Abstract

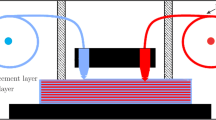

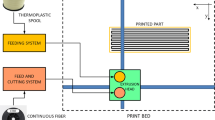

3D-printed thermoplastic parts with continuous fiber reinforcement are known to offer mechanical performance that is highly dependent on design variables and printing parameters. In this work, the role of the reinforcement distribution on the mechanical response of glass fiber-reinforced thermoplastics printed using the fused filament fabrication (FFF) technique is evaluated. Laminates with alternating and continuous reinforcement architecture as well as different fiber orientations such as isotropic (0°, 90°, and 45°) and concentric configurations are characterized from monotonic tensile and flexural loads. The resulting superior macromechanical performance in terms of higher stiffness and strength achieved in samples reinforced with alternating fiber plies is correlated with the micromechanical fractography characteristics and interlaminar shear capacity.

Similar content being viewed by others

References

Vyavahare S, Kumar S, Panghal D (2020) Experimental study of surface roughness, dimensional accuracy and time of fabrication of parts produced by fused deposition modelling. Rapid Prototyp J 26:1535–1554. https://doi.org/10.1108/RPJ-12-2019-0315

Ning F, Cong W, Hu Y, Wang H (2017) Additive manufacturing of carbon fiber-reinforced plastic composites using fused deposition modeling: effects of process parameters on tensile properties. J Compos Mater 51:451–462. https://doi.org/10.1177/0021998316646169

Jardin RT, Tuninetti V, Tchuindjang JT, Hashemi N, Carrus R, Mertens A, Duchêne L, Tran HS, Habraken AM (2020) Sensitivity analysis in the modelling of a high speed steel thin-wall produced by directed energy deposition. Metals (Basel) 10:1554. https://doi.org/10.3390/met10111554

Wang X, Jiang M, Zhou Z, Gou J, Hui D (2017) 3D printing of polymer matrix composites: a review and prospective. Compos B Eng 110:442–458. https://doi.org/10.1016/J.COMPOSITESB.2016.11.034

Tekinalp HL, Kunc V, Velez-Garcia GM, Duty CE, Love LJ, Naskar AK, Blue CA, Ozcan S (2014) Highly oriented carbon fiber-polymer composites via additive manufacturing. Compos Sci Technol 105:144–150. https://doi.org/10.1016/j.compscitech.2014.10.009

Goodridge RD, Shofner ML, Hague RJM, McClelland M, Schlea MR, Johnson RB, Tuck CJ (2011) Processing of a polyamide-12/carbon nanofibre composite by laser sintering. Polym Testing 30:94–100. https://doi.org/10.1016/j.polymertesting.2010.10.011

Bai J, Goodridge RD, Hague RJ, Song M (2012) Carbon nanotube reinforced polyamide 12 nanocomposites for laser sintering. In: Proceedings for the 2012 International Solid Freeform Fabrication Symposium, pp. 98–107. https://doi.org/10.26153/tsw/15336

Yang C, Tian X, Liu T, Cao Y, Li D (2017) 3D printing for continuous fiber reinforced thermoplastic composites: mechanism and performance. Rapid Prototyping Journal 23:209–215. https://doi.org/10.1108/RPJ-08-2015-0098

Zhuo P, Li S, Ashcroft IA, Jones AI (2021) Material extrusion additive manufacturing of continuous fibre reinforced polymer matrix composites: a review and outlook. Compos B Eng 224:109143. https://doi.org/10.1016/j.compositesb.2021.109143

Matsuzaki R, Ueda M, Namiki M, Jeong TK, Asahara H, Horiguchi K, Nakamura T, Todoroki A, Hirano Y (2016) Three-dimensional printing of continuous-fiber composites by in-nozzle impregnation. Sci Rep 6:1–7. https://doi.org/10.1038/srep23058

Zhuo P, Li S, Ashcroft I, Jones A, Pu J (2017) 3D printing of continuous fibre reinforced thermoplastic composites. In: 21st International conference on composite materials, ICCM 2017, Xi’an, China

Kalsoom U, Peristyy A, Nesterenko PN, Paull B (2016) A 3D printable diamond polymer composite: a novel material for fabrication of low cost thermally conducting devices. RSC Adv 6:38140–38147. https://doi.org/10.1039/c6ra05261d

Shabaniverki S, Juárez JJ (2021) Directed assembly of particles for additive manufacturing of particle-polymer composites. Micromachines 12:1–24. https://doi.org/10.3390/mi12080935

Ning F, Cong W, Qiu J, Wei J, Wang S (2015) Additive manufacturing of carbon fiber reinforced thermoplastic composites using fused deposition modeling. Compos B Eng 80:369–378. https://doi.org/10.1016/j.compositesb.2015.06.013

Díaz-Rodríguez JG, Pertúz-Comas AD, González-Estrada OA (2021) Mechanical properties for long fibre reinforced fused deposition manufactured composites. Compos B Eng 211:108657. https://doi.org/10.1016/j.compositesb.2021.108657

Somireddy M, Singh CV, Czekanski A (2020) Mechanical behaviour of 3D printed composite parts with short carbon fiber reinforcements. Eng Fail Anal 107:104232. https://doi.org/10.1016/j.engfailanal.2019.104232

Garzon-Hernandez S, Arias A, Garcia-Gonzalez D (2020) A continuum constitutive model for FDM 3D printed thermoplastics. Compos B Eng 201:108373. https://doi.org/10.1016/j.compositesb.2020.108373

Shanmugam V, Das O, Babu K, Marimuthu U, Veerasimman A, Johnson DJ, Neisiany RE, Hedenqvist MS, Ramakrishna S, Berto F (2021) Fatigue behaviour of FDM-3D printed polymers, polymeric composites and architected cellular materials. Int J Fatigue 143:106007. https://doi.org/10.1016/J.IJFATIGUE.2020.106007

Krzikalla D, Měsíček J, Halama R, Hajnyš J, Pagáč M, Čegan T, Petrů J (2022) On flexural properties of additive manufactured composites: experimental, and numerical study. Compos Sci Technol 218:109182. https://doi.org/10.1016/J.COMPSCITECH.2021.109182

Ravoori D, Prajapati H, Talluru V, Adnan A, Jain A (2019) Nozzle-integrated pre-deposition and post-deposition heating of previously deposited layers in polymer extrusion based additive manufacturing. Addit Manuf 28:719–726. https://doi.org/10.1016/j.addma.2019.06.006

Hermosilla R, Oñate A, Castillo R, De la Fuente A, Sepúlveda J, Escudero B, Vargas-Silva G, Tuninetti V, Melendrez M, Medina C (2023) Influence stacking sequence and heat treatments on the out-of-plane mechanical properties of 3D-printed fiberglass-reinforced thermoplastics. Int J Adv Manuf Technol 125:4753–4764. https://doi.org/10.1007/S00170-023-11050-8/FIGURES/12

Ravi AK, Deshpande A, Hsu KH (2016) An in-process laser localized pre-deposition heating approach to inter-layer bond strengthening in extrusion based polymer additive manufacturing. J Manuf Process 24:179–185. https://doi.org/10.1016/j.jmapro.2016.08.007

Pascual-González C, Iragi M, Fernández A, Fernández-Blázquez JP, Aretxabaleta L, Lopes CS (2020) An approach to analyse the factors behind the micromechanical response of 3D-printed composites. Compos B Eng 186:107820. https://doi.org/10.1016/j.compositesb.2020.107820

Ravoori D, Salvi S, Prajapati H, Qasaimeh M, Adnan A, Jain A (2021) Void reduction in fused filament fabrication (FFF) through in situ nozzle-integrated compression rolling of deposited filaments. Virtual Phys Prototyp 16:146–159. https://doi.org/10.1080/17452759.2021.1890986

Yamawaki M, Kouno Y (2018) Fabrication and mechanical characterization of continuous carbon fiber-reinforced thermoplastic using a preform by three-dimensional printing and via hot-press molding. Adv Compos Mater 27:209–219. https://doi.org/10.1080/09243046.2017.1368840

Omuro R, Ueda M, Matsuzaki R, Todoroki A, Hirano Y (2017) Three-dimensional printing of continuous carbon fiber reinforced thermoplastics by in-nozzle impregnation with compaction roller. In: 21st International conference on composite materials, ICCM 2017, Xi’an, China

Sun Q, Rizvi GM, Bellehumeur CT, Gu P (2008) Effect of processing conditions on the bonding quality of FDM polymer filaments. Rapid Prototyp J 14:72–80. https://doi.org/10.1108/13552540810862028

Turner BN, Strong R, Gold SA (2014) A review of melt extrusion additive manufacturing processes: I Process design and modeling. Rapid Prototyp J 20:192–204. https://doi.org/10.1108/RPJ-01-2013-0012

Salas A, Medina C, Vial JT, Flores P, Canales C, Tuninetti V, Jaramillo AF, Meléndrez MF (2021) Ultrafast carbon nanotubes growth on recycled carbon fibers and their evaluation on interfacial shear strength in reinforced composites. Sci Rep 11:5000. https://doi.org/10.1038/s41598-021-84419-y

Brenken B, Barocio E, Favaloro A, Kunc V, Pipes RB (2018) Fused filament fabrication of fiber-reinforced polymers: a review. Addit Manuf 21:1–16. https://doi.org/10.1016/j.addma.2018.01.002

Khudiakova A, Arbeiter F, Spoerk M, Wolfahrt M, Godec D, Pinter G (2019) Inter-layer bonding characterisation between materials with different degrees of stiffness processed by fused filament fabrication. Addit Manuf 28:184–193. https://doi.org/10.1016/j.addma.2019.05.006

Türk DA, Brenni F, Zogg M, Meboldt M (2017) Mechanical characterization of 3D printed polymers for fiber reinforced polymers processing. Mater Des 118:256–265. https://doi.org/10.1016/j.matdes.2017.01.050

Chacón JM, Caminero MA, García-Plaza E, Núñez PJ (2017) Additive manufacturing of PLA structures using fused deposition modelling: effect of process parameters on mechanical properties and their optimal selection. Mater Des 124:143–157. https://doi.org/10.1016/j.matdes.2017.03.065

Kulkarni P, Dutta D (1997) Deposition strategies and resulting part stiffnesses in layered manufacturing. Proc ASME Des Eng Tech Conf 2: 23rd Des Autom Conf, California, USA. https://doi.org/10.1115/DETC97/DAC-3987

Casavola C, Cazzato A, Moramarco V, Pappalettere C (2016) Orthotropic mechanical properties of fused deposition modelling parts described by classical laminate theory. Mater Des 90:453–458. https://doi.org/10.1016/j.matdes.2015.11.009

Somireddy M, Czekanski A (2017) Mechanical characterization of additively manufactured parts by FE modeling of mesostructure. J Manuf Mater Process 1:1–21. https://doi.org/10.3390/jmmp1020018

Salas A, Oñate Á, Escudero B, Medina C, Tuninetti V, Meléndrez M (2022) Effect of 05% CNT reinforcement of a glass fiber composite on strength and cyclic damage induced by transverse and out-of-plane compressive loads. J Compos Mater 56:2895–2906. https://doi.org/10.1177/00219983221106522

Caminero MA, Chacón JM, García-Moreno I, Reverte JM (2018) Interlaminar bonding performance of 3D printed continuous fibre reinforced thermoplastic composites using fused deposition modelling. Polym Testing 68:415–423. https://doi.org/10.1016/j.polymertesting.2018.04.038

Shi K, Yan Y, Mei H, Chen C, Cheng L (2021) 3D printing Kevlar fiber layer distributions and fiber orientations into nylon composites to achieve designable mechanical strength. Addit Manuf 39:101882. https://doi.org/10.1016/j.addma.2021.101882

Pyl L, Kalteremidou KA, Van Hemelrijck D (2018) Exploration of specimen geometry and tab configuration for tensile testing exploiting the potential of 3D printing freeform shape continuous carbon fibre-reinforced nylon matrix composites. Polym Testing 71:318–328. https://doi.org/10.1016/j.polymertesting.2018.09.022

Markforged, Material Datasheet: Composites, (n.d.). http://static.markforged.com/downloads/composites-data-sheet.pdf (accessed March 5, 2022).

ASTM, D3039/D3039M-17 (2017) Standard test method for tensile properties of polymer matrix composite materials. https://doi.org/10.1520/D3039_D3039M-17

ASTM, D3518 (2018) Standard test method for in-plane shear response of polymer matrix composite materials by tensile test of a ±45° Laminate. ASTM International, Philadelphia. https://doi.org/10.1520/D3518_D3518M-18

Van Paepegem W, De Baere I, Lamkanfi E, Degrieck J (2007) Poisson’s ratio as a sensitive indicator of (fatigue) damage in fibre-reinforced plastics, Fatigue and Fracture of Engineering. Mater Struct 30:269–276. https://doi.org/10.1111/j.1460-2695.2007.01095.x

Van Paepegem W, De Baere I, Lamkanfi E, Degrieck J (2010) Monitoring quasi-static and cyclic fatigue damage in fibre-reinforced plastics by Poisson’s ratio evolution. Int J Fatigue 32:184–196. https://doi.org/10.1016/j.ijfatigue.2009.02.026

Van Paepegem W, Degrieck J (2002) A new coupled approach of residual stiffness and strength for fatigue of fibre-reinforced composites. Int J Fatigue 24:747–762. https://doi.org/10.1016/S0142-1123(01)00194-3

Lupone F, Padovano E, Venezia C, Badini C (2022) Experimental characterization and modeling of 3D printed continuous carbon fibers composites with different fiber orientation produced by FFF process. Polymers 14:426. https://doi.org/10.3390/polym14030426

Parmiggiani A, Prato M, Pizzorni M (2021) Effect of the fiber orientation on the tensile and flexural behavior of continuous carbon fiber composites made via fused filament fabrication. Int J Adv Manuf Technol 114:2085–2101. https://doi.org/10.1007/s00170-021-06997-5

Dickson AN, Barry JN, McDonnell KA, Dowling DP (2017) Fabrication of continuous carbon, glass and Kevlar fibre reinforced polymer composites using additive manufacturing. Addit Manuf 16:146–152. https://doi.org/10.1016/j.addma.2017.06.004

Naranjo-Lozada J, Ahuett-Garza H, Orta-Castañón P, Verbeeten WMH, Sáiz-González D (2019) Tensile properties and failure behavior of chopped and continuous carbon fiber composites produced by additive manufacturing. Addit Manuf 26:227–241. https://doi.org/10.1016/j.addma.2018.12.020

van de Werken N, Hurley J, Khanbolouki P, Sarvestani AN, Tamijani AY, Tehrani M (2019) Design considerations and modeling of fiber reinforced 3D printed parts. Compos B Eng 160:684–692. https://doi.org/10.1016/j.compositesb.2018.12.094

Chacón JM, Caminero MA, Núñez PJ, García-Plaza E, García-Moreno I, Reverte JM (2019) Additive manufacturing of continuous fibre reinforced thermoplastic composites using fused deposition modelling: effect of process parameters on mechanical properties. Compos Sci Technol 181:107688. https://doi.org/10.1016/j.compscitech.2019.107688

Ferreira RTL, Amatte IC, Dutra TA, Bürger D (2017) Experimental characterization and micrography of 3D printed PLA and PLA reinforced with short carbon fibers. Compos B Eng 124:88–100. https://doi.org/10.1016/j.compositesb.2017.05.013

Martín MJ, Auñón JA, Martín F (2021) Influence of infill pattern on mechanical behavior of polymeric and composites specimens manufactured using fused filament fabrication technology. Polymers 13:2934. https://doi.org/10.3390/polym13172934

Bárnik F, Vaško M, Sága M, Handrik M, Sapietová A (2019) Mechanical properties of structures produced by 3D printing from composite materials. MATEC Web Conf 254:01018. https://doi.org/10.1051/matecconf/201925401018

Varna J, Joffe R, Akshantala NV, Talreja R (1999) Damage in composite laminates with off-axis plies. Compos Sci Technol 59:2139–2147. https://doi.org/10.1016/S0266-3538(99)00070-6

Mujika F (2007) On the effect of shear and local deformation in three-point bending tests. Polym Testing 26:869–877. https://doi.org/10.1016/j.polymertesting.2007.06.002

Caminero MA, Rodríguez GP, Muñoz V (2016) Effect of stacking sequence on Charpy impact and flexural damage behavior of composite laminates. Compos Struct 136:345–357. https://doi.org/10.1016/j.compstruct.2015.10.019

Iragi M, Pascual-González C, Esnaola A, Lopes CS, Aretxabaleta L (2019) Ply and interlaminar behaviours of 3D printed continuous carbon fibre-reinforced thermoplastic laminates; effects of processing conditions and microstructure. Addit Manuf 30:100884. https://doi.org/10.1016/j.addma.2019.100884

Tian X, Liu T, Yang C, Wang Q, Li D (2016) Interface and performance of 3D printed continuous carbon fiber reinforced PLA composites. Compos A Appl Sci Manuf 88:198–205. https://doi.org/10.1016/j.compositesa.2016.05.032

Author information

Authors and Affiliations

Contributions

Andrés De la Fuente: investigation, methodology, and data curation. Rodrigo Castillo: writing—original draft and review and editing; Angelo Oñate: conceptualization, data curation, and writing—review and editing. Rodolfo Hermosilla: methodology. Benjamín Escudero: resources. Joaquín Sepulveda: resources. Gustavo Vargas-Silva: writing—review and editing. Víctor Tuninetti: formal analysis, visualization, and writing—review and editing. Manuel F. Meléndrez: conceptualization and resources. Carlos Medina: conceptualization, resources, methodology, writing—review and editing, and supervision.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

De la Fuente, A., Castillo, R., Oñate, A. et al. Quantifying the influence of reinforcement architecture on the planar mechanical properties of 3D-printed continuous fiber-reinforced thermoplastic composites. Int J Adv Manuf Technol 127, 1575–1583 (2023). https://doi.org/10.1007/s00170-023-11569-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11569-w