Abstract

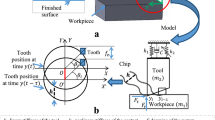

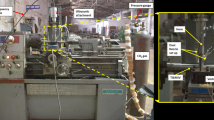

Ball screw feed systems serve as the feed components of machine tools, and its dynamic characteristics directly affect the machining quality of workpieces and reliability of ball screws. In this paper, the lateral equivalent dynamic model of ball screw feed systems is established considering the bending vibration of the ball screw, nut location, and joints based on the Euler–Bernoulli beam theory. Subsequently, the dynamic parameters of joints are identified according to the measured dynamic stiffness using the particle swarm optimization (PSO) algorithm with the determined initial range of stiffness and damping. The robustness of the dynamic model is verified by experiments conducted at different nut locations. In addition, the nonlinear dynamic model is established and the effects of cutting force, bearing clearance, and nut motion on dynamic characteristics are investigated. The numerical results indicate that bearing clearance mainly affects the equilibrium position of worktable vibration, while the cutting force at different rotational and moving speeds of the nut mainly affects the vibration mode of the worktable, but the vibration mode is always a quasi-periodic motion. The established dynamic model and numerical analysis results provide a useful understanding of the dynamic characteristics of ball screw feed systems.

Similar content being viewed by others

Availability of data and materials

All data generated or analyzed in this study are included in the present article.

Code availability

The authors make sure we have permissions for the use of software, and the availability of the custom code.

References

Zhang X, Zhang J, Zhang W, Liang T, Liu H, Zhao W (2018) Integrated modeling and analysis of ball screw feed system and milling process with consideration of multi-excitation effect. Mech Syst Signal Process 98:484–505. https://doi.org/10.1016/j.ymssp.2017.05.011

Altintas Y, Verl A, Brecher C, Uriarte L, Pritschow G (2011) Machine tool feed drives. CIRP Ann 60(2):779–796. https://doi.org/10.1016/j.cirp.2011.05.010

Deng C, Yin G, Fang H, Meng Z (2015) Dynamic characteristics optimization for a whole vertical machining center based on the configuration of joint stiffness. Int J Adv Manuf Technol 76(5–8):1225–1242. https://doi.org/10.1007/s00170-014-6355-9

Cheng Q, Qi B, Liu Z, Zhang C, Xue D (2019) An accuracy degradation analysis of ball screw mechanism considering time-varying motion and loading working conditions. Mech Mach Theory 134:1–23. https://doi.org/10.1016/j.mechmachtheory.2018.12.024

Chen JS, Huang YK, Cheng CC (2004) Mechanical model and contouring analysis of high-speed ball-screw drive systems with compliance effect. Int J Adv Manuf Technol 24(3):241–250. https://doi.org/10.1007/s00170-003-1777-9

Vicente DA, Hecker RL, Villegas FJ, Flores GM (2012) Modeling and vibration mode analysis of a ball screw drive. Int J Adv Manuf Technol 58(1):257–265. https://doi.org/10.1007/s00170-011-3375-6

Feng GH, Pan YL (2012) Investigation of ball screw preload variation based on dynamic modeling of a preload adjustable feed-drive system and spectrum analysis of ball-nuts sensed vibration signals. Int J Mach Tools Manuf 52(1):85–96. https://doi.org/10.1016/j.ijmachtools.2011.09.008

Chen YJ, Tang WC, Zhang SG (2012) Nonlinear dynamics behaviors of ball screws with preload considered. Adv Mater Res 510(2012):304–309. https://doi.org/10.4028/www.scientific.net/AMR.510.304

Zhou Y, Xu XS, Wang GX, Cao XH (2013) Study on axial vibration of feed drives and rolling vibration of ball screw. J Cent South Univ 44.10(2013):4069–4073

Zhang J, Zhang H, Du C, Zhao W (2016) Research on the dynamics of ball screw feed system with high acceleration. Int J Mach Tools Manuf 111:9–16. https://doi.org/10.1016/j.ijmachtools.2016.09.001

Duan M, Lu H, Zhang X, Zhang Y, Li Z, Liu Q (2018) Dynamic modeling and experiment research on twin ball screw feed system considering the joint stiffness. Symmetry 10(12):686. https://doi.org/10.3390/sym10120686

Xu M, Cai B, Li C, Zhang H, Liu Z, He D, Zhang Y (2020) Dynamic characteristics and reliability analysis of ball screw feed system on a lathe. Mech Mach Theory 150:103890. https://doi.org/10.1016/j.mechmachtheory.2020.103890

Okwudire CE, Altintas Y (2009) Hybrid modeling of ball screw drives with coupled axial, torsional, and lateral dynamics. J Mech Des 131:7. https://doi.org/10.1115/1.3125887

Okwudire CE, Zhao P (2012) Reduction of vibrations in ball screw driven machine tools by the optimal selection of nut parameters. Int Manuf Sci Eng Conf 5499:597–604. https://doi.org/10.1115/MSEC2012-7283

Dong L, Tang W (2013) Hybrid modeling and analysis of structural dynamic of a ball screw feed drive system. Mechanics 19(3):316–323. https://doi.org/10.5755/j01.mech.19.3.4662

Dong L, Tang W, Liu L (2013) Hybrid modeling and time-varying analysis of vibration for a ball screw drive. J Vib Shock 32(20):196–202

Zhang H (2015) Dynamic analysis of the machine drive system. J Mech Sci Technol 29(12):5205–5215. https://doi.org/10.1007/s12206-015-0718-5

Zhang L, Wang T, Wang G, Tian S (2017) Hybrid dynamic modeling and analysis of a ball-screw-drive spindle system. J Mech Sci Technol 31(10):4611–4618. https://doi.org/10.1007/s12206-017-0907-5

Zhang GP, Huang YM, Shi WH, Fu WP (2003) Predicting dynamic behaviours of a whole machine tool structure based on computer-aided engineering. Int J Mach Tools Manuf 43(7):699–706. https://doi.org/10.1016/S0890-6955(03)00026-9

Zhang Z, Cheng Q, Qi B, Tao Z (2021) A general approach for the machining quality evaluation of S-shaped specimen based on POS-SQP algorithm and Monte Carlo method. J Manuf Syst 60:553–568. https://doi.org/10.1016/j.jmsy.2021.07.020

Yang T, Lin CS (2004) Identifying the stiffness and damping parameters of a linear servomechanism. Mech Based Des Struct Mach 32(3):283–304. https://doi.org/10.1081/SME-200027937

Dhupia JS, Ulsoy AG, Katz R, Powalka B (2008) Experimental identification of the nonlinear parameters of an industrial translational guide for machine performance evaluation. J Vib Control 14(5):645–668. https://doi.org/10.1177/1077546307081325

Arora V, Van Der Hoogt PJM, Aarts RG, Boer A (2011) Identification of stiffness and damping characteristics of axial air-foil bearings. Int J Mech Mater Des 7(3):231–243. https://doi.org/10.1007/s10999-011-9161-7

Zhang H, Yuan JT, Hong ZH (2011) Experimental research on identification of dynamic characteristic parameters of rolling guide’s joint. China Mech Eng 22(4):415

Zhu J, Zhang T, Wang J, Li X (2016) Axial dynamic characteristic parameters identification of rolling joints in a ball screw feed drive system. Proc Inst Mech Eng C J Mech Eng Sci 230(14):2449–2462. https://doi.org/10.1177/0954406215597955

Lee W, Lee CY, Jeong YH, Min BK (2014) Distributed component friction model for precision control of a feed drive system. IEEE/ASME Trans Mechatron 20(4):1966–1974. https://doi.org/10.1109/TMECH.2014.2365958

Liu L, Wu Z (2015) Comprehensive parameter identification of feed servo systems with friction based on responses of the worktable. Mech Syst Signal Process 64:257–265. https://doi.org/10.1016/j.ymssp.2015.04.012

Du F, Zhang M, Wang Z, Yu C, Feng X, Li P (2018) Identification and compensation of friction for a novel two-axis differential micro-feed system. Mech Syst Signal Process 106:453–465. https://doi.org/10.1016/j.ymssp.2018.01.004

Fu Z, Yang W, Wang X, Leopold J (2015) Analytical modelling of milling forces for helical end milling based on a predictive machining theory. Procedia Cirp 31:258–263. https://doi.org/10.1016/j.procir.2015.03.013

Funding

The authors disclosed receipt of the following financial support for the research, authorship, and/or publication of this article: This study was supported by the National Natural Science Foundation of China (grant numbers: 51875008, 51505012, and 51575014).

Author information

Authors and Affiliations

Contributions

Xiangsheng Gao conceived the modeling and analysis, and wrote the manuscript as well. Xiangrang Zhang and Jingshuo Yang conducted the experiment and modeling. Zhongtao Fu conducted the data analysis. Min Wang and Tao Zan supervised this work and revised the manuscript.

Corresponding author

Ethics declarations

Ethical approval

The article follows the guidelines of the Committee on Publication Ethics (COPE) and involves no studies on human or animal subjects.

Consent to participate

Not applicable.

Consent for publication

All the authors approve the publication of this article.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gao, X., Zhang, X., Yang, J. et al. Dynamic modeling and analysis on lateral vibration of ball screw feed system. Int J Adv Manuf Technol 124, 4211–4229 (2023). https://doi.org/10.1007/s00170-022-09525-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-09525-1