Abstract

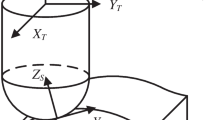

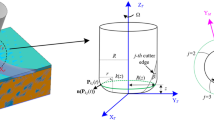

Due to the processing mechanism difference, the raceway topography of the screw processed by whirling milling and by the traditional method is very different, which has a great impact on the load distribution. Based on the homogeneous coordinate transformation, a novel model is established to calculate the raceway surface topography of the whirling milling ball screw. The validity of the raceway model is proved by comparing the result with Liu’s theoretical and experimental results. Then, the influence of the machining parameters on the raceway profile is studied. On this basis, the load distribution of the whirling milling ball screw under different axial forces and processing parameters is studied by considering the raceway topography as raceway error. The findings indicate that the tool ring’s rotational speed, the workpiece’s rotational speed, the number of tools, and eccentricity all affect the raceway form. The load distribution of whirling milling ball screws is highly dependent on the raceway’s surface topography.

Similar content being viewed by others

References

Liang T, Lu D, Yang X, Zhang J, Ma X, Zhao W (2016) Feed fluctuation of ball screw feed systems and its effects on part surface quality. Int J Mach Tool Manu 101:1–9

Sreejith PS, Ngoi B (2000) Dry machining: Machining of the future. J Mater Process Tech 101(1):287–291

Liu C, He Y, Wang Y, Li Y, Wang Y (2019) An investigation of surface topography and workpiece temperature in whirling milling machining. Int J Mech Sci 164:105182

Arrazola P, Zel T, Umbrello D, Davies M, Jawahir I (2013) Recent advances in modelling of metal machining processes. Cirp Ann-Manuf Techn 62(2):695–718

Beruvides G, Castano F, Haber R, Quiza R, Villalonga A (2017) Coping with complexity when predicting surface roughness in milling processes: hybrid incremental model with optimal parametrization. Complexity

Pereira R, Brando LC, de Paiva A, Ferreira JR, DaVim JP (2017) A review of helical milling process. Int J Mach Tool Manu 120:27–48

Liu C, He Y, Li Y, Wang Y, Wang Y (2020) Predicting residual properties of ball screw raceway in whirling milling based on machine learning. Mearsurement 173(25)

He Y, Wang L, Wang Y, Li Y, Hao C (2019) An analytical model for predicting specific cutting energy in whirling milling process. J Clean Prod 240:118181

He Y, Liu C, Wang Y, Li Y, Wang Y (2019) Analytical modeling of temperature distribution in lead-screw whirling milling considering the transient un-deformed chip geometry. Int J Mech Sci 157:619–632

Liu C, He Y, Wang Y, Li Y, Wang Y (2020) Effects of process parameters on cutting temperature in dry machining of ball screw. ISA T 101:493–502

Mohan LV, Shunmugam MS (2007) Simulation of whirling process and tool profiling for machining of worms. J Mater Process Tech 185(1-3):191–197

Wang ZH, Wang BX, Yuan JT (2018) Modeling of surface topography based on cutting vibration in ball-end milling of thin-walled parts. Int J Adv Manuf Tech 101:1837–1854

Chen W, Lu L, Xie W, Huo D, Yang K (2018) A new surface topography-based method to quantify axial error of high speed milling cutters. J Manuf Sci E-T Asme 140(11):111014

Bertolaso R, Cheikh M, Barranger Y, Dupré J, Germaneau A, Doumalin P (2014) Experimental and numerical study of the load distribution in a ball-screw system. J Mech Sci Technol 28:1411–1420

Mei XS, Tsutsumi M, Tao T, Sun NG (2003) Study on the load distribution of ball screws with errors. Mech Mach Theory 38(11):1257–1269

Zhen N, An Q (2017) Analysis of stress and fatigue life of ball screw with considering the dimension errors of balls. Int J Mech Sci 137:68–76

Zhao JJ, Lin MX, Song XC, Guo QZ (2019) Investigation of load distribution and deformations for ball screws with the effects of turning torque and geometric errors. Mech Mach Theory 141:95–116

Liu C, Zhao C, Meng X, Wen B (2020) Static load distribution analysis of ball screws with nut position variation. Mech Mach Theory 151(4):103893

Chen YJ, Tang WJ (2014) Dynamic contact stiffness analysis of a double-nut ball screw based on a quasi-static method. Mech Mach Theory 73:76–90

Liu J, Feng HT, Zhou CG (2022) Static load distribution and axial static contact stiffness of a preloaded double-nut ball screw considering geometric errors. Mech Mach Theory 167: 104460

Wei CC, Lin JF, Horng JH (2009) Analysis of a ball screw with a preload and lubrication. Tribol Int 42(11):1816–1831

Zhou CG, Xie JL, Feng HT (2021) Investigation of the decompression condition of double-nut ball screws considering the influence of the geometry error and additional elastic unit. Mech Mach Theory 156:104164

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Author contribution

All authors contributed to the conception and design. Material preparation, data collection, and analysis were conducted by Lei Lv, Changhou Lu, and Shujiang Chen. The first draft of the manuscript was written by Lei Lv and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Changhou Lu and Shujiang Chen contributed equally to this work.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lv, L., Lu, C. & Chen, S. Surface modeling and load distribution analysis of ball screw formed by whirling milling. Int J Adv Manuf Technol 125, 1603–1614 (2023). https://doi.org/10.1007/s00170-022-10634-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-10634-0