Abstract

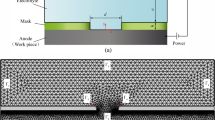

Through-mask electrochemical micromachining (TMEMM) has been widely used in the machining of micro-structures because of its high processing efficiency, no electrode loss, and no residual stress. In order to solve the problem of poor structure uniformity in the process of TMEMM, this paper proposed a moving cathode TMEMM technology on the basis of conventional TMEMM and made a microgroove array based on the moving cathode TMEMM technology. Firstly, the numerical analysis of moving cathode TMEMM was carried out by COMSOL finite element analysis software. The influence of different machining parameters on the anodic micro-groove etching profile was studied and the nonuniformity of the etching depth was calculated. The simulation results show that moving cathode TMEMM can improve the etching depth uniformity of microgroove array structure. Secondly, on the basis of numerical simulation, TMEMM experiments were carried out. The experimental results indicate that the moving cathode TMEMM method can effectively improve the size uniformity of microgroove array. It can be observed by microscope that the microgroove array obtained by TMEMM with a moving cathode has good structural morphology and higher uniformity. Compared with conventional TMEMM, the uniformity of TMEMM with moving cathode improved by 68.3% and the simulation results are basically consistent with the experimental results. The moving cathode TMEMM method can greatly improve the uniformity of microgroove array.

Similar content being viewed by others

References

Tong X, Zheng JY, Fu MW (2022) Numerical and experimental study of the size effect on deformation behavior and quality of microembossed multi-channel structures. J Manuf Process 78:363–375

Zheng G, Lin Y (2021) Tribological properties of micro-groove cemented carbide by laser processing. Micromachines 12(5):486

Su Y, Li Z, Li L, Wang J, Gao H, Wang G (2017) Cutting performance of micro-textured polycrystalline diamond tool in dry cutting. J Manuf Process 27:1–7

Zhang S, Lin L, Chen G, Tang H, Zeng J, Yuan W, Tang Y (2019) Experimental study on the capillary performance of aluminum micro-grooved wicks with reentrant cavity array. Int J Heat Mass Transf 139:917–927

Lim K, Lee K, Ki H, Lee J (2022) Enhancement of flow boiling heat transfer by laser-induced periodic surface structures using femtosecond laser. Int J Heat Mass Transf 196:123229

Baldhoff T, Nock V, Marshall AT (2018) Through-mask electrochemical micromachining. J Electrochem Soc 165(16):E841

Baldhoff T, Nock V, Marshall AT (2017) Through-mask electrochemical micromachining of aluminum in phosphoric acid. J Electrochem Soc 164(9):E194

Tsai TH, Lin MY, Huang WL (2021) The optimization of parameters using Taguchi-method in through-mask electrochemical machining. Sādhanā 46:1–7

Chen X, Qu N, Li H (2015) Improvement of dimensional uniformity on micro-dimple arrays generated by electrochemical micro-machining with an auxiliary electrode. Int J Adv Manuf Technol 80:1577–1585

Raffelstetter P, Mollay B (2010) On the modeling of shape evolution in through-mask electrochemical micromachining of complex patterned substrates. Electrochim Acta 55(6):2149–2157

Chun K, Jin D, Kim S, Lee E (2017) Comparison between wire mesh and plate electrodes during wide-pattern machining on invar fine sheet using through-mask electrochemical micromachining. J Mech Sci Technol 31:1851–1859

Zhang X, Qu N, Chen X (2016) Sandwich-like electrochemical micromachining of micro-dimples. Surf Coat Technol 302:438–447

Zhao C, Ming P, Zhang X, Qin G, Shen J, Yan L, Zheng X, Cao J (2020) Through-mask electrochemical micromachining with reciprocating foamed cathode. Micromachines 11(2):188

Pan Y, Hou Z, Qu N (2019) Improvement in accuracy of micro-dimple arrays prepared by micro-electrochemical machining with high-pressure hydrostatic electrolyte. Int J Adv Manuf Technol 100:1767–1777

Fan G, Chen X, Saxena KK, Liu J, Guo Z (2020) Jet electrochemical micromachining of micro-grooves with conductive-masked porous cathode. Micromachines 11(6):557

Kendall T, Bartolo P, Gillen D, Diver C (2019) A review of physical experimental research in jet electrochemical machining. Int J Adv Manuf Technol 105:651–667

Leese RJ, Ivanov A (2016) Electrochemical micromachining: an introduction. Adv Mech Eng 8(1):1687814015626860

Haisch T, Mittemeijer EJ, Schultze JW (2004) High rate anodic dissolution of 100Cr6 steel in aqueous NaNO3 solution. J Appl Electrochem 34:997–1005

Ryu SH (2015) Eco-friendly ECM in citric acid electrolyte with microwire and microfoil electrodes. Int J Precis Eng Manuf 16:233–239

Hume EC, Deen WM, Brown RA (1984) Mass transfer analysis of electrodeposition through polymeric masks. J Electrochem Soc 131(6):1251

Luo JK, Chu DP, Flewitt AJ, Spearing SM, Fleck NA, Milne WI (2005) Uniformity control of Ni thin-film microstructures deposited by through-mask plating. J Electrochem Soc 152(1):C36–C41

Funding

This work was supported by the National Key Research and Development Program of China (No. 2022YFB4600102), the Natural Science Foundation of Hebei Province of China (No. E2022201028), and National Natural Science Foundation of China (No. 51975103).

Author information

Authors and Affiliations

Contributions

Ke Zhai: all experiments, design of device, and writing; Feng Zhou: material preparation and writing; Yikui Wen: part of the electrochemical experiments and characterization; Wenya Xu: data collection and analysis. Liqun Du: conceptualization, methodology, writing, and supervision of students.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhai, K., Zhou, F., Wen, Y. et al. Study on the uniformity of microgrooves in through-mask electrochemical micromachining with moving cathode. Int J Adv Manuf Technol 127, 2737–2744 (2023). https://doi.org/10.1007/s00170-023-11629-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11629-1