Abstract

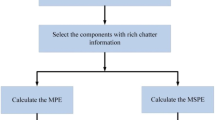

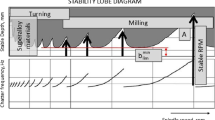

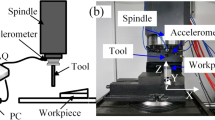

Chatter is an uncontrollable and unattenuated vibration that results in large oscillations between the workpiece and the cutting tool and has a detrimental effect on the surface quality, the tool life and the health of the machine tool components. As a result, it is one of the key limitations that hinders the productivity and quality of the milling process and is a key barrier for the autonomous operation of milling machine tools. Therefore, systems that can detect chatter, based on process-generated signals, are of utmost importance for the formation of a closed-loop control system that can suppress chatter during the process. Most existing approaches lack adaptability to different machining scenarios, since they use manually defined thresholds for the decision-making between chatter and stable machining, while being validated in a limited set of machining operations, running the risk of overfitting. This work proposes a method for chatter detection based on vibration signals in milling. An optimized version of variational mode decomposition (VMD) is used, where its hyperparameters can be selected automatically online, making it fully adaptable to different machining scenarios. Through VMD, the vibration signals are decomposed, and the modes with chatter rich information are selected for further analysis. Features are extracted from these modes in the time and frequency domains and are used to train a support vector machine classifier to predict the stability status of the process. The proposed approach presents a high classification performance (93% accuracy) and rapid detection speed (26.1 ms), which makes it a promising solution for real-time implementation.

Similar content being viewed by others

Availability of data and material

Not applicable.

Code availability

Not applicable.

References

Chryssolouris G (2006) Manufacturing systems: theory and practice. Springer-Verlag, New York, USA

Mia M, Królczyk G, Maruda R, Wojciechowski S (2019) Intelligent optimization of hard-turning parameters using evolutionary algorithms for smart manufacturing. Materials 12:879. https://doi.org/10.3390/ma12060879

Stavropoulos P, Mourtzis D (2022) Chapter 10 - Digital twins in industry 4.0, Editor(s): Dimitris Mourtzis, Design and Operation of Production Networks for Mass Personalization in the Era of Cloud Technology, Elsevier, Pages 277–316, ISBN 9780128236574. https://doi.org/10.1016/B978-0-12-823657-4.00010-5

Stavropoulos P, Bikas H, Avram O et al (2020) Hybrid subtractive–additive manufacturing processes for high value-added metal components. Int J Adv Manuf Technol 111:645–655. https://doi.org/10.1007/s00170-020-06099-8

Stavropoulos P, Papacharalampopoulos A, Souflas T (2020) Indirect online tool wear monitoring and model-based identification of process-related signal. Adv Mech Eng 12(5). https://doi.org/10.1177/1687814020919209

Stavropoulos P, Chantzis D, Doukas C, Papacharalampopoulos A, Chryssolouris G (2013) Monitoring and control of manufacturing processes: a review. (CIRP CMMO) Procedia CIRP, 14th CIRP Conference on Modelling of Machining Operations, 13–14 June, Turin, Italy. https://doi.org/10.1016/j.procir.2013.06.127

Kuntoğlu M, Aslan A, Pimenov DY, Usca ÜA, Salur E, Gupta MK, Mikolajczyk T, Giasin K, Kapłonek W, Sharma S (2021) A review of indirect tool condition monitoring systems and decision-making methods in turning: critical analysis and trends. Sensors 21:108. https://doi.org/10.3390/s21010108

Liu C, Xu X (2017) Cyber-physical machine tool – the era of machine tool 4.0. Procedia CIRP 63:70–75, ISSN 2212–8271. https://doi.org/10.1016/j.procir.2017.03.078

Bikas H, Stavropoulos P, Chryssolouris G (2017) Efficient machining of aero-engine components: challenges and outlook. Int J Mechatron Manuf Syst (IJMMS) 9(4):345–369. https://doi.org/10.1504/IJMMS.2016.082871

Taylor FW (1907) On the art of cutting metals. American society of mechanical engineers, New York, USA

Tlusty J, Polacek M (1963) The stability ofmachine tools against self-excited vibrations in machining. Int Res Prod Eng ASME 1:465–474

Tobias SA, Fishwick W (1958) A theory of regenerative chatter. The Engineer – London 205:139–239

Altintaş Y, Budak E (1995) Analytical prediction of stability lobes in milling. CIRP Ann 44(1):357–362. ISSN 0007–8506. https://doi.org/10.1016/S0007-8506(07)62342-7

Budak E, Ozturk E, Tunc LT (2009) Modeling and simulation of 5-axis milling processes. CIRP Ann 58(1):347–350. ISSN 0007–8506. https://doi.org/10.1016/j.cirp.2009.03.044

Wojciechowski S, Twardowski P, Pelic M (2014) Cutting forces and vibrations during ball end milling of inclined surfaces. Procedia CIRP 14:113–118. https://doi.org/10.1016/j.procir.2014.03.102

Erhan Budak L, Tunç T, Salih Alan H, Özgüven N (2012) Prediction of workpiece dynamics and its effects on chatter stability in milling. CIRP Ann 61(1):339–342. ISSN 0007–8506. https://doi.org/10.1016/j.cirp.2012.03.144

Wojciechowski S, Mrozek K (2017) Mechanical and technological aspects of micro ball end milling with various tool inclinations. Int J Mech Sci 134:424–435. https://doi.org/10.1016/j.ijmecsci.2017.10.032

Cordes M, Hintze W, Altintas Y (2019) Chatter stability in robotic milling. Roboti Comput Integr Manuf 55(Part A):11–18. ISSN 0736–5845. https://doi.org/10.1016/j.rcim.2018.07.004

Oleaga I, Pardo C, Zulaika JJ, Bustillo A (2018) A machine-learning based solution for chatter prediction in heavy-duty milling machines. Measurement 128:34–44. https://doi.org/10.1016/j.measurement.2018.06.028

Munoa J, Beudaert X, Dombovari Z, Altintas Y, Budak E, Brecher C, Stepan G (2016) Chatter suppression techniques in metal cutting. CIRP Ann 65(2):785–808. https://doi.org/10.1016/j.cirp.2016.06.004

Yue C, Gao H, Liu X, Liang SY, Wang L (2019) A review of chatter vibration research in milling. Chin J Aeronaut 32(2):215–242. https://doi.org/10.1016/j.cja.2018.11.007

Aslan D, Altintas Y (2018) On-line chatter detection in milling using drive motor current commands extracted from CNC. Int J Mach Tools Manuf 132:64–80. https://doi.org/10.1016/j.ijmachtools.2018.04.007

Bleicher F, Schörghofer P, Habersohn C (2018) In-process control with a sensory tool holder to avoid chatter. J Mach Eng 18(3):16–27. https://doi.org/10.5604/01.3001.0012.4604

Bergmann B, Reimer S (2021) Online adaption of milling parameters for a stable and productive process. CIRP Ann 70(1):341–344. https://doi.org/10.1016/j.cirp.2021.04.086

Matsubara A, Takata K, Furusawa M (2020) Experimental study of thin-wall milling vibration using phase analysis and a piezoelectric excitation test. CIRP Ann 69(1):317–320. https://doi.org/10.1016/j.cirp.2020.04.066

Munoa J, Beudaert X, Erkorkmaz K, Iglesias A, Barrios A, Zatarain M (2015) Active suppression of structural chatter vibrations using machine drives and accelerometers. CIRP Ann 64(1):385–388. https://doi.org/10.1016/j.cirp.2015.04.106

Möhring H-C, Wiederkehr P, Erkorkmaz K, Kakinuma Y (2020) Self-optimizing machining systems. CIRP Ann 69(2):740–763. https://doi.org/10.1016/j.cirp.2020.05.007

Pimenov DY, Bustillo A, Wojciechowski S et al (2022) Artificial intelligence systems for tool condition monitoring in machining: analysis and critical review. J Intell Manuf. https://doi.org/10.1007/s10845-022-01923-2

Bustillo A, Reis R, Machado AR et al (2022) Improving the accuracy of machine-learning models with data from machine test repetitions. J Intell Manuf 33:203–221. https://doi.org/10.1007/s10845-020-01661-3

Liu C, Zhu L, Ni C (2018) Chatter detection in milling process based on VMD and energy entropy. Mech Syst Signal Process 105:169–182. https://doi.org/10.1016/j.ymssp.2017.11.046

Liu X, Wang Z, Li M et al (2021) Feature extraction of milling chatter based on optimized variational mode decomposition and multi-scale permutation entropy. Int J Adv Manuf Technol 114:2849–2862. https://doi.org/10.1007/s00170-021-07027-0

Yang K, Wang G, Dong Y, Zhang Q, Sang L (2019) Early chatter identification based on an optimized variational mode decomposition. Mech Syst Signal Process 115:238–254. https://doi.org/10.1016/j.ymssp.2018.05.052

Zhang Z, Li H, Meng G, Tu X, Cheng C (2016) Chatter detection in milling process based on the energy entropy of VMD and WPD. Int J Mach Tools Manuf 108:106–112. https://doi.org/10.1016/j.ijmachtools.2016.06.002

Li K, He S, Li B, Liu H, Mao X, Shi C (2020) A novel online chatter detection method in milling process based on multiscale entropy and gradient tree boosting. Mech Syst Signal Process. https://doi.org/10.1016/j.ymssp.2019.106385

Perez-Canales D, Vela-Martinez L, Jauregui-Correa JC, Alvarez-Ramirez J (2012) Analysis of the entropy randomness index for machining chatter detection. Int J Mach Tools Manuf 62:39–45. https://doi.org/10.1016/j.ijmachtools.2012.06.007

Chen Y, Li H, Hou L, Wang J, Bu X (2018) An intelligent chatter detection method based on EEMD and feature selection with multi-channel vibration signals. Measurement 127:356–365. https://doi.org/10.1016/j.measurement.2018.06.006

Ji Y, Wang X, Liu Z et al (2017) EEMD-based online milling chatter detection by fractal dimension and power spectral entropy. Int J Adv Manuf Technol 92:1185–1200. https://doi.org/10.1007/s00170-017-0183-7

Fu Y, Zhang Y, Zhou H et al (2016) Timely online chatter detection in end milling process. Mech Syst Signal Process 75:668–688. https://doi.org/10.1016/j.ymssp.2016.01.003

Cao H, Zhou K, Chen X (2015) Chatter identification in end milling process based on EEMD and nonlinear dimensionless indicators. Int J Mach Tools Manuf 92:52–59. https://doi.org/10.1016/j.ijmachtools.2015.03.002

Cao H, Lei Y, He Z (2013) Chatter identification in end milling process using wavelet packets and Hilbert-Huang transform. Int J Mach Tools Manuf 69:11–19. https://doi.org/10.1016/j.ijmachtools.2013.02.007

Chen Y, Li H, Jing X et al (2019) Intelligent chatter detection using image features and support vector machine. Int J Adv Manuf Technol 102:1433–1442. https://doi.org/10.1007/s00170-018-3190-4

Kuljanic E, Totis G, Sortino M (2009) Development of an intelligent multisensor chatter detection system in milling. Mech Syst Signal Process 23(5):1704–1718. https://doi.org/10.1016/j.ymssp.2009.01.003

Sun H, Zhang X, Wang J (2016) Online machining chatter forecast based on improved local mean decomposition. Int J Adv Manuf Technol 84:1045–1056. https://doi.org/10.1007/s00170-015-7785-8

Cao H, Yue Y, Chen X et al (2017) Chatter detection in milling process based on synchrosqueezing transform of sound signals. Int J Adv Manuf Technol 89:2747–2755. https://doi.org/10.1007/s00170-016-9660-7

Dragomiretskiy K, Zosso D (2014) Variational mode decomposition. IEEE Trans Signal Process 62(3):531–544. https://doi.org/10.1109/TSP.2013.2288675

Juan Li Yu, Chen CL (2021) Application of an improved variational mode decomposition algorithm in leakage location detection of water supply pipeline. Measurement. https://doi.org/10.1016/j.measurement.2020.108587

Zhang X, Sun T, Wang Y, Wang K, Shen Yi (2020) A parameter optimized variational mode decomposition method for rail crack detection based on acoustic emission technique. Nondestruct Test Eval. https://doi.org/10.1080/10589759.2020.1785447

Mourtzis D (2020) Simulation in the design and operation of manufacturing systems: state of the art and new trends, Int J Prod Res 58(7):1927–1949. https://doi.org/10.1080/00207543.2019.1636321

Chen H-G, Shen J-Y, Chen W-H, Huang C-S, Yi Y-Y, Qian J-C (2019) Grinding chatter detection and identification based on BEMD and LSSVM. Chin J Mech Eng. https://doi.org/10.1186/s10033-018-0313-7

Pedregosa F et al (2011) Scikit-learn: machine learning in python. J Mach Learn Res 12:2825–2830

Funding

This research has been partially funded by the H2020 EU Project DIMOFAC—Digital Intelligent MOdular FACtories, G.A. 870092.

Author information

Authors and Affiliations

Contributions

Panagiotis Stavropoulos: Conceptualization, funding acquisition, validation, project administration, resources, writing—review and editing. Thanassis Souflas: Formal analysis, methodology, investigation, data curation, software, visualization, writing—original draft. Christos Papaioannou: Methodology, investigation, data curation, writing—original draft. Harry Bikas: Formal analysis, validation, visualization, writing—original draft. Dimitris Mourtzis: Conceptualization, writing—review and editing.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Stavropoulos, P., Souflas, T., Papaioannou, C. et al. An adaptive, artificial intelligence-based chatter detection method for milling operations. Int J Adv Manuf Technol 124, 2037–2058 (2023). https://doi.org/10.1007/s00170-022-09920-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-09920-8