Abstract

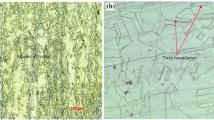

Dissimilar joints are often used by the oil and gas industry to join components such as forged flanges and piping used in subsea operations. The technique consists of buttering the forged flange before the closure weld is made. After the buttering runs, the forged flange is subjected to a post-weld heat treatment. However, the true effectiveness of this procedure has been questioned after failures began to occur in the fusion zone of the forging piece and nickel alloy. The present work aims to investigate the influence of post-weld heat treatment on the mechanical and microstructural behavior of the buttered dissimilar interface of AISI 4130 steel with nickel alloys. Gas metal arc welding processes in continuous and pulsed current modes were employed. AWS ERNiCrMo-3 (Inconel 625) and AWS ERNiCrMo-15 (Inconel 725) solid wires were used as filler metals. Post-weld heat treatment was performed on the buttered plates. The microstructure at the interface of the buttered fusion line were characterized by optical microscopy and scanning electron microscopy. Microhardness analyses were performed at the interface of the buttered weld. The results showed that gas metal arc welding process with pulsed current mode and Inconel 625 as filler metal showed lower levels of dilution and greater control of the partially diluted zones, proving to be more suitable for this type of application. It was also found that regardless of the welding procedure, post-weld heat treatment made the interface more brittle.

Similar content being viewed by others

Availability of data and material

All data are available and can be sent at any time.

Code availability

Not applicable.

References

Dodge M, Dong H, Gittos M (2014) Effect of post-weld heat treatment on microstructure evolution in dissimilar joints for subsea oil and gas systems. Mater Res Innov 18 (sup4):S4–907-S904–913

Dai T, Lippold JC (2018) The effect of postweld heat treatment on hydrogen-assisted cracking of 8630/Alloy 625 overlay. Weld World 62(3):581–599

Deng D (2014) Welding of Dissimilar metals and post weld heat treatment. Encyclopedia of Thermal Stresses. Springer, pp 6573–6580

Deng D, Ogawa K, Kiyoshima S, Yanagida N, Saito K (2009) Prediction of residual stresses in a dissimilar metal welded pipe with considering cladding, buttering and post weld heat treatment. Comput Mater Sci 47(2):398–408

Burk JD, Ribardo CL (2010) SS: Thunder horse and Atlantis deepwater frontier developments in the Gulf of Mexico: thunder horse materials, welding and corrosion challenges and solutions. Offshore Technology Conference. OnePetro, Houston, Texas, USA, pp 1–11

Fenske J, Robertson I, Ayer R, Hukle M, Lillig D, Newbury B (2012) Microstructure and hydrogen-induced failure mechanisms in Fe and Ni alloy weldments. Metall and Mater Trans A 43(9):3011–3022

Haldorsen LM, Rørvik G, Dodge M, Sotoudeh K (2017) Recent experiences with cracking of load bearing dissimilar metal welds on subsea production systems. In: International Conference on Offshore Mechanics and Arctic Engineering. American Society of Mechanical Engineers, Trondheim, Norway, pp 1–13

Kvaale PE, Ha brekke T, Ro̸rvik G (2004) Experience with qualification and use of stainless steels in subsea pipelines. In: International Conference on Offshore Mechanics and Arctic Engineering. Vancouver, British Columbia, Canada, pp 945–952

Beaugrand VC, Smith LS, Gittos MF (2009) Hydrogen embrittlement of 8630M/625 subsea dissimilar joints: factors that influence the performance. In: International Conference on Offshore Mechanics and Arctic Engineering. Honolulu, Hawaii, pp 227–236

Milititsky M, Gittos M, Smith S, Marques V (2010) Assessment of dissimilar metal interfaces for sub-sea application under cathodic protection. In: Material Science and Technology. ASM International United States

NACE MR0175/ISO 15156-2, 2009. Petroleum and natural gas industries – Material for use in H2S-containing environments in oil and gas production –. Part 2: Cracking resistant carbon and low alloy steels, and the use of cast irons. International Standard

Olden V, Kvaale PE, Simensen PA, Aaldstedt Sv, Solberg JK (2003) The effect of PWHT on the material properties and micro structure in inconel 625 and inconel 725 buttered joints. In: International Conference on Offshore Mechanics and Arctic Engineering. Cancun, Mexico, pp 109–115

Fondeviole A, Vignes A (1984) Execution and characterization of dissimilar-metal joints: stainless steel or Ni-Cr-Fe alloy to 20M5M or 16 MND5 steel. Press Vessel Technol 2:823–836

Alexandrov BT, Lippold J, Sowards J, Hope A, Saltzmann D (2013) Fusion boundary microstructure evolution associated with embrittlement of Ni–base alloy overlays applied to carbon steel. Weld World 57(1):39–53

Gittos MF, Gooch TG (1992) The interface below stainless steel and nickel-alloy claddings. Weld J 71(12):461s–472s

Dai T, Lippold J (2017) Tempering behavior of the fusion boundary region of an F22/625 weld overlay. Weld J 96(12):467s–480s

Rajan K, Deshpande P, Narasimhan K (2002) Effect of heat treatment of preform on the mechanical properties of flow formed AISI 4130 steel tubes—a theoretical and experimental assessment. J Mater Process Technol 125:503–511

Jaffe L, Swartz B (1944) Time-temperature relations in tempering steel, Experimental report, 586 Report Number WAL 310/21. Watertown Arsenal Laboratory, Mass

ASTM E3-11, Standard guide for preparation of metallographic specimens, ASTM International, West Conshohocken (2011)

Beaugrand VCM, Smith LS,Gittos MF (2009) Subsea dissimilar joints: failure mechanisms and opportunities for mitigation. NACE International Corrosion Conference and Expo, Paper No. 09305

Silva CC, De Miranda HC, Farias JP (2013) Chemistry and Crystallographic Evaluation of Ni-based Alloy and Steel Dissimilar Interface. In: DebRoy T, David SA, DuPont J, Koseki T, Bhadeshia HK (eds) Proceedings of the 9th International Conference on Trends in Welding Research. ASM International, pp 344–352

Batista R, Araújo E, Fraga R, Maciel T (2016) Caracterização a interface de depósitos de solda de Inconel 625 sobre aços AISI 8630 e AISI 4130 temperados e revenidos. In: Anais do 22º Congresso Brasileiro de Engenharia e Ciência dos Materiais, 2016. Metallum Congressos Técnicos e Científicos São Paulo, pp 6–10

Acknowledgements

The authors of the work would like to thank the National Council for Scientific and Technological Development (CNPq) of Brazil for the financial support to carry out the research.

Funding

This research was supported by the National Council for Scientific and Technological Development (CNPq) of Brazil.

Author information

Authors and Affiliations

Contributions

Conceptualization: R. de Santana Silva, H. D. Carvajal Fals, J. H. Ferreira da Silva. Data curation: R. de Santana Silva, M. C. Sánchez Orozco, H. D. Carvajal Fals, J. H. Ferreira da Silva. Formal analysis: R. de Santana Silva, M. C. Sánchez Orozco, H. D. Carvajal Fals, J. H. Ferreira da Silva. Investigation: R. de Santana Silva, M. C. Sánchez Orozco, H. D. Carvajal Fals, J. H. Ferreira da Silva. Methodology: R. de Santana Silva, H. D. Carvajal Fals, J. H. Ferreira da Silva. Supervision: H. D. Carvajal Fals. Validation: M. C. Sánchez Orozco, H. D. Carvajal Fals. Writing–original draf: R. de Santana Silva, H. D. Carvajal Fals, J. H. Ferreira da Silva. Writing–review and editing: M. C. Sánchez Orozco, H. D. Carvajal Fals.

Corresponding author

Ethics declarations

Ethics approval

The authors consciously assure that this manuscript is their original work, which has not been previously published elsewhere. The paper is not currently being considered for publication elsewhere and reflects the authors’ own research and analysis in a truthful and complete manner. All authors have read and agreed to the published version of the manuscript.

Consent to participate

The authors voluntarily agree to participate in this research.

Consent for publication

The authors grant the publisher the sole and exclusive license of the full copyright in the contribution.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

de Santana Silva, R., Sánchez Orozco, M.C., Carvajal Fals, H.D. et al. Influence of post-weld heat treatment in buttered interface of AISI 4130 and Inconel alloy welded joints. Int J Adv Manuf Technol 126, 2905–2916 (2023). https://doi.org/10.1007/s00170-023-11274-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11274-8