Abstract

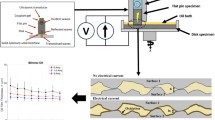

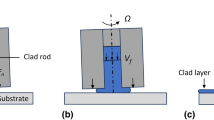

This experimental research work is conducted to determine statistical models of wear evolution and surface roughness components in a misaligned contaminated EHL rolling contact. To achieve this goal, experiments were realized on an original test rig representing the real operating conditions of gears or roller bearings. In fact, the rolling contact tests are carried out using the contact between two steel disks with the presence of misalignment defect and solid contaminants within lubricant oil. In order to investigate the influence of four operating input variables like misalignment angle (α), rotational velocity (V), load (Q), and contaminant concentration (C) on the studied responses (i.e., wear (W) and surface roughness components (Ra, Rt, and Rz)), the Box-Behnken design (BBD) was adopted. Thereafter, the results obtained were analyzed using both response surface methodology (RSM) and analysis of variance (ANOVA). It is found that the rotational velocity (V) is the most significant factor affecting the wear (W) and the surface roughness components (Ra, Rt, and Rz) of a misaligned contaminated EHL rolling contact with 75.51%, 79.2%, 89.07%, and 59.65% of contributions, respectively, whereas load (Q), misalignment angle (α), contaminant concentration (C), and two-level interaction effect (α × C and C × Q) are significant factors but have a lesser effect on the wear variability with 8.23%, 5.57%, 2.42%, 2.68%, and 2.62% contributions, respectively. It is also deduced that the misalignment angle (α) is statistically significant when studying the mean depth roughness (Rz) with 15.67% of contributions. Finally, it is revealed that the obtained higher values of determination coefficient (more than 90%) show clearly the reliable of the implemented quadratic models.

Similar content being viewed by others

References

Das S, Guha SK, Chattopadhyay AK (2002) On the steady-state performance of misaligned hydrodynamic journal bearings lubricated with micropolar fluids. Tribol Int 35:201–210

Bouyer J, Fillon M (2002) An experimental analysis of misalignment effects on hydrodynamic plain journal bearing performances. J Tribol 124:313–319

Dick A, Lin C, Wang Y, Wang QJ (2004) Thermal validation of a misaligned grease-lubricated journal bearing model. Proc Instn Mech Engrs Part J: J Eng 218, special issue paper 423

Boucherit H, Lahmar M, Bou-Said B (2008) Misalignment effects on steady-state and dynamic behaviour of compliant journal bearings lubricated with couple stress fluids. Lubr Sci 20:241–268

Ohta H, Sato Y, Ueki Y (2015) Effects of misaligned rails on the friction force–displacement curves of a linear ball bearing system in low-speed operation. Proc Instn Mech Engrs Part J: J Eng 229:1469–1478

Tong VC, Hong SW (2018) Study on the running torque of angular contact ball bearings subjected to angular misalignment. Proc Instn Mech Engrs Part J: J Eng 232:890–909

Some S, Guha SK (2019) Steady-state performance analysis of misaligned double layered porous journal bearings under coupled stress lubrication with slip flow and additives percolation effect. Proc Instn Mech Engrs Part J: J Eng 233:841–858

Han Y, Fu Y (2020) Influence of micro-grooves on the lubrication performance of a misaligned bearing. Proc Instn Mech Engrs Part J: J Eng 234:887–899

Liangliang L, Zhang D, Yonghui X (2019) Effect of misalignment on the dynamic characteristic of MEMS gas bearing considering rarefaction effect. Tribol Int 139:22–35

Abdou K, Saber E (2020) Effect of rotor misalignment on stability of journal bearings with finite width. Alex Eng J 59(5):3407–34117

Xiao L, Xu Y, Sun X, Xu H, Zhang L (2022) Experimental investigation on the effect of misalignment on the wear failure for spline couplings. Eng Fail Anal 131:105755

Sahu K, Sharma SC, Ram N (2022) Misalignment and surface irregularities effect in MR fluid journal bearing. Int J Mech Sci 221:107196

Kumar P, Hirani H (2021) Misalignment effect on gearbox failure: an experimental study. Measurement 169:108492

Shehata A, Adnan MA, Mohammed OD (2019) Modeling the effect of misalignment and tooth microgeometry on helical gear pair in mesh. Eng Fail Anal 106:104190

Zhao X, Xiao S (2021) A three-dimensional model of gas foil bearings and the effect of misalignment on the static performance of the first and second generation foil bearings. Tribol Int 156:106821

Xu T, Yang L, Wu W, Wang K (2021) Effect of angular misalignment of inner ring on the contact characteristics and stiffness coefficients of duplex angular contact ball bearings. Mech Mach Theory 157:104178

Parmar V, Saran VH, Harsha SP (2021) Effect of dynamic misalignment on the vibration response, trajectory followed and defect-depth achieved by the rolling-elements in a double-row spherical rolling-element bearing. Mech Mach Theory 162:104366

Lubrecht AA, Venner CH, Lane S, Jacobson B, Ioannides E (1990) Surface damage comparison of theoretical and experimental endurance lives of rolling bearings. Proc Jpn Int Tribol Conf. Nagoya (Japan) 185

Lubrecht A A, Dwyer Joyce RS, Ioannides E (1992) Analysis of the influence of indentations on contact life. In: Dowson D et al (eds.) Proceeding of 19 Leeds-Lyon Symposium on Tribol Elsevier (Amsterdam) 21:173−181

Ai X, Cheng HS (1994) The influence of moving dent on point EHL contacts. Tribol Trans 37:323−335

Nixon HP, Zantopulos H (1995) Fatigue life performance comparisons of tapered roller bearings with debris damaged raceways. Lubr Eng 51(9):732−736

Xiaolan A, Lee SC (1996) Effect of slide to roll ratio on interior stresses around a dent in EHL contacts. Tribol Trans 39(4):881−889

Dwyer Joyce RS, Hamer JC, Sayles RS, Ioannides E (1992) Lubricant screening for debris effects to improve fatigue and wear life. In: Dowson D et al (eds.) Proceeding of 18 Leeds-Lyon Symposium on Tribology Elsevier (Amsterdam) 57−63

Nelias D, Sainsot P, Flamand L (1992) Deformation of a particular metallic contaminant and role on surface damage in high-speed ball bearings. In: Dowson D et al (eds.) Proceeding of 18 Leeds-Lyon Symposium on Tribol Elsevier (Amsterdam), 21:145−151

Cann PME, Hamer JC, Sayles RS, Spikes HA, Ioannides E (1996) Direct observation of particle entry and deformation in rolling EHD contact. In: D. Dowson et al (eds.) Proceeding of 22 Leeds-Lyon Symposium on Tribology Elsevier (Amsterdam), 127−134

Dwyer Joyce RS, Heymer J (1996) The entrainment of solid particles into rolling elastohydrodynamics contacts. In: Dowson D et al(eds.) Proceedig of 22 Leeds-Lyon Symposium on Tribol Elsevier (Amsterdam) 135−140

Ville F, Nelias D (1998) Influence of the nature and size of solid particles on the indentation features in EHL contacts. In: Dowson Det al (eds.) Proceeding of 24 Leeds-Lyon Symposium on Tribol Elsevier (Amsterdam), 399−409

Wan GTY, Spikes H (1988) The behaviour of suspended solid particles in rolling and sliding elastohydrodynamic contacts. STLE Tribol Trans 31:12−21

Grieve D G, Dwyer Joyce R S, Beynon J H (2001) Abrasive wear of railway track by solid contaminants. Proceeding IMech E Part F: J Rail Rapid Transit 215(3):193−205

Wu J, Mao J, Cao W, Xie YB (2014) Characterization of wear-debris group in online visual ferrographic images. Proceeding IMech E Part J: J Eng Tribol 228(11):1298−1307

Beninca FP, Romero MC, Camporez RM, Neto CAR, Strey NF, Scandian C (2023) Evolution of morphology, microstructure and hardness of bodies and debris during sliding wear of carbon steels in a closed tribosystem. Wear 523:204809. https://doi.org/10.1016/j.wear.2023.204809

Kumar A, Ghosh SA (2019) Size distribution analysis of wear debris generated in HEMM engine oil for reliability assessment: a statistical approach. Measurement 131:412–418

Lin CL, Meehan PA (2021) Morphological and elemental analysis of wear debris naturally formed in grease lubricated railway axle bearings. Wear 484–485:203994

Biblouet N, Houpert L, Lubrecht AA (2012) Contact stress and rolling contact fatigueof indented contacts: part I, numerical analysis. Proc IMechE Part J: J Eng Tribol 227(4):310–318

Sari MR, Haiahem A, Flamand L (2007) Effect of lubricant contamination on gear wear. TribolLett 27:119–126

Bouchireb A, Sari MR (2015) Effect of solid particles on gear tooth failure. J Cent South Univ 22(5):1667–1675

Sari MR, Ville F, Haiahem A, Flamand L (2010) Effect of lubricant contamination on friction and wear in an EHL sliding contact. Mechanika 2(82):43–49

Sari MR, Maatallah S, Adjabi R, Khochemane L (2016) Experimental and statistical investigation on the failure of contaminated elastohydrodynamic lubrication rolling contact. ProcIMechE Part J: J EngTribol 230(3):300–322

Maatallah S, Sari MR, Khochemane L (2016) Effect of lubricant contamination on EHL rolling contact: response surface methodology. Eng Trans 64(1):69–88

Ramadan MA (2018) Friction and wear of sand contaminated lubricated sliding. Friction 6(4):457–463

Funding

The authors would like to thank the Algerian Ministry of Higher Education and Scientific Research (MESRS) for granting financial support for PRFU Research Project—Code: A11N01UN230120190004 (Badji Mokhtar University, Annaba).

Author information

Authors and Affiliations

Contributions

Not applicable.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mostefaoui, A., Sari, M.R., Kezzar, M. et al. Statistical investigation on the failure of misaligned contaminated EHL rolling contacts using response surface methodology. Int J Adv Manuf Technol 127, 1225–1242 (2023). https://doi.org/10.1007/s00170-023-11438-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11438-6