage J, Dubar M, Chicot D (2014) An experimental analysis and modeling of the work-softening transient due to dynamic recrystallization. Int J Plast 54:113–131

Galindo-Nava EI, Rivera-Díaz-del-Castillo PEJ (2013) Thermostatistical modelling of hot deformation in FCC metals. Int J Plast 47:202–221

Hajkazemi J, Zarei-Hanzaki A, Sabet M, Khoddam S (2011) Double-hit compression behavior of TWIP steels. Mater Sci Eng A 530:233–238

Kumar SS, Raghu T, Bhattacharjee PP, Rao GA, Borah U (2015) Constitutive modeling for predicting peak stress characteristics during hot deformation of hot isostatically processed nickel-base superalloy. J Mater Sci 50(19):6444–6456

Chen X-M et al (2015) Microstructural evolution of a nickel-based superalloy during hot deformation. Mater Des 77:41–49

Zhang P, Hu C, Ding C, Zhu Q, Qin H (2015) Plastic deformation behavior and processing maps of a Ni-based superalloy. Mater Des 1980-2015 65:575–584

Kong Y, Chang P, Li Q, Xie L, Zhu S (2015) Hot deformation characteristics and processing map of nickel-based C276 superalloy. J Alloys Compd 622:738–744

Humphreys FJ, Hatherly M (2012) Recrystallization and related annealing phenomena. Elsevier

Fulop S, McQueen HJ (1972) Mechanisms of deformation in the hot working of nickel-base superalloys. In Superalloys: processing

Liu Y-X, Lin YC, Zhou Y (2017) 2D cellular automaton simulation of hot deformation behavior in a Ni-based superalloy under varying thermal-mechanical conditions. Mater Sci Eng A 691:88–99

Lin YC, Luo S-C, Yin L-X, Huang J (2018) Microstructural evolution and high temperature flow behaviors of a homogenized Sr-modified Al-Si-Mg alloy. J Alloys Compd 739:590–599

Luton MJ, Sellars CM (1969) Dynamic recrystallization in nickel and nickel-iron alloys during high temperature deformation. Acta Metall 17(8):1033–1043

Sellars: On the mechanism of hot deformation - Google Scholar. https://scholar.google.com/scholar_lookup?title=On%20the%20mechanism%20of%20hot%20deformation&author=C.%20M.%20Sellars%20&author=W.%20J.%20McTegart&publication_year=1966. Accessed 19 Sep 2021

Medeiros SC, Prasad Y, Frazier WG, Srinivasan R (2000) Microstructural modeling of metadynamic recrystallization in hot working of IN 718 superalloy. Mater Sci Eng A 293(1–2):198–207

Gujrati R, Gupta C, Jha JS, Mishra S, Alankar A (2019) Understanding activation energy of dynamic recrystallization in Inconel 718. Mater Sci Eng A 744:638–651

Shahri MG, Hosseini SR, Salehi M (2015) Formation of nano/ultrafine grains in AISI 321 stainless steel using advanced thermo-mechanical process. Acta Metall Sin Engl Lett 28(4):499–504

Mandal S, Bhaduri AK, Sarma VS (2012) Role of twinning on dynamic recrystallization and microstructure during moderate to high strain rate hot deformation of a Ti-modified austenitic stainless steel. Metall Mater Trans A 43(6):2056–2068

Park SH, Lee JH, Yu H, Yoon J, You BS (2014) Effect of cold pre-forging on the microstructure and mechanical properties of extruded Mg–8Sn–1Al–1Zn alloy. Mater Sci Eng A 612:197–201

Brandon DG (1966) The structure of high-angle grain boundaries. Acta Metall 14(11):1479–1484

Underwood EE (1970) Quantitative stereology

Beladi H, Cizek P, Hodgson PD (2009) Dynamic recrystallization of austenite in Ni-30 Pct Fe model alloy: microstructure and texture evolution. Metall Mater Trans A 40(5):1175–1189

Jin Y et al (2016) Evolution of the annealing twin density during δ-supersolvus grain growth in the nickel-based superalloy Inconel™ 718. Metals 6(1):5

Shekhar S, King AH (2008) Strain fields and energies of grain boundary triple junctions. Acta Mater 56(19):5728–5736

Yu T, Hansen N, Huang X (2011) Recovery by triple junction motion in aluminium deformed to ultrahigh strains. Proc R Soc Math Phys Eng Sci 467(2135):3039–3065

Mandal S et al (2008) Evolution and characterization of dynamically recrystallized microstructure in a titanium-modified austenitic stainless steel using ultrasonic and EBSD techniques. Philos Mag 88(6):883–897

Field DP, Bradford LT, Nowell MM, Lillo TM (2007) The role of annealing twins during recrystallization of Cu. Acta Mater 55(12):4233–4241

Bozzolo N, Souaï N, Logé RE (2012) Evolution of microstructure and twin density during thermomechanical processing in a γ-γ’nickel-based superalloy. Acta Mater 60(13–14):5056–5066

Pande CS, Imam MA, Rath BB (1990) Study of annealing twins in FCC metals and alloys. Metall Trans A 21(11):2891–2896

Wang W et al (2014) Influence of stored energy on twin formation during primary recrystallization. Mater Sci Eng A 589:112–118

Prithiv TS, Bhuyan P, Pradhan SK, Sarma VS, Mandal S (2018) A critical evaluation on efficacy of recrystallization vs. strain induced boundary migration in achieving grain boundary engineered microstructure in a Ni-base superalloy. Acta Mater 146:187–201

Jamaati R, Toroghinejad MR, Amirkhanlou S, Edris H (2015) Microstructural evolution of nanostructured steel-based composite fabricated by accumulative roll bonding. Mater Sci Eng A 639:298–306

Barrabes SR, Kassner ME, Pérez-Prado MT, Evangelista E (2004) Geometric dynamic recrystallization in α-zirconium at elevated temperatures. In: Materials Science Forum (vol. 467, p 1145–1150). Trans Tech Publications Ltd

Feng D, Zhang XM, Liu SD, Deng YL (2014) Constitutive equation and hot deformation behavior of homogenized Al–7.68 Zn–2.12 Mg–1.98 Cu–0.12 Zr alloy during compression at elevated temperature. Mater Sci Eng A 608:63–72

Funding

This work was conducted as part of the “ENABLE” project funded by the European Union's Marie Sklodowska-Curie Actions (MSCA) Innovative Training Networks (ITN) H2020-MSCA-ITN-2017 under the grant agreement Number 764979. P. Yadav has received support from the additive team at LORTEK, Spain for printing the Inconel 718 samples at their facility.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by Pinku Yadav, Corinne Arvieu, Olivier Rigo and Eric Lacoste. The first draft of the manuscript was written by Pinku Yadav and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors have no relevant financial or non-financial interests to disclose.

Conflict of interest

The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yadav, P., Rigo, O., Arvieu, C. et al. Thermomechanical response of additively manufactured Inconel 718 during hot torsion tests. Int J Adv Manuf Technol 128, 4339–4355 (2023). https://doi.org/10.1007/s00170-023-12018-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12018-4