Abstract

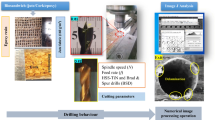

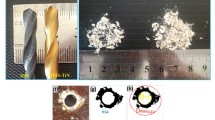

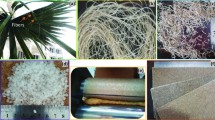

The use of cutting tools for material removal operations is commonplace in the production of biocomposite materials. However, the inability of electro-erosion to be applied to non-conductive biocomposites has led to the need for alternative methods. In this regard, the use of abrasive waterjet and conventional machining techniques such as drilling have emerged as viable options. This research seeks to explore and evaluate the effectiveness of these conventional methods for machining biocomposites, highlighting their significance in the development of efficient manufacturing processes for biocomposite materials. In actual applications, the delamination factor (Fd) is frequently employed to control drilling-related damage. This can be accomplished by carefully choosing the ideal process parameters. Feed rate (f), spindle speed (N), and drill diameter (d) are the three most significant variables affecting the drilling quality. A combination of artificial neural network with genetic algorithm (ANN-GA) and multi-objective response surface methodology (RSM) was used in this experiment to identify the best machining equipment for the hybrid sisal/cork biosandwich. This study’s major goal was to lower the Fd of an HSS-Co twist drill that was built using various drilling settings. The study’s findings showed that the HSS-Co tool with a 7-mm diameter, 2500-rpm spindle speed, and 50-mm/min feed rate was more successful in reaching a minimum delamination of 1.054.

Similar content being viewed by others

Data availability

Not applicable.

Code availability

Not applicable.

References

Mahdi E, Hernández Ochoa DR, Vaziri A et al (2020) Khalasa date palm leaf fiber as a potential reinforcement for polymeric composite materials. Compos Struct 108:223–233. https://doi.org/10.1016/j.compstruct.2020.113501

Haas W, Krausmann F, Wiedenhofer D, Heinz M (2015) How circular is the global economy?: An assessment of material flows, waste production, and recycling in the European Union and the world in 2005. J Ind Ecol 19:765–777. https://doi.org/10.1111/jiec.12244

Lekrine A, Belaadi A, Makhlouf A, Amroune S, Bourchak M, Satha H, Jawaid M (2022) Structural, thermal, mechanical and physical properties of Washingtonia filifera fibres reinforced thermoplastic biocomposites. Mater Today Commun 31:103574. https://doi.org/10.1016/j.mtcomm.2022.103574

Pastukhov LV, Govaert LE (2021) Plasticity-controlled failure of fibre-reinforced thermoplastics. Compos Part B Eng 209:108635. https://doi.org/10.1016/j.compositesb.2021.108635

Saaidia A, Belaadi A, Haddad A (2022) Moisture absorption of cork-based biosandwich material extracted from Quercussuber L. plant: ANN and Fick’s modelling. J Nat Fibers 19:12486–12503. https://doi.org/10.1080/15440478.2022.2072996

Belaadi A, Saaidia A, Boumaaza M, Alshahrani H, Bourchak M (2023) Modeling moisture absorption of flax/sisal reinforced hybrid biocomposites using Fick’s and ANN methods. J Nat Fibers 20:1–14. https://doi.org/10.1080/15440478.2022.2140322

John MJ, Thomas S (2008) Biofibres and biocomposites. Carbohydr Polym 71:343–364. https://doi.org/10.1016/j.carbpol.2007.05.040

Holbery J, Houston D (2006) Natural-fiber-reinforced polymer composites in automotive applications. JOM 58

Cherief M, Belaadi A, Boumaaza M, Bourchak M (2021) The effect of geometry on the flexural properties of cellular structures reinforced with natural fibres: statistical approach. J Nat Fibers 19:8448–8462. https://doi.org/10.1080/15440478.2021.1964134

Cherief M, Belaadi A, Bouakba M et al (2020) Behaviour of lignocellulosic fibre-reinforced cellular core under low-velocity impact loading: Taguchi method. Int J Adv Manuf Technol. https://doi.org/10.1007/s00170-020-05393-9

Zimniewska M, Laurentowska M, Bogacz E et al (2010) Influence of sportswear made from polyester and man-made cellulosic fibres on the energy cost of physical effort. Fibres Text East Eur 80:94–99

T. Karthik RR and PG sustainable luxury natural fibers—production, properties, and prospects

Ngo T-D (2018) Natural fibers for sustainable bio-composites. Nat Artif Fiber-Reinforced Compos as Renew Sources. https://doi.org/10.5772/intechopen.71012

Friedrich D (2021) Thermoplastic moulding of wood-polymer composites (WPC): a review on physical and mechanical behaviour under hot-pressing technique. Compos Struct 262:113649. https://doi.org/10.1016/j.compstruct.2021.113649

Atagur M, Seki Y, Oncu O et al (2020) Evaluating of reinforcing effect of Ceratonia Siliqua for polypropylene: tensile, flexural and other properties. Polym Test 89:106607. https://doi.org/10.1016/j.polymertesting.2020.106607

Boumaaza M, Belaadi A, Bourchak M et al (2023) Optimization of flexural properties and thermal conductivity of Washingtonia plant biomass waste biochar reinforced bio-mortar. J Mater Res Technol 23:3515–3536. https://doi.org/10.1016/j.jmrt.2023.02.009

Sarasini F, Tirillò J, Lampani L et al (2019) Static and dynamic characterization of agglomerated cork and related sandwich structures. Compos Struct 212:439–451. https://doi.org/10.1016/j.compstruct.2019.01.054

Belaadi A, Bourchak M, Aouici H (2016) Mechanical properties of vegetal yarn: Statistical approach. Compos Part B Eng 106:139–153. https://doi.org/10.1016/j.compositesb.2016.09.033

Belaadi A, Amroune S, Bourchak M (2019) Effect of eco-friendly chemical sodium bicarbonate treatment on the mechanical properties of flax fibres: Weibull statistics. Int J Adv Manuf Technol. https://doi.org/10.1007/s00170-019-04628-8

Boumaaza M, Belaadi A, Bourchak M (2021) The effect of alkaline treatment on mechanical performance of natural fibers-reinforced plaster: optimization using RSM. J Nat Fibers 18:2220–2240. https://doi.org/10.1080/15440478.2020.1724236

Boumaaza M, Belaadi A, Bourchak M (2022) Systematic review on reinforcing mortars with natural fibers: challenges of environment-friendly option. J Nat Fibers 0:1–25. https://doi.org/10.1080/15440478.2022.2060408

Zhou Y, Fan M, Chen L (2016) Interface and bonding mechanisms of plant fibre composites: An overview. Compos Part B: Eng 101:31–45

Rajmohan T, Vinayagamoorthy R, Mohan K (2019) Regression modeling and optimization of machinability behavior of glass-coir-polyester hybrid composite using factorial design methodology. J Thermoplast Compos Mater 32:1282–1302. https://doi.org/10.1177/0892705718796541

Dutta S, Kim NK, Das R, Bhattacharyya D (2019) Effects of sample orientation on the fire reaction properties of natural fibre composites. Compos Part B Eng 157:195–206. https://doi.org/10.1016/j.compositesb.2018.08.118

Merli R, Preziosi M, Acampora A, Lucchetti MC, Petrucci E (2020) Recycled fibers in reinforced concrete: A systematic literature review. J Clean Prod 248:119207. https://doi.org/10.1016/j.jclepro.2019.119207

Boumaaza M, Belaadi A, Bourchak M (2021) The effect of alkaline treatment on mechanical performance of natural fibers-reinforced plaster: part II optimization comparison between ANN and RSM statistics. J Nat Fibers 19:8367–8382. https://doi.org/10.1080/15440478.2021.1964129

Jaouadi M, M’sahli S, Sakli F (2009) Optimization and characterization of pulp extracted from the Agave americana L. fibers. Text Res J 79:110–120. https://doi.org/10.1177/0040517508090781

Makhlouf A, Belaadi A, Amroune S et al (2022) Elaboration and characterization of flax fiber reinforced high density polyethylene biocomposite: effect of the heating rate on thermo-mechanical properties. J Nat Fibers 19:3928–3941. https://doi.org/10.1080/15440478.2020.1848737

Bedjaoui A, Belaadi A, Amroune S, Madi B (2019) Impact of surface treatment of flax fibers on tensile mechanical properties accompanied by a statistical study. Int J Integr Eng 6:10–17

Lotfi A, Li H, Dao DV (2019) Effect of drilling parameters on delamination and hole quality in drilling flax fiber reinforced bio-composites BT - sustainable design and manufacturing 2018. In: Dao D, Howlett RJ, Setchi R, Vlacic L (eds). Springer International Publishing, Cham, pp 71–81

Lotfi A, Li H, Dao DV (2020) Analytical and experimental investigation of the parameters in drilling flax/poly(lactic acid) bio-composite laminates. Int J Adv Manuf Technol 109:503–521. https://doi.org/10.1007/s00170-020-05668-1

Benzannache N, Belaadi A, Boumaaza M, Bourchak M (2021) Improving the mechanical performance of biocomposite plaster/ Washingtonian filifira fibres using the RSM method. J Build Eng 33:101840. https://doi.org/10.1016/j.jobe.2020.101840

Belaadi A, Boumaaza M, Alshahrani H et al (2022) Drilling performance prediction of HDPE/Washingtonia fiber biocomposite using RSM, ANN, and GA optimization. Int J Adv Manuf Technol 123:1543–1564. https://doi.org/10.1007/s00170-022-10248-6

Benzidane R, Sereir Z, Bennegadi ML et al (2018) Morphology, static and fatigue behavior of a natural UD composite: the date palm petiole ‘wood.’ Compos Struct 203:110–123. https://doi.org/10.1016/j.compstruct.2018.06.122

Djoudi T, Hecini M, Scida D, Djebloun Y (2019) Physico-mechanical characterization of composite materials based on date palm tree fibers physico-mechanical characterization of composite materials based on date palm tree fibers. J Nat Fibers 0:1–14. https://doi.org/10.1080/15440478.2019.1658251

Belaadi A, Amroune S, Seki Y et al (2022) Extraction and characterization of a new lignocellulosic fiber from Yucca treculeana L. leaf as potential reinforcement for industrial biocomposites. J Nat Fibers 19:12235–12250. https://doi.org/10.1080/15440478.2022.2054895

Belaadi A, Boumaaza M, Alshahrani H, Bourchak M (2022) Mechanical properties of natural cellulosic Yucca treculeana L. fiber for biocomposites applications: statistical analysis. J Nat Fibers 19:15501–15518. https://doi.org/10.1080/15440478.2022.2128505

Mercy JL, Sivashankari P, Sangeetha M et al (2020) Genetic optimization of machining parameters affecting thrust force during drilling of pineapple fiber composite plates – an experimental approach. J Nat Fibers 19:1729–1740. https://doi.org/10.1080/15440478.2020.1788484

Nagamadhu M, Upadhya R, Sehgal S, Vijay Kumar S, Basavaraj H, (2020) Mechanical and drilling process characterisation of herringbone sisal fabric reinforced vinyl ester sandwich composites. Adv Mater Process Technol 8:110–127. https://doi.org/10.1080/2374068X.2020.1855963

Geng D, Liu Y, Shao Z et al (2019) Delamination formation, evaluation and suppression during drilling of composite laminates: a review. Compos Struct 216:168–186. https://doi.org/10.1016/j.compstruct.2019.02.099

Rao YS, Mohan NS, Shetty N, Shivamurthy B (2019) Drilling and structural property study of multi-layered fiber and fabric reinforced polymer composite - a review. Mater Manuf Process 34:1549–1579. https://doi.org/10.1080/10426914.2019.1686522

Niranjan DB, Shivashankar GS, Sreenivas Rao KV, Praveen R (2017) Optimization of cutting process parameters on AL6061 using ANOVA and TAGUCHI method. Mater Today Proc 4:10845–10849. https://doi.org/10.1016/j.matpr.2017.08.037

Nagamadhu M, Jeyaraj P, Kumar GM (2019) Characterization and mechanical properties of sisal fabric reinforced polyvinyl alcohol green composites: effect of composition and loading direction. Mater Res Express 6:125320. https://doi.org/10.1088/2053-1591/ab56b3

Ojo SO, Ismail SO, Paggi M, Dhakal HN (2017) A new analytical critical thrust force model for delamination analysis of laminated composites during drilling operation. Compos Part B Eng 124:207–217. https://doi.org/10.1016/j.compositesb.2017.05.039

Tabet Z, Belaadi A, Boumaaza M, Bourchak M (2021) Drilling of a bidirectional jute fibre and cork-reinforced polymer biosandwich structure: ANN and RSM approaches for modelling and optimization. Int J Adv Manuf Technol 117:3819–3839. https://doi.org/10.21203/rs.3.rs-503708/v1

Krishnaraj V, Zitoune R, Davim JP (2013) Effects of drilling parameters on mechanical strength BT - drilling of polymer-matrix composites. In: Krishnaraj V, Zitoune R, Davim JP (eds) Springer. Berlin Heidelberg, Berlin, Heidelberg, pp 85–96

Chandramohan D, Marimuthu K (2011) Drilling of natural fiber particle reinforced polymer composite material. Int J Adv Eng Res Stud I:134–145

Jayabal S, Natarajan U (2011) Drilling analysis of coir-fibre-reinforced polyester composites. Bull Mater Sci 34:1563–1567. https://doi.org/10.1007/s12034-011-0359-y

Venkateshwaran N, ElayaPerumal A (2013) Hole quality evaluation of natural fiber composite using image analysis technique. J Reinf Plast Compos 32:1188–1197. https://doi.org/10.1177/0731684413486847

Sridharan V, Muthukrishnan N (2013) Optimization of machinability of polyester/modified jute fabric composite using grey relational analysis (GRA). Procedia Eng 64:1003–1012. https://doi.org/10.1016/j.proeng.2013.09.177

Durão LMP, Gonçalves DJS, Tavares JMRS et al (2013) Drilling delamination outcomes on glass and sisal reinforced plastics. Mater Sci Forum 730–732:301–306. https://doi.org/10.4028/www.scientific.net/MSF.730-732.301

Belaadi A, Boumaaza M, Alshahrani H, Bourchak M (2022) Delamination in drilling of jute/cork-reinforced polymer biosandwich materials: optimization by response surface methodology and genetic algorithm. Int J Adv Manuf Technol 122:2095–2111. https://doi.org/10.1007/s00170-022-10001-z

Dembri I, Belaadi A, Boumaaza M et al (2022) Drilling performance of short Washingtonia filifera fiber–reinforced epoxy biocomposites: RSM modeling. Int J Adv Manuf Technol 121:7833–7850. https://doi.org/10.1007/s00170-022-09849-y

Belaadi A, Laouici H, Bourchak M (2020) Mechanical and drilling performance of short jute fibre-reinforced polymer biocomposites: statistical approach. Int J Adv Manuf Technol 106:1989–2006. https://doi.org/10.1007/s00170-019-04761-4

Adda B, Belaadi A, Boumaaza M, Bourchak M (2021) Experimental investigation and optimization of delamination factors in the drilling of jute fiber–reinforced polymer biocomposites with multiple estimators. Int J Adv Manuf Technol 116:2885–2907. https://doi.org/10.1007/s00170-021-07628-9

Belaadi A, Boumaaza M, Amroune S, Bourchak M (2020) Mechanical characterization and optimization of delamination factor in drilling bidirectional jute fibre-reinforced polymer biocomposites. Int J Adv Manuf Technol 111:2073–2094. https://doi.org/10.1007/s00170-020-06217-6

Boumaaza M, Belaadi A, Alshahrani H et al (2023) Response surface methodology optimization of palm rachis biochar content and temperature effects on predicting bio-mortar compressive strength, porosity and thermal conductivity. J Nat Fibers 20:2162184. https://doi.org/10.1080/15440478.2022.2162184

Boumaaza M, Belaadi A, Bourchak M et al (2022) Comparative study of flexural properties prediction of Washingtonia filifera rachis biochar bio-mortar by ANN and RSM models. Constr Build Mater 318:125985. https://doi.org/10.1016/j.conbuildmat.2021.125985

Karaduman Y (2018) Experimental investigation on the flexural and dynamic mechanical properties of jute fiber/cork-reinforced polyester sandwich composites. BioResources 13:3958–3970. https://doi.org/10.15376/BIORES.13.2.3958-3970

Azuan SAS (2013) Effects of drilling parameters on delamination of coconut meat husk reinforced polyester composites. Adv Environ Biol 7:1097–1100. https://doi.org/10.1007/978-3-642-38345-8_6

Qiu X, Li P, Li C et al (2018) Study on chisel edge drilling behavior and step drill structure on delamination in drilling CFRP. Compos Struct 203:404–413. https://doi.org/10.1016/j.compstruct.2018.07.007

Mohamad A, Zain AM, Mohd Yusof N et al (2019) Modeling and optimization of machining parameters using regression and cuckoo search in deep hole drilling process. In: Computational Science and Engineering. Trans Tech Publications Ltd, pp 177–184

Abd-Elwahed MS (2022) Drilling Process of GFRP composites: modeling and optimization using hybrid ANN. Sustainability 14:6599. https://doi.org/10.3390/su14116599

Acknowledgements

The authors are thankful to Deanship of Scientific Research and under the supervision of the Scientific and Engineering Research Centre at Najran University for funding this work under the Research centers Funding program grant code (NU/RCP/SERC/12/10).

Funding

This project was funded by the Deanship of Scientific Research and under the supervision of the Scientific and Engineering Research Centre at Najran University grant code (NU/RCP/SERC/12/10).

Author information

Authors and Affiliations

Contributions

Ahmed Belaadi: conceptualization, investigation, methodology, supervision, writing, review, and editing.

Messaouda Boumaaza: conceptualization, investigation, writing—review and editing.

Hassan Alshahrani: investigation, writing—review and editing.

Mohammad K. A. Khan: investigation, writing—review and editing.

Mostefa Bourchak: investigation, writing—review and editing.

Corresponding author

Ethics declarations

Ethics approval

The work contains no libelous or unlawful statements, does not infringe on the rights of others, or contains material or instructions that might cause harm or injury.

Consent to participate

The authors consent to participate.

Consent for publication

The authors consent to publish.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Belaadi, A., Boumaaza, M., Alshahrani, H. et al. Optimization of drilling process parameters of sisal/cork-reinforced epoxy biosandwich structure by multi-objective RSM and hybrid ANN-GA models. Int J Adv Manuf Technol 127, 4271–4289 (2023). https://doi.org/10.1007/s00170-023-11791-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11791-6