Abstract

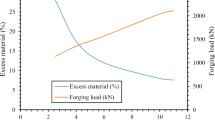

Accurate prediction of deformation and stress distribution on stamping die components is critical to guarantee structure reliability and lightweight design. This work aims to propose a new method for predicting die structural behaviors and reducing total weight based on numerical simulation. Sheet metal forming simulation was firstly conducted to obtain the accurate forming contact force. The linear static structural analyses under different load conditions were performed to investigate the deformation and stress distribution of the die structure. Topology optimization was employed to realize the lightweight design on the premise of ensuring structural safety. According to the manufacturing techniques and initial optimization results, the die structure was redesigned to guarantee the manufacturability of the new structure. The proposed methodology has several advantages of decreasing model scale, precluding intricate contact condition settings as well as time saving. A long beam stamping die used for forming automobile panels was selected to validate the proposed methodology, and about 18% weight reduction was achieved.

Similar content being viewed by others

Availability of data and materials

Not applicable.

References

Xie Y, Yue Y, Tang W, Feng M, Guo Y, Wang D, Zhu Y (2020) Topology optimization of blank holders in nonisothermal stamping of magnesium alloys based on discrete loads. Int J Adv Manuf Technol 106:671–681

Sun Y, Chen Q, Sun W (2015) Numerical simulation of extrusion process and die structure optimization for a complex magnesium doorframe. Int J Adv Manuf Technol 80(1–4):495–506

Li G, Long X, Zhou M (2019) A new design method based on feature reusing of the non-standard cam structure for automotive panels stamping dies. J Intell Manuf 30(5):2085–2100

Li X, Qian L, Sun C, Ning W (2021) The effect of loading mode on isothermal local loading forming of magnesium alloy rib-web component. Int J Adv Manuf Technol 114:2485–2497

Pereira MP, Yan W, Rolfe BF (2010) Sliding distance, contact pressure and wear in sheet metal stamping. Wear 268(11–12):1275–1284

Pereira MP, Yan W, Rolfe BF (2008) Contact pressure evolution and its relation to wear in sheet metal forming. Wear 265(11–12):1687–1699

Rafiee R, Rolfe BF, Yan WY (2008) Simulation of contact pressure in sheet metal trimming/blanking process. Adv Mater Res 41–42:463–468

Zhang L, Zhao G, Li HP (2010) Research on stress-strain field and fatigue lifetime of the hot stamping die. Appl Mech Mater 34–35:1630–1634

Sun J, Lee K, Lee H (2000) Effects of geometry and fillet radius on die stresses in stamping processes. J Mater Process Technol 104:254–264

Wang H, Xie H, Liu Q, Shen Y, Wang P, Zhao L (2018) Structural topology optimization of a stamping die made from high-strength steel sheet metal based on load mapping. Struct Multidiscip Optim 58(2):769–784

Nie Y, Lin Y, Sun W, Huang T (2015) A methodology for optimal lightweight design of moulds and dies: a case study. In: Proceedings of ASME 2015 International Mechanical Engineering Congress and Exposition. Houston, Texas, USA, pp 13–19

Xu D, Chen J, Tang Y, Cao J (2012) Topology optimization of die weight reduction for high-strength sheet metal stamping. Int J Mech Sci 59(1):73–82

Haufe A, Roll K, Bogon P (2008) Sheet metal forming simulation with elastic tools in LS-DYNA. In: Proceedings of the 7th international conference and workshop on numerical simulation of 3D sheet metal forming processses. Interlaken, Switzerland, pp 743–748

Nilsson A, Birath F (2007) Topology optimization of a stamping die. In: Proceedings of the 9 th international conference on numerial methods in industrial forming processes. pp 449–454

Hamasaki H, Nakazono M, Hino R, Yoshida F, Manabe H, Kondo H, Toropov V (2014) Stiffness improvement of stamping die by means of topology optimization. Adv Mater Res 939:266–273

Burkart M, Liewald M, Wied J, Todzy T, Hartmann M, Müller M (2020) Optimization of a part holder design considering dynamic loads during return stroke of tool and ram. Procedia Manuf 47:861–866

Hasebe N, Iida J (1983) Intensity of corner and stress concentration factor. J Eng Mech 109(1):346–356

Hill R (1948) A theory of the yielding and plastic flow of anisotropic metals. Proc R Soc Lond Ser A 193:281–297

Yu S, Long M, Chen H, Chen D, Liu T, Duan H, Cao J (2018) Stress and friction distribution around slab corner in continuous casting mold with different corner structures. Metall Mater Trans B 49(3):866–876

Koşar F, Yaman K (2020) Structural design of an auto panel die component based on the contact pressure using topology optimization. Adv Mater Res 1158:165–176

Funding

This work was supported by the Open Research Fund of the State Key Laboratory of High-Performance Complex Manufacturing (Kfkt2020-13).

Author information

Authors and Affiliations

Contributions

T Su: methodology, data collection, and writing-original draft; T He: data collection and writing-reviewing; R Yang: methodology and data collection; M Li: conceptualization, investigation, funding acquisition, writing-original draft, and editing.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Su, T., He, T., Yang, R. et al. Topology optimization and lightweight design of stamping dies for forming automobile panels. Int J Adv Manuf Technol 121, 4691–4702 (2022). https://doi.org/10.1007/s00170-022-09683-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-09683-2