Abstract

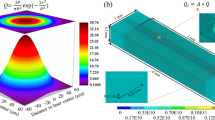

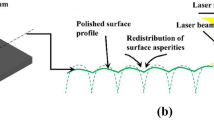

The variation of melting width and depth with laser power and scanning speed was investigated experimentally to study the melting pool’s influence law during lase polishing Ti-6Al-4V alloy. A three-dimensional transient model of laser polishing was established to learn the process of linear orbital scanning in the laser polishing process deeply. The surface evolution law of melting pool under the Marangoni effect is analyzed. The changing scenario of laser melting width, depth, and surface profile morphology could be achieved by selecting three cross sections. Comparing with experimental results, the relative error between the actual data and the simulated results are 9.7% and 1.7% for melting width and depth, respectively. It is demonstrated that the three-dimensional transient model of laser polishing could be trustworthy for further analysis.

Similar content being viewed by others

Data availability

All authors confirm that all data and materials reported in this paper are available.

Code availability

Not applicable.

References

Temmler A, Liu D, Preußner J, Oeser S, Luo J, Poprawe R, Schleifenbaum JH (2020) Influence of laser polishing on surface roughness and microstructural properties of the remelted surface boundary layer of tool steel H11. Mater Des 192:108689. https://doi.org/10.1016/j.matdes.2020.108689

Chen JC, Ouyang ZP, Du XW, Wei YH (2022) Weld pool dynamics and joining mechanism in pulse wave laser beam welding of Ti-6Al-4V titanium alloy sheets assembled in butt joint with an air gap. Opt Laser Technol 146:107558. https://doi.org/10.1016/j.optlastec.2021.107558

Juliana SS, Sankhya M, Mohamad B, Torsten W, Peter GW, Hans JS, Wilhelm P (2020) Laser polishing of additively manufactured Ti-6Al-4V: microstructure evolution and material properties. J Laser Appl 32(2):022019. https://doi.org/10.2351/7.0000065

Rosa B, Mognol P, Hascoët JY (2016) Modelling and optimization of laser polishing of additive laser manufacturing surfaces. Rapid Prototyp J 22(6):956–964. https://doi.org/10.1108/RPJ-12-2014-0168

Li P, Zhou J, Gong Y, Meng X, Lu J (2021) Effect of post-heat treatment on the microstructure and mechanical properties of laser metal deposition Inconel 718. J Mech Sci Technol 35(7):2871–2878. https://doi.org/10.1007/s12206-021-0610-4

Shen H, Pan YQ, Zhou J, Yao ZQ (2017) Forming mechanism of bump shape in pulsed laser melting of stainless steel. J Heat Transfer 139(6):1062301.1–062301.10. https://doi.org/10.1115/1.4035710

Bai H, Wang YQ, Dong X, Wang B, Liu HZ, Lu BH (2015) Mechanism and size characteristics of micro crack on polished Ti-6Al-4V. J Xi’An Jiaotong Univ 49(12):117–123. https://doi.org/10.7652/xjtuxb20151220019

Vadali M, Chao M, Duffie NA, Pfefferkorn FE (2012) Pulsed laser micro polishing: surface prediction model. J Manuf Process 14(3):307–315. https://doi.org/10.1016/j.jmapro.2012.03.001

Sim BC, Kim WS (2005) Melting and dynamic-surface deformation in laser surface heating. Int J Heat Mass Transf 48(6):1137–1144. https://doi.org/10.1016/j.ijheatmasstransfer.2004.08.032

Mohajerani S, Miller JD, Tutunea-Fatan OR, Bordatchev EV (2017) Thermo-physical modelling of track width during laser polishing of h13 tool steel. Procedia Manuf 10:708–719. https://doi.org/10.1016/j.promfg.2017.07.026

Chao M, Vadali M, Duffie NA, Pfefferkorn FE, Li XC (2013) Melt pool flow and surface evolution during pulsed laser micro polishing of Ti-6Al-4V. J Manuf Sci Eng 135(6):061023.1–061023.8. https://doi.org/10.1115/1.4025819

Kou S, Sun DK (1985) Fluid flow and weld penetration in stationary arc welds. Metall Trans A 16(2):203–213. https://doi.org/10.1007/BF02815302

Li K, Zhao ZY, Zhou HM, Zhou H, Yin J, Zhang W, Zhou GY (2021) Numerical simulation of effect of different initial morphologies on melt hydrodynamics in laser polishing of Ti-6Al-4V. Micromachines 12:581. https://doi.org/10.3390/mi12050581

Xu ZF, Ouyang WT, Liu YF, Jiao JK, Liu YZ, Zhang WW (2021) Effects of laser polishing on surface morphology and mechanical properties of additive manufactured TiAl components. J Manuf Process 65:51–59. https://doi.org/10.1016/j.jmapro.2021.03.014

Marimuthu S, Triantaphyllou A, Antar M, Wimpenny D, Morton H, Beard M (2015) Laser polishing of selective laser melted components. Int J Mach Tools Manuf 95:97–104. https://doi.org/10.1016/j.ijmachtools.2015.05.002

Jaritngam P, Tangwarodomnukun V, Qi H, Dumkum C (2020) Surface and subsurface characteristics of laser polished Ti-6Al-4V titanium alloy. Opt Laser Technol 126:106102. https://doi.org/10.1016/j.optlastec.2020.106102

Park SH, Liu PP, Yi K, Choi G, Jhang KY, Sohn H (2021) Mechanical properties estimation of additively manufactured metal components using femtosecond laser ultrasonics and laser polishing. Int J Mach Tools Manuf 166:103745. https://doi.org/10.1016/j.ijmachtools.2021.103745

Ai YW, Liu XY, Huang Y, Yu L (2022) The analysis of asymmetry characteristics during the fiber laser welding of dissimilar materials by numerical simulation. Int J Adv Manuf Technol 119:3293–3301. https://doi.org/10.1007/S00170-021-08312-8

Li HY, Wang X, Zhang JJ, Wang BY, Breisch M, Hartmaier A, Rostotskyi L, Voznyy V, Liu Y (2022) Experimental investigation of laser surface texturing and related biocompatibility of pure titanium. Int J Adv Manuf Technol 119:5993–6005. https://doi.org/10.1007/s00170-022-08710-6

Ramos-Grez JA, Bourell DL (2004) Reducing surface roughness of metallic freeform-fabricated parts using non-tactile finishing methods. Int J Mater Prod Technol 21(4):297–316. https://doi.org/10.1504/IJMPT.2004.004944

Chen L, Richter B, Zhang XZ, Ren XD, Pfefferkorn FE (2020) Modification of surface characteristics and electrochemical corrosion behavior of laser powder bed fused stainless-steel 316L after laser polishing. Addit Manuf 32:101013. https://doi.org/10.1016/j.addma.2019.101013

Li K, Zhou HM, Zhao ZY, Zhou H, Yin J, Jin JC (2021) A study on transient molten pool dynamics in laser polishing of Ti-6Al-4V using numerical simulation. J Manuf Process 65:478–490. https://doi.org/10.1016/j.jmapro.2021.03.045

Yan TY, Zhan XH, Gao QY, Ling WL (2021) Influence of laser power on molten pool flow field of laser-MIG hybrid welded Invar alloy. Opt Laser Technol 133:106539. https://doi.org/10.1016/j.optlastec.2020.106539

Wang CY, Zhou JZ, Zhang T, Meng XK, Li PF, Huang S (2022) Numerical simulation and solidification characteristics for laser cladding of Inconel 718. Opt Laser Technol 149:107843. https://doi.org/10.1016/j.optlastec.2021.107843

Wang W, Liu Q, Yang G, Qin LY, Xue X (2014) A numerical simulation for fluid flow and temperature fluid in the molten pool of laser cladding on titanium alloy. Appl Laser 34(05):389–394. https://doi.org/10.3788/AL20143405.389

Pong-Ryol J, Tae-Sok J, Nam-Chol K, Kum-Hyok J (2016) Laser micro-polishing for metallic surface using UV nano-second pulse laser and CW laser. Int J Adv Manuf Technol 85:2367–2375. https://doi.org/10.1007/s00170-015-7992-3

Li K, Zhao ZY, Zhou HM, Zhou H, Jin JC (2020) Numerical analyses of molten pool evolution in laser polishing Ti-6Al-4V. J Manuf Process 58:574–584. https://doi.org/10.1016/j.jmapro.2020.08.045

Zhang C, Zhou J, Shen H (2017) Role of capillary and thermocapillary forces in laser polishing of metals. J Manuf Sci Eng 139:041019.1–041019.11. https://doi.org/10.1115/1.4035468

Liang CY, Hu YZ, Liu N, Hu JY (2020) Laser polishing of Ti-6Al-4V fabricated by selective laser melting. Metals 10(2):191. https://doi.org/10.3390/met10020191

Li K, Zhao ZY, Zhou HM, Zhou H, Jin JC (2020) Numerical analysis of effect of different initial morphologies on molten pool flows. Key Eng Mater 861:491–498. https://doi.org/10.4028/www.scientific.net/KEM.861.491

Zhang C, Li XW, Gao M (2020) Effects of circular oscillating beam on heat transfer and melt flow of laser melting pool. J Mater Res Technol 9(4):9271–9282. https://doi.org/10.1016/j.jmrt.2020.06.030

Yuan WH, Chen H, Cheng T, Wei QS (2020) Effects of laser scanning speeds on different states of the molten pool during selective laser melting: simulation and experiment. Mater Des 189:108542. https://doi.org/10.1016/j.matdes.2020.108542

Guo LY, Li YQ, Geng SN, Wang CM, Jiang P (2022) Numerical and experimental analysis for morphology evolution of 6061 aluminum alloy during nanosecond pulsed laser cleaning. Surf Coat Technol 432:128056. https://doi.org/10.1016/j.surfcoat.2021.128056

Xiong AH, Ding JQ, Liu YH, Zhang XM, Shao SJ (2019) A numerical simulation for the molten pool of laser cladding on titanium alloy. Appl Laser 39(03):381–386. https://doi.org/10.14128/j.cnki.al.20193903.381

Zhou H, Zhou HM, Zhao ZY, Li K, Yin J (2021) Numerical simulation and verification of laser-polishing free surface of S136D die steel. Metals 11(3):400. https://doi.org/10.3390/MET11030400

Temmler A, Liu D, Luo J, Poprawe R (2020) Influence of pulse duration and pulse frequency on micro-roughness for laser micro polishing (LμP) of stainless steel AISI 410. Appl Surf Sci 510:145272.1–145272.24. https://doi.org/10.1016/j.apsusc.2020.145272

Tong YQ, Zhang A, Fu YH, Yao HB, Zhou JZ, Chen XM, Ren XD (2019) Research on on-line detection of plasma spectroscopy in laser cleaning of the carbon fiber reinforced polymer. Spectrosc Spect Anal 39(08):2388–2394. https://doi.org/10.3964/j.issn.1000-0593(2019)08-2388-07

Funding

This study was financially supported by the National Natural Science Foundation of China (No. 51905322) and the China postdoctoral Science Foundation (No. 2021T140420).

Author information

Authors and Affiliations

Contributions

Ke Che: writing–original draft, experiment, investigation, writing–review and editing, and methodology; Yanhou Liu: conceptualization, writing–review and editing, and conceptualization; Jian Liu: investigation; Juan Ma: investigation; and Jinguo Han: investigation.

Corresponding author

Ethics declarations

Ethics approval

The authors state that the present work is in compliance with the ethical standards.

Consent to participate

Not applicable.

Consent for publication

All authors agree to publish.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Che, K., Liu, Y., Liu, J. et al. Simulation and experimental study on width and depth of melting pool in laser polishing Ti-6Al-4V alloy. Int J Adv Manuf Technol 123, 1707–1720 (2022). https://doi.org/10.1007/s00170-022-10289-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-10289-x