Abstract

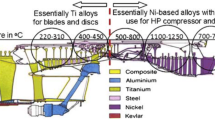

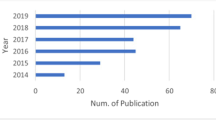

Nickel-based alloys have great application value in aerospace, biomedical industry, chemical industry, and other fields. However, nickel-based alloys are known to be difficult to process, which will generate a lot of heat and friction during processing, which limits the application range of nickel-based alloys. Therefore, a large amount of cutting fluid needs to be used during processing, and the cutting fluid will cause harm to human health and the environment. In order to solve these problems, scholars proposed to use the minimum quantity lubrication (MQL) to replace the conventional flood cooling lubrication technique. Recently, many papers have proposed to use MQL for lubrication /cooling in the processing of nickel-based alloys. However, few studies have approached this topic comprehensively. To bridge this gap, this study conducts a comprehensive literature review of the progress made in the processing of nickel-based alloys using various MQL methods. It should be noted that these studies are divided into four categories: vegetable oil-based MQL, cryogenic cooling-based MQL, solid lubricant-based MQL, and electrostatic atomization-based MQL. It is crucial to compare the advantages of these cooling and lubricating technologies in machining nickel-based alloys, analyze their experimental results, and assess their impact on machining quality and tool wear. This review reveals that compared to traditional MQL, vegetable oil-based MQL is more energy-saving and environmentally friendly, resulting in approximately 30% improvement in surface quality and a 50% reduction in tool wear. The addition of solid lubricants to vegetable oil further enhances its lubrication performance. Cryogenic cooling-based MQL enables the attainment of finer grains and smaller sawtooth chips. Electrostatic atomization MQL, by altering the atomization process of traditional MQL, produces more uniform droplets, leading to a 42.4% reduction in tool wear and a 47% improvement in machined surface quality. The purpose of this paper is to help researchers identify existing gaps and to enable MQL to improve the processing quality and application range of nickel-based alloys. Finally, the present technical challenges and future research directions are put forward.

Similar content being viewed by others

Abbreviations

- MQL:

-

Minimum quantity lubrication

- Cryo-MQL, CMQL:

-

Cryogenic minimum quantity lubrication

- EMQL, EL:

-

Electrostatic minimum quantity lubrication

- Al2O3 :

-

Aluminum oxide

- ZnO:

-

Zinc oxide

- Gr:

-

Graphene

- LN2 :

-

Liquid nitrogen

- CO2 :

-

Liquid carbon dioxide

- scCO2 :

-

Supercritical carbon dioxide

- MWFs:

-

Metal working fluids

- MoS2 :

-

Molybdenum disulfide

- ZrO2 :

-

Zirconium dioxide

- CNT:

-

Carbon nanotubes

- PCD:

-

Polycrystalline diamond

- SiO2 :

-

Silica dioxide

- TOPSIS:

-

Technique for order preference by similarity to an ideal solution

- CAPB:

-

Coco-amido-propyl-betaine

- SDBS:

-

Sodium-dodecyl-benzenesulfonate

- ANOVA:

-

Analysis of variance

- CDA:

-

Composite desirability approach

- AHP:

-

Analytical hierarchy process

- SEM:

-

Scanning electron microscope

- COPRAS:

-

Complex proportional assessment

- scCO2 + OoW:

-

Supercritical carbon dioxide based minimum quantity lubrication with oil droplets cutting fluid

- MRR:

-

Metal removal rate

- RSM:

-

Response surface method

- NMQL:

-

Nano-fluid minimum quantity lubrication

- Ag:

-

Silver

- Q:

-

Flow velocity

- SDS:

-

Sodium dodecyl sulfate

- TGRA:

-

Taguchi grey relational analysis

- NP:

-

Nanoparticles

- SiC:

-

Silicon carbide

- WS2 :

-

Micron-scale tungsten disulfide

- PVD:

-

Physical vapor deposition

- MLG:

-

Multilayer graphene

- CSI:

-

Conference on Surface Integrity

- BUE:

-

Built up age

- SCE:

-

Specific cutting energy

References

Thakur A, Gangopadhyay S (2016) State-of-the-art in surface integrity in machining of nickel-based super alloys. Int J Mach Tools Manuf 100:25–35

Zhu D, Zhang X, Ding H (2013) Tool wear characteristics in machining of nickel-based superalloys. Int J Mach Tools Manuf 64:60–77

Kim EJ, Lee CM (2019) A study on the optimal machining parameters of the induction assisted milling with Inconel 718. Materials 12(2):233

Abdul Halim NH, Che Haron CH, Abdul Ghani J (2020) Sustainable machining of hardened Inconel 718: a comparative study. Int J Precis Eng Manuf 21:1375–1387

Ratnam C, Kumar KA, Murthy B et al (2018) An experimental study on boring of Inconel 718 and multi response optimization of machining parameters using response surface methodology. Materials Today: Proceedings 5(13):27123–27129

Dai H, Dai W, Hu Z, et al (2023) Advanced composites inspired by biological structures and functions in nature: architecture design, strengthening mechanisms, and mechanical-functional responses. Advanced Science 2207192

Liang X, Liu Z, Wang B (2019) State-of-the-art of surface integrity induced by tool wear effects in machining process of titanium and nickel alloys: a review. Measurement 132:150–181

Asala G, Andersson J, Ojo OA (2019) A study of the dynamic impact behaviour of IN 718 and ATI 718plus® superalloys. Phil Mag 99(4):419–437

Ulutan D, Ozel T (2011) Machining induced surface integrity in titanium and nickel alloys: a review. Int J Mach Tools Manuf 51(3):250–280

Venkatesan K, Ramanujam R (2016) Statistical approach for optimization of influencing parameters in laser assisted machining (lam) of Inconel alloy. Measurement 89:97–108

Ay M, Çaydaş U, Hasçalik A (2010) Effect of traverse speed on abrasive water jet machining of age hardened Inconel 718 nickel-based superalloy. Mater Manuf Processes 25(10):1160–1165

Dudzinski D, Devillez A, Moufki A et al (2004) A review of developments towards dry and high speed machining of Inconel 718 alloy. Int J Mach Tools Manuf 44(4):439–456

Ray A et al (2014) Cutting fluid selection for sustainable design for manufacturing: an integrated theory. Procedia Mater Sci 6:450–459

Reddy NSK, Nouari M, Yang M (2010) Development of electrostatic solid lubrication system for improvement in machining process performance. Int J Mach Tools Manuf 50(9):789–797

Sharma VS, Dogra M, Suri N (2009) Cooling techniques for improved productivity in turning. Int J Mach Tools Manuf 49(6):435–453

Rahim E, Ibrahim M, Rahim A et al (2015) Experimental investigation of minimum quantity lubrication (MQL) as a sustainable cooling technique. Procedia CIRP 26:351–354

He T, Liu N, Xia H, et al (2022) Progress and trend of minimum quantity lubrication (MQL): a comprehensive review. J Clean Prod 135809

Fratila D, Caizar C (2011) Application of Taguchi method to selection of optimal lubrication and cutting conditions in face milling of ALMg3. J Clean Prod 19(6–7):640–645

Eltaggaz A, Hegab H, Deiab I, Kishawy H (2018) Hybrid nano-fluid-minimum quantity lubrication strategy for machining austempered ductile iron (ADI). Int J Interact Design Manuf (IJIDeM) 12(4):1273–1281

Osman KA, Ünver HÖ, Şeker U (2019) Application of minimum quantity lubrication techniques in machining process of titanium alloy for sustainability: a review. Int J Adv Manuf Technol 100:2311–2332

Banerjee N, Sharma A (2019) Improving machining performance of TI-6AL-4V through multi-point minimum quantity lubrication method. Proc Inst Mech Eng Part B: J Eng Manuf 233(1):321–336

Fitrina S, Kristiawan B, Surojo E, et al (2018) Influence of minimum quantity lubrication with Al2O3 nanoparticles on cutting parameters in drilling process. In: AIP Conference Proceedings, AIP Publishing LLC 030056

Sharif MN, Pervaiz S, Deiab I (2017) Potential of alternative lubrication strategies for metal cutting processes: a review. Int J Adv Manuf Technol 89:2447–2479

Boubekri N, Shaikh V, Foster PR (2010) A technology enabler forgreen machining: minimum quantity lubrication (MQL). J Manuf Technol Manag 21(5):556–566

Kurgin S, M. Dasch J, L. Simon D, et al (2014) A comparison of two minimum quantity lubrication delivery systems. Industrial Lubrication and Tribology 66(1):151–159

Goindi GS, Sarkar P (2017) Dry machining: a step towards sustainable machining–challenges and future directions. J Clean Prod 165:1557–1571

Boswell B, Islam MN, Davies IJ et al (2017) A review identifying the effectiveness of minimum quantity lubrication (MQL) during conventional machining. Int J Adv Manuf Technol 92:321–340

De Bartolomeis A, Newman ST, Jawahir I et al (2021) Future research directions in the machining of Inconel 718. J Mater Process Technol 297:117260

Gupta MK, Mia M, Jamil M et al (2020) Machinability investigations of hardened steel with biodegradable oil-based MQL spray system. Int J Adv Manuf Technol 108:735–748

Wang X, Li C, Zhang Y, et al (2022) Tribology of enhanced turning using biolubricants: a comparative assessment. Tribology International 107766

Lawal SA, Choudhury IA, Nukman Y (2012) Application of vegetable oil-based metalworking fluids in machining ferrous metals—a review. Int J Mach Tools Manuf 52(1):1–12

Alaba E, Kazeem R, Adebayo A et al (2023) Evaluation of palm kernel oil as cutting lubricant in turning AISI 1039 steel using Taguchi-grey relational analysis optimization technique. Adv Ind Manuf Eng 6:100115

Ross NS, Ananth MBJ, Jafferson J, et al (2022) Performance assessment of vegetable oil–based MQL in milling of additively manufactured alsi10mg for sustainable production. Biomass Conversion and Biorefinery 1–18

Rahim EA, Sasahara H (2011) An analysis of surface integrity when drilling Inconel 718 using palm oil and synthetic ester under MQL condition. Mach Sci Technol 15(1):76–90

Wang Y, Li C, Zhang Y et al (2016) Experimental evaluation of the lubrication properties of the wheel/workpiece interface in minimum quantity lubrication (MQL) grinding using different types of vegetable oils. J Clean Prod 127:487–499

Li B, Li C, Zhang Y et al (2016) Grinding temperature and energy ratio coefficient in MQL grinding of high-temperature nickel-base alloy by using different vegetable oils as base oil. Chin J Aeronaut 29(4):1084–1095

Gupta MK, Song Q, Liu Z et al (2021) Environment and economic burden of sustainable cooling/lubrication methods in machining of Inconel-800. J Clean Prod 287:125074

Cui X, Li C, Zhang Y et al (2023) Comparative assessment of force, temperature, and wheel wear in sustainable grinding aerospace alloy using biolubricant. Front Mech Eng 18(1):3

Saleem MQ, Mehmood A (2022) Eco-friendly precision turning of superalloy Inconel 718 using MQL based vegetable oils: tool wear and surface integrity evaluation. J Manuf Process 73:112–127

Sahoo SP, Pandey K, Datta S (2022) Performance of uncoated/coated carbide inserts during MQL (sunflower oil) assisted machining of Inconel 718 superalloy. Sādhanā 47(4):193

Guo S, Li C, Zhang Y et al (2018) Analysis of volume ratio of castor/soybean oil mixture on minimum quantity lubrication grinding performance and microstructure evaluation by fractal dimension. Ind Crops Prod 111:494–505

Wickramasinghe K, Sasahara H, Abd Rahim E et al (2021) Recent advances on high performance machining of aerospace materials and composites using vegetable oil-based metal working fluids. J Clean Prod 310:127459

Duan Z, Li C, Zhang Y et al (2023) Mechanical behavior and semiem pirical force model of aerospace aluminum alloy milling using nano biological lubricant. Front Mech Eng 18(1):4

Vardhanapu M, Chaganti PK, Tarigopula P (2023) Characterization and machine learning-based parameter estimation in mql machining of a superalloy for developed green nano-metalworking fluids. J Braz Soc Mech Sci Eng 45(3):154

Pal A, Chatha SS, Sidhu HS (2022) Assessing the lubrication performance of various vegetable oil-based nano-cutting fluids via eco-friendly MQL technique in drilling of AISI 321 stainless steel. J Braz Soc Mech Sci Eng 44(4):148

Mao C, Zhang J, Huang Y et al (2013) Investigation on the effect of nanofluid parameters on MQL grinding. Mater Manuf Processes 28(4):436–442

Kang M, Kim K, Shin S et al (2008) Effect of the minimum quantity lubrication in high-speed end-milling of AIS D2 cold-worked die steel (62 HRC) by coated carbide tools. Surf Coat Technol 202(22–23):5621–5624

Kumar CRV, Ramamoorthy B (2007) Performance of coated tools during hard turning under minimum fluid application. J Mater Process Technol 185(1–3):210–216

Dhar N, Kamruzzaman M, Ahmed M (2006) Effect of minimum quantity lubrication (MQL) on tool wear and surface roughness in turning aisi-4340 steel. J Mater Process Technol 172(2):299–304

Yücel A, Yıldırım ÇV, Sarıkaya M et al (2021) Influence of MoS2 based nanofluid-MQL on tribological and machining characteristics in turning of AA 2024 T3 aluminum alloy. J Market Res 15:1688–1704

Singh G, Gupta MK, Hegab H et al (2020) Progress for sustainability in the mist assisted cooling techniques: a critical review. Int J Adv Manuf Technol 109:345–376

Wang X, Song Y, Li C, et al (2023) Nanofluids application in machining: a comprehensive review. The International Journal of Advanced Manufacturing Technology 1–52

Chinchanikar S, Kore SS, Hujare P (2021) A review on nanofluids in minimum quantity lubrication machining. J Manuf Process 68:56–70

Zhang Y, Li C, Jia D et al (2015) Experimental evaluation of the lubrication performance of MoS2/CNT nanofluid for minimal quantity lubrication in Ni-based alloy grinding. Int J Mach Tools Manuf 99:19–33

Saatçi E, Yapan YF, Uysal MU, et al (2023) Orthogonal turning of AISI 310S austenitic stainless steel under hybrid nanofluid-assisted MQL and a sustainability optimization using NSGA-II and TOPSIS. Sustainable Materials and Technologies. e00628

Usluer E, Emiroğlu U, Yapan YF et al (2023) Investigation on the effect of hybrid nanofluid in MQL condition in orthogonal turning and a sustainability assessment. Sustain Mater Technol 36:e00618

Makhesana MA, Patel KM, Krolczyk GM et al (2023) Influence of MoS2 and graphite-reinforced nanofluid-MQL on surface roughness, tool wear, cutting temperature and microhardness in machining of Inconel 625. CIRP J Manuf Sci Technol 41:225–238

Yang Y, Yang M, Li C et al (2023) Machinability of ultrasonic vibration-assisted micro-grinding in biological bone using nanolubricant. Front Mech Eng 18(1):1

Khanna N, Airao J, Nirala CK et al (2022) Novel sustainable cryo-lubrication strategies for reducing tool wear during ultrasonic-assisted turning of Inconel 718. Tribol Int 174:107728

Demirsöz R, Korkmaz ME, Gupta MK (2022) A novel use of hybrid cryo-MQL system in improving the tribological characteristics of additively manufactured 316 stainless steel against 100 cr6 alloy. Tribol Int 173:107613

Pusavec F, Hamdi H, Kopac J et al (2011) Surface integrity in cryogenic machining of nickel based alloy-Inconel 718. J Mater Process Technol 211(4):773–783

Jerold BD, Kumar MP (2013) The influence of cryogenic coolants in machining of TI-6AL-4V. Journal of manufacturing science and engineering 135(3)

Priarone PC, Klocke F, Faga MG et al (2016) Tool life and surface integrity when turning titanium aluminides with PCD tools under conventional wet cutting and cryogenic cooling. Int J Adv Manuf Technol 85:807–816

Cordes S, Hübner F, Schaarschmidt T (2014) Next generation high performance cutting by use of carbon dioxide as cryogenics. Procedia Cirp 14:401–405

Yeo SD, Kiran E (2005) Formation of polymer particles with supercritical fluids: a review. The Journal of Supercritical Fluids 34(3):287–308

Stephenson D, Skerlos SJ, King AS et al (2014) Rough turning Inconel 750 with supercritical CO2-based minimum quantity lubrication. J Mater Process Technol 214(3):673–680

Lewis J (1997) Supercritical carbon dioxide spray systems~0 8. Metal finishing

Hyatt JA (1984) Liquid and supercritical carbon dioxide as organic solvents. J Org Chem 49(26):5097–5101

Khosravi J, Azarhoushang B, Barmouz M et al (2022) High-speed milling of TI6AL4V under a supercritical CO2+ MQL hybrid cooling system. J Manuf Process 82:1–14

Paturi UMR, Maddu YR, Maruri RR et al (2016) Measurement and analysis of surface roughness in ws2 solid lubricant assisted minimum quantity lubrication (MQL) turning of Inconel 718. Procedia Cirp 40:138–143

Marques A, Suarez MP, Sales WF et al (2019) Turning of Inconel 718 with whisker-reinforced ceramic tools applying vegetable-based cutting fluid mixed with solid lubricants by MQL. J Mater Process Technol 266:530–543

Makhesana M, Patel K, Mawandiya B (2021) Environmentally conscious machining of Inconel 718 with solid lubricant assisted minimum quantity lubrication. Met Powder Rep 76:S24–S29

de Souza RR, de Paiva RL, Gelamo RV et al (2021) Study on grinding of Inconel 625 and 718 alloys with cutting fluid enriched with multilayer graphene platelets. Wear 476:203697

Tebaldo V, di Confiengo GG, Faga MG (2017) Sustainability in machining:“eco-friendly” turning of Inconel 718. surface characterisation and economic analysis. J Clean Prod 140:1567–1577

Xu W, Li C, Zhang Y, et al (2022) Electrostatic atomization minimum quantity lubrication machining: from mechanism to application. Int J Extreme Manuf

Reddy N, Yang M (2010) Development of an electrostatic lubrication system for drilling of SCM 440 steel. Proc Inst Mech Eng Part B: J Eng Manuf 224(2):217–224

Li C, Jia D, Wang S, et al (2016) Nano fluid electrostatic atomization controllable jet minimal quantity lubrication grinding system. US Patent 9 511 478

Xu X, Huang S, Wang M et al (2017) A study on process parameters in end milling of aisi-304 stainless steel under electrostatic minimum quantity lubrication conditions. Int J Adv Manuf Technol 90:979–989

Huang S, Yao W, Hu J et al (2015) Tribological performance and lubrication mechanism of contact-charged electrostatic spray lubrication technique. Tribol Lett 59(2):28

Huang S, Lv T, Wang M et al (2018) Effects of machining and oil mist parameters on electrostatic minimum quantity lubrication–EMQL turning process. Int J Precision Eng Manuf-Green Technol 5:317–326

Rajaguru J, Arunachalam N (2020) A comprehensive investigation on the effect of flood and MQL coolant on the machinability and stress corrosion cracking of super duplex stainless steel. J Mater Process Technol 276:116417

Li K, Aghazadeh F, Hatipkarasulu S et al (2003) Health risks from exposure to metal-working fluids in machining and grinding operations. Int J Occup Saf Ergon 9(1):75–95

Guo S, Li C, Zhang Y et al (2017) Experimental evaluation of the lubrication performance of mixtures of castor oil with other vegetable oils in MQL grinding of nickel-based alloy. J Clean Prod 140:1060–1076

Sen B, Gupta MK, Mia M et al (2021) Performance assessment of minimum quantity castor-palm oil mixtures in hard-milling operation. Materials 14(1):198

Jia D, Li C, Zhang Y et al (2017) Specific energy and surface roughness of minimum quantity lubrication grinding Ni-based alloy with mixed vegetable oil-based nanofluids. Precis Eng 50:248–262

Sankaranarayanan R, Krolczyk G et al (2021) A comprehensive review on research developments of vegetable-oil based cutting fluids for sustainable machining challenges. J Manuf Process 67:286–313

Emami M, Sadeghi MH, Sarhan AAD et al (2014) Investigating the minimum quantity lubrication in grinding of AL2O3 engineering ceramic. J Clean Prod 66:632–643

Sharma J, Sidhu BS (2014) Investigation of effects of dry and near dry machining on AISI D2 steel using vegetable oil. J Clean Prod 66:619–623

Sarıkaya M, Güllü A (2015) Multi-response optimization of minimum quantity lubrication parameters using Taguchi-based grey relational analysis in turning of difficult-to-cut alloy Haynes 25. J Clean Prod 91:347–357

Rahim E, Sasahara H (2011) A study of the effect of palm oil as MQL lubricant on high speed drilling of titanium alloys. Tribol Int 44(3):309–317

Hu Y, Dang H, Liu W et al (2000) Friction characteristics of vegetable oil fatty acids. Lubr Oil 15(4):38–40

Zhang Y, Li C, Jia D et al (2015) Experimental evaluation of nanoparticles in jet MQL grinding nickel-based alloys. Modular Mach Tool Autom Manuf Tech 6:113–117

Ye B, Yu W, Wang B et al (2005) Rheological and tribological characteristics of chemically modified castor oil. Lubr Eng 1:37–38

Jiugen W, Jianzhong Z (2005) On formation and breakup of boundary lubricating layer. Lubrication Engineering-Huangpu- 6(172):4

Debnath S, Reddy MM, Yi QS (2014) Environmental friendly cutting fluids and cooling techniques in machining: a review. J Clean Prod 83:33–47

Huang B, Changhe L, Zhang Y et al (2021) Advances in fabrication of ceramic corundum abrasives based on sol–gel process. Chin J Aeronaut 34(6):1–17

Li B, Li C, Zhang Y et al (2017) Heat transfer performance of MQL grinding with different nanofluids for Ni-based alloys using vegetable oil. J Clean Prod 154:1–11

Virdi RL, Chatha SS, Singh H (2021) Experimental investigations on the tribological and lubrication behaviour of minimum quantity lubrication technique in grinding of Inconel 718 alloy. Tribol Int 153:106581

Virdi RL, Chatha SS, Singh H (2020) Machining performance of Inconel-718 alloy under the influence of nanoparticles based minimum quantity lubrication grinding. J Manuf Process 59:355–365

Makhesana MA, Patel KM (2022) Performance assessment of vegetable oil-based nanofluid in minimum quantity lubrication (MQL) during machining of Inconel 718. Adv Mater Process Technol 8(3):3182–3198

Virdi RL, Chatha SS, Singh H (2022) Processing characteristics of different vegetable oil-based nanofluid MQL for grinding of Ni-Cr alloy advances in materials and processing technologies 8(1):210–223

Makhesana MA, Patel KM, Khanna N (2022) Analysis of vegetable oil-based nano-lubricant technique for improving machinability of Inconel 690. J Manuf Process 77:708–721

Danish M, Gupta MK, Rubaiee S et al (2021) Influence of graphene reinforced sunflower oil on thermo-physical, tribological and machining characteristics of Inconel 718. J Market Res 15:135–150

Ali MAM, Azmi AI, Murad MN et al (2020) Roles of new bio-based nanolubricants towards eco-friendly and improved machinability of Inconel 718 alloys. Tribol Int 144:106106

Ghadimi A, Metselaar IH (2013) The influence of surfactant and ultrasonic processing on improvement of stability, thermal conductivity and viscosity of titania nanofluid. Exp Thermal Fluid Sci 51:1–9

Ali M, Azmi A, Khalil A (2017) Parametric effects of turning TI-6AL-4V alloys with aluminum oxide nanolubricants with sdbs. In: AIP Conference Proceedings, AIP Publishing LLC 020116

Khooshechin M, Fathi S, Salimi F et al (2020) The influence of surfactant and ultrasonic processing on improvement of stability and heat transfer coefficient of CuO nanoparticles in the pool boiling. Int J Heat Mass Transf 154:119783

Gupta MK, Jamil M, Wang X et al (2019) Performance evaluation of vegetable oil-based nano-cutting fluids in environmentally friendly machining of inconel-800 alloy. Materials 12(17):2792

Venkatesan K, Mathew AT, Devendiran S et al (2019) Machinability study and multi-response optimization of cutting force, surface roughness and tool wear on CNC turned Inconel 617 superalloy using AL2O3 nanofluids in coconut oil. Procedia Manufacturing 30:396–403

Zhou F, Liang Y, Liu W (2009) Ionic liquid lubricants: designed chemistry for engineering applications. Chem Soc Rev 38(9):2590–2599

Goindi G, Sarkar P, Jayal A et al (2018) Investigation of ionic liquids as additives to canola oil in minimum quantity lubrication milling of plain medium carbon steel. Int J Adv Manuf Technol 94:881–896

Wypych G (2022) Self-healing materials: principles and technology. Elsevier

Reeves CJ, Siddaiah A, Menezes PL (2018) Tribological study of imidazolium and phosphonium ionic liquid-based lubricants as additives in carboxylic acid-based natural oil: Advancements in environmentally friendly lubricants. J Clean Prod 176:241–250

Jiménez AE, Bermúdez MD (2008) Imidazolium ionic liquids as additives of the synthetic ester propylene glycol dioleate in aluminium–steel lubrication. Wear 265(5–6):787–798

Mordukhovich G, Qu J, Howe JY et al (2013) A low-viscosity ionic liquid demonstrating superior lubricating performance from mixed to boundary lubrication. Wear 301(1–2):740–746

Sani ASA, Abd Rahim E, Sharif S et al (2019) The influence of modified vegetable oils on tool failure mode and wear mechanisms when turning AISI 1045. Tribol Int 129:347–362

Pandey A, Kumar R, Sahoo A et al (2020) Performance analysis of trihexyltetradecylphosphonium chloride ionic fluid under MQL condition in hard turning. Int J Automot Mech Eng 17(1):7629–7647

Wang A, Chen L, Jiang D et al (2014) Vegetable oil-based ionic liquid microemulsion biolubricants: Effect of integrated surfactants. Ind Crops Prod 62:515–521

Qu J, Luo H, Chi M et al (2014) Comparison of an oil-miscible ionic liquid and ZZDP as a lubricant anti-wear additive. Tribol Int 71:88–97

Pandey A, Kumar R, Sahoo AK et al (2019) A brief review on ionic fluids and its application in machining. Materials Today: Proceedings 18:4441–4448

Sani ASA, Abd Rahim E, Sharif S et al (2019) Machining performance of vegetable oil with phosphonium-and ammonium-based ionic liquids via MQL technique. J Clean Prod 209:947–964

Zhu L, Dong J, Ma Y et al (2019) Synthesis and investigation of halogen-free phosphonium-based ionic liquids for lubrication applications. Tribol Trans 62(6):943–954

Maruda RW, Krolczyk GM, Wojciechowski S et al (2020) Evaluation of turning with different cooling-lubricating techniques in terms of surface integrity and tribologic properties. Tribol Int 148:106334

Maruda RW, Legutko S, Krolczyk GM et al (2015) An influence of active additives on the formation of selected indicators of the condition of the x10crni18-8 stainless steel surface layer in MQCL conditions. Int J Surf Sci Eng 9(5):452–465

Davis B, Schueller JK, Huang Y (2015) Study of ionic liquid as effective additive for minimum quantity lubrication during titanium machining. Manuf Lett 5:1–6

Babu MN, Anandan V, Babu MD (2021) Performance of ionic liquid as a lubricant in turning Inconel 825 via minimum quantity lubrication method. J Manuf Process 64:793–804

Grzesik W, Niesłony P, Habrat W et al (2018) Investigation of tool wear in the turning of Inconel 718 superalloy in terms of process performance and productivity enhancement. Tribol Int 118:337–346

Cantero J, Díaz-Álvarez J, Miguélez M et al (2013) Analysis of tool wear patterns in finishing turning of Inconel 718. Wear 297(1–2):885–894

Khanna N, Shah P et al (2020) Comparative analysis of dry, flood, MQL and cryogenic CO2 techniques during the machining of 15-5-PH SS alloy. Tribol Int 146:106196

Şirin Ş, Yıldırım ÇV, Kıvak T et al (2021) Performance of cryo-genically treated carbide inserts under sustainable cryo-lubrication assisted milling of Inconel x750 alloy. Sustain Mater Technol 29:e00314

Pereira O, Rodríguez A, Fernández-Abia A et al (2016) Cryogenic and minimum quantity lubrication for an eco-efficiency turning of AISI 304. J Clean Prod 139:440–449

Busch K, Hochmuth C, Pause B et al (2016) Investigation of cooling and lubrication strategies for machining high-temperature alloys. Procedia CIRP 41:835–840

Manimaran G, Anwar S, Rahman MA et al (2021) Investigation of surface modification and tool wear on milling Nimonic 80a under hybrid lubrication. Tribol Int 155:106762

Jamil M, Khan AM, Gupta MK et al (2020) Influence of CO2-snow and subzero MQL on thermal aspects in the machining of TI-6AL-4V. Appl Therm Eng 177:115480

Nimel Sworna Ross K, Manimaran G (2019) Effect of cryogenic coolant on machinability of difficult-to-machine Ni–Cr alloy using PVD-TIAIN ncoated WC tool. J Braz Soc Mech Sci Eng 41:1–14

Ross NS, Mia M, Anwar S et al (2021) A hybrid approach of cooling lubrication for sustainable and optimized machining of Ni-based industrial alloy. J Clean Prod 321:128987

Pereira O, Celaya A, Urbikaín G et al (2020) CO2 cryogenic milling of Inconel 718: cutting forces and tool wear. J Market Res 9(4):8459–8468

Zhang H, Dang J, An Q et al (2022) Investigation of machinability in milling of Inconel 718 with solid Sialon ceramic tool using supercritical carbon dioxide (scCO2)-based cooling conditions. Ceram Int 48(4):4940–4952

Yildiz Y, Nalbant M (2008) A review of cryogenic cooling in machining processes. Int J Mach Tools Manuf 48(9):947–964

Pusavec F, Deshpande A, Yang S et al (2014) Sustainable machining of high temperature nickel alloy–Inconel 718: part 1–predictive performance models. J Clean Prod 81:255–269

Danish M, Gupta MK, Rubaiee S et al (2021) Influence of hybrid cryo-MQL lubri-cooling strategy on the machining and tribological characteristics of Inconel 718. Tribol Int 163:107178

Yıldırım ÇV, Kıvak T, Sarıkaya M et al (2020) Evaluation of tool wear, surface roughness/topography and chip morphology when machining of Ni-based alloy 625 under MQL, cryogenic cooling and cryo-MQL. J Market Res 9(2):2079–2092

Yıldırım ÇV (2019) Experimental comparison of the performance of nanofluids, cryogenic and hybrid cooling in turning of Inconel 625. Tribol Int 137:366–378

Sarıkaya M, Yılmaz V, Güllü A (2016) Analysis of cutting parameters and cooling/lubrication methods for sustainable machining in turning of Haynes 25 superalloy. J Clean Prod 133:172–181

Yıldırım ÇV, Kıvak T, Sarıkaya M et al (2017) Determination of MQL parameters contributing to sustainable machining in the milling of nickel-base superalloy waspaloy. Arab J Sci Eng 42:4667–4681

Su Y, Gong L, Li B et al (2016) Performance evaluation of nanofluid MQL with vegetable-based oil and ester oil as base fluids in turning. Int J Adv Manuf Technol 83:2083–2089

Nguyen TK, Do I, Kwon P (2012) A tribological study of vegetable oil enhanced by nano-platelets and implication in MQL machining. Int J Precis Eng Manuf 13:1077–1083

Vasu V, Kumar KM (2011) Analysis of nanofluids as cutting fluid in grinding en-31 steel. Nano-Micro Letters 3:209–214

Hosokawa A, Hoshino G, Koyano T et al (2018) Cutting characteristics of PVD-coated tools deposited by filtered arc deposition (FAD) method. CIRP Ann 67(1):83–86

ulHaq MA, Hussain S, Ali MA et al (2021) Evaluating the effects of nano-fluids based MQL milling of IN 718 associated to sustainable productions. J Clean Prod 310:127463

Sarhan AA, Sayuti M, Hamdi M (2012) Reduction of power and lubricant oil consumption in milling process using a new SiO2 nanolubrication system. Int J Adv Manuf Technol 63:505–512

Behera BC, Ghosh S, Rao PV et al (2016) Application of nanofluids during minimum quantity lubrication: a case study in turning process. Tribol Int 101:234–246

Sarkar J (2011) A critical review on convective heat transfer correlations of nanofluids. Renew Sustain Energy Rev 15(6):3271–3277

Sarıkaya M, Şirin Ş, Yıldırım ÇV et al (2021) Performance evaluation of whisker-reinforced ceramic tools under nano-sized solid lubricants assisted MQL turning of co-based Haynes 25 superalloy. Ceram Int 47(11):15542–15560

Bertolini R, Ghiotti A, Bruschi S (2021) Graphene nanoplatelets as additives to MQL for improving tool life in machining Inconel 718 alloy. Wear 476:203656

Sharma AK, Tiwari AK, Dixit AR (2015) Mechanism of nanoparticles functioning and effects in machining processes: a review. Materials Today: Proceedings 2(4–5):3539–3544

Yıldırım ÇV, Sarıkaya M, Kıvak T et al (2019) The effect of addition of hBN nanoparticles to nanofluid-MQL on tool wear patterns, tool life, roughness and temperature in turning of Ni-based Inconel 625. Tribol Int 134:443–456

Şirin Ş, Sarıkaya M, Yıldırım ÇV et al (2021) Machinability performance of nickel alloy x–750 with Sialon ceramic cutting tool under dry, MQL and hBN mixed nanofluid-MQL. Tribol Int 153:106673

Chetan BC, Behera S, Ghosh PV, Rao (2016) Application of nanofluids during minimum quantity lubrication: A case study in turning process. Tribol Int 101:234–246

Zhang Y, Li C, Jia D et al (2016) Experimental study on the effect of nanoparticle concentration on the lubricating property of nanofluids for MQL grinding of Ni-based alloy. J Mater Process Technol 232:100–115

Musavi SH, Davoodi B, Niknam S (2019) Effects of reinforced nanoparticles with surfactant on surface quality and chip formation morphology in MQL-turning of superalloys. J Manuf Process 40:128–139

Korkmaz ME, Gupta MK, Boy M et al (2021) Influence of duplex jets MQL and nano-MQL cooling system on machining performance of Nimonic 80a. J Manuf Process 69:112–124

Behera BC, Alemayehu H, Ghosh S et al (2017) A comparative study of recent lubri-coolant strategies for turning of Ni-based superalloy. J Manuf Process 30:541–552

Şirin Ş, Kıvak T (2021) Effects of hybrid nanofluids on machining performance in MQL-milling of Inconel x–750 superalloy. J Manuf Process 70:163–176

Bermingham M, Kirsch J, Sun S et al (2011) New observations on tool life, cutting forces and chip morphology in cryogenic machining TI-6AL-4V. Int J Mach Tools Manuf 51(6):500–511

Barewar SD, Kotwani A, Chougule SS et al (2021) Investigating a novel Ag/ZnO based hybrid nanofluid for sustainable machining of Inconel 718 under nanofluid based minimum quantity lubrication. J Manuf Process 66:313–324

Zhang X, Li C, Zhang Y et al (2017) Lubricating property of MQL grinding of al2o3/sic mixed nanofluid with different particle sizes and microtopography analysis by cross-correlation. Precis Eng 47:532–545

Allam I (1991) Solid lubricants for applications at elevated temperatures: A review. J Mater Sci 26:3977–3984

Reddy NSK, Rao PV (2006) Experimental investigation to study the effect of solid lubricants on cutting forces and surface quality in end milling. Int J Mach Tools Manuf 46(2):189–198

Paturi UMR, Narala SKR (2015) Experimental investigation to study the effect of electrostatic micro-solid lubricant–coated carbide tools on machinability parameters in turning. Proc Inst Mech Eng Part B: J Eng Manuf 229(5):693–702

Pavan RB, Venu Gopal A, Amrita M et al (2019) Experimental investigation of graphene nanoplatelets–based minimum quantity lubrication in grinding Inconel 718. Proc Inst Mech Eng Part B: J Eng Manuf 233(2):400–410

Alberts M, Kalaitzidou K, Melkote S (2009) An investigation of graphite nanoplatelets as lubricant in grinding. Int J Mach Tools Manuf 49(12–13):966–970

De Oliveira D, Da Silva R, Gelamo R (2019) Influence of multilayer graphene platelet concentration dispersed in semi-synthetic oil on the grinding performance of Inconel 718 alloy under various machining conditions. Wear 426:1371–1383

Tazehkandi AH, Shabgard M, Pilehvarian F (2015) On the feasibility of a reduction in cutting fluid consumption via spray of biodegradable vegetable oil with compressed air in machining Inconel 706. J Clean Prod 104:422–435

Cui X, Li C, Zhang Y et al (2022) Grindability of titanium alloy using cryogenic nanolubricant minimum quantity lubrication. J Manuf Process 80:273–286

Singh G, Aggarwal V, Singh S et al (2022) Experimental investigation and performance optimization during machining of Hastelloy C-276 using green lubricants. Materials 15(15):5451

Cui X, Sun N, Guo J et al (2022) Green multi-biomimetic spontaneous oil-transport microstructure and its effects on energy consumption in sustainable intermittent cutting. J Clean Prod 367:133035

Cabanettes F, Faverjon P, Sova A et al (2017) MQL machining: from mist generation to tribological behavior of different oils. Int J Adv Manuf Technol 90:1119–1130

Gupta K, Laubscher R, Davim JP et al (2016) Recent developments in sustainable manufacturing of gears: a review. J Clean Prod 112:3320–3330

Lv T, Xu X, Yu A et al (2021) Ambient air quantity and cutting performances of water-based fe3o4 nanofluid in magnetic minimum quantity lubrication. Int J Adv Manuf Technol 115(5–6):1711–1722

Krolczyk GM, Maruda RW, Krolczyk JB et al (2019) Ecological trends in machining as a key factor in sustainable production–a review. J Clean Prod 218:601–615

Wei Z, Ning H, Liang L et al (2014) Investigation on the influence of system parameters on ambient air quality in minimum quantity lubrication milling process. J Mech Eng 50(13):184–189

Zhai SR, Albritton D (2020) Airborne particles from cooking oils: Emission test and analysis on chemical and health implications. Sustain Cities Soc 52:101845

Lee T, Gany F (2013) Cooking oil fumes and lung cancer: a review of the literature in the context of the us population. J Immigr Minor Health 15:646–652

Hadad M (2015) An experimental investigation of the effects of machining parameters on environmentally friendly grinding process. J Clean Prod 108:217–231

Huo Y, Wang J, Zuo Z et al (2015) Visualization of the evolution of charged droplet formation and jet transition in electrostatic atomization. Phys Fluids 27(11):114105

Jia D, Li C, Liu J, et al (2023) Prediction model of volume average diameter and analysis of atomization characteristics in electrostatic atomization minimum quantity lubrication. Friction pp 1–25

Lv T, Huang S, Liu E et al (2018) Tribological and machining characteristics of an electrostatic minimum quantity lubrication (EMQL) technology using graphene nano-lubricants as cutting fluids. J Manuf Process 34:225–237

Huang S, Lv T, Wang M et al (2018) Enhanced machining performance and lubrication mechanism of electrostatic minimum quantity lubrication-EMQL milling process. Int J Adv Manuf Technol 94:655–666

Huang S, Lv T, Xu X et al (2018) Experimental evaluation on the effect of electrostatic minimum quantity lubrication (EMQL) in end milling of stainless steels. Mach Sci Technol 22(2):271–286

Shah P, Gadkari A, Sharma A et al (2021) Comparison of machining performance under MQL and ultra-high voltage EMQL conditions based on tribological properties. Tribol Int 153:106595

Xu X, Lv T, Luan Z et al (2019) Capillary penetration mechanism and oil mist concentration of AL2O3 nanoparticle fluids in electrostatic minimum quantity lubrication (EMQL) milling. Int J Adv Manuf Technol 104:1937–1951

Su Y, Gong L, Cao H, et al (2016) Optimization of electrostatic atomization cutting using 3d fesimulation of electrostatic field. In: Key Engineering Materials, Trans Tech Publ, 1255–1262

De Bartolomeis A, Newman ST, Shokrani A (2020) Initial investigation on surface integrity when machining Inconel 718 with conventional and electrostatic lubrication. Procedia CIRP 87:65–70

De Bartolomeis A, Newman ST, Shokrani A (2021) High-speed milling Inconel 718 using electrostatic minimum quantity lubrication (EMQL). Procedia CIRP 101:354–357

Airao J, Khanna N, Nirala CK (2022) Tool wear reduction in machining Inconel 718 by using novel sustainable cryo-lubrication techniques. Tribol Int 175:107813

Salvi H, Vesuwala H, Raval P et al (2023) Sustainability analysis of additive+ subtractive manufacturing processes for Inconel 625. Sustain Mater Technol 35:e00580

Bailey A (1984) Electrostatic phenomena during powder handling. Powder Technol 37(1):71–85

Funding

This study was supported by a research project financed by the National Natural Science Foundation of China (number 5217052158).

Author information

Authors and Affiliations

Contributions

Conceptualization, Shu Zhou; software, Dazhong Wang and Shujing Wu; writing review, Guquan Gu and Guojun Dong; editing, Qinglong An, Hun Guo, and Changhe Li. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Competing interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhou, S., Wang, D., Wu, S. et al. Minimum quantity lubrication machining nickel base alloy: a comprehensive review. Int J Adv Manuf Technol 131, 2407–2445 (2024). https://doi.org/10.1007/s00170-023-11721-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11721-6