Abstract

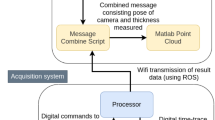

To solve the problems that traditional manual inspection results cannot be visualized and automatic detection equipment is complex and non-maneuverable, a manual ultrasonic C-Scan testing method based on encoder positioning is proposed. By analyzing the characteristics of the ultrasonic A-Scan signal, an acquisition method for ultrasonic A-Scan signal characteristic parameters is established. Based on the encoder position technology, an encoder positioning manual ultrasonic scanning (EPMUC) testing system is proposed. The EPMUC testing system, which is composed of an acoustic system, positioning system and data processing system, is established. Manual ultrasonic C-Scan tests are performed on parts of a titanium alloy-brazed honeycomb sample with manual preset debonding defects and an actual titanium alloy-brazed honeycomb part with the EPMUC testing system. The test results show that the EPMUS system can effectively identify the honeycomb area and honeycomb wall area in the honeycomb structure and can detect manual preset debonding defects in the sample. The maximum detection deviation is 4.4 mm, and the imaging accuracy can reach 1 mm.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Wang, Z.: Recent advances in novel metallic honeycomb structure. Compos. B. Eng. 166, 731–741 (2019)

Xie, Z., Zhao, W., Wang, X., Hang, J., Yue, X., Zhou, X.: Low-velocity impact behaviour of titanium honeycomb sandwich structures. J. Sandw. Struct. Mater. 20, 1009–1027 (2017)

Queheillalt, D.T., Wadley, H.N.G.: Titanium alloy lattice truss structures. Mater. Des. 30, 1966–1975 (2009)

Yang, X., Sun, Y., Yang, J., Pan, Q.: Out-of-plane crashworthiness analysis of bio-inspired aluminum honeycomb patterned with horseshoe mesostructured. Thin Wall Struct. 125, 1–11 (2018)

Liu, S., Zhang, Y., Liu, P.: New analytical model for heat transfer efficiency of metallic honeycomb structures. Int. J. Heat Mass Transf. 51, 6254–6258 (2008)

Hong, S., Pan, J., Tyan, T., Prasad, P.: Quasi-static crush behavior of aluminum honeycomb specimens under compression dominant combined loads. Int. J. Plast. 22, 73–109 (2006)

Dharmasena, K.P., Wadley, H.N.G., Xue, Z., Hutchinso, J.W.: Mechanical response of metallic honeycomb sandwich panel structures to high-intensity dynamic loading. Int. J. Impact. Eng. 35, 1063–1074 (2008)

Côté, F., Deshpande, V.S., Fleck, N.A., Evans, A.G.: The out-of-plane compressive behavior of metallic honeycombs. Mater. Sci. Eng. A. 380, 272–280 (2004)

Rodriguez-Ramirez, J.D.D., Castanie, B., Bouvet, C.: Experimental and numerical analysis of the shear nonlinear behaviour of Nomex honeycomb core: application to insert sizing. Compos. Struct. 193, 121–139 (2018)

Garam, K., Ronald, S., Waterloo, T.: Investigating the effects of fluid intrusion on Nomex honeycomb sandwich structures with carbon fiber facesheets. Compos. Struct. 206, 535–549 (2018)

Chen, Z., Yan, N.: Investigation of elastic moduli of Kraft paper honeycomb core sandwich panels. Compos. B. Eng. 43, 2107–2114 (2012)

Toribio, M.G., Spearing, S.M.: Compressive response of notched glass-fiber epoxy/honeycomb sandwich panels. Compos. Part A Appl. Sci. Manuf. 32, 859–370 (2001)

Shahdin, A., Mezeix, L., Bouvet, C., Morlier, J., Gourinat, Y.: Fabrication and mechanical testing of glass fiber entangled sandwich beams: a comparison with honeycomb and foam sandwich beams. Compos. Struct. 90, 404–412 (2009)

Evans, A.G., Hutchinson, J.W., Fleck, N.A., Ashby, M.F., Wadley, H.N.G.: The topological design of multifunctional cellular metals. Prog. Mater. Sci. 46, 309–327 (2001)

Wadley, H.N.G., Fleck, N.A., Evans, A.G.: Fabrication and structural performance of periodic cellular metal sandwich structures. Compos. Sci. Technol. 63, 2331–2343 (2003)

Wadley, H.N.G.: Multifunctional periodic cellular metals. Philos. Trans. Royal Soc. A 364, 31–68 (2006)

Kiran, M.P.S., Balasundar, I., Gopinath, K., Raghu, T.: Parametric study on factors influencing the stiffness of honeycomb sandwich panels using impulse excitation technique. J. Sandw. Struct. Mater. 21, 115–134 (2019)

Fatemi, J., Lemmen, M.H.J.: Effective thermal/mechanical properties of honeycomb core panels for hot structure applications. J. Spacecraft Rockets 46, 514–525 (2009)

Jing, Y., Xiong, H., Shang, Y., Wang, J., Cheng, Y., Jiang, J.: Design TiZrCuNi filler materials for vacuum brazing TA15 alloy. J. Mater. Process. Tech. 53, 328–335 (2020)

Shapiro, A., Rabinkin, A.: State of the art of titanium-based brazing filler metals. Weld. J. 82, 36–43 (2003)

Sandin, T.: What’s happening with aerospace brazing. Weld. J. 92, 56–58 (2013)

Beeranur, R., Waghmare, K.K., Singh, R.K.: Characterization of vacuum brazing of SS 304 and alumina ceramic with active brazing alloy. Procedia Mater. Sci. 5, 969–977 (2014)

Williams, J.C., Boyer, R.R.: Opportunities and issues in the application of titanium alloys for aerospace components. Metals 10, 705–726 (2020)

Zhao, H., Zhou, Z., Fan, J., Li, G., Sun, G.: Application of lock-in thermography for the inspection of disbonds in titanium alloy honeycomb sandwich structure. Infrared Phys. Technol. 81, 69–78 (2017)

Thomas, R.H., Lou, W., Joseph, L.R.: Rapid inspection of composite skin-honeycomb core structures with ultrasonic guided waves. J. Compos. Mater. 37, 929–939 (2003)

Ghabezi, P., Farahani, M., Shahmirzaloo, A., Ghorbani, H., Harrison, N.M.: Defect evaluation of the honeycomb structures formed during the drilling process. Int. J. Damage Mech. 29, 454–466 (2020)

Lestari, W., Qiao, P.Z.: Damage detection of fiber-reinforced polymer honeycomb sandwich beams. Compos. Struct. 67, 365–673 (2005)

Avdelidis, N.P., Hawtin, B.C., Almond, D.P.: Transient thermography in the assessment of defects of aircraft composites. NDT E Int. 36, 433–439 (2003)

Ahmed, A., Alkhader, M., Abu-Nabah, B.: In-plane elastic wave propagation in aluminum honey-comb cores fabricated by bonding corrugated sheets. J. Sandw. Struct. Mater. 21, 2949–2974 (2019)

Kažys, R., Demčenko, A., Žukauskas, E., Mažeika, L.: Air-coupled ultrasonic investigation of multi-layered composite materials. Ultrasonics 44, 819–822 (2006)

Hsu, D.K.: Nondestructive Evaluation of sandwich structures: a review of some inspection techniques. J. Sandw. Struct. Mater. 11, 275–291 (2009)

Saxena, I.F., Guzman, N., Hui, K., Mal, A.K.: Disbond detection in a composite honeycomb structure of an aircraft vertical stabilizer by fiber Bragg gratings detecting guided ultrasound waves. P. I. Mech. Eng. C J. Mec. 231(16), 3001–3010 (2017)

Zhang, R., Chen, Y., Fu, D.: Manual scan ultrasonic feature imaging testing of composite material. J. Mater. Eng. 4, 34–38 (2003)

Hu, W., Gang, T., Wang, J.: Ultrasonic testing technology of weld defect based on video positioning. Trans. China Weld. Inst. 32, 49–52 (2011)

Acknowledgement

The authors would like to thank all the members in Composite Testing Technology Center and Composite Technology Center who help a lot in this project. They also thank the anonymous reviewers for their critical and constructive review of the manuscript. This study was co-supported by the National Major Project of China (No. JPPT-KF2016–6-1).

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Fu, T., Liu, S. (2022). Encoder Positioning Manual Ultrasonic C-Scan Testing Method and Applications. In: Proceedings of the 5th China Aeronautical Science and Technology Conference. Lecture Notes in Electrical Engineering, vol 821. Springer, Singapore. https://doi.org/10.1007/978-981-16-7423-5_48

Download citation

DOI: https://doi.org/10.1007/978-981-16-7423-5_48

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-7422-8

Online ISBN: 978-981-16-7423-5

eBook Packages: EngineeringEngineering (R0)