Abstract

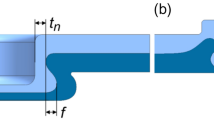

To solve the problems of low strength and unsatisfactory connection quality of single joining technology, a method of clinch-adhesive hybrid joining of steel/aluminum sheets with partially glued and inclined wall die was proposed. Al5052 aluminum alloy and Q235 steel were used as sample materials, finite element simulation combined with actual experiments was adopted, the effect of the gluing process on the strength of clinch-adhesive hybrid joints on the inclined wall die was explored, and the failure forms and failure mechanisms of the joints in shear and peel experiments were studied. The results showed that the partial gluing process is more effective than complete gluing. The interlock of the partially glued hybrid joints was increased by 144% compared to the fully glued joints, but the neck thickness value was reduced by only 10.6%. The shear strength and peel strength of partially glued hybrid joints were higher than those of fully glued hybrid joints and clinch joints. The failure mode of the hybrid joints under shear and peel loads was a mixed failure comprising interface failure and upper sheet separation failure.

Similar content being viewed by others

References

Alves L, Martins P (2013) Single-stroke mechanical joining of sheet panels to tubular profiles. J Manuf Process 15(1):151-157

Balawender T, Sadowski T, Golewski P (2012) Numerical analysis and experiments of the clinch-bonded joint subjected to uniaxial tension. Computat Mater Sci 64:270–272

Calabrese L, Galtieri G, Borsellino C et al (2016) Durability of hybrid clinch-bonded steel/aluminum joints in salt spray environment. Int J Adv Manuf Technol 87(9):3137–3147

Chen C, Zhao S, Cui M, et al (2017) Study on the flat-reshaping technology with no rivet for joining aluminium alloy sheet of the automobile

Chen J, Qiu Z, Zhou Y et al (2016) Performances of clinch-bonded hybrid joints between steel-aluminum sheets. J Harbin Inst Technol 48(7):169–175

Chen Y, Li M, Yang X et al (2020) Durability and mechanical behavior of cfrp/al structural joints in accelerated cyclic corrosion environments. Int J Adhesion Adhesives 102(102):695

Chu Y, Sun L, Li L (2019) Lightweight scheme selection for automotive safety structures using a quantifiable multi-objective approach. J Cleaner Prod 241(118):316

Deepati AK, Alhazmi W, Benjeer I (2021) Mechanical characterization of aa5083 aluminum alloy welded using resistance spot welding for the lightweight automobile body fabrication. Mater Today Proc 45:5139–5148

Eshtayeh M, Hrairi M (2016) Multi objective optimization of clinching joints quality using grey-based taguchi method. Int J Adv Manuf Technol 87(1):233–249

Etemadi S, Hahn O, Roll K (2012) Simulation of hybrid joining technologies using the example of clinch-bonding

Hahn O, Meschut G, Bergau M et al (2014) Self-pierce riveting and hybrid joining of boron steels in multi-material and multi-sheet joints. Proc CIRP 18:192–196

Han X, Chen C, Liu C et al (2018) Predictive model of tensile strength in flat clinching. J Mech Eng 54:61–68

Joost WJ, Krajewski PE (2017) Towards magnesium alloys for high-volume automotive applications. Scripta Mater 128:107–112

Lambiase F, Di Ilio A (2014) An experimental study on clinched joints realized with different dies. Thin-Walled Struct 85:71–80

Lee CJ, Lee JM, Lee KH et al (2014) Development of hybrid clinched structure by using multi-cohesive zone models. Int J Precision Eng Manuf 15(6):1015–1022

Lin PC, Fang JC, Lin JW et al (2020) Preheated (heat-assisted) clinching process for al/cfrp cross-tension specimens. Materials 13(18):4170

Liu Z, Lu J, Zhu P (2016) Lightweight design of automotive composite bumper system using modified particle swarm optimizer. Composite Struct 140:630–643

Luo S, Yao J, Li J, et al (2020) Influence of forging velocity on temperature and phases of forged ti-6al-4v turbine blade. J Mater Res Technol 9(6):12,043–12,051

Marques E, da Silva LF (2008) Joint strength optimization of adhesively bonded patches. J Adhesion 84(11):915–934

Qiu ZX, Zhou YJ, Chen JQ (2015) Research of the forming laws in the clinching process between steel-aluminum sheets with different strength series. Mach Design Manuf

Wang M, Chen Y, Han Y et al (2022) Steel-aluminum plastic clinching of an inclined wall die. Int J Adv Manuf Technol 121(9):6243–6253

Zhao L, He X, Xing B et al (2015) Influence of sheet thickness on fatigue behavior and fretting of self-piercing riveted joints in aluminum alloy 5052. Mater Design 87:1010–1017

Funding

This study was supported by the Project of International Scientific and Technological Innovation Cooperation (Grant No. 2021YFH0031).

Author information

Authors and Affiliations

Contributions

Menghan Wang conceived and designed the experiments; Yifeng Chen and Yan Han performed the experiments; Lei Li and Menglong Du analyzed the data; Menglong Du and Yifeng Chen wrote the paper.

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare no potential conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Menghan, W., Menglong, D., Yifeng, C. et al. Influence of the mechanism of gluing processes on the strength of clinch-adhesive hybrid joining process of steel/aluminum plates. Int J Adv Manuf Technol 127, 3325–3336 (2023). https://doi.org/10.1007/s00170-023-11464-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11464-4