Abstract

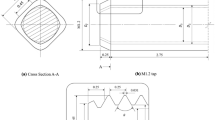

Tools with unequal fluteless spacing (UFS) feature are used to cut different materials. The UFS tool and a traditional tool differ in terms of the angle between the two cutting edges. The UFS tool experiences smaller axial and radial cutting forces than the traditional tool so cutting vibration is reduced, tool life is increased, and the surface roughness of the workpiece increases. This study uses the smaller hole diameter (D), spindle speed (N), and cutting fluid concentration (C) for the central composite design (CCD). Minitab statistical software is used for the second-order response surface modeling of the maximum thread-filling rate (f) and the minimum torque (T) for micro-forming M1.2 mm taps using UFS on AL-7075 aluminum alloy. The analysis of variance (ANOVA) results for f and T show that D and C are the important parameters that affect f, and D, N, and C significantly affect T. Compared with the predicted conditions, the errors in f and T for the experiment are 2.51% and 2.25%, respectively. This study shows that the two second-order mathematical models that are derived using CCD and the response surface method (RSM) feature good prediction accuracy.

Similar content being viewed by others

Data availability

All necessary data are shown in the figures and tables within the document. The raw data can be made available upon request.

Code availability

Not applicable.

References

WarringtonC KapoorSG, DeVor RE (2005) Experimental investigation of thread formation in form tapping. J Manuf Sci Eng 127:829–836

Agapiou JS (1994) Evaluation of the effect of high speed machining on tapping. J Eng Ind 116:457–462

Ivanov VK (1997) Rolling of internal threads. J Mater Process Technol 72:214–220

Chowdhary S, Ozdoganlar OB, Kapoor S, DeVor R (2002) Modeling and analysis of internal thread forming. Trans NAMRC/SME 30:329–336

Chowdhary S, DeVor RE, Kapoor SG (2003) Modeling forces including elastic recovery for internal thread forming. J Manuf Sci Eng 125:681–688

Fromentin G, Poulachon G, Moisan A, Julien B, Giessler J (2005) Precision and surface integrity of threads obtained by form tapping. Manuf Technol CIRP Ann 54:519–522

Fromentin G, Poulachon G, Moisan A (2006) An experimental and analytical method for investigating plastic flow in form tapping. Inter J Form Process 9:457–472

Stéphan P, Mathurin F, Guillot J (2011) Analytical study of maximal tapping torque during forming screw process. J Mater Process Technol 211:212–221

Stéphan P, Mathurin F, Guillot J (2012) Experimental study of forming and tightening processes with thread forming screws. J Mater Process Technol 212:766–775

Carvalho AO, Brandão LC, Panzera TH, Lauro CH (2012) Analysis of form threads using fluteless taps in cast magnesium alloy (AM60). J Mater Process Technol 212:1753–1760

Huang XL, Li XF, Zuo DW, Miu H, Shi DB (2012) Effect of structural parameters of extrusion tap on torque during forming process of internal thread by cold extrusion. Tool Eng 10:18–22

Pereira IC, Faria AE, Da Silva MB (2013) Influence of feed rate and threaded length in thread forming and tapping operations. Lect Notes Eng Comp Sci 3:1781–1784

Dias LD, Brandão LC, Ribeiro Filho SLM, Coelho RT (2014) Processing of threads on a magnesium alloy using a special process. Mater Manuf Process 29:748–753

Landeta JF, Valdivielso AF, López de Lacalle LN, GirotF Pérez JM (2015) Wear of form taps in threading of steel cold forged parts. J Manuf Sci Eng 137:031002_1-031002_11

Oliveira J, Filho S, Brandão L (2019) Investigation of the influence of coating and the tapered entry in the internal forming tapping process. Int J Adv Manuf Technol 101:1051–1063

Monka P, Monkova K, Modrak V, Hric S, Pastucha P (2019) Study of a tap failure at the internal threads machining. Eng Fail Analy 100:25–36

Pereira IC, Vianello PI, Boing D, Guimarães G, Da Silva MB (2020) An approach to torque and temperature thread by thread on tapping. Int J Adv Manuf Technol 106:4891–4901

Swis A, Soussi H, Abid M, Krichen A (2019) Internal and interface shear behaviors of cut and form tapping thread. Int J Adv Manuf Technol 105:3463–3475

Ren J, Yan XG (2022) Tapping simulation to reduce radial pitch diameter difference of threads. Int J Adv Manuf Technol 119:3091–3103

Brandão G, Do Carmo Silva P, De Freitas S, Pereira R, Lauro C, Brandão L (2020) State of the art on internal thread manufacturing: a review. Int J Adv Manuf Technol 110:3445–3465

Chen ZZ, Li ZL, Niu JB, Zhu LM (2020) Chatter detection in milling processes using frequency-domain Rényi entropy. Int J Adv Manuf Technol 106:877–890

Acknowledgements

The authors gratefully acknowledge the support of the Ministry of Science and Technology of the Republic of China, through Grant nos. MOST 108-2221-E-262-002-MY2.

Funding

The authors received the financial support of the Ministry of Science and Technology of the Republic of China (MOST 108–2221-E-262–002-MY2).

Author information

Authors and Affiliations

Contributions

Ming-Chang Wu: conceptualization, guided experimental process, supervision, and writing—review and editing the draft. Chien-Chung Chen: data curation, characterization, validation, analysis, and writing—original draft. Yen-Cheng Huang: conducted the tapping experiments and collection of data and software/plots. Hsing-Ming Teng: reading and summarization of all literature and writing—review and editing the draft. Ling-Sheng Hsu: conducted the manufacture of forming tap. Chung-Chen Tsao: conceptualization, project administration, funding acquisition, and revised some grammar. All the authors have read and agreed to the published version of the manuscript.

Corresponding authors

Ethics declarations

Ethical approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wu, MC., Chen, C., Huang, YC. et al. Study on micro-forming taps with unequal fluteless spacing. Int J Adv Manuf Technol 125, 4073–4081 (2023). https://doi.org/10.1007/s00170-023-11000-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11000-4