Abstract

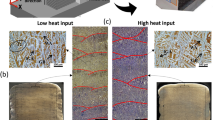

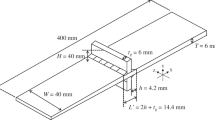

In this paper, the copper-based welding wire was used to complete the double-layer billet assembling, and bimetal Ti/steel clad plates were successfully prepared by hot rolling. The transverse bonding strength distribution was studied through microstructure characterization and the finite element method (FEM). The influence factors of oxidation, temperature, and stress were discussed. The results showed that the bond strength exhibited a transverse heterogeneity, which was 294 MPa at the width center and gradually decreased to 101 MPa at the width edge. Correspondingly, the interface at the center was well bonded while it contained cracks and voids at the edge. The oxidation occurred only at the edge for cracking in the weld during rolling, which deteriorated the bonding strength. The temperature along the width direction had little effect on the bonding strength for its small drop. Compared with these, the decreased normal stress from center to edge caused by the width resistance and metal flow characteristics was the main reason for the transverse heterogeneity of bonding strength. Based on this, a transverse bonding strength prediction equation considering the distribution of stress and bonding strength was proposed, and the relative error of it was 8 ~ 15%.

Similar content being viewed by others

References

Zhu M, Wu W, Qian W et al (2021) A brief review on welding of stainless steel clad plates: issues and future perspectives. Int J Adv Manuf Technol 115:49–59. https://doi.org/10.1007/s00170-021-07218-9

Wu T, Yang C (2022) Interfacial evolution and mechanical behavior of explosively welded titanium/steel joint under subsequent heat treatment process. Int J Adv Manuf Technol 121:6303–6314. https://doi.org/10.1007/s00170-022-09739-3

Li B, He W, Chen Z et al (2020) Evolution of interface and collaborative deformation between Ti and steel during hot roll bonding. Mater Charact 164:110354. https://doi.org/10.1016/j.matchar.2020.110354

Zhao Z, Tariq J, Tang J et al (2020) Microstructural evolutions and mechanical characteristics of Ti/steel clad plates fabricated through cold spray additive manufacturing followed by hot-rolling and annealing. Mater Des 185:108249. https://doi.org/10.1016/j.matdes.2019.108249

Song J, Kostka A, Veehmayer M, Raabe D (2011) Hierarchical microstructure of explosive joints: example of titanium to steel cladding. Mater Sci Eng A 528:2641–2647. https://doi.org/10.1016/j.msea.2010.11.092

Liu JG, Cai WC, Liu L et al (2017) Investigation of interfacial structure and mechanical properties of titanium clad steel sheets prepared by a brazing-rolling process. Mater Sci Eng A 703:386–398. https://doi.org/10.1016/j.msea.2017.06.095

Kriegel MJ, Wetzel MH, Fabrichnaya O, Rafaja D (2022) Binary Ti–Fe. system Part II: modelling of pressure-dependent phase stabilities. Calphad Comput Coupling Phase Diagrams Thermochem 76:102383. https://doi.org/10.1016/j.calphad.2021.102383

Jiang HT, Yan XQ, Liu JX, Duan XG (2014) Effect of heat treatment on microstructure and mechanical property of Ti-steel explosive-rolling clad plate. Trans Nonferrous Met Soc China 24(3):697–704. https://doi.org/10.1016/S1003-6326(14)63113-7

Bagheri B, Abbasi M, Sharifi F, Abdollahzadeh A (2022) Different attempt to improve friction stir brazing: effect of mechanical vibration and rotational speed. Met Mater Int 28:2239–2251. https://doi.org/10.1007/s12540-021-01121-4

SalimiyanRizi V, Abbasi M, Bagheri B (2022) Investigation on intermetallic compounds formation and effect of reinforcing particles during friction stir vibration brazing. J Mater Eng Perform 31:3369–3381. https://doi.org/10.1007/s11665-021-06443-3

Tadashi M, En T, Kenji I (1990) Effects of carbon content on the diffusion bonding of iron and steel to titanium. Isij Int 30:978–984. https://doi.org/10.2355/isijinternational.30.978

Yu C, Xiao H, Li N, et al (2017) Effect of DT4 interlayer on properties of hot-roll bonding TA2/Q235B plate. IOP Conf Ser Mater Sci Eng 229 https://doi.org/10.1088/1757-899X/229/1/012017

Luo Z, Wang G, Xie G et al (2013) Interfacial microstructure and properties of a vacuum hot roll-bonded titanium-stainless steel clad plate with a niobium interlayer. Acta Metall Sin (English Lett) 26:754–760. https://doi.org/10.1007/s40195-013-0283-9

Li BX, Chen ZJ, He WJ et al (2019) Effect of interlayer material and rolling temperature on microstructures and mechanical properties of titanium/steel clad plates. Mater Sci Eng A 749:241–248. https://doi.org/10.1016/j.msea.2019.02.018

Wang JZ, Yan XB, Yan JY, Rong Y, Yan P, Liu Y (2009) Inserter materials in production of Ti-steel composite plate, Nonferr. Met. 61, 39 (2009). https://kns.cnki.net/kcms/detail/detail.aspx?FileName=YOUS200904008&DbName=CJFQ2009

Yu C, Fu L, Xiao H et al (2021) Effect of carbon content on the microstructure and bonding properties of hot-rolling pure titanium clad carbon steel plates. Mater Sci Eng A 820:141572. https://doi.org/10.1016/j.msea.2021.141572

Yang han D, Luo an Z, Xieming G et al (2019) Interfacial microstructure and properties of a vacuum roll-cladding titanium-steel clad plate with a nickel interlayer. Mater Sci Eng A 753:49–58. https://doi.org/10.1016/j.msea.2019.03.008

Atasoy E, Kahraman N (2008) Diffusion bonding of commercially pure titanium to low carbon steel using a silver interlayer. Mater Charact 59:1481–1490. https://doi.org/10.1016/j.matchar.2008.01.015

Chen S, Zhang M, Huang J et al (2014) Microstructures and mechanical property of laser butt welding of titanium alloy to stainless steel. Mater Des 53:504–511. https://doi.org/10.1016/j.matdes.2013.07.044

Yang han D, Luo an Z, Xieming G et al (2018) Effect of vacuum level on microstructure and mechanical properties of titanium–steel vacuum roll clad plates. J Iron Steel Res Int 25:72–80. https://doi.org/10.1007/s42243-017-0009-8

Yan JC, Zhao DS, Wang CW et al (2009) Vacuum hot roll bonding of titanium alloy and stainless steel using nickel interlayer. Mater Sci Technol 25:914–918. https://doi.org/10.1179/174328408X365766

Elrefaey A, Tillmann W (2009) Solid state diffusion bonding of titanium to steel using a copper base alloy as interlayer. J Mater Process Technol 209:2746–2752. https://doi.org/10.1016/j.jmatprotec.2008.06.014

Mou G, Hua X, Wang M, Li F (2019) Effects of Ni addition on removing Fe-Ti intermetallic compounds in cold metal transfer arc-brazed TC4/304L dissimilar joints. J Manuf Process 38:104–112. https://doi.org/10.1016/j.jmapro.2019.01.012

Hao X, Dong H, Yu F et al (2021) Arc welding of titanium alloy to stainless steel with Cu foil as interlayer and Ni-based alloy as filler metal. J Mater Res Technol 13:48–60. https://doi.org/10.1016/j.jmrt.2021.04.054

Wu Y, Wang T, Ren Z et al (2022) Evolution mechanism of microstructure and bond strength based on interface diffusion and IMCs of Ti/steel clad plates fabricated by double-layered hot rolling. J Mater Process Technol 310:117780. https://doi.org/10.1016/j.jmatprotec.2022.117780

Kundu S, Chatterjee S (2008) Diffusion bonding between commercially pure titanium and micro-duplex stainless steel. Mater Sci Eng A 480:316–322. https://doi.org/10.1016/j.msea.2007.07.033

Zhao DS, Yan JC, Wang Y, Yang SQ (2009) Relative slipping of interface of titanium alloy to stainless steel during vacuum hot roll bonding. Mater Sci Eng A 499:282–286. https://doi.org/10.1016/j.msea.2007.11.112

Abbasi M, Bagheri B, Sharifi F, Abdollahzadeh A (2021) Friction stir vibration brazing (FSVB): an improved version of friction stir brazing. Weld World 65:2207–2220. https://doi.org/10.1007/s40194-021-01173-5

Yang han D, Luo an Z, Xieming G, Misra RDK (2018) Effect of interfacial compounds on mechanical properties of titanium–steel vacuum roll-cladding plates. Mater Sci Technol (United Kingdom) 34:1700–1709. https://doi.org/10.1080/02670836.2018.1472911

Bagheri B, Abbasi M, Sharifi F, Abdollahzadeh A (2022) Investigation into novel multipass friction stir vibration brazing of carbon steels. Mater Manuf Process 37:921–932. https://doi.org/10.1080/10426914.2021.2006220

Wachowski M, Gloc M, Ślęzak T et al (2017) The effect of heat treatment on the microstructure and properties of explosively welded titanium-steel plates. J Mater Eng Perform 26:945–954. https://doi.org/10.1007/s11665-017-2520-2

Li B, Chen Z, He W et al (2019) Effect of titanium grain orientation on the growth of compounds at diffusion bonded titanium/steel interfaces. Mater Charact 148:243–251. https://doi.org/10.1016/j.matchar.2018.12.029

Vaneghi AH, Bagheri B, Shamsipur A et al (2022) Investigations into the formation of intermetallic compounds during pinless friction stir spot welding of AA2024-Zn-pure copper dissimilar joints. Weld World 66:2351–2369. https://doi.org/10.1007/s40194-022-01366-6

Kundu S, Chatterjee S (2010) Evolution of interface microstructure and mechanical properties of titanium/304 stainless steel diffusion bonded joint using Nb interlayer. ISIJ Int 50:1460–1465. https://doi.org/10.2355/isijinternational.50.1460

Qin B, Sheng GM, Huang JW et al (2006) Phase transformation diffusion bonding of titanium alloy with stainless steel. Mater Charact 56:32–38. https://doi.org/10.1016/j.matchar.2005.09.015

Zhao Z, Tang J, Tariq N et al (2020) Effect of rolling temperature on microstructure and mechanical properties of Ti/steel clad plates fabricated by cold spraying and hot-rolling. Mater Sci Eng A 795:139982. https://doi.org/10.1016/j.msea.2020.139982

Ghosh M, Bhanumurthy K, Kale GB et al (2004) Strength of the diffusion bonded joints between CP Ti and 304 stainless steel processed below and above β-transus. ISIJ Int 44:388–395. https://doi.org/10.2355/isijinternational.44.388

Bay N, Clemensen C, Juelstorp TW (1985) Bond strength in cold roll bonding. Ann CIRP 34:221–224. https://doi.org/10.1016/S0007-8506(07)61760-0

Govindaraj NV, Lauvdal S, Holmedal B (2013) Tensile bond strength of cold roll bonded aluminium sheets. J Mater Process Technol 213:955–960. https://doi.org/10.1016/j.jmatprotec.2013.01.007

Funding

The authors would like to thank the support from the National Key Research and Development Program (2018YFA0707300), Major Program of National Natural Science Foundation of China (U22A20188).

Author information

Authors and Affiliations

Contributions

Yue Wu: investigation, methodology, data curation, writing original draft; Tao Wang: conceptualization, methodology; Tingting Zhang: writing—review and editing; Zhongkai Ren: microstructure analysis.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wu, Y., Wang, T., Zhang, T. et al. Transverse heterogeneity of bonding strength in Ti/steel clad plates fabricated by hot rolling with bimetal assembling. Int J Adv Manuf Technol 126, 5033–5046 (2023). https://doi.org/10.1007/s00170-023-11369-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11369-2