Abstract

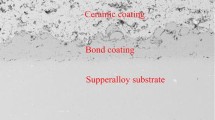

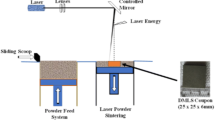

The hole machining of 8 wt% Y2O3-stabilized ZrO2 (8YSZ) thermal barrier coating (TBC) on Inconel 718 superalloy was carried out by electrical discharge machining (EDM) technology. The experimental phenomena, the element composition, and the phase transitions were analyzed by scanning electron microscope (SEM), energy-dispersive X-ray spectroscopy (EDS), X-ray photoelectron spectroscopy (XPS), and X-ray diffraction (XRD). The observation of microscopic morphology and EDS analysis for the machined 8YSZ surface showed that there were four kinds of debris particles deposited: molten brass particle, the vaporized brass particle, molten 8YSZ particle, and the vaporized 8YSZ particle. The debris particles are produced by physical deposition and chemical adsorption of molten and vaporized electrode and workpiece materials. In addition, the chemical reactions in the discharge gap were analyzed. The analysis results indicated that not only the adsorption of pyrolytic carbon but also the deposition of brass and the chemistry of 8YSZ promote the formation of the conductive layer on the 8YSZ TBC. Furthermore, the effects of the phase transitions on machining quality were studied. The XRD analysis illustrated that 8YSZ existed on the machined surface in cubic and tetragonal phases. The brittle fracture and delamination occur on the surface of thermal-barrier-coated superalloys (TBCs) by thermoelastic stress and transformation stress of phase. Finally, based on the characteristics of each processing stage and the phase transitions occur at 8YSZ coating, the 8 forming stages of conductive layer during EDM drilling process for TBCs were proposed.

Similar content being viewed by others

Data availability

Not applicable.

Code availability

Not applicable.

References

Lacaze J, Hazotte A (1990) Directionally solidified materials: nickel-base superalloys for gas turbines. Textures Microstruct 13:601079. https://doi.org/10.1155/TSM.13.1

Huda Z, Edi P (2013) Materials selection in design of structures and engines of supersonic aircrafts: a review. Mater Des 46:552–560. https://doi.org/10.1016/j.matdes.2012.10.001

Kliuev M, Boccadoro M, Perez R, Dal Bó W, Stirnimann J, Kuster F, Wegener K (2016) EDM drilling and shaping of cooling holes in inconel 718 turbine blades. Procedia CIRP 42:322–327. https://doi.org/10.1016/j.procir.2016.02.293

Pineau A, Antolovich SD (2009) High temperature fatigue of nickel-base superalloys—a review with special emphasis on deformation modes and oxidation. Eng Fail Anal 16:2668–2697. https://doi.org/10.1016/j.engfailanal.2009.01.010

Miller RA (1997) Thermal barrier coatings for aircraft engines: history and directions. J Therm Spray Technol 6(1):35–42. https://doi.org/10.1007/BF02646310

Sahith MS, Ga G, Kumar RS (2018) Development and analysis of thermal barrier coatings on gas turbine blades—a review. Mater Today Proc 5:2746–2751. https://doi.org/10.1016/j.matpr.2018.01.060

Wee S, Do J, Kim K, Lee C, Seok C, Choi BG, Choi Y, Kim W (2020) Review on mechanical thermal properties of superalloys and thermal barrier coating used in gas turbines. Appl Sci 10(16):5476. https://doi.org/10.3390/app10165476

Kumar V, Kandasubramanian B (2016) Processing and design methodologies for advanced and novel thermal barrier coatings for engineering applications. Particuol 27:1–28. https://doi.org/10.1016/j.partic.2016.01.007

Padture NP, Gell M, Jordan EH (2002) Thermal barrier coatings for gas-turbine engine applications. Sci 296(5566):280–284. https://doi.org/10.1126/science.1068609

Bogard DG, Thole KA (2006) Gas turbine film cooling. J Propuls Power 22(2):249–270. https://doi.org/10.2514/1.18034

Cheng Y, Wang L, Yuan F (2017) Key technologies and problems of thermal barrier coating applicationon aeroengine turbine vane and blade. Aeronaut Manuf Technol 15:28–34. https://doi.org/10.16080/j.issn1671-833x.2017.15.028

Klocke F, Klink A, Veselovac D, Aspinwall DK, Soo LS, Schmidt M, Levy G, Kruth JP (2014) Turbomachinery component manufacture by application of electrochemical, electro-physical and photonic processes. CIRP Ann Manuf Technol 63:703–726. https://doi.org/10.1016/j.cirp.2014.05.004

Hou S, Bai J (2021) A geometric prediction model of surface morphology in micro-EDM considering stochastic characteristics of discharge crater size. Int J Adv Manuf Technol 117(3–4):1147–1162. https://doi.org/10.1007/s00170-021-07795-9

Renjie J, Yonghong L, Yanzhen Z, Fei W (2011) Machining performance of silicon carbide ceramic in end electric discharge milling. Int J Refract Hard Met 29(1):117–122. https://doi.org/10.1016/j.ijrmhm.2010.09.001

Fukuzawa Y, Tani T, Iwane E, Mohri N (1995) A new machining method for insulating ceramics with an electrical discharge phenomenon. J Ceram Soc Jpn 103(1202):1000–1005. https://doi.org/10.2109/jcersj.103.1000

Mohri N, Fukuzawa Y, Tani T, Saito N, Katsushi F (1996) Assisting electrode method for machining insulating ceramics. CIRP Ann 45(1):201–204. https://doi.org/10.1016/S0007-8506(07)63047-9

Muttamara A, Fukuzawa Y, Mohri N, Tani T (2003) Probability of precision micro-machining of insulating Si3N4 ceramics by EDM. J Mater Process Technol 140:243–247. https://doi.org/10.1016/S0924-0136(03)00745-3

Hanaoka D, Fukuzawa Y, Ramirez C, Miranzo P, Osendi MI, Belmonte M (2013) Electrical discharge machining of ceramic/carbon nanostructure composites. Procedia CIRP 6:95–100. https://doi.org/10.1016/j.procir.2013.03.033

Zhang G, Guo Y, Wang L (2016) Experimental study on the machining of inclined holes for thermal barrier-coated nickel superalloys by EDM. J Mater Eng Perform 25:4574–4580. https://doi.org/10.1007/s11665-016-2287-x

Liu H, Wang Z, Wang Y, Li H (2016) Self-induced electrical discharge machining of Ni-Al2O3 functionally graded materials. Int J Adv Manuf Technol 83:587–594. https://doi.org/10.1007/s00170-015-7568-2

Kumar NM, Kumaran SS, Kumaraswamidhas LA (2016) High temperature investigation on EDM process of Al 2618 alloy reinforced with Si3N4, ALN and ZrB2 in-situ composites. J Alloy Compd 633:755–768. https://doi.org/10.1016/j.jallcom.2015.12.175

Guo Y, Zhang G, Wang L, Hu Y (2016) Optimization of parameters for EDM drilling of thermal-barrier-coated nickel superalloys using gray relational analysis method. Int J Adv Manuf Technol 83:1595–1605. https://doi.org/10.1007/s00170-015-7685-y

Wang L, Chi G, Chen L, Guo Y (2018) Interfacial characteristics investigation for one-step EDM drilling of cooling holes in TBCs. J Mater Eng Perform 27:6719–6728. https://doi.org/10.1007/s11665-018-3728-5

Beck T, Trunova O, Herzog R, Singheiser L (2012) TBCs for gas turbines under thermomechanical loadings: failure behaviour and life prediction. EPJ Web Conf 33:02001. https://doi.org/10.1051/epjconf/20123302001

Kitazawa R, Tanaka M, Kagawa Y, Liu YF (2010) Damage evolution of TBC system under in-phase thermo-mechanical tests. Mater Sci Eng B-Adv 173(1–3):130–134. https://doi.org/10.1016/j.mseb.2009.12.022

Lauwers B, Kruth JP, Liu W, Eeraerts W, Schacht B, Bleys P (2004) Investigation of material removal mechanisms in EDM of composite ceramic materials. J Mater Process Technol 149(1–3):347–352. https://doi.org/10.1016/j.jmatprotec.2004.02.013

Wang L, Guo Y, Zhang G (2017) Investigation on conductive layer, delamination, and recast layer characteristics of electro-discharge machined holes in TBCs. J Mater Eng Perform 26:2394–2403. https://doi.org/10.1007/s11665-017-2654-2

Liu Y, Guo Y, Wang L, Zhang Y, Feng Y (2020) Effects of discharge status in AE-EDM of 8YSZ ceramic. Procedia CIRP 95:488–493. https://doi.org/10.1016/j.procir.2020.02.269

Keyvani A, Saremi M, Sohi MH (2011) Oxidation resistance of YSZ-alumina composites compared to normal YSZ TBC coatings at 1100 ◦C. J Alloy Compd 509:8370–8377. https://doi.org/10.1016/j.jallcom.2011.05.029

Trice RW, Jennifer SuY, Mawdsley JR, Faber KT, De Arellano-López AR, Wang H, Poter WD (2002) Effect of heat treatment on phase stability, microstructure, and thermal conductivity of plasma-sprayed YSZ. J Mater Sci 37:2359–2365. https://doi.org/10.1023/A:1015310509520

Abbas NM, Solomon DG, Bahari MF (2007) A review on current research trends in electrical discharge machining (EDM). Int J Mach Tools Manuf 47(7–8):1214–1228. https://doi.org/10.1016/j.ijmachtools.2006.08.026

Yan MT, Liao YS (1998) Adaptive control of the WEDM process using the fuzzy control strategy. J Manuf Syst 17(4):263–274. https://doi.org/10.1016/S0278-6125(98)80074-5

Xiang H, Lu X, Li J (2014) Influence of carbon on phase stability of tetragonal ZrO2. Ceram Int 40:5645–5651. https://doi.org/10.1016/j.ceramint.2013.10.159

Berger LM, Gruner W, Langholf E, Stolle S (1999) On the mechanism of carbothermal reduction processes of TiO2 and ZrO2. Int J Refract Met Hard Mater 17(1–3):235–243. https://doi.org/10.1016/S0263-4368(98)00077-8

Long Y, Javed A, Chen J, Chen Z, Xiong X (2014) Phase composition, microstructure and mechanical propertiesof ZrC coatings produced by chemical vapor deposition. Ceram Int 40:707–713. https://doi.org/10.1016/j.ceramint.2013.06.059

Kim J, Suh YJ (2017) Temperature- and pressure-dependent elastic properties, thermal expansion ratios, and minimum thermal conductivities of ZrC, ZrN, and Zr(C0.5N0.5). Ceram Int 43:12968–12974. https://doi.org/10.1016/j.ceramint.2017.06.195

Song R, Liu N, Zhang H, Liu Z, Cai W (2009) Properties, preparation and applications of zirconium carbide ceramics. Cemented Carbide 26(2):134–140. https://doi.org/10.3969/j.issn.1003-7292.2009.02.015. (Chinese)

Islam MN, Ghosh TB, Chopra KL, Acharya HN (1996) XPS and X-ray diffraction studies of aluminum-doped zinc oxide transparent conducting films. Thin Solid Films 280(1–2):20–25. https://doi.org/10.1016/0040-6090(95)08239-5

Hayez V, Franquet A, Hubin A, Terryn H (2004) XPS study of the atmospheric corrosion of copper alloys of archaeological Interest. Surf Interface Anal 36:876–879. https://doi.org/10.1002/sia.1790

Scott HG (1975) Phase relationships in the zirconnia-yttria system. J Mater Sci 10:1527–1535. https://doi.org/10.1007/BF01031853

Schulz U, Fritscher K, Peters M (1997) Thermocyclic behavior of variously stabilized EB-PVD thermal barrier coatings. J Eng Gas Turbines Power 119(4):917–921. https://doi.org/10.1115/1.2817074

Jiang K, Liu S, Wang X (2017) Phase stabilityand thermal conductivity of nanostructured tetragonal yttria-stabilized zirconia thermal barrier coatings deposited by air-plasma spraying. Ceram Int 43(15):12633–12640. https://doi.org/10.1016/j.ceramint.2017.06.142

Duwez P, Frank H, Brown J, Francis O (1951) The zirconia-yttria system. J Electrochem Soc 98:356–362. https://doi.org/10.1149/1.2778219

Vendrell X, West AR (2018) Electrical properties of yttria-stabilized zirconia, YSZ single crystal: local AC and long range DC conduction. J Electrochem Soc 165(11):F966–F975. https://doi.org/10.1149/2.0881811jes

Funding

This work is supported by the National Natural Science Foundation of China (No. 51875132).

Author information

Authors and Affiliations

Contributions

Yang Liu: conceptualization, investigation, methodology, data curation, writing-original draft. Li Wang: conceptualization, experimentation, methodology, validation, writing—review and editing. Yongfeng Guo: resources, project administration, supervision, funding acquisition. Yerui Feng: writing—review and editing. Yunlong Du: investigation.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

All authors have read and agreed to the published version of the manuscript.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, Y., Wang, L., Guo, Y. et al. Investigation on surface morphology and phase transition characteristics in EDM for 8YSZ TBC on Inconel 718 superalloy. Int J Adv Manuf Technol 124, 3615–3630 (2023). https://doi.org/10.1007/s00170-022-10738-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-10738-7