Abstract

In this work, machine learning approach based on polynomial regression was explored to analyze the optimal processing parameters and predict the target particle sizes for ball milling of alumina ceramics. Data points were experimentally collected by measuring the particle sizes. Prediction interval (PI)-based optimization methods using polynomial regression analysis are proposed. As a first step, functional relations between processing parameters (inputs) and quality responses (outputs) are derived by applying the regression analysis. Later, based on these relations, objective functions to be maximized are defined by desirability approach. Finally, the proposed PI-based methods optimize both parameter points and intervals of the target mill for accomplishing user-specified target responses. The optimization results show that the PI-based point optimization methods can select and recommend statistically reliable optimized parameter points even though unique solutions for the objective functions do not exist. From the results of confirmation experiments, it is established that the optimized parameter points can produce desired final powders with quality responses quite similar to the target responses.

Similar content being viewed by others

Data availability

All data generated or mentioned in this study are included in this published article.

Code availability

No code was provided in this manuscript.

Abbreviations

- L :

-

Number of quality responses (inputs)

- p :

-

Number of processing parameters (outputs)

- y l, x j :

-

lTh output, and jth input

- \(\hat{y}_{l} ({\mathbf{x}})\) :

-

Regression function for lth output yl

- \(\hat{y}_{l} ({\mathbf{x}}_{{{\text{new}}}} )\) :

-

Output of lth regression function for new input vector xnew

- \([PI_{LB}^{l} ({\mathbf{x}}_{{{\text{new}}}} ),PI_{UB}^{l} ({\mathbf{x}}_{{{\text{new}}}} )]\) :

-

Prediction interval for \(\hat{y}_{l} ({\mathbf{x}}_{{{\text{new}}}} )\)

- \(PI_{k}^{l}\) :

-

Length of prediction interval \([PI_{LB}^{l} ({\mathbf{x}}_{k}^{*} ),PI_{UB}^{l} ({\mathbf{x}}_{k}^{*} )]\)

- PI k :

-

Total length of L prediction intervals obtained by summing all the standardized values of \(PI_{k}^{1} ,...,PI_{k}^{L}\)

- \({\mathbf{I}}_{{{\text{imp}}{.}}} \in \Re^{L \times p}\) :

-

Importance matrix that consists of importance values of p inputs for L outputs

- d l(∙):

-

Desirability function for lth output yl

- y l ,target :

-

Target value for lth output yl

- y l ,min, y l ,max :

-

Lower and upper limits of lth output yl

- D(x):

-

Overall desirability function (objective function for multiple response optimization problem)

- \({\mathbf{x}}^{*} = [x_{1}^{*} ,...,x_{p}^{*} ]^{T}\) :

-

Optimized parameter point

- \({\mathbf{x}}_{LB}^{*} ,{\mathbf{x}}_{UB}^{*}\) :

-

Lower and upper bounds for defining optimized parameter intervals

- \([x_{LB,j}^{*} ,x_{UB,j}^{*} ]\) :

-

Optimized parameter interval for jth input

- J L × p :

-

L By p matrix of ones

- δ l :

-

Small positive increment

- W lj, \(\overline{W}_{lj}\) :

-

(l, j)Th element of W = JL×p − Iimp., and standardized values of Wlj

- \(\times_{j = 1}^{p} [x_{j}^{*} - \delta_{l} \overline{W}_{lj} ,x_{j}^{*} + \delta_{l} \overline{W}_{lj} ]\) :

-

p-Dimensional hyper-rectangle centered at x*

- v m, V :

-

Vertices of hyper-rectangle, and vertex set composed of all vm

- ML:

-

Machine learning

- PI:

-

Prediction interval

- ANN:

-

Artificial neural networks

- PSD:

-

Particle size distribution

- RSM:

-

Response surface method

- GA:

-

Genetic algorithm

- AVOVA:

-

Analysis of variance

- CCD:

-

Central composite design

- MRO:

-

Multiple response optimization

- MC:

-

Monte Carlo

- PSO:

-

Particle swarm optimization

- RMSE:

-

Root mean squared error

- ECDF:

-

Empirical cumulative distribution function

References

Schmidt J, Marques MRG, Botti S, Marques MAL (2019) Recent advances and applications of machine learning in solid-state materials science. NPJ Comput Mater 5:83

Yang K, Xu X, Yang B, Cook B, Ramos H, Krishnan NMA, Smedskjaer MM, Hoover C, Bauchy M (2019) Predicting the Young’s modulus of silicate glasses using high-throughput molecular dynamics simulations and machine learning. Sci Rep 9:8739

Liu H, Zhang T, Krishnan NMA, Smedskjaer MM, Ryan JV, Gin S, Bauchy M (2019) Predicting the dissolution kinetics of silicate glasses by topology-informed machine learning. NPJ Mater Degrad 3:32

Wei J, Chu X, Sun X-Y, Xu K, Deng H-X, Chen J, Wei Z, Lei M (2019) Machine learning in materials science. Infomat 1:338–358

Liu H, Fu Z, Yang K, Xu X, Bauchy M (2021) Machine learning for glass science and engineering: a review. J Non-Cryst Solids 557:119419

Yang H, Zhang Z, Zhang J, Zeng XC (2018) Machine learning and artificial neural network prediction of interfacial thermal resistance between graphene and hexagonal boron nitride. Nanoscale 10:19092

He J, Li J, Liu C, Wang C, Zhang Y, Wen C, Xue D, Cao J, Su Y, Qiao L, Bai Y (2021) Machine learning identified materials descriptors for ferroelectricity. Acta Mater 209:116815

Kerner J, Dogan A, Recum HV (2021) Machine learning and big data provide crucial insight for future biomaterials discovery and research. Acta Biomater 130:54–65

Rodrigues JF Jr, Florea L, de Oliveira MCF, Diamond D, Oliveira ON Jr (2021) Big data and machine learning for materials science. Discov Mater 1:12

Liu Y, Niu C, Wang Z, Gan Y, Zhu Y, Sun S, Shen T (2020) Machine learning in materials genome initiative: a review. J Mater Sci Technol 57:113–122

Kaufmann K, Maryanovsky D, Mellor WM, Zhu C, Rosengarten AS, Harrington TJ, Oses C, Toher C, Curtarolo S, Vecchio KS (2020) Discovery of high-entropy ceramics via machine learning. Npj Comput Mater 6:42

Kaufmann K, Vecchio KS (2020) Searching for high entropy alloys: a machine learning approach. Acta Mater 198:178–222

Qin J, Liu Z, Ma M, Li Y (2021) Machine learning approaches for permittivity prediction and rational design of microwave dielectric ceramics. J Materiomics 7:1284–1293

Qu N, Liu Y, Liao M, Lai Z, Zhou F, Cui P, Han T, Yang D, Zhu J (2019) Ultra-high temperature ceramics melting temperature prediction via machine learning. Ceram Int 45:18551–18555

Yang P, Wu S, Wu H, Lu D, Zou W, Chu L, Shao Y, Wu S (2021) Prediction of bending strength of Si3N4 using machine learning. Ceram Int 47:23919–23926

Reed JS (1995) Principles of ceramics processing, 2nd edn. Wiley, New York

Suryanarayana C (2001) Mechanical alloying and milling. Prog Mater Sci 46:1–184

Janot R, Guérard D (2005) Ball-milling in liquid media: applications to the preparation of anodic materials for lithium-ion batteries. Prog Mater Sci 50:1–92

Frances C, Laguerie C (1998) Fine wet grinding of an alumina hydrate in a ball mill. Powder Technol 99:147–153

Shin H, Lee S, Jung HS, Kim JB (2013) Effect of ball size and powder loading on the milling efficiency of a laboratory-scale wet ball mill. Ceram Int 39:8963–8968

Mulenga FK, Moys MH (2014) Effects of slurry pool volume on milling efficiency. Powder Technol 256:428–435

Wagih A, Fathy A, Kabeel AM (2018) Optimum milling parameters for production of highly uniform metal-matrix nanocomposites with improved mechanical properties. Adv Powder Technol 29:2527–2537

Oh HM, Park YJ, Kim HN, Ko JW, Lee HK (2021) Effect of milling ball size on the densification and optical properties of transparent Y2O3 ceramics. Ceram Int 47:4681–4687

Hou TH, Su CH, Liu WL (2007) Parameters optimization of a nano-particle wet milling process using the Taguchi method, response surface method and genetic algorithm. Powder Technol 173:153–162

Zhang FL, Zhu M, Wang CY (2008) Parameters optimization in the planetary ball milling of nanostructured tungsten carbide/cobalt powder. Int J Refract Met Hard Mat 26:329–333

Ma J, Zhu SG, Wu CX, Zhang ML (2009) Application of back-propagation neural network technique to high-energy planetary ball milling process for synthesizing nanocomposite WC-MgO powders. Mater Des 30:2867–2874

Charkhi A, Kazemian H, Kazemeini M (2010) Optimized experimental design for natural clinoptilolite zeolite ball milling to produce nano powders. Powder Technol 203:389–396

Toraman OY, Katırcıoglu D (2011) A study on the effect of process parameters in stirred ball mill. Adv Powder Technol 22:26–30

Celep O, Aslan N, Alp İ, Taşdemir G (2011) Optimization of some parameters of stirred mill for ultra-fine grinding of refractory Au/Ag ores. Powder Technol 208:121–127

Ebadnejad A, Karimi GR, Dehghani H (2013) Application of response surface methodology for modeling of ball mills in copper sulphide ore grinding. Powder Technol 245:292–296

Canakci A, Erdemir F, Varol T, Patir A (2013) Determining the effect of process parameters on particle size in mechanical milling using the Taguchi method: measurement and analysis. Measurement 46:3532–3540

Patil AG, Anandhan S (2015) Influence of planetary ball milling parameters on the mechano-chemical activation of fly ash. Powder Technol 281:151–158

Erdemir F (2017) Study on particle size and X-ray peak area ratios in high energy ball milling and optimization of the milling parameters using response surface method. Measurement 112:53–60

Petrović S, Rožić L, Jović V, Stojadinović S, Grbić B, Radić N, Lamovec J, Vasilić R (2018) Optimization of a nanoparticle ball milling process parameters using the response surface method. Adv Powder Technol 29:2129–2139

Hajji H, Nasr S, Millot N, Salem EB (2019) Study of the effect of milling parameters on mechanosynthesis of hydroxyfluorapatite using the Taguchi method. Powder Technol 356:566–580

Santosh T, Rahul KS, Eswaraiah C, Rao DS, Venugopal R (2020) Optimization of stirred mill parameters for fine grinding of PGE bearing chromite ore, Particul. Sci Technol 9:1–13

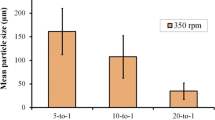

Wu J, Jin S-H, Raju K, Lee Y, Lee H-K (2021) Analysis of individual and interaction effects of processing parameters on wet grinding performance in ball milling of alumina ceramics using statistical methods. Ceram Int 47:31202–31213

Draper NR, Smith H (1998) Applied regression analysis, 3rd edn. John Wiley & Sons Inc, New York

Montgomery DC, Peck EA, Vining GG (2012) Introduction to linear regression analysis, 5th edn. Wiley, New Jersey

Aggarwal A, Singh H, Kumar P, Singh M (2008) Optimizing power consumption for CNC turned parts using response surface methodology and Taguchi’s technique-a comparative analysis. J Mater Process Technol 200:373–384

Costa N, Garcia J (2016) Using a multiple response optimization approach to optimize the coefficient of performance. Appl Therm Eng 96:137–143

Mostafanezhad H, Menghari HG, Esmaeili S, Shirkharkolaee EM (2018) Optimization of two-point incremental forming process of AA1050 through response surface methodology. Measurement 127:21–28

Parida MK, Joardar H, Rout AK, Routaray I, Mishra BP (2019) Multiple response optimizations to improve performance and reduce emissions of Argemone Mexicana biodiesel-diesel blends in a VCR engine. Appl Therm Eng 148:1454–1466

Yaliwal VS, Banapurmath NR, Gaitonde VN, Malipatil MD (2019) Simultaneous optimization of multiple operating engine parameters of a biodiesel-producer gas operated compression ignition (CI) engine coupled with hydrogen using response surface methodology. Renew Energy 139:944–959

Deng B, Shi Y, Yu T, Kang C, Zhao P (2018) Multi-response parameter interval sensitivity and optimization for the composite tape winding process. Materials 11:220

Chen Z, Shi Y, Lin X, Yu T, Zhao P, Kang C, He X, Li H (2019) Analysis and optimization of process parameter intervals for surface quality in polishing Ti-6Al-4V blisk blade. Results Phys 12:870–877

Castillo ED (2007) Process optimization: a statistical approach. Springer Science & Business Media, LLC, New York

Candioti LV, De Zan MM, Cámara MS, Goicoechea HC (2014) Experimental design and multiple response optimization using the desirability function in analytical methods development. Talanta 124:123–138

Mohanty S, Mishra A, Nanda BK, Routara BC (2018) Multi-objective parametric optimization of nano powder mixed electrical discharge machining of AlSiCp using response surface methodology and particle swarm optimization. Alex Eng J 57:609–619

Yu J, Yang S, Kim J, Lee Y, Lim KT, Kim S, Ryu S-S, Jeong H (2020) A confidence interval-based process optimization method using second-order polynomial regression analysis. Processes 8:1206

Kennedy J, Eberhart R (1995) Particle swarm optimization. Proceedings of ICNN'95 - International Conference on Neural Networks 4:1942–1948

Engelbrecht AP (2007) Computational intelligence: an introduction, 2nd edn. John Wiley & Sons Ltd, England

Del Valle Y, Venayagamoorthy GK, Mohagheghi S, Hernandez JC, Harley RG (2008) Particle swarm optimization: basic concepts, variants and applications in power systems. IEEE Trans Evol Comput 12:171–195

Dayar T, Orhan MC (2016) Cartesian product partitioning of multi-dimensional reachable state spaces. Probab Eng Inform Sci 30:413–430

Razavi-Tousi SS, Szpunar JA (2015) Effect of ball size on steady state of aluminum powder and efficiency of impacts during milling. Powder Technol 284:149–158

Funding

This work was supported by the Ministry of Trade, Industry and Energy (MOTIE) and the Korea Evaluation Institute of Industrial Technology (KEIT) research funding (Grant No. 20003891), and in part by Electronics and Telecommunications Research Institute (ETRI) grant funded by the Korean government [22ZD1120, Regional Industry ICT Convergence Technology Advancement and Support Project in Daegu-Gyeongbuk].

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethics approval

This study does not involve ethical issues.

Consent to participate

All authors agreed to participate in this research.

Consent for publication

All authors have reviewed the final version of manuscript and approve it for publication.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yu, J., Raju, K., Jin, SH. et al. A machine learning approach for ball milling of alumina ceramics. Int J Adv Manuf Technol 123, 4293–4308 (2022). https://doi.org/10.1007/s00170-022-10430-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-10430-w