Abstract

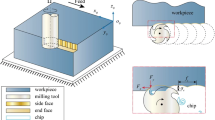

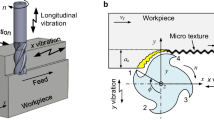

Because of the low rigidity of thin-walled parts, the cutting vibration is commonly encountered and has a vital influence on machined surface quality. Theoretical simulation of surface topography is one of the main methods to evaluate and control surface quality in practice. In this paper, a simulation model of surface topography is developed based on cutting edge motion model that incorporates the dynamics of thin-walled parts milling system. The theoretical model used to describe the trajectory of cutting edge takes tool vibration and workpiece vibration into account. Then, the influence of system vibration on surface topography is investigated. Particularly, a new method is proposed in this paper to predict the texture interval, texture distribution, and residual height for different milling areas by identifying the dynamic characteristics of thin-walled parts. In addition, the validity of surface topography model is conducted by experiment. The results show that the simulated topography is consistent with the experimental topography, and the model is proved to be able to predict roughness accurately.

Similar content being viewed by others

References

Li ZL, Tuysuz O, Zhu LM, Altintas Y (2018) Surface form error prediction in five-axis flank milling of thin-walled parts. Int J Mach Tools Manuf 128:21–32

Denkena B, Boess V, Nespor D, Floeter F, Rust F (2015) Engine blade regeneration: a literature review on common technologies in terms of machining. Int J Adv Manuf Technol 81(5–8):917–924

Zhang Z, Li HG, Liu XB, Zhang WY, Meng G (2018) Chatter mitigation for the milling of thin-walled workpiece. Int J Mech Sci 138:262–271

Butt MA, Yang YQ, Pei XZ, Liu Q (2018) Five-axis milling vibration attenuation of freeform thin-walled part by eddy current damping. Precis Eng 51:682–690

Lu C (2008) Study on prediction of surface quality in machining process. J Mater Process Technol 205(1–3):439–450

Benardos PG, Vosniakos GC (2003) Predicting surface roughness in machining: a review. Int J Mach Tools Manuf 43(8):833–844

Quinsat Y, Lavernhe S, Lartigue C (2011) Characterization of 3D surface topography in 5-axis milling. Wear 271(3–4):590–595

Peng ZX, Jiao L, Yan P, Yuan MX, Gao SF, Yi J, Wang XB (2018) Simulation and experimental study on 3D surface topography in micro-ball-end milling. Int J Adv Manuf Technol 96(5–8):1943–1958

Buj-Corral I, Vivancos-Calvet J, Dominguez-Fernandez A (2012) Surface topography in ball-end milling processes as a function of feed per tooth and radial depth of cut. Int J Mach Tools Manuf 53(1):151–159

Zhao K, Hockauf R, Liu ZB, Zhao WX, Wang XB, Wang DQ (2018) Kinematic and stochastic surface topography of workpiece made of Al7075 in flank milling. Int J Adv Manuf Technol 96(5–8):2735–2745

Lazoglu I (2003) Sculpture surface machining: a generalized model of ball-end milling force system. Int J Mach Tools Manuf 43(5):453–462

Zhang Q, Zhang S, Shi WH (2018) Modeling of surface topography based on relationship between feed per tooth and radial depth of cut in ball-end milling of AISI H13 steel. Int J Adv Manuf Technol 95(9–12):4199–4209

Wang ZH, Yuan JT, Yin ZB, Hu XQ (2016) Surface topography and roughness of high-speed milled AlMn1Cu. Chin J Mech Eng 29(6):1200–1207

Zhang C, Guo S, Zhang HY, Zhou LS (2013) Modeling and predicting for surface topography considering tool wear in milling process. J Adv Manuf Technol 68(9–12):2849–2860

Omar OEEK, El-Wardany T, Ng E, Elbestawi MA (2007) An improved cutting force and surface topography prediction model in end milling. Int J Mach Tools Manuf 47(7–8):1263–1275

Li B, Cao YL, Chen WH, Pan J (2017) Geometry simulation and evaluation of the surface topography in five-axis ball-end milling. Int J Adv Manuf Technol 93(5–8):1651–1667

Hao YS, Liu Y (2017) Analysis of milling surface roughness prediction for thin-walled parts with curved surface. Int J Adv Manuf Technol 93(5–8):2289–2297

González H, Calleja A, Pereira O, Ortega N, de Lacalle LNL, Barton M (2018) Super abrasive machining of integral rotary components using grinding flank tools. Metals 8(1):833–844

Peigne G, Paris H, Brissaud D, Gouskov A (2004) Impact of the cutting dynamics of small radial immersion milling operations on machined surface roughness. Int J Mach Tools Manuf 44(11):1133–1142

Surmann T, Enk D (2007) Simulation of milling tool vibration trajectories along changing engagement conditions. Int J Mach Tools Manuf 47(9):1442–1448

Surmann T, Biermann D (2008) The effect of tool vibrations on the flank surface created by peripheral milling. CIRP Ann Manuf Technol 57(1):375–378

Jiang H, Long XH, Meng G (2008) Study of the correlation between surface generation and cutting vibrations in peripheral milling. J Mater Process Technol 208(1–3):229–238

Liang XG, Yao ZG (2013) Dynamic-based simulation for machined surface topography in 5-axis ball-end milling. J Mech Eng 49(6):171–178

Liang XG, Yao ZG (2013) Study on milling stability with varying time delay in 5-axis ball-end finishing. Shanghai Jiao Tong University 2013:109–119

Arizmendi M, Campa FJ, Fernandez J, de Lacalle LNL, Gil A, Bilbao E, Veiga F, Lamikiz A (2009) Model for surface topography prediction in peripheral milling considering tool vibration. CIRP Ann Manuf Technol 58(1):93–96

Arizmendi M, Fernandez J, de Lacalle LNL, Lamikiz A, Gil A, Sanchez JA, Campa FJ, Veiga F (2008) Model development for the prediction of surface topography generated by ball-end mills taking into account the tool parallel axis offset. Experimental validation. CIRP Ann Manuf Technol 57(1):101–104

Lee KY, Kang MC, Jeong YH, Lee DW, Kim JS (2001) Simulation of surface roughness and profile in high-speed end milling. J Mater Process Technol 113(1–3):410–415

Peng FY, Wu J, Fang ZL, Yuan S, Yan R, Bai QS (2013) Modeling and controlling of surface micro-topography feature in micro-ball-end milling. J Adv Manuf Technol 67(9–12):2657–2670

Peng FY, Fang ZL, Wu J (2012) Three-dimensional surface topography simulation of ultraprecision milling based on point cloud. Journal of Huazhong University of Science and Technology. Nature Science 40(8):1–6

Altintas Y, Lee P (1998) Mechanics and dynamics of ball end milling. J Manuf Sci Eng 120(4):684–692

Engin S, Altintas Y (2001) Mechanics and dynamics of general milling cutters. Part I: helical end mills. Int J Mach Tools Manuf 41(15):2195–2212

Gradisek J, Kalveram M, Weinert K (2004) Mechanistic identification of specific force coefficients for a general end mill. Int J Mach Tools Manuf 44(4):401–414

Qu S, Zhao JB, Wang TR (2016) Three-dimensional stability prediction and chatter analysis in milling of thin-walled plate. J Adv Manuf Technol 86(5–8):2291–2300

Funding

This work was supported by the National Natural Science Foundation of China (No. 51775280 and No. 51675285), and the National Science and Technology Major Project (2013ZX04002-011).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, Z., Wang, B. & Yuan, J. Modeling of surface topography based on cutting vibration in ball-end milling of thin-walled parts. Int J Adv Manuf Technol 101, 1837–1854 (2019). https://doi.org/10.1007/s00170-018-3095-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-3095-2