Abstract

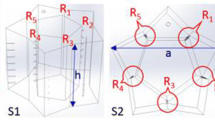

In this paper, a prototype of a reference block with disk reflectors for sensitivity calibration of ultrasonic testing system with angle beam probes was designed and produced. This paper aims to investigate the possibility for sensitivity calibration of ultrasonic angle beam probes with disk reflectors, with flat reference surfaces. The reference blocks with three artificially produced disk reflectors, located at angles of 45°, 60°, and 70°, were made by additive manufacturing technology direct metal laser sintering (DMLS), since DMLS has provided the possibility of producing components with complex inner geometries, which traditional processes could not produce. The exact size of the reference block is obtained by using CT scanning, and the equivalent reflector size (ERS) is estimated by the distance gain size (DGS) diagram and using DGS mode of the ultrasonic instrument by Pulse-Echo. The results are compared with each other and with both the nominal values and the exact size, obtained by CT scan.

Similar content being viewed by others

Data availability

Not applicable.

Code availability

Not applicable.

References

Rieder H, Spies M, Bamberg J, Henkel B 2016 On and offline ultrasonic inspection of additively manufactured components e Journal of Nondestructive Testing https://ndt.net/?id=19607

Aleshina NP, Murashova VV, Shchipakova NA, Krasnova IS, Lozhkova DS (2016) Experimental research into possibilities and peculiarities of ultrasonic testing of additive manufactured parts. Russ J Nondestruct Test 52:685–690. https://doi.org/10.1134/S1061830916120020

Riahi M, Javidrad HR (2020) Production of ultrasonic test piece by utilization of additive manufacturing technique. Russ J Nondestruct Test 56:843–852. https://doi.org/10.1134/S106183092010006X

Koester L, Roberts RA, Barnard DJ, Chakrapani S, Singh S, Hogan R, Bond LJ (2017) NDE of additively manufactured components with embedded defects (Reference Standards) using conventional and advanced ultrasonic methods. AIP Conf Proc 1806:1484–1492. https://doi.org/10.1063/1.4974721

Cerniglia D, Scafidi M, Pantano A, Rudlin J (2015) Inspection of additive-manufactured layered components. Ultrasonic 62:292–298. https://doi.org/10.1016/j.ultras.2015.06.001

Zuo X, Zhang W, Chen Y, Oliveira JP, Zeng Z, Li Y, Luo Z, Ao S 2022 Wire based directed energy deposition of NiTiTa shape memory alloys microstructure phase transformation, electrochemistry X ray visibility and mechanical properties Addit Manuf 59 https://doi.org/10.1016/j.addma.2022.103115

Zhang Zhang W, Shen J, Oliveira JP, Kooi BJ, Pei Y 2023 Crystallographic orientation dependent deformation characteristics of additive manufactured interstitial strengthened high entropy alloys Scr Mater 222 https://doi.org/10.1016/j.scriptamat.2022.115049

Li S, Li JY, Jiang ZW et al 2022 Controlling the columnar to equiaxed transition during directed energy deposition of Inconel 625 Addit Manuf 57 https://doi.org/10.1016/j.addma.2022.102958

Waller J, Saulsberry R, Parker BH, Hodges KL, Burke ER, Taminger KM 2014 Nondestructive evaluation of additive manufacturing state of the discipline report https://ntrs.nasa.gov/citations/20140016447

Waller J 2018 Nondestructive testing of additive manufactured metal parts used in aerospace applications STM international webinar pp 93 124. https://ntrs.nasa.gov/api/citations/20180001858/downloads/20180001858.pdf. Accessed 2 December 2022

Honarvar F, Varvani-Farahani A 2020 A review of ultrasonic testing applications in additive manufacturing defect evaluation material characterization and process control Ultrasonics 108 https://doi.org/10.1016/j.ultras.2020.106227

Ziółkowski G, Chlebus E, Szymczyk P, Kurzac J (2014) Application of X-ray CT method for discontinuity and porosity detection in 316L stainless steel parts produced with SLM technology. Arch Civ Mech Eng 14:608–614. https://doi.org/10.1016/j.acme.2014.02.003

Villarraga H, Lee C, Corbett T, Tarbutton JA, Smith, ST 2016 Inspection of embedded internal features in additive manufactured metal parts using metrological X ray computed tomography ASPE/euspen 2016 Summer Topical Meeting Dimensional Accuracy and Surface Finish in Additive Manufacturing 64

Kruth JP, Bartcher M, Carmignato S, Schmitt R, De Chiffre L, Weckenmann A (2011) Computed tomography for dimensional metrology. CIRP Ann Manuf Technol 60:821–842. https://doi.org/10.1016/j.cirp.2011.05.006

Berke M 2000 Introduction to the basic principles NDT.net https://www.ndt.net/article/v05n09/berke/berke4.htm. Accessed 28 April 2022

Non-destructive testing ultrasonic testing specification for calibration block No 2 ISO 7963 2006 EN ISO 7963 2010

https://www.bakerhughes.com/waygate-technologies. Accessed 20 May 2022

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Morana Mihaljević conceived the presented idea. The first draft of the manuscript was written by Karlo Kožić. Maria Grozdanić investigates the topic and previous research on similar topics. All CT scans and CT measurements were performed by Marko Katić. Morana Mihaljević and Damir Markučič provided support for the case study and supervised the findings of this work. All authors discussed the results and contributed to the final manuscript.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mihaljević, M., Markučič, D., Katić, M. et al. Design of additive manufactured reference block with disk reflectors for sensitivity calibration of ultrasonic angle beam probes. Int J Adv Manuf Technol 126, 1907–1918 (2023). https://doi.org/10.1007/s00170-023-11214-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11214-6