Abstract

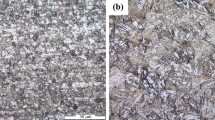

In this study, a number of models for estimating the mechanical attributes of dissimilar joints produced by resistance spot welding (RSW) of bake-hardening (BH) 220 steel and high-strength low-alloy (HSLA) 420 steel were developed based on regression analysis. Welding conditions were achieved via design of experiment (DOE), and the Box-Behnken design (BBD) method was selected. Welding time, welding current and electrode pressure were recorded as input parameters, while maximum displacement, peak load and failure energy of the welded samples accomplished from tensile shear tests were outputs. The influence of the welding current is superior to the influence of the welding time on the increase of the weld strength as stated by the analysis of variations (ANOVA). Relatively high welding heat input conditions enhance the mechanical attributes of the welds by increasing the nugget size. The largest mechanical properties obtained under the optimum welding conditions are welding time of 14 cycles, welding current of 10.8 kA and electrode force of 0.4 MPa. By verifying the regression models of the optimal welding conditions, the experimental results of the welded specimens with the maximum mechanical properties are about maximum displacement of 2.69 mm, peak load of 11.10 kN and failure energy of 23.90 J. The results show that the proposed spot weld strength models have an estimated accuracy of 5.32%. Due to the complete growth of austenite grains, the martensite in the coarse grain heat-affected zone (CGHAZ) is much larger than that of other zones, while in the HAZ at the side of BH steel, other phases besides martensite are also spotted, such as bainite, Widmanstätten ferrite and grain boundary ferrite. This is because BH steel has a lower carbon content. All welded specimens display hardening in the fine grain heat-affected zone (FGHAZ).

Similar content being viewed by others

Data availability

Not relevant.

Code availability

Not relevant.

References

Kazasidis M, Pantelis D, Caballero FG, Capdevila C, Cassidy J, Bilalis E, Lupoi R (2021) Dissimilar welding between conventional and high strength low alloy naval steels with the use of robotic metal cored arc welding. Int J Adv Manuf Technol 113:2895–2907

Özkul İ, Şehirli S, Akkurt A (2022) Effects of laser and electron beam welding on the mechanical properties of bake hardening sheets. Mater Test 64(1):88–97

Yaghoobi F, Jamaati R, Aval HJ (2022) Resistance spot welding of high-strength DP steel and nano/ultrafine-grained IF steel sheets. Mater Chem Phys 281:125909

Nieto J, Guerrero-Mata MP, Colas R, Mani A (2006) Experimental investigation on resistance spot welding of galvannealed HSLA steel. Sci Technol Weld Joining 11(6):717–722

Mi K, Ml K, Biro E, Zhou Y (2008) Microstructure and mechanical properties of resistance spot welded advanced high strength steels. Mater Trans 49(7):1629–1637

Janardhan G, Kishore K, Dutta K, Mukhopadhyay G (2020) Tensile and fatigue behavior of resistance spot-welded HSLA steel sheets: effect of pre-strain in association with dislocation density. Mater Sci Eng, A 793:139796

Zhao D, Vdonin N, Bezgans Y, Radionova L, Bykov V, Glebov L (2023) Mechanical attributes and microstructural characteristics of resistance spot-welded HSLA 420 steel joints. Int J Adv Manuf Technol 124:3505–3518

Zhao D, Vdonin N, Radionova L, Glebov L, Bykov V (2022) Optimization of post-weld tempering parameters for HSLA 420 steel in resistance spot welding process. Int J Adv Manuf Technol 123:1811–1823

Pawar S, Singh AK, Kaushik L, Park KS, Shim J, Choi SH (2022) Characterizing local distribution of microstructural features and its correlation with microhardness in resistance spot welded ultra-low-carbon steel: experimental and finite element characterization. Mater Charact 194:112382

Zhao D, Vdonin N, Bezgans Y, Radionova L, Glebov L (2023) Correlating electrode degradation with weldability of galvanized BH 220 steel during the electrode failure process of resistance spot welding. Crystals 13(1):39

Kekik M, Özen F, Onar V, Aslanlar S (2022) Investigation effect of resistance spot welding parameters on dissimilar DP1000HF/CP800 steel joints. Sādhanā 47(4):203

Janardhan G, Mukhopadhyay G, Kishore K, Dutta K (2020) Resistance spot welding of dissimilar interstitial-free and high-strength low-alloy steels. J Mater Eng Perform 29:3383–3394

Pouranvari M, Ranjbarnoodeh E (2013) Failure mode of HSLA/DQSK dissimilar steel resistance spot welds. Ironmak Steelmak 40(4):276–281

Rajalingam P, Rajakumar S, Balasubramanian V, Sonar T, Kavitha S (2023) Tensile shear fracture load bearing capability, softening of HAZ and microstructural characteristics of resistance spot welded DP-1000 steel joints. Mater Test 65(1):94–110

Marshall DV, Bhattacharya D, Speer JG (2021) Influence of paint baking on the energy absorption and failure mode of resistance spot welds in TRIP1180 steel. J Manuf Sci Eng 143(9):094501

Boriwal L, Sarviya RM, Mahapatra MM (2021) Process analysis and regression modelling of resistance spot welded joints of austenitic stainless steel 304L and low carbon steel sheets by using surface response methodology. Proc Inst Mech Eng Part E: J Process Mech Eng 235(1):24–33

Abioye TE, Redzuan FB, Zuhailawati H, Anasyida AS, Suhaina I, Bankong BD, Akintayo TC (2021) Prediction of tensile shear strength of resistance spot welded AA 5052 using regression analysis model. Mater Des Appl III:259–273

Rath S, Tripathy A, Tripathy AR (2020) Prediction of new active cases of coronavirus disease (COVID-19) pandemic using multiple linear regression model. Diabetes Metab Syndr 14(5):1467–1474

Valaee-Tale M, Sheikhi M, Mazaheri Y, Ghaini FM, Usefifar GR (2020) Criterion for predicting expulsion in resistance spot welding of steel sheets. J Mater Process Technol 275:116329

Gutema EM, Gopal M, Lemu HG (2022) Minimization of surface roughness and temperature during turning of aluminum 6061 using response surface methodology and desirability function analysis. Materials 15(21):7638

Bae JH, Park YD, Lee M (2021) Optimization of welding parameters for resistance spot welding of AA3003 to galvanized DP780 steel using response surface methodology. Int J Automot Technol 22:585–593

Feujofack Kemda BV, Barka N, Jahazi M, Osmani D (2020) Optimization of resistance spot welding process applied to A36 mild steel and hot dipped galvanized steel based on hardness and nugget geometry. Int J Adv Manuf Technol 106:2477–2491

Lee Y, Park S, Choi M, Park J, Han H, Lee K, Kang N (2023) Effectiveness of using low-strength-grade filler wires for 800 MPa grade ultra-high-strength steels laser beam welds. Steel Res Int 94(2):2200248

Soomro IA, Pedapati SR, Awang M (2022) A review of advances in resistance spot welding of automotive sheet steels: emerging methods to improve joint mechanical performance. Int J Adv Manuf Technol 118(5–6):1335–1366

Onar V (2022) Mechanical and microstructural characterizations of resistance spot welded dissimilar TWIP/304L stainless steel. Trans Indian Inst Met 75(7):1731–1739

Funding

The authors wish to thank the Russian Science Foundation (22–29-20095) for funding.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethics approval

Ethical approval is not a requirement as the tests and experiments in this study are not on humans or animals.

Consent to participate

All authors are in agreement with the participation.

Consent for publication

This article has been agreed to be published by all authors.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhao, D., Vdonin, N., Radionova, L. et al. Resistance spot welding of high-strength low-alloyed (HSLA) 420 steel and bake-hardening (BH) 220 steel. Int J Adv Manuf Technol 128, 1441–1453 (2023). https://doi.org/10.1007/s00170-023-12013-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12013-9