Abstract

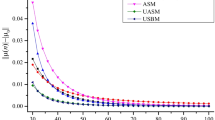

The stability prediction is an effective approach to suppress the unstable milling process caused by the regenerative chatter. Through updating a numerical solution scheme (NSS), a fast prediction method is proposed in this paper. Firstly, a NSS is constructed by combining the Lagrange polynomial and Euler’s method. Then, the solution of the differential equations described the milling process is transformed into the initial-value problem of the equation which is expressed by the built NSS over each small discrete time interval. Subsequently, the state transition matrix over one tooth passing period is established to predict the stability lobe diagram (SLD) via the Floquet theory. Finally, the computational performances of the proposed method are verified by the single and two DOF dynamic models. Compared with the complete discretization scheme, the computational accuracy and efficiency of the proposed method are increased by 2.69 times and 2.01 times, respectively. The proposed method reduces the computational accuracy by 2.16 times in comparison to the first-order full-discretization method, but it increases the computational efficiency by 2.2 times.

Similar content being viewed by others

Data availability

The data can be available from the corresponding author.

Code availability

Not applicable.

References

Totis G, Albertelli P, Torta M, Sortino M, Monno M (2017) Upgraded stability analysis of milling operations by means of advanced modeling of tooling system bending. Int J Mach Tools Manuf 113:19–34

Yang Y, Zhang WH, Ma YC, Wan M (2016) Chatter prediction for the peripheral milling of thin-walled workpieces with curved surfaces. Int J Mach Tools Manuf 109:36–48

Gu YX, Chen BS, Zhang HW, Guan ZQ (2001) Precise time-integration method with dimensional expanding for structural dynamic equations. AIAA J 39(12):2394–2399

Ding Y, Zhu LM, Zhang XJ, Ding H (2010) A full-discretization method for prediction of milling stability. Int J Mach Tools Manuf 50(5):502–509

Insperger T, Stépán G (2004) Updated semi-discretization method for periodic delay-differential equations with discrete delay. Int J Numer Meth Eng 61:117–141

Ding Y, Zhu LM, Zhang XJ, Ding H (2010) Second-order full-discretization method for milling stability prediction. Int J Mach Tools Manuf 50(10):926–932

Quo Q, Sun YW, Jiang Y (2012) On the accurate calculation of milling stability limits using third-order full-discretization method. Int J Mach Tools Manuf 62:61–66

Liu YL, Zhang DH, Wu BH (2012) An efficient full-discretization method for prediction of milling stability. Int J Mach Tools Manuf 63:44–48

Liu YL, Fischer A, Eberhard P, Wu BH (2015) A high-order full-discretization method using Hermite interpolation for periodic time-delayed differential equations. Acta Mech Sin 31(03):406–415

Qin CJ, Tao JF, Liu CL (2019) A novel stability prediction method for milling operations using the holistic-interpolation scheme. Proc IMechE, Part C: J Mech Eng Sci 233(13): 4463-4475

Ji YJ, Wang XB, Liu ZB, Wang HJ, Wang KJ, Wang DQ (2019) Stability prediction of five-axis ball-end finishing milling by considering multiple interaction effects between the tool and workpiece. Mech Syst Signal Process 131:261–287

Ji YJ, Wang LY, Song Y, Wang HJ, Liu ZB (2022) Investigation of robotic milling chatter stability prediction under different cutter orientations by an updated full-discretization method. J Sound Vib 536:117150

Ozoegwu CG, Omenyi SN, Ofochebe SM (2015) Hyper-third order full-discretization methods in milling stability prediction. Int J Mach Tools Manuf 92:1–9

Ding Y, Zhu LM, Zhang XJ, Ding H (2011) Numerical integration method for prediction of milling stability. J Manuf Sci Eng 133(3):1–9

Li WT, Wang LP, Yu G (2020) An accurate and fast milling stability prediction approach based on the Newton-Cotes rules. Int J Mech Sci 177:105469

Zhang Z, Li HG, Meng G, Liu C (2015) A novel approach for the prediction of the milling stability based on the Simpson method. Int J Mach Tools Manuf 99:43–47

Ozoegwu CG (2016) High order vector numerical integration schemes applied in state space milling stability analysis. Appl Math Comput 273:1025–1040

Xia Y, Wan Y, Luo XC, Liu ZQ, Song QH (2021) An improved numerical integration method to predict the milling stability based on the Lagrange interpolation scheme. Int J Adv Manuf Technol 116(7):2111–2123

Xia Y, Wan Y, Su GS, Du J, Zhang PR, Xu CH (2022) An improved numerical integration method for prediction of milling stability using the Lagrange-Simpson interpolation scheme. Int J Adv Manuf Technol 120(11–12):8105–8115

Tao JF, Qin CJ, Liu CL (2017) Milling stability prediction with multiple delays via the extended Adams-Moulton-based method. Math Probl Eng 2017:1–15

Yang Y, Yuan JW, Tie D, Wan M, Zhang WH (2023) An efficient and accurate chatter prediction method of milling processes with a transition matrix reduction scheme. Mech Syst Signal Process 182:109535

Qin CJ, Tao JF, Shi HT, Xiao DY, Li BC, Liu CL (2020) A novel Chebyshev-wavelet-based approach for accurate and fast prediction of milling stability. Precis Eng 62:244–255

Dun YC, Zhu LD, Wang SH (2020) Multi-modal method for chatter stability prediction and control in milling of thin-walled workpiece. Appl Math Model 80:602–624

Li MZ, Zhang GJ, Huang Y (2013) Complete discretization scheme for milling stability prediction. Nonlinear Dyn 71(1):187–199

Sun T, Qin LF, Fu YC, Hou JM (2019) Chatter stability of orthogonal turn-milling analyzed by complete discretization method. Precis Eng 56:87–95

Xie QZ (2016) Milling stability prediction using an improved complete discretization method. Int J Adv Manuf Technol 83(5):815–821

Lv SJ, Zhao Y (2021) Stability of milling process with variable spindle speed using Runge–Kutta-based complete method. Math Probl Eng 2021:1–10

Funding

This research was funded by the National Natural Science Foundation of China (Grant No. 51975336), Key Research and Development Program of Shandong Province (Grant No. 2020JMRH0202), the Natural Science Foundation of Shandong Province (Grant No. ZR2022QE241), the New Old Energy conversion Major Industrial Tackling Project of Shandong Province (Grant No. 2021–13), and Key Research and Development Program of Jining City (2021DZP005).

Author information

Authors and Affiliations

Contributions

Yan Xia, Yi Wan, and Guosheng Su contributed to the conceptualization and methodology; Yan Xia, Peirong Zhang, and Jin Du performed the investigation and analysis; Yan Xia wrote the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix 1 Coefficient matrixes for single and two DOF milling systems

Appendix 1 Coefficient matrixes for single and two DOF milling systems

The coefficient matrixes for the single DOF milling system can be described as

where h(t) is the cutting force coefficient.

The coefficient matrixes for the two DOF milling system can be described as

with

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xia, Y., Wan, Y., Du, J. et al. Fast prediction of chatter stability in milling process based on an updated numerical solution scheme. Int J Adv Manuf Technol 123, 4041–4050 (2022). https://doi.org/10.1007/s00170-022-10483-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-10483-x