Abstract

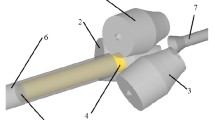

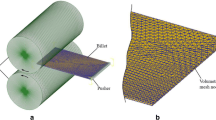

The results of mathematical modeling of the process of combined rolling-extrusion (CRE) of a round billet in closed box calibers are presented. With the help of the created models, dependences were obtained and regularities were established for the influence of process parameters, as well as friction conditions at the contact of metal with rolls and a die on its feasibility. The variational problem of finding the geometric and energy-power characteristics of the investigated combined rolling-extrusion process from the dimensionless parameters of the deformation zone is solved. The analysis was carried out and dependences were obtained to determine the distance between the die and the common axis of the rolls, the coefficients of the stressed state and power in a wide range of change in dimensionless parameters that unambiguously characterize the deformation zone of the investigated process. Using the developed models, a quantitative assessment of the feasibility of the CRE process was carried out, the force and torque were calculated for the guaranteed implementation of combined rolling-extrusion, and the geometric dimensions of the roll and extruding tool for the combined processing units CRE-200 and CRE-400 were selected. Checking the adequacy of the developed mathematical models was carried out using experimental data on the production of rods from alloy 01417 on these units. Estimation of the error in the calculated values of the geometrical and energy-power parameters of the investigated CRE process showed that for the selected range of dimensionless parameters of the deformation zone, it does not exceed 10% in comparison with the experimental data.

Similar content being viewed by others

Data availability

Not applicable.

References

Gorbunov YA (2015) The role and prospects of rare earth metals in the development of physical-mechanical characteristics and applications of deformable aluminum alloys. Journal of Siberian Federal University. Eng Technol 8(5):636–645. http://journal.sfu-kras.ru/en/article/19784 Accessed 17 Jan 2023

Belyy DI (2012) Aluminium alloys for leads of cable products. Kabeli i Provoda 1:8–15

Czerwinski F, Amirkhiz BS (2020) On the Al-Al11Ce3 eutectic transformation in aluminum-cerium binary alloys. Materials 13(20):4549. https://doi.org/10.3390/ma13204549Accessed17Jan2023

Czerwinski F (2020) Critical assessment 36: assessing differences between the use of cerium and scandium in aluminium alloying. Mater Sci Technol (United Kingdom), 36(3):255–263. https://www.tandfonline.com/doi/full/10.1080/02670836.2019.1702775 Accessed 17 Jan 2023

Belov NA, Korotkova NO, Akopyan TK, Timofeev VN (2020) Structure and properties of Al-0.6%Zr-0.4%Fe-0.4%Si (wt.%) wire alloy manufactured by electromagnetic casting. 72(4):1561–1570. https://doi.org/10.1007/s11837-019-03875-0 Accessed 17 Jan 2023

Simlandi S, Barman N, Chattopadhyay H (2013) Studies on transport phenomena during continuous casting of an Al-alloy in presence of electromagnetic stirring. Trans Indian Inst Met 66(2):141–146. https://doi.org/10.1007/s12666-012-0205-yAccessed17Jan2023

Tani M, Zeze M, Toh T, Tsunenari K (2013) Electromagnetic casting technique for slab casting. Nippon steel technical report. 104:56–61. https://www.nipponsteel.com/en/tech/report/nsc/pdf/104-11.pdf Accessed 17 Jan 2023

Yu-bo Zuo, Jian-zhong Cui, Dan Mou, Qing-feng Zhu, Xiang-jie Wang, Lei Li (2014) Effect of electromagnetic field on microstructure and macrosegregation of flat ingot of 2524 aluminium alloy. Trans. Nonferrous Metals Soc China. 24:2408–2413. https://www.sciencedirect.com/science/article/abs/pii/S1003632614633641 Accessed 17 Jan 2023

Liao H, Wu Y, Wang Y (2015) Microstructure evolution of Al-0.35%Si-0.2%Mg-0.3%Ce alloy during hot extrusion and its contributions to performances. J Mater Eng Perform, 24(6), 2503–2510. https://link.springer.com/article/10.1007/s11665-015-1485-2 Accessed 17 Jan 2023

Liao H, Liu Y, Lü C, Wang Q (2017) Mechanisms for Ce-induced remarkable improvement of conductivity in Al alloys. J Mater Res, 32(3), 566–574. https://www.cambridge.org/core/journals/journal-of-materials-research/article/abs/mechanisms-for-ceinduced-remarkable-improvement-of-conductivity-in-al-alloys/9DD686C179F53B383C0A1E17B2527FB4# Accessed 17 Jan 2023

Shi ZM, Gao K, Shi YT, Wang Y (2017) Microstructure and mechanical properties of rare-earth-modified Al−1Fe binary alloys. Mater Sci Eng: A, 632:62–71. https://www.sciencedirect.com/science/article/abs/pii/S0921509315001963 Accessed 17 Jan 2023

Zhang M, Wang H, Han W, Zhang M, Li Y, Wang Y, Xue Y, Ma F, Zhang X (2014) Electrochemical extraction of cerium and formation of Al–Ce alloy from CeO2 assisted by AlCl3 in LiCl–KCl melts. Sci China Chem, 57(11), 1477–1482. https://link.springer.com/article/10.1007/11426-014-5214-8 Accessed 17 Jan 2023

Mogucheva A, Zyabkin D, Kaibyshev R (2012) Effect of the thermomechanical processing on microstructure and properties of an Al-Ce alloy. Mater Sci Forum 706–709:361–366. https://doi.org/10.4028/www.scientific.net/MSF.706-709.361Accessed17Jan2023

Belov NA, Alabin AN, Teleuova AR (2012) Comparative analysis of alloying additives as applied to the production of heat-resistant aluminum-base wires. Met Sci Heat Treat, 53(9–10):455–459. https://link.springer.com/article/10.1007/s11041-012-9415-5 Accessed 17 Jan 2023

Zhang Y, Wei F, Mao J, Niu G (2019) The difference of La and Ce as additives of electrical conductivity aluminum alloys. Mater Charact, 158:109963. https://www.sciencedirect.com/science/article/abs/pii/S1044580319312847?via%3Dihub Accessed 17 Jan 2023

Zhu R, Su Y, Qin X, Hu N, Lu L (2019) Effect of rare earth elements on the microstructure and properties of a die-cast aluminum alloy. Materialpruefung/Mater Test 61(2):159–163. https://doi.org/10.3139/120.111299Accessed17Jan2023

He Ya, Liu J, Qiu Sh, Deng Zh, Zhang J, Shen Ya (2017) Microstructure evolution and mechanical properties of Al-La alloys with varying La contents. Mater Sci Eng A, 701, 134–142. https://www.sciencedirect.com/science/article/abs/pii/S0921509317307876 Accessed 17 Jan 2023

Yang Q, Bu FQ, Meng FC, Qiu X, Zhang DP, Zheng T, Liu XJ, Meng J (2015) The improved effects by the combinative addition of lanthanum and samarium on the microstructures and the tensile properties of high-pressure die-cast Mg-4Al-based alloy. Mater Sci Eng A, 628:319–326. https://www.sciencedirect.com/science/article/abs/pii/S0921509315000660 Accessed 17 Jan 2023

Jiang W, Fan Z, Dai Y, Li C (2014) Effects of rare earth elements addition on microstructures, tensile properties and fractography of A357 alloy. Mater Sci Eng A, 597, 237–244. https://www.sciencedirect.com/science/article/abs/pii/S0921509314000264 Accessed 17 Jan 2023

Huang X, Yan H (2013) Effect of trace La addition on the microstructure and mechanical property of as-cast ADC12 Al-alloy. J Wuhan Univ Technol-Materials Sci Ed 28:202–205

Ye W, Yan X, Zhang X, Liu E, Liu C, Di C, Miao Y (2019) Effects of trace cerium on as-cast microstructure and electrical conductivity of industrial pure aluminum. Tezhong Zhuzao Ji Youse Hejin/Special Casting and Nonferrous Alloys 39(10), 1149–1150 and 1151. https://doi.org/10.15980/j.tzzz.2019.10.027

Yuan W, Liang Zh, Zhang Ch, Wei L (2012) Effects of La addition on mechanical properties and thermal-resistant properties of Al-Mg-Si-Zr alloys based on AA6201. Mater Des, 34, 788–792. https://www.sciencedirect.com/science/article/abs/pii/S026130691100481X Accessed 17 Jan 2023

Feng W, Jian M, Chunfang L, HuiHua L (2018) Effect of trace elements La, Ti and homogenization on electrical properties of pure aluminum. Rare Metal Mater Eng, 47:3257–3263. https://www.sciencedirect.com/science/article/abs/pii/S1875537218302297 Accessed 17 Jan 2023

Lü C-L, Liao H-C, Liu Y, Wang Q-G (2015) Effect of Ce on castability, mechanical properties and electric conductivity of commercial purity aluminum. China Foundry, 12:277–284. http://ff.foundryworld.com/uploadfile/2015081939445589.pdf Accessed 17 Jan 2023

Cao XH, Wang SJ (2011) Influences of annealing and deformation on the high temperature internal friction spectra of Al-0.013%Wt Ce alloy. Adv Mater Res, 197–198:1573–1576. https://doi.org/10.4028/www.scientific.net/AMR.197-198.1573 Accessed 17 Jan 2023

Yao D, Xia Y, Qiu F, Jiang Q (2011) Effects of La addition on the elevated temperature properties of the casting Al–Cu alloy. Mater Sci Eng A, 528:1463–1466. https://www.sciencedirect.com/science/article/abs/pii/S0921509310012116 Accessed 17 Jan 2023

Du J, Ding D, Zhang W, Xu Z, Gao Y, Chen G, You X, Chen R, Huang Y, Tang J (2018) Effect of Ce addition on the microstructure and properties of Al-Cu-Mn-Mg-Fe lithium battery shell alloy. Mater Char, 142:252–260. https://www.sciencedirect.com/science/article/abs/pii/S1044580317335374 Accessed 17 Jan 2023

Huang X, Yan H (2013) Effect of trace la addition on the microstructure and mechanical property of as-cast ADC12 Al-alloy. J Wuhan Univ Technol-Mat Sci Edit 28(1):202–205. https://doi.org/10.1007/s11595-013-0665-xAccessed17Jan2023

Lu T, Pan Y, Wu J, Tao S, Chen Y (2015) Effects of La addition on the microstructure and tensile properties of Al-Si-Cu-Mg casting alloys. Int J Miner Metall Mater, 22, 405–410. https://link.springer.com/article/10.1007/s12613-015-1086-y Accessed 17 Jan 2023

Liao HC, Liu Y, Lu CL, Wang QG (2015) Effect of Ce addition on castability, mechanical properties and electric conductivity of Al-0.3Si-0.2 Mg alloy. Int J Cast Metals Res, 28:213–220. https://www.tandfonline.com/doi/abs/10.1179/1743133615Y.0000000002?journalCode=ycmr20 Accessed 17 Jan 2023

Vijeesh V, Prabhu KN (2015) The effect of addition of Ce and Sr on the solidification path of Al–8Si–2Cu alloy. Trans Indian Inst Met, 68:1119–1123. https://link.springer.com/article/10.1007/s12666-015-0656-z Accessed 17 Jan 2023

Li H-Y, Zhao F, Yang S-L (2020) Effect of Ce-rich rare earth addition on microstructure and electrical conductivity of aluminum alloy. Zhongguo Youse Jinshu Xuebao/Chinese Journal of Nonferrous Metals 30(4):719–727. https://doi.org/10.11817/j.ysxb.1004.0609.2020-39488

Medvedev AE, Murashkin MY, Enikeev NA, Bikmukhametov I, Valiev RZ, Hodgson PD, Lapovok R (2019) Effect of the eutectic Al-(Ce,La) phase morphology on microstructure, mechanical properties, electrical conductivity and heat resistance of Al-4.5(Ce,La) alloy after SPD and subsequent annealing. J Alloys Compd, 796:321–330. https://www.sciencedirect.com/science/article/abs/pii/S0925838819316640 Accessed 17 Jan 2023

Murashkin MY, Sabirov I, Medvedev AE, Enikeev NA, Lefebvre W, Valiev RZ, Sauvage X (2016) Mechanical and electrical properties of an ultrafine grained Al-8.5wt. % RE (RE=5.4wt.% Ce, 3.1wt.% La) alloy processed by severe plastic deformation. Mater Des, 90:433–442. https://www.sciencedirect.com/science/article/abs/pii/S0264127515307413 Accessed 17 Jan 2023

Valiev RZ, Murashkin MY, Sabirov I (2014) A nanostructural design to produce high-strength Al alloys with enhanced electrical conductivity. Scripta Mater, 76:13–16. https://www.sciencedirect.com/science/article/abs/pii/S1359646213006015 Accessed 17 Jan 2023

Matveeva I, Dovzhenko N, Sidelnikov S, Trifonenkov L, Baranov V, Lopatina E (2013) Development and research of new aluminium alloys with transition and rare-earth metals and equipment for production of wire for electrotechnical applications by methods of combined processing, Light Metals 2012 - TMS 2013 Annual Meeting and Exhibition, March 3, 2013 - March 7, 2013, Minerals, Metals and Materials Society, San Antonio, TX, United states, 443–447

Mogucheva AA, Zyabkin DV, Kaibyshev RO (2012) Effect of annealing on the structure and properties of aluminium alloy Al-8%MM. Met Sci Heat Treat, 53:450–454. https://link.springer.com/article/10.1007/s11041-012-9414-6#:~:text=Annealing%20of%20aluminum%20alloy%20Al,transforms%20into%20a%20globular%20phase.&text=Annealing%20at%20600%C2%B0C%20for%2010%20h%20yields%20a,longitudinal%20and%20transverse%20direction%20respectively Accessed 17 Jan 2023

Medvedev AE, Murashkin MY, Enikeev NA, Valiev RZ, Hodgson PD, Lapovok R (2018) Enhancement of mechanical and electrical properties of Al-RE alloys by optimising rare-earth concentration and thermo-mechanical treatment. J Alloys Compd, 745:696–704. https://www.sciencedirect.com/science/article/abs/pii/S0925838818307369 Accessed 17 Jan 2023

Ji C, Huang H (2020) A review of the twin-roll casting process for complex section products. ISIJ Int, 60(10):2165–2175. https://www.jstage.jst.go.jp/article/isijinternational/60/10/60_ISIJINT-2020-149/_article 17 Jan 2023

Voroshilov DS, Sidelnikov SB, Rudnitsky EA (2015) Developing technology obtaining wire from high alloyed alloys Al-REM system using the methods of combined treatment. Journal of Siberian Federal University. Eng Technol 8(1):61–65. https://elib.sfu-kras.ru/bitstream/handle/2311/16709/06_Sidelnikov.pdf?sequence=1 Accessed 17 Jan 2023

Sidelnikov SB, Galiev RI, Bersenev AS, Voroshilov DS (2018) Application and research twin roll casting-extruding process for production longish deformed semi-finished products from aluminum alloys. Mater Sci Forum 918:13–20. https://doi.org/10.4028/www.scientific.net/MSF.918.13Accessed17Jan2023

Sidelnikov SB, Timofeev VN, Gorokhov YV, Voroshilov DS, Galiev RI, Motkov MM, Kuzemchenko VA, Nikiforov PN (2019) Comparative analysis of properties of wires from alloys of al-rem system, obtained using the methods of continuous extrusion. International J Eng Adv Technol 8(2):300–304. https://www.ijeat.org/wp-content/uploads/papers/v8i2s2/B10630182S219.pdf Accessed 17 Jan 2023

Sidelnikov SB, Voroshilov DS, Pervukhin MV, Motkov MM (2019) Development and research of technology for producing electrotechnical wire from alloys of the Al – REM system, obtained with the application of combined machining methods. Tsvetnye Metally 9:63–68. https://www.rudmet.ru/journal/1853/article/31547/ Accessed 17 Jan 2023

Sidelnikov S, Voroshilov D, Motkov M, Voroshilova M, Bespalov V (2020) Development of combined machining modes, investigation of mechanical properties and structure of deformed semi-finished products from alloy 01417. Mater Sci Forum 992:498–503. https://doi.org/10.4028/www.scientific.net/MSF.992.498Accessed17Jan2023

Sidelnikov S, Sokolov R, Voroshilov D, Motkov M, Bespalov V, Voroshilova M, Sokolova S, Rudnitskiy E, Lebedeva O, Borisyuk V (2020) Modeling the process of obtaining bars from aluminum alloy 01417 by combined rolling-extruding method with application of the deform-3D complex. Key Eng Mater 861:540–546. https://doi.org/10.4028/www.scientific.net/KEM.861.540Accessed17Jan2023

Sidelnikov S, Voroshilov D, Motkov M, Bespalov V, Voroshilova M (2021) Experimental and analytical assessment of the power parameters of the combined rolling-extruding process using a round billet from alloy 01417 obtained using an electromagnetic mold. Key Eng Mater 887:300–305. https://doi.org/10.4028/www.scientific.net/KEM.887.300Accessed17Jan2023

Sidelnikov SB, Voroshilov DS, Motkov MM, Timofeev VN, Konstantinov IL, Dovzhenko NN, Lopatina ES, Bespalov VM, Sokolov RE, Mansurov YuN, Voroshilova MV (2021) Investigation structure and properties of wire from the alloy of Al-REM system obtained with the application of casting in the electromagnetic mold, combined rolling-extruding, and drawing. Int J Adv Manuf Technol 114:2633–2649. https://doi.org/10.1007/s00170-021-07054-xAccessed17Jan2023

Sidelnikov SB, Dovzhenko NN, Zagirov NN (2005) Combined and complex methods of processing non-ferrous metals and alloys. MAKS Press, Moscow

Pervukhin MV, Figurovskiy DK, Golovenko EA, Sergeev NV, Yu M Khatsayuk (2011) Quick crystallization of high-alloy aluminium alloys in an electromagnetic field. Bulletin of Higher Educational Institutions North Caucasus region. Tech Sci 2:47–51. https://elibrary.ru/download/elibrary_16339336_29878060.pdf Accessed 17 Jan 2023

Avdulov AA, Usynina GP, Sergeev NV, Gudkov IS (2017) Distinctive features of the structure and characteristics of long-length light gauge ingots from aluminium alloys, cast into electromagnetic crystallizer. Tsvetnye Metally 7:73–77. https://doi.org/10.17580/tsm.2017.07.12

Kolmogorov VL (2001) Mechanics of metal forming: a textbook for universities. Yekaterinburg: UGTU–UPI

Smirnov VK, Shilov VA, Inatovich YV (2010) Roll calibration. Textbook for universities. Edition 2, revised and enlarged. Moscow: Teplotekhnik

Smirnov VK, Shilov VA, Inatovich YuV (1987) Roll calibration. Metallurgy, Moscow

Smirnov VK, Tarnovskiy IY, Shilov VA (1970) Technique for solving the variational equation by a numerical method in the study of rolling in calibers. Theory and technology of rolling 67:92–98

Ageev LM, Sukharev LM (1974) Theoretical comparison of energy consumption and efficiency of rolling-drawing and conventional rolling processes. Metal forming: Sverdlovsk, UPI named after S.M. Kirov 2:45–52

Patent RF № 2792327. Unit for continious casting, rolling and pressing of metal. Sidelnikov S.B., Lopatina E.S., Voroshilov D.S., Motkov M.M., Galiev R.I., Konstantinov I.L., Durnopyanov A.V., Belokonova I.N., Voroshilova M.V.; Publ. 21 March 2023, Bull. №9. https://www.fips.ru/ofpstorage/Doc/IZPM/RUNWC1/000/000/002/792/327/%D0%98%D0%97-02792327-00001/document.pdf Accessed 28 March 2023

Patent RF № 2689460. Installation forcontinuous casting, rolling, pressing and drawing of welding wire and ligature bars from non-ferrous metals and alloys. Baranov V.N., Zenkin E.Yu., Sidelnikov S.B., Krokhin A.Yu., Dovzhenko I.N., Voroshilov D.S., Samchuk A.P., Yakivyuk O.V., Belokonova I.N., Frolov V.A.; Publ. 28 May 2019, Bull. №16. https://www.fips.ru/ofpstorage/Doc/IZPM/RUNWC1/000/000/002/689/460/%D0%98%D0%97-02689460-00001/document.pdf Accessed 28 March 2023

Funding

The research was carried out within the framework of the state assignment of the Ministry of Science and Higher Education of the Russian Federation (scientific theme code FSRZ-2020-0013).

Author information

Authors and Affiliations

Contributions

The authors declare that they are all participants in the work and none of them performed only administrative functions.

Corresponding author

Ethics declarations

Ethical approval

The work contains no libelous or unlawful statements, does not infringe on the rights of others, or contains material or instructions that might cause harm or injury.

Consent to participate

The authors consent to participate.

Consent for publication

The authors consent to publish.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Voroshilov, D.S., Sidelnikov, S.B., Konstantinov, I.L. et al. Simulation of combined rolling-extrusion process for round section billets in closed box caliber. Int J Adv Manuf Technol 127, 2893–2910 (2023). https://doi.org/10.1007/s00170-023-11586-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11586-9