Abstract

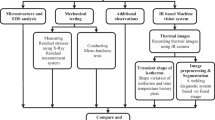

This paper proposes to qualify the minimal quality deviation that can be detected by a near-infrared camera during aluminum wire arc additive manufacturing. First, a review of the literature is done to highlight the interest in monitoring the melt pool in industrial condition for thermal management during manufacturing. It points out the relevance of the use of a near-infrared camera for steels, but it has to be demonstrated for aluminum alloys. Indeed, the melt pool of the aluminum is significantly dimmer and less distinct than the melt pool of the steels. An experimental design is proposed to qualify the minimal quality deviation that can be detected on a thin wall. The chosen default to correlate with the thermal deviation is the width of the wall. A method is proposed to extract a thermal metric from the camera image and to analyze its sensitivity to a width deviation of the wall. The paper shows the correlation between the width of the wall and the thermal metric for different heat conditions. Moreover, the thermal metric is sensitive to width deviation either on the wall scale or on the bead scale. It indicates the relevance of a near-infrared camera to detect heat accumulation-induced width deviation during wire arc additive manufacturing of aluminum alloy.

Similar content being viewed by others

References

Xia C, Pan Z, Polden J et al (2020) A review on wire arc additive manufacturing: monitoring, control and a framework of automated system. J Manuf Syst 15. https://doi.org/10.1016/j.jmsy.2020.08.008

Ding D, Pan Z, Cuiuri D, Li H (2015) Wire-feed additive manufacturing of metal components: technologies, developments and future interests. Int J Adv Manuf Technol 81:465–481. https://doi.org/10.1007/s00170-015-7077-3

Chen X, Kong F, Fu Y et al (2021) A review on wire-arc additive manufacturing: typical defects, detection approaches, and multisensor data fusion-based model. Int J Adv Manuf Technol 117:707–727. https://doi.org/10.1007/s00170-021-07807-8

Rodríguez-González P, Ruiz-Navas EM, Gordo E (2023) Wire arc additive manufacturing (WAAM) for aluminum-lithium alloys: a review. Materials 16:1375. https://doi.org/10.3390/ma16041375

Béraud N, Chergui A, Limousin M et al (2022) An indicator of porosity through simulation of melt pool volume in aluminum wire arc additive manufacturing. Mech Ind 23:1. https://doi.org/10.1051/meca/2021052

Marinelli G, Martina F, Ganguly S, Williams S (2019) Development of wire + arc additive manufacturing for the production of large-scale unalloyed tungsten components. Int J Refract Met Hard Mater 16. https://doi.org/10.1016/j.ijrmhm.2019.05.009

Ding J, Colegrove P, Mehnen J et al (2011) Thermo-mechanical analysis of wire and arc additive layer manufacturing process on large multi-layer parts. Comput Mater Sci 50:3315–3322. https://doi.org/10.1016/j.commatsci.2011.06.023

Sun J, Hensel J, Köhler M, Klaus D (2021) Residual stress in wire and arc additively manufactured aluminum components. J Manufac Process 65:97–111. https://doi.org/10.1016/j.jmapro.2021.02.021

Laghi V, Palermo M, Gasparini G et al (2019) Geometrical characterization of wire-and-arc additive manufactured steel element. Adv Mater Lett 10:695–699. https://doi.org/10.5185/amlett.2019.0019

Yildiz AS, Davut K, Koc B, Yilmaz O (2020) Wire arc additive manufacturing of high-strength low alloy steels: study of process parameters and their influence on the bead geometry and mechanical characteristics. Int J Adv Manuf Technol 108:3391–3404. https://doi.org/10.1007/s00170-020-05482-9

Tonelli L, Laghi V, Palermo M et al (2021) AA5083 (Al–Mg) plates produced by wire-and-arc additive manufacturing: effect of specimen orientation on microstructure and tensile properties. Prog Addit Manuf 6:479–494. https://doi.org/10.1007/s40964-021-00189-z

Wu B, Pan Z, Ding D et al (2018) A review of the wire arc additive manufacturing of metals: properties, defects and quality improvement. J Manuf Process 35:127–139. https://doi.org/10.1016/j.jmapro.2018.08.001

Köhler M, Hensel J, Dilger K (2020) Effects of thermal cycling on wire and arc additive manufacturing of Al-5356 components. Metals 10:952. https://doi.org/10.3390/met10070952

Bikas H, Stavropoulos P, Chryssolouris G (2016) Additive manufacturing methods and modelling approaches: a critical review. Int J Adv Manuf Technol 83:389–405. https://doi.org/10.1007/s00170-015-7576-2

Raghunath N, Pandey PM (2007) Improving accuracy through shrinkage modelling by using Taguchi method in selective laser sintering. Int J Mach ToolsManuf 47:985–995. https://doi.org/10.1016/j.ijmachtools.2006.07.001

Chergui A, Villeneuve F, Béraud N, Vignat F (2022) Thermal simulation of wire arc additive manufacturing: a new material deposition and heat input modelling. Int J Interact Des Manuf. https://doi.org/10.1007/s12008-021-00824-7

Stavropoulos P, Chantzis D, Doukas C et al (2013) Monitoring and control of manufacturing processes: a review. Procedia CIRP 8:421–425. https://doi.org/10.1016/j.procir.2013.06.127

Xu F, Dhokia V, Colegrove P et al (2018) Realisation of a multi-sensor framework for process monitoring of the wire arc additive manufacturing in producing Ti-6Al-4V parts. Int J Comput Integr Manuf 31:785–798. https://doi.org/10.1080/0951192X.2018.1466395

Davies GJ, Garland JG (1975) Solidification structures and properties of fusion welds. Int Metall Rev 20:83–108. https://doi.org/10.1179/imtlr.1975.20.1.83

Halisch C, Radel T, Tyralla D, Seefeld T (2020) Measuring the melt pool size in a wire arc additive manufacturing process using a high dynamic range two-colored pyrometric camera. Weld World 64:1349–1356. https://doi.org/10.1007/s40194-020-00892-5

García de la Yedra A, Pfleger M, Aramendi B et al (2019) Online cracking detection by means of optical techniques in laser-cladding process. Struct Control Health Monit 26:e2291. https://doi.org/10.1002/stc.2291

Xiong J, Lei Y, Chen H, Zhang G (2017) Fabrication of inclined thin-walled parts in multi-layer single-pass GMAW-based additive manufacturing with flat position deposition. J Mater Process Technol 240:397–403. https://doi.org/10.1016/j.jmatprotec.2016.10.019

Rouquette S, Cambon C, Bendaoud I, Soulié F (2020) Estimation of the heat source parameters during the deposition of SS316L wire with GMAW-CMT process: application to additive manufacturing. Société Française de Thermique. https://doi.org/10.25855/SFT2020-128

Dellarre A, Limousin M, Beraud N (2023) Melt pool acquisition using near-infrared camera in aluminum wire arc additive manufacturing. In: Gerbino S, Lanzotti A, Martorelli M et al (eds) Advances on Mechanics, Design Engineering and Manufacturing IV. Springer International Publishing, Cham, pp 803–814

Cambon C, Bendaoud I, Rouquette S, Soulié F (2022) A WAAM benchmark: from process parameters to thermal effects on weld pool shape, microstructure and residual stresses. Mater Today Commun 33:104235. https://doi.org/10.1016/j.mtcomm.2022.104235

Manokruang S, Vignat F, Museau M, Linousin M (2021) Model of weld beads geometry produced on surface temperatures by wire and arc additive manufacturing (WAAM). IOP Conf Ser: Mater Sci Eng 1063:012008. https://doi.org/10.1088/1757-899X/1063/1/012008

Montevecchi F, Venturini G, Grossi N et al (2018) Idle time selection for wire-arc additive manufacturing: a finite element-based technique. Addit Manuf 21:479–486. https://doi.org/10.1016/j.addma.2018.01.007

Bradski G, Kaehler A (2008) Learning OpenCV: computer vision with the OpenCV library. O’Reilly Media, Inc.

Dellarre A, Béraud N, Tardif N, Vignat F, Villeneuve F, Limousin M (2022) Qualify a near-infrared camera to detect thermaldeviation during aluminum alloy wire arc additive manufacturing. Recherche Data Gouv. https://doi.org/10.57745/7HF7KG

Acknowledgements

This work made use of the facilities of the platform S.mart Grenoble Alpes. The authors thank the staff of S.mart Grenoble Alpes, especially Devos Camille and Duong Quoc-Bao for their help on 0-V detection.

Funding

This work benefited from the support of the project METALICANR-21-CE10-0003 of the French National Research Agency (ANR).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection, and analysis were performed by Anthony Dellarre and Nicolas Béraud. The first draft of the manuscript was written by Anthony Dellarre, and all authors commented on previous versions of the manuscript. All authors read and approved the final version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Dellarre, A., Béraud, N., Tardif, N. et al. Qualify a NIR camera to detect thermal deviation during aluminum WAAM. Int J Adv Manuf Technol 127, 625–634 (2023). https://doi.org/10.1007/s00170-023-11587-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11587-8