Abstract

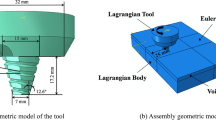

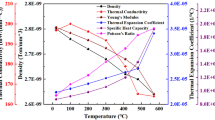

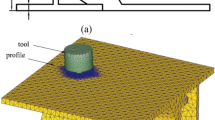

T he advanced heavy-duty launch vehicle fuel tank is made of 2219 aluminum alloy with a thickness of 18 mm now and is welded by friction stir welding (FSW) process. The large thickness results in the axial force in FSW process exceeding 50 kN. The axial force affects the generation of frictional heat and the plastic flow of welding material, which ultimately affects the welding quality. Predicting axial force is the premise of control of the process based on axial force. Most of the existing studies simplify the geometric morphology of the tool during modeling because the complex shape of the tool deforms the mesh excessively and causes the simulation to stop. To achieve the prediction of axial force and investigate the influence of process parameters on axial force, a simulation model of FSW thick 2219 aluminum alloy plate considering the geometric morphology of the tool is established using ABAQUS/CEL based on fluid–structure coupling finite element method. The variation curve of axial force with time during the welding process is obtained, and the validity of the model is verified by FSW experiments. The maximum relative error between the predicted peak axial force and the experimental results is 12.9%, and the average relative error between the predicted axial force and the experimental data in welding stage is 15.1%. Variation law of axial force with rotational speed and welding speed is explored. The research lays a foundation for the control of axial force in FSW thick 2219 aluminum alloy plate.

Similar content being viewed by others

Data availability

All data generated or analyzed during this study are included in this manuscript.

Code availability

The code is available on request.

References

Wang FF, Xie YM, Wu HQ, Ma F, Hang YX (2022) Mechanical performances and corrosion behaviors of friction stir welded and TIG welded 2219 aluminum alloy joints. Trans China Weld Instit 43(06):43–49+115. https://doi.org/10.12073/j.hjxb.20220103001

Tang WK, Yang XQ, Zhao HH, Guo LJ (2020) Numerical analysis of stationary shoulder friction stir welding process for aluminum alloy thick-plate. Aeronautical Manuf Technol 63(11):41–49. https://doi.org/10.16080/j.issn1671-833x.2020.11.041

Singh G, Singh K, Singh J (2012) Effect of axial force on mechanical and metallurgical properties of friction stir welded AA6082 joints. Manuf Sci Technol 383–390:3356–3360. https://doi.org/10.4028/www.scientific.net/AMR.383-390.3356

Chen SJ, Kong DB, Dong JT, Jiang XQ, Yuan T (2021) Influence of process parameters on axial force and transverse force of robot friction stir welding. Chinese J Nonferrous Metals 31(04):956–967. https://doi.org/10.11817/j.ysxb.1004.0609.2021-36598

Zhao X, Kalya P, Landers RG, Krishnamurthy K (2008) Design and implementation of nonlinear force controllers for friction stir welding processes. J Manuf science Eng-Trans ASME 130(6):061011. https://doi.org/10.1115/1.3006326

Wang QX, Hu XW, Pang JZ, Yin YH, Li BZ (2017) Experimental investigations of axial force monitoring and control for friction stir welding process. J Donghua Univ (English Edition) 34(04):498–502. https://doi.org/10.19884/j.1672-5220.2017.04.003

Ji PF, Zhang ZB, Zhao GH, Wang J, Qiao S (2022) Effect of rotation speed on microstructure and properties of 20 mm thick AA2219 friction stir welded plates. Aerospace Mater Technol 52(03):56–61. https://doi.org/10.12044/j.issn.1007-2330.2022.03.009

Arora KS, Pandey S, Schaper M, Kumar R (2010) Effect of process parameters on friction stir welding of aluminum alloy 2219–T87. Int J Adv Manuf Technol 50(9–12):941–952. https://doi.org/10.1007/s00170-010-2560-3

He DQ, Luo JW, Wang HJ, Liu R (2016) Study on relationship between process parameters and welding force of friction stir welding. Hot Work Technol 45(19):232–234. https://doi.org/10.14158/j.cnki.1001-3814.2016.19.064

Doude H, Schneider J, Patton B, Stafford S, Waters T, Varner C (2015) Optimizing weld quality of a friction stir welded aluminum alloy. J Mater Process Technol 222:188–196. https://doi.org/10.1016/j.jmatprotec.2015.01.019

Kumar R, Singh K, Pandey S (2012) Process forces and heat input as function of process parameters in AA5083 friction stir welds. Trans Nonferrous Metals Soc China 22(2):288–298. https://doi.org/10.1016/S1003-6326(11)61173-4

Xiao X, Liu B, Mao YQ, Lai MB, He JN, Lu YJ (2019) Effect of welding process parameters and stir pin morphology on axial pressure of aluminum alloy friction stir welding. Hot Work Technol 48(23):172–176. https://doi.org/10.14158/j.cnki.1001-3814.2019.23.045

Luo HT, Wu TK, Fu J, Wang W, Chen N, Wang HN (2019) Welding characteristics analysis and application on spacecraft of friction stir welded 2A14-T6 aluminum alloy. Materials 12(3):480. https://doi.org/10.3390/ma12030480

Jain R, Pal SK, Singh SB (2016) A study on the variation of forces and temperature in a friction stir welding process: a finite element approach. J Manuf Process 23:278–286. https://doi.org/10.1016/j.jmapro.2016.04.008

Buffa G, Hua J, Shivpuri R, Fratini L (2006) A continuum based fem model for friction stir welding—model development. Mater Sci Eng A-Structural Mater Properties Microstructure Process 419(1–2):389–396. https://doi.org/10.1016/j.msea.2005.09.040

Yang JS, Liu HL, Huang CZ, Wang LM, Li JZ (2020) Numerical simulation of friction stir welding between steel and aluminum dissimilar metal based on fluent. Welding Technol 49(08):11–15+105. https://doi.org/10.13846/j.cnki.cn12-1070/tg.2020.08.003

Crawford R, Cook GE, Strauss AM, Nunes AC (2006) A mechanistic study of the friction stir welding process. AIAA 57th Int Astronautical Congress 8:5589–5595

Cox C, Lammlein D, Strauss A, Cook G (2010) Modeling the control of an elevated tool temperature and the affects on axial force during friction stir welding. Mater Manuf Process 25(11):1278–1282. https://doi.org/10.1080/10426914.2010.490863

Ansari M A, Behnagh R A (2019) Numerical study of friction stir welding plunging phase using smoothed particle hydrodynamics. Model Simulation Mater Sci Eng 27 (5). https://doi.org/10.1088/1361-651X/ab1ca7

Salloomi KN (2019) Fully coupled thermomechanical simulation of friction stir welding of aluminum 6061–T6 alloy T-joint. J Manuf Process 45:746–754. https://doi.org/10.1016/j.jmapro.2019.06.030

Choudhary A K, Jain R (2022) Numerical prediction of various defects and their formation mechanism during friction stir welding using coupled Eulerian-Lagrangian technique. Mechanics Adv Mater Structures. (Published online) https://doi.org/10.1080/15376494.2022.2053911

Liu XL, Xie P, Wimpory R, Li WY, Lai RL, Li MJ, Chen DF, Liu YT, Zhao HY (2019) Residual stress, microstructure and mechanical properties in thick 6005A–T6 aluminium alloy friction stir welds. Metals 9(7):803. https://doi.org/10.3390/met9070803

Zhu Z, Wang M, Zhang HJ, Zhang X, Yu T (2017) Thermal-mechanical coupled simulation on residual stress and distortion of high-strength aluminum alloy sheet after friction stir welding. J Plasticity Eng 24(02):217–222

Wu X Y, Luo W, Wang Y S, Jiang H T (2021) Simulation on friction stir welding 7055 aluminum alloy based on CEL model. Trans China Welding Instit 42(07):44–50+59+100–101. https://doi.org/10.12073/j.hjxb.20200811001

Ansari MA, Samanta A, Behnagh RA, Ding H (2019) An efficient coupled Eulerian-Lagrangian finite element model for friction stir processing. Int J Adv Manuf Technol 101(5–8):1495–1508. https://doi.org/10.1007/s00170-018-3000-z

Xu W F, Liu J H, Zhu H Q (2010) Numerical simulation of thermal field of friction stir welding 2219 aluminum alloy thick plate. Transa China Welding Instit 31(02): 63–66+78+116.

Chen YY, Zhou WT (2019) Study on friction stir welding force of aluminum alloy. Hot Work Technol 48(11):169–172

Funding

The research was supported by the National Key Research and Development Program of China (Grant No. 2019YFA0709003) and Dalian Science and Technology Innovation Fund (Grant No. 2020JJ26GX041). The financial contributions are gratefully acknowledged.

Author information

Authors and Affiliations

Contributions

Le Teng: Conceptualization, Methodology, Software, Validation, Writing-original draft, Investigation, Writing-review and editing.

Xiaohong Lu: Conceptualization, Supervision, Methodology, Funding acquisition, Project administration.

Yihan Luan: Data curation, Software, Investigation.

Shixuan Sun: Formal analysis.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

The authors consent that the work entitled as “Predicting axial force in friction stir welding thick 2219 aluminum alloy plate” for possible publication in International Journal of Advanced Manufacturing Technology.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Teng, L., Lu, X., Luan, Y. et al. Predicting axial force in friction stir welding thick 2219 aluminum alloy plate. Int J Adv Manuf Technol 126, 1025–1034 (2023). https://doi.org/10.1007/s00170-023-11175-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11175-w