Abstract

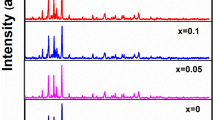

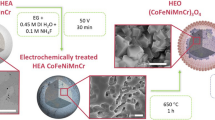

Fe2AlB2 is one of many ternary transition metal borides called MAB phases, which attracted interest owing to its magnetocaloric effect and magnetic properties. Herein, the molten salt-shielded synthesis (MS3) of Fe2AlB2 powder is studied using potassium bromide “KBr” in an open-air atmosphere. The synthesis process of the MAB phase, from Fe, Al, and B elemental powders, was studied with and without Sn additive in the temperature range of 900–1200 °C. The obtained powders were analyzed using XRD, TDA, GTA, and SEM analysis. The corresponding results revealed a successful synthesis of nearly pure Fe2AlB2 phase at 1000 °C for only one hour of holding time, beyond which FeB impurities form. These results show the efficiency of KBr (with Sn as a synthesis aid “additive”) in increasing the reactivity of this MAB phase in terms of the lowest synthesis temperature and time reported to date.

Similar content being viewed by others

References

Jeitschko W (1969) The crystal structure of Fe2AlB2. Acta Crystallogr Sect B 25:163–165. https://doi.org/10.1107/S0567740869001944

Jeitschko W (1966) Die Kristallstruktur von MoAlB. Monatshefte für Chemie und verwandte Teile anderer Wissenschaften 97:1472–1476. https://doi.org/10.1007/BF00902599

Jeitschko W, Nowotny H, Benesovsky F (1964) Carbides of formula T2MC. J Less Common Met 7:133–138. https://doi.org/10.1016/0022-5088(64)90055-4

Ade M, Hillebrecht H (2015) Ternary borides Cr2AlB2, Cr3AlB4, and Cr4AlB6: the first members of the series (CrB2)nCrAl with n = 1, 2, 3 and a unifying concept for ternary borides as MAB-phases. Inorg Chem 54:6122–6135. https://doi.org/10.1021/acs.inorgchem.5b00049

Kota S, Sokol M, Barsoum MW (2020) A progress report on the MAB phases: atomically laminated, ternary transition metal borides. Int Mater Rev 65:226–255. https://doi.org/10.1080/09506608.2019.1637090

Kota S, Verger L, Natu V et al (2021) Thermal stability of the nanolayered Fe2AlB2 in nitrogen and argon atmospheres. J Am Ceram Soc 104:733–739. https://doi.org/10.1111/jace.17492

Kota S, Agne M, Zapata-Solvas E et al (2017) Elastic properties, thermal stability, and thermodynamic parameters of MoAlB. Phys Rev B 95:144108. https://doi.org/10.1103/PhysRevB.95.144108

Kota S, Agne MT, Imasato K et al (2022) Effect of texturing on thermal, electric and elastic properties of MoAlB, Fe2AlB2, and Mn2AlB2. J Eur Ceram Soc 42:3183–3191. https://doi.org/10.1016/j.jeurceramsoc.2022.02.024

Kota S, Zapata-Solvas E, Ly A et al (2016) Synthesis and characterization of an alumina forming nanolaminated boride: MoAlB. Sci Rep 6:26475. https://doi.org/10.1038/srep26475

Cheng Y, Lv ZL, Chen XR, Cai LC (2014) Structural, electronic and elastic properties of AlFe2B2: first-principles study. Comput Mater Sci 92:253–257. https://doi.org/10.1016/j.commatsci.2014.05.048

Kota S, Zapata-Solvas E, Chen Y et al (2017) Isothermal and cyclic oxidation of MoAlB in air from 1100 degrees C to 1400 degrees C. J Electrochem Soc 164:C930–C938. https://doi.org/10.1149/2.1891713jes

Bei G, van der Zwaag S, Kota S et al (2019) Ultra-high temperature ablation behavior of MoAlB ceramics under an oxyacetylene flame. J Eur Ceram Soc 39:2010–2017. https://doi.org/10.1016/j.jeurceramsoc.2019.01.016

Benamor A, Kota S, Chiker N et al (2019) Friction and wear properties of MoAlB against Al2O3 and 100Cr6 steel counterparts. J Eur Ceram Soc 39:868–877. https://doi.org/10.1016/j.jeurceramsoc.2018.10.026

Benamor A, Hadji Y, Kota S et al (2022) Friction and wear characteristics of the nanolaminated ternary transition metal boride: Mn2AlB2. Wear 492–493:204232. https://doi.org/10.1016/j.wear.2021.204232

Yu Z, Tan H, Wang S et al (2020) High-temperature tribological behaviors of MoAlB ceramics sliding against Al2O3 and Inconel 718 alloy. Ceram Int 46:14713–14720. https://doi.org/10.1016/j.ceramint.2020.02.275

Lu X, Li S, Zhang W et al (2019) Crack healing behavior of a MAB phase: MoAlB. J Eur Ceram Soc 39:4023–4028. https://doi.org/10.1016/j.jeurceramsoc.2019.05.059

Bennett SP, Kota S, ElBidweihy H et al (2020) Magnetic and magnetocaloric properties of Fe2AlB2 synthesized by single-step reactive hot pressing. Scr Mater 188:244–248. https://doi.org/10.1016/j.scriptamat.2020.07.042

Barua R, Lejeune BT, Ke L et al (2018) Anisotropic magnetocaloric response in AlFe2B2. J Alloys Compd 745:505–512. https://doi.org/10.1016/j.jallcom.2018.02.205

Zhou Y, Xiang H, Dai F-Z, Feng Z (2017) Electrical conductive and damage-tolerant nanolaminated MAB phases Cr2AlB2, Cr3AlB4 and Cr4AlB6. Mater Res Lett 5:440–448. https://doi.org/10.1080/21663831.2017.1317047

ElMassalami M, da S Oliveira D, Takeya H (2011) On the ferromagnetism of AlFe2B2. J Magn Magn Mater 323:2133–2136. https://doi.org/10.1016/j.jmmm.2011.03.008

Lewis LH, Barua R, Lejeune B (2015) Developing magnetofunctionality: coupled structural and magnetic phase transition in AlFe2B2. J Alloys Compd 650:482–488. https://doi.org/10.1016/j.jallcom.2015.07.255

Bai Y, Sun D, Li N et al (2019) High-temperature mechanical properties and thermal shock behavior of ternary-layered MAB phases Fe2AlB2. Int J Refract Met Hard Mater 80:151–160. https://doi.org/10.1016/j.ijrmhm.2019.01.010

Tan X, Chai P, Thompson CM, Shatruk M (2013) Magnetocaloric effect in AlFe2B2: toward magnetic refrigerants from earth-abundant elements. J Am Chem Soc 135:9553–9557. https://doi.org/10.1021/ja404107p

Li N, Bai Y, Wang S et al (2017) Rapid synthesis, electrical, and mechanical properties of polycrystalline Fe2AlB2 bulk from elemental powders. J Am Ceram Soc 100:4407–4411. https://doi.org/10.1111/jace.15058

Liu J, Li S, Yao B et al (2018) Rapid synthesis and characterization of a nanolaminated Fe2AlB2 compound. J Alloys Compd 766:488–497. https://doi.org/10.1016/j.jallcom.2018.06.352

Wang B, Zhou A, Hu Q, Wang L (2017) Synthesis and oxidation resistance of V2AlC powders by molten salt method. Int J Appl Ceram Technol 14:873–879. https://doi.org/10.1111/ijac.12723

Tian W-B, Wang P-L, Kan Y-M, Zhang G-J (2008) Cr2AlC powders prepared by molten salt method. J Alloys Compd 461:L5–L10. https://doi.org/10.1016/j.jallcom.2007.06.094

Guo X, Wang J, Yang S et al (2013) Preparation of Ti3SiC2 powders by the molten salt method. Mater Lett 111:211–213. https://doi.org/10.1016/j.matlet.2013.08.077

Wang Y, Yang LX, Liu RJ et al (2021) Ternary-layered Cr2AlB2 synthesized from Cr, Al, and B powders by a molten salt-assisted method. Powder Technol 387:354–362. https://doi.org/10.1016/j.powtec.2021.04.042

Dash A, Vaßen R, Guillon O, Gonzalez-Julian J (2019) Molten salt shielded synthesis of oxidation prone materials in air. Nat Mater 18:465–470. https://doi.org/10.1038/s41563-019-0328-1

Dey M, Javaid S, Clifford D et al (2022) Synthesis of nanolayered ternary borides powders (MAB phases) by sustainable molten salt shielded synthesis/sintering (MS3) process. J Mater Sci 57:2436–2454. https://doi.org/10.1007/s10853-021-06779-0

Kota S, Wang W, Lu J et al (2018) Magnetic properties of Cr2AlB2, Cr3AlB4, and CrB powders. J Alloys Compd 767:474–482. https://doi.org/10.1016/j.jallcom.2018.07.031

Roy C, Banerjee P, Bhattacharyya S (2020) Molten salt shielded synthesis (MS3) of Ti2AlN and V2AlC MAX phase powders in open air. J Eur Ceram Soc 40:923–929. https://doi.org/10.1016/j.jeurceramsoc.2019.10.020

Dash A, Sohn YJ, Vaßen R et al (2019) Synthesis of Ti3SiC2 MAX phase powder by a molten salt shielded synthesis (MS3) method in air. J Eur Ceram Soc 39:3651–3659. https://doi.org/10.1016/j.jeurceramsoc.2019.05.011

Tabares E, Jiménez-Morales A, Tsipas SA (2021) Study of the synthesis of MAX phase Ti3SiC2 powders by pressureless sintering. Boletín la Soc Española Cerámica y Vidr 60:41–52. https://doi.org/10.1016/j.bsecv.2020.01.004

Liu J, Li S, Yao B et al (2018) Thermal stability and thermal shock resistance of Fe2AlB2. Ceram Int 44:16035–16039. https://doi.org/10.1016/j.ceramint.2018.06.042

Abenojar J, Velasco F, Martinez MA (2006) Differential thermal analysis of the Al+20% (Fe–50%B) system. J Solid State Chem 179:2787–2790. https://doi.org/10.1016/j.jssc.2005.12.037

Hanner LA, Kota S, Barsoum MW (2021) Formation mechanisms of Cr2AlB2, Cr3AlB4, and Fe2AlB2 MAB phases. Mater Res Lett 9:323–328. https://doi.org/10.1080/21663831.2021.1912843

Chee AKW (2022) The mechanistic determination of doping contrast from fermi level pinned surfaces in the scanning electron microscope using energy-filtered imaging and calculated potential distributions. Microsc Microanal 28:1538–1549. https://doi.org/10.1017/S1431927622000642

Chee AKW, Broom RF, Humphreys CJ, Bosch EGT (2011) A quantitative model for doping contrast in the scanning electron microscope using calculated potential distributions and Monte Carlo simulations. J Appl Phys 109:13109. https://doi.org/10.1063/1.3524186

Drouelle E, Brunet V, Cormier J et al (2020) AMER. J Am Ceram Soc 103:1270–1280. https://doi.org/10.1111/jace.16780

Liang B, Wang M, Sun J et al (2009) Preparation of Ti3AlC2 by mechanically activated sintering with Sn aids. Int J Refract Met Hard Mater 27:927–930. https://doi.org/10.1016/j.ijrmhm.2009.03.002

Mingxing A, Hongxiang Z, Yang Z et al (2006) Synthesis of Ti3AlC2 powders using Sn as an additive. J Am Ceram Soc 89:1114–1117. https://doi.org/10.1111/j.1551-2916.2005.00818.x

Li S-B, Zhai H-X, Bei GP et al (2006) Formation of Ti3AlC2 by mechanically induced self-propagating reaction in Ti–Al–C system at room temperature. Mater Sci Technol 22:667–672. https://doi.org/10.1179/174328406X91050

Krasnowski M (2017) Phase transformations during mechanical alloying and subsequent heating of FeAlB powders. J Alloys Compd 706:110–115. https://doi.org/10.1016/j.jallcom.2017.02.242

Dubois S, Bei GP, Tromas C et al (2010) Synthesis, microstructure, and mechanical properties of Ti3Sn(1–x)AlxC2 MAX phase solid solutions. Int J Appl Ceram Technol 7:719–729. https://doi.org/10.1111/j.1744-7402.2010.02554.x

Acknowledgements

The authors would like to gratefully thank the working staff at the Technical Platform of Physico-Chemical Analysis (PTAPC-Laghouat-CRAPC), Laghouat, Algeria, for performing TGA and TDA analysis.

Funding

This work was funded by la Direction Générale de la Recherche Scientifique et du Développement Technologique (DGRSDT), Algeria.

Author information

Authors and Affiliations

Contributions

All authors contributed to the present study. Powder preparation and experimental work were performed by H. Benamor. The first draft of the manuscript was written by H. Benamor, and all authors commented on previous versions of the manuscript. A. Benamor, N. Chiker, and M. Hakem contributed to XRD data analysis. Pr. M. Krea contributed to the analysis of TGA and TDA analysis. Pr. O. Bouras, Pr. T. Sahraoui, and Pr. M. Hadji contributed to language corrections, study conception, and design. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Benamor, H., Benamor, A., Chiker, N. et al. Molten salt shielded synthesis of the nanolaminated transition metal boride Fe2AlB2. Int J Adv Manuf Technol 125, 5211–5219 (2023). https://doi.org/10.1007/s00170-023-11086-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11086-w