Abstract

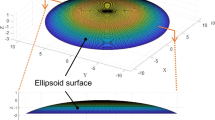

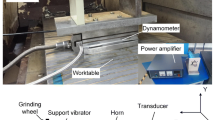

This paper presents an experimental investigation on ultrasonic vibration–assisted magnetorheological finishing (VAMRF) process for improved material removal rate (MRR) and surface finishing on glass optics polishing. An additional process parameter, i.e., vibrating motion, is added in the magnetorheological finishing (MRF) process for corrective polishing of glass optics. Influence function, a material removal characteristic of the process and necessary for deterministic processing, was calculated experimentally for the VAMRF. The results show that hybrid VAMRF provides approximately 20% higher MRR (14.3 nm/min) as compared to that of conventional Ball End MRF (BEMRF), which is 11.9 nm/min. Better surface micro-roughness improvement observed in VAMRF process (3.05 nm) as compared to that in BEMRF process (5.1 nm) from initial value (7.06 nm) in surface of N-BK7 glass workpiece. The developed hybrid process is applied in corrective polishing of glass optics of 25 mm diameter, and it is demonstrated that the figure error (RMS) of the surface has reduced down to 34 nm from 131 nm. Experimental results show that the developed hybrid finishing process is a promising candidate for corrective polishing of optics.

Similar content being viewed by others

Data availability

All the datasets supporting the results are included within the article.

References

Kumar JS, Paul PS, Raghunathan G, Alex DG (2019) A review of challenges and solutions in the preparation and use of magnetorheological fluids. Int J Mech Mater Eng 14:1–18

Raju A, Choi SB, Ferdaus MM (2018) A state of art on magnetorheological materials and their potential applications. J Intell Mater Syst Struct 29:2051–2095

Burhannuddin NL, Nordin NA, Mazlan SA, Aziz S, Khumaira NKS, Ja- mari M, Ubaidillah, (2021) Physicochemical characterization and rheolog- ical properties of magnetic elastomers containing different shapes of cor- roded carbonyl iron particles. Sci Rep 11:868–868

Sadiq A, Shunmugam MS (2010) A novel method to improve finish on non-magnetic surfaces in magneto-rheological abrasive honing process, Tribology International, 43, 5–6. ISSN 1122–1126:0301-679X

Baghel PK, Gavel KS, Khan GS, Kumar R (2022) Line contact ring magnetorheological finishing process for precision polishing of optics. Appl Opt 61:2582–2590

Singh AK, Jha S, Pandey PM (2011) Design and development of nanofinishing process for 3D surfaces using ball end MR finishing tool. Int J Mach Tools Manuf 51:142–151

Singh AK, Jha S, Pandey PM (2013) Mechanism of material removal in ball end magnetorheological finishing process. Wear 302:1180–1191

Singh AK, Jha S, Pandey PM (2012) Nanofinishing of fused silica glass using ball-end magnetorheological finishing tool. Mater Manuf Processes 27:1139–1144

Alam Z, Iqbal F, Ganesan S, Jha S (2018) Nanofinishing of 3D surfaces by automated five-axis CNC ball end magnetorheological finishing machine using customized controller. Int J Adv Manuf Technol 100:1031–1042

Gupta K, Jain NK, Laubscher RF (2016) Overview of hybrid machining processes. In: Hybrid Machining Processes, Springer, pp 1–7

Judal KB, Yadava V, Pathak D (2013) Experimental investigation of vibration assisted cylindrical-magnetic abrasive finishing of aluminum workpiece. Mater Manuf Processes 28:1196–1202

Yin S, Shinmura T (2004) A comparative study: polishing characteris- tics and its mechanisms of three vibration modes in vibration-assisted magnetic abrasive polishing. Int J Mach Tools Manuf 44:383–390

Mulik RS, Pandey PM. (2016) Experimental investigations and optimization of ultrasonic assisted magnetic abrasive finishing process. Proc Inst Mech Eng, Part B: J Eng Manuf

Mulik RS, Pandey PM (2012) Experimental investigations and modeling of finishing force and torque in ultrasonic assisted magnetic abrasive finishing. ASME J Manuf Sci Eng 134(5):051008

Song D, Zhao J, Ji S, Zhou X (2016) Development of a novel two-dimensional ultrasonically actuated polishing process. AIP Advances 6:115105–115105

Wang Y, Zhang Y, Kang R, Ji F (2021) An elementary approximation of dwell time algorithm for ultra-precision computer-controlled optical surfacing. Micromachines 12(5):471

Ghosh G, Dalabehera RK, Sidpara A (2019) Parametric study on influence function in magnetorheological finishing of single crystal silicon. Int J Adv Manuf Technol 100:1043–1054

Baghel PK, Kumar R (2021) Estimation of magnetorheological fluid constituent’s concentration for efficient finishing process. Mater Manuf Processes 36:626–635

Preston FW (1927) The theory and design of plate glass polishing machines. J Soc Glass Technol 11:214–256

Alam Z, Jha S (2017) Modeling of surface roughness in ball end magnetorheological finishing (BEMRF) process Wear. Volumes 374–375(15):54–62

Acknowledgements

The authors are thankful to Director, CSIR-CSIO, Chandigarh, for providing the fabrication and metrology facilities. The authors acknowledge the help received from the technical staff and members of the Optical Precision Laboratory of CSIR-CSIO in the experiments and measurements.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

All the authors agree to transfer copyright of this article to the Publisher.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Baghel, P.K., Mishra, V., Kumar, R. et al. Ultrasonic vibration–assisted magnetorheological hybrid finishing process for glass optics. Int J Adv Manuf Technol 125, 2265–2276 (2023). https://doi.org/10.1007/s00170-023-10819-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-10819-1