Abstract

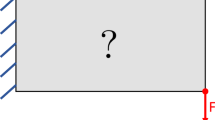

Automatic engraving machines have several industrial applications, such as nameplates, identification codes, and bar code engraving. It can also be used for engraving messages or pictures on decorative items in homes. Additionally, the proposed algorithm can be extended for obtaining the paths for 3D printers. The engraving process happens when the designs, messages, or pictures are carved into any item. The cost of engraving can be optimized by minimizing the movements of the automatic engraving machine. The movements include engraving motions and air motions. This work proposes a fast algorithm for obtaining the engraving path that guarantees the air motions are at most 150% of the optimal. Optimum engraving paths are commonly obtained using exponential time algorithms. The proposed algorithm is a 3/2 approximation algorithm that obtains the engraving path in polynomial time. The experimental results indicate that the proposed algorithm computes an efficient engraving path in a short time.

Similar content being viewed by others

Data availability

Not applicable.

Code availability

Not applicable.

References

Dong G, Zhang X, Cui G (2011) Application of genetic algorithm on optimization of engraving paths. In: 2011 International Conference on Multimedia Technology (IEEE) pp. 4850–4853

Oysu C, Bingul Z (2009) Application of heuristic and hybrid-gasa algorithms to tool-path optimization problem for minimizing airtime during machining. Eng Appl Artif Intell 22(3):389–396

Wu Z, Wu J, Zhao M, Feng L, Liu K (2020) Two-layered ant colony system to improve engraving robot’s efficiency based on a large-scale tsp model. Neural Comput Appl pp 1–11

Eapen NA, Heckendorn RB (2021) Cutting path optimization for an automatic cutter in polynomial time using a 3/2 approximation algorithm. Int J Adv Manuf Technol 113(11):3667–3679

Rodrigues AM, Ferreira JS (2012) Cutting path as a rural postman problem: solutions by memetic algorithms. International Journal of Combinatorial Optimization Problems and Informatics (IJCOPI) 3(1):31–46

Hajad M, Tangwarodomnukun V, Jaturanonda C, Dumkum C (2019) Laser cutting path optimization using simulated annealing with an adaptive large neighborhood search. Int J Adv Manuf Technol 103(1):781–792

Liang A, Yang H, Sun L, Sun M (2022) A three-layered multifactorial evolutionary algorithm with parallelization for large-scale engraving path planning. Electronics 11(11):1712

Petunin A (2019) General model of tool path problem for the cnc sheet cutting machines. IFAC-PapersOnLine 52(13):2662–2667

Petunin A, Chentsov P, Polishchuk E, Ukolov S, Martynov V (2020) Optimum routing algorithms for control programs design in the cam systems for cnc sheet cutting machines. In: AIP conference proceedings, AIP Publishing LLC, 2312:020005

Tavaeva A, Petunin A, Krotov V (2017) About effectiveness of special cutting techniques application during development of automatic methods of tool path optimization applied to cnc thermal cutting machines. In: Computer Science and Information Technologies (CSIT) pp 221–226

Tavaeva A, Petunin A, Polishchuk E (2019a) Methods of cutting cost minimizing in problem of tool route optimization for cnc laser machines. In: International Conference on Industrial Engineering (IEEE) Springer pp 447–455

Tavaeva A, Petunin A, Ukolov S, Krotov V (2019b) A cost minimizing at laser cutting of sheet parts on cnc machines. In: International Conference on Mathematical Optimization Theory and Operations Research (MOTOR) Springer pp 422–437

Silva EF, Oliveira LT, Oliveira JF, Toledo FMB (2019) Exact approaches for the cutting path determination problem. Comput Oper Res 112

Oliveira LT, Silva EF, Oliveira JF, Toledo FMB (2020) Integrating irregular strip packing and cutting path determination problems: A discrete exact approach. Comput Ind Eng 149

O’Rourke J et al (1998) Computational geometry in C. Cambridge University Press

Cormen TH, Leiserson CE, Rivest RL, Stein C (2009) Introduction to algorithms. MIT press

Van Kreveld M, Schwarzkopf O, de Berg M, Overmars M (2000) Computational geometry algorithms and applications. Springer

Chew LP (1989) Constrained delaunay triangulations. Algorithmica 4(1–4):97–108

Gibbons A (1985) Algorithmic graph theory. Cambridge University Press

Fleischner H (1990) Eulerian graphs and related topics, vol 1. Elsevier

Bourke P (1997) Hershey vector font. http://paulbourke.net/dataformats/hershey/

Hershey AV (1967) Calligraphy for computers, vol 2101. US Naval Weapons Laboratory

Author information

Authors and Affiliations

Contributions

Neeta A. Eapen: conceptualization, methodology, software, writing - original draft preparation. Robert B. Heckendorn: conceptualization, methodology, writing - review and editing.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

The authors declare that The International Journal of Advanced Manufacturing Technology has the consent to publish this manuscript.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Eapen, N.A., Heckendorn, R.B. PENGRAV: a practical polynomial time algorithm for optimizing the engraving path of an automatic engraving machine using a 3/2 approximation algorithm. Int J Adv Manuf Technol 123, 1721–1732 (2022). https://doi.org/10.1007/s00170-022-10148-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-10148-9