Abstract

Oriented to the application of new generation strategic aircraft, M28 (Ti-4Al-5Mo-5 V-6Cr-1Nb) is a novel metastable β titanium alloy with outstanding strength. The research on the machining of such hard-to-machine material remains inadequate. To investigate the machinability of M28, milling experiments were made with the uncoated WC–Co carbide insert. The cutting force and tool life of M28 were compared with those of Ti-6Al-4 V in varying cutting speeds. The tool wear mode was also analyzed. The cutting force of M28 increases with cutting speed significantly, especially in high-speed cutting where it can reach as high as 132% of that of Ti-6Al-4 V. The “transgranular cut” of M28 contributes to the high cutting force. A much shorter tool life in cutting M28, ranging from 0.88% to 13.82% of that of Ti-6Al-4 V, was found in the experiment. Serious edge chipping occurred at the normal cutting speed as the result of stress concentration and abrasion of the secondary \(\alpha\) precipitation. In high-speed cutting, chip adhesion, comb cracks, and tool plastic deformation were found at the edge as the result of the high temperature. In addition, the semi-crater at the worn edge tip was formed by the interaction of high-frequency cutting impact, carbide thermal softening, and diffusion wear. A better understanding of the machinability of M28 is conducive to the improvement in manufacture in the aviation industry.

Similar content being viewed by others

Availability of data and material

Not applicable. Code availability Not applicable.

Code availability

Not applicable.

References

Zs ZHU (2013) Research and development of new-brand titanium alloys of high performance for aeronautical applications (in Chinese). Aviation Industry Press, Beijing

Chen W, LIU YX, LI ZQ (2020) Research status and development trend of high-strength β titanium alloys(in Chinese). J Aeronaut Mater 40(03):63–76

Cotton JD, Briggs RD, Boyer RR, Tamirisakandala S, Russo P, Shchetnikov N, Fanning JC (2015) State of the art in beta titanium alloys for airframe applications. JOM 67(6):1281–1303. https://doi.org/10.1007/s11837-015-1442-4

Leyens C, Peters M (2003) Titanium and titanium alloys. Wiley‐VCH Verlag GmbH & Co. KGaA, Weinheim https://doi.org/10.1002/3527602119.ch2

Yumak N, Aslantaş K (2020) A review on heat treatment efficiency in metastable β titanium alloys: the role of treatment process and parameters. J Mater Res Technol 9(6):15360–15380. https://doi.org/10.1016/j.jmrt.2020.10.088

Singh P, Pungotra H, Kalsi NS (2017) On the characteristics of titanium alloys for the aircraft applications. Mater Today Proc 4(8):8971–8982. https://doi.org/10.1016/j.matpr.2017.07.249

Machai C, Biermann D (2011) Machining of β-titanium-alloy Ti–10V–2Fe–3Al under cryogenic conditions: Cooling with carbon dioxide snow. J Mater Process Technol 211(6):1175–1183. https://doi.org/10.1016/j.jmatprotec.2011.01.022

Zlatin N, Field M (1973) Procedures and precautions in machining titanium alloys. In: Jaffee RI, Burte HM, editors. Titanium Science and Technology. Springer US, Boston, MA 489–504. https://doi.org/10.1007/978-1-4757-1346-6_37

Machai C, Biermann D (2011) Machining of a hollow shaft made of β-titanium Ti-10V-2Fe-3Al. IEEE Int Symp Assemb Manuf 1–6. https://doi.org/10.1109/ISAM.2011.5942364

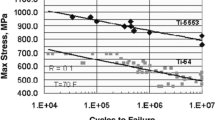

Arrazola PJ, Garay A, Iriarte LM, Armendia M, Marya S, Le Maître F (2009) Machinability of titanium alloys (Ti6Al4V and Ti555.3). J Mater Process Technol 209(5):2223–2230. https://doi.org/10.1016/j.jmatprotec.2008.06.020

Ezugwu EO (2004) High speed machining of aero-engine alloys. J Braz Soc Mech Sci Eng 26:1–11. https://doi.org/10.1590/S1678-58782004000100001

Machai C, Iqbal A, Biermann D, Upmeier T, Schumann S (2013) On the effects of cutting speed and cooling methodologies in grooving operation of various tempers of β-titanium alloy. J Mater Process Technol 213(7):1027–1037. https://doi.org/10.1016/j.jmatprotec.2013.01.021

Rahman Rashid RA, Sun S, Wang G, Dargusch MS (2011) Machinability of a near beta titanium alloy. Proc Inst Mech Eng Part B J Eng Manuf 225(12):2151–2162. https://doi.org/10.1177/2041297511406649

Sun Y, Huang B, Puleo DA, Jawahir IS (2015) Enhanced machinability of Ti-5553 alloy from cryogenic machining: Comparison with MQL and flood-cooled machining and modeling. Procedia CIRP 31:477–482. https://doi.org/10.1016/j.procir.2015.03.099

Bai D, Sun J, Chen W, Wang T (2017) Wear mechanisms of WC/Co tools when machining high-strength titanium alloy TB6 (Ti-10V-2Fe-3Al). Int J Adv Manuf Technol 90(9):2863–2874. https://doi.org/10.1007/s00170-016-9607-z

Ikuta A, Shinozaki K, Masuda H, Yamane Y, Kuroki H, Fukaya Y (2002) Consideration of the adhesion mechanism of Ti alloys using a cemented carbide tool during the cutting process. J Mater Process Technol 127(2):251–255. https://doi.org/10.1016/S0924-0136(02)00152-8

Tascioglu E, Gharibi A, Kaynak Y (2019) High speed machining of near-beta titanium Ti-5553 alloy under various cooling and lubrication conditions. Int J Adv Manuf Technol 102(9):4257–4271. https://doi.org/10.1007/s00170-019-03291-3

Pimenov DY, Mia M, Gupta MK, Machado AR, Tomaz ÍV, Sarikaya M, Wojciechowski S, Mikolajczyk T, Kapłonek W (2021) Improvement of machinability of Ti and its alloys using cooling-lubrication techniques: a review and future prospect. J Mater Res Technol 11:719–753. https://doi.org/10.1016/j.jmrt.2021.01.031

Mouritz AP (2012) Introduction to aerospace materials. Woodhead Publishing, UK https://doi.org/10.1533/9780857095152.202

Nguyen T, Park K-H, Wang X, Olortegui-Yume J, Wong T, Schrock D, Kim W, Kwon P, Kramer B (2015) The genesis of tool wear in machining. ASME Int Mech Eng Congress Expo. https://doi.org/10.1115/IMECE2015-52531

Huang S, Zhao Q, Wu C, Lin C, Zhao Y, Jia W, Mao C (2021) Effects of β-stabilizer elements on microstructure formation and mechanical properties of titanium alloys. J Alloys Compd 876:160085. https://doi.org/10.1016/j.jallcom.2021.160085

Sidhu SS, Singh H, Gepreel MAH (2021) A review on alloy design, biological response, and strengthening of β-titanium alloys as biomaterials. Mater Sci Eng C 121:111661. https://doi.org/10.1016/j.msec.2020.111661

Bania PJ (1994) Beta titanium alloys and their role in the titanium industry. JOM 46(7):16–19. https://doi.org/10.1007/BF03220742

Yu P-J, Hsu Y-Y, Wang S-H, Yang J-R, Yang Y-L, Chang H-Y, Chen C-Y, Chen H-R (2020) Comparison of dynamic-aging creep and pre-aged creep in Ti-15–3 beta titanium alloy. Mater Sci Eng A 798:140135. https://doi.org/10.1016/j.msea.2020.140135

Klocke F (2011) Manufacturing processes 1: Cutting. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-642-11979-8

Abele E, Hasenfratz C, Bücker M (2017) Modeling of process forces with respect to technology parameters and tool wear in milling Ti6Al4V. Prod Eng 11(3):285–294. https://doi.org/10.1007/s11740-017-0739-2

Komanduri R (1982) Some clarifications on the mechanics of chip formation when machining titanium alloys. Wear 76(1):15–34. https://doi.org/10.1016/0043-1648(82)90113-2

Vishnu J, Sankar M, Rack HJ, Rao N, Singh AK, Manivasagam G (2020) Effect of phase transformations during aging on tensile strength and ductility of metastable beta titanium alloy Ti–35Nb–7Zr–5Ta-0.35O for orthopedic applications. Mater Sci Eng A 779:139127. https://doi.org/10.1016/j.msea.2020.139127

Ankem S, Seagle S (1984) Heat treatment of metastable beta titanium alloys. In: Boyer RRRH (ed) Beta Titanium Alloys in the 80’s. TMS, USA, pp 107–126

Emani SV, Ramos dos Santos AFC, Shaw LL, Chen Z (2016) Investigation of microstructure and mechanical properties at low and high temperatures of WC–6wt% Co. Int J Refract Metals Hard Mater 58:172–181. https://doi.org/10.1016/j.ijrmhm.2016.04.009

Buss K, Mari D (2004) High temperature deformation mechanisms in cemented carbides and cermets studied by mechanical spectroscopy. Mater Sci Eng A 370(1):163–167. https://doi.org/10.1016/j.msea.2002.12.004

Milman YV, Luyckx S, Goncharuck VA, Northrop JT (2002) Results from bending tests on submicron and micron WC–Co grades at elevated temperatures. Int J Refract Metals Hard Mater 20(1):71–79. https://doi.org/10.1016/S0263-4368(01)00072-5

Ezugwu EO, Wang ZM (1997) Titanium alloys and their machinability—a review. J Mater Process Technol 68(3):262–274. https://doi.org/10.1016/S0924-0136(96)00030-1

Bouzakis KD, Bouzakis E, Kombogiannis S, Makrimallakis S, Skordaris G, Michailidis N, Charalampous P, Paraskevopoulou R, M’Saoubi R, Aurich JC, Barthelmä F, Biermann D, Denkena B, Dimitrov D, Engin S, Karpuschewski B, Klocke F, Özel T, Poulachon G, Rech J, Schulze V, Settineri L, Srivastava A, Wegener K, Uhlmann E, Zeman P (2014) Effect of cutting edge preparation of coated tools on their performance in milling various materials. CIRP J Manuf Sci Technol 7(3):264–273. https://doi.org/10.1016/j.cirpj.2014.05.003

Kindermann P, Schlund P, Sockel HG, Herr M, Heinrich W, Görting K, Schleinkofer U (1999) High-temperature fatigue of cemented carbides under cyclic loads. Int J Refract Metals Hard Mater 17(1):55–68. https://doi.org/10.1016/S0263-4368(99)00014-1

Wright TW (2002) The physics and mathematics of adiabatic shear bands. Cambridge University Press, UK

Shivpuri R, Hua J, Mittal P, Srivastava AK, Lahoti GD (2002) Microstructure-mechanics interactions in modeling chip segmentation during titanium machining. CIRP Ann 51(1):71–74. https://doi.org/10.1016/S0007-8506(07)61468-1

Abdel-Aal HA, Nouari M, El Mansori M (2009) Influence of thermal conductivity on wear when machining titanium alloys. Tribol Int 42(2):359–372. https://doi.org/10.1016/j.triboint.2008.07.005

Ginting A, Nouari M (2006) Experimental and numerical studies on the performance of alloyed carbide tool in dry milling of aerospace material. Int J Mach Tools Manuf 46(7):758–768. https://doi.org/10.1016/j.ijmachtools.2005.07.035

Özel T, Sima M, Srivastava AK, Kaftanoglu B (2010) Investigations on the effects of multi-layered coated inserts in machining Ti–6Al–4V alloy with experiments and finite element simulations. CIRP Ann 59(1):77–82. https://doi.org/10.1016/j.cirp.2010.03.055

Mari D, Bolognini S, Feusier G, Viatte T, Benoit W (1999) Experimental strategy to study the mechanical behaviour of hardmetals for cutting tools. Int J Refract Metals Hard Mater 17(1):209–225. https://doi.org/10.1016/S0263-4368(98)00078-X

Armendia M, Garay A, Iriarte LM, Arrazola PJ (2010) Comparison of the machinabilities of Ti6Al4V and TIMETAL® 54M using uncoated WC–Co tools. J Mater Process Technol 210(2):197–203. https://doi.org/10.1016/j.jmatprotec.2009.08.026

Zhang S, Li JF, Deng JX, Li YS (2008) Investigation on diffusion wear during high-speed machining Ti-6Al-4V alloy with straight tungsten carbide tools. Int J Adv Manuf Technol 44(1):17–25. https://doi.org/10.1007/s00170-008-1803-z

Wong T, Kim W, Kwon P (2004) Experimental support for a model-based prediction of tool wear. Wear 257(7):790–798. https://doi.org/10.1016/j.wear.2004.03.010

Min W, Min W, Youzhen Z (1988) Diffusion wear in milling titanium alloys. Mater Sci Technol 4(6):548–553. https://doi.org/10.1179/mst.1988.4.6.548

Krakhmalev PV, Adeva Rodil T, Bergström J (2007) Influence of microstructure on the abrasive edge wear of WC–Co hardmetals. Wear 263(1):240–245. https://doi.org/10.1016/j.wear.2006.10.019

Bai D, Sun J, Chen W, Du D (2016) Molecular dynamics simulation of the diffusion behaviour between Co and Ti and its effect on the wear of WC/Co tools when titanium alloy is machined. Ceram Int 42(15):17754–17763. https://doi.org/10.1016/j.ceramint.2016.08.103

Graves A, Norgren S, Wan W, Singh S, Kritikos M, Xiao C, Crawforth P, Jackson M (2021) On the mechanism of crater wear in a high strength metastable β titanium alloy. Wear 484–485:203998. https://doi.org/10.1016/j.wear.2021.203998

Odelros S, Kaplan B, Kritikos M, Johansson M, Norgren S (2017) Experimental and theoretical study of the microscopic crater wear mechanism in titanium machining. Wear 376–377:115–124. https://doi.org/10.1016/j.wear.2017.01.10

Bai DS, Sun JF, Wang K, Chen WY (2018) Diffusion behavior and wear mechanism of WC/Co tools when machining of titanium alloy. Solid State Phenomena 279:60–66. https://doi.org/10.4028/www.scientific.net/SSP.279.60

Kaplan B, Odelros S, Kritikos M, Bejjani R, Norgren S (2018) Study of tool wear and chemical interaction during machining of Ti6Al4V. Int J Refract Metals Hard Mater 72:253–256. https://doi.org/10.1016/j.ijrmhm.2017.12.012

Roa JJ, Simison S, Grasso J, Arcidiacono M, Escalada L, Soldera F, García J, Sosa AD (2020) Cyclic contact fatigue of cemented carbides under dry and wet conditions: Correlation between microstructure, damage and electrochemical behavior. Int J Refract Metals Hard Mater 92:105279. https://doi.org/10.1016/j.ijrmhm.2020.105279

Nerz J, Kushner B, Rotolico A (1992) Microstructural evaluation of tungsten carbide-cobalt coatings. J Therm Spray Technol 1(2):147–152. https://doi.org/10.1007/BF02659015

Kreimer GS, Vakhovskaya MR (1965) The effect of carbon content on the mechanical properties of tungsten carbide-cobalt hard alloys. Soviet Powder Metall Metal Ceram 4(6):454–459. https://doi.org/10.1007/BF00773965

Zhang ML, Zhu SG, Zhu SX (2006) Carbon content change and its influence on structure and properties of ultrafine and nano-cemented carbide (in Chinese). Mater Rep 08:65–68

Bondarenko VP, Pavlotskaya EG (1997) Hydrogen-containing chemically active gas medium for controlling carbon content of tungsten-base hard alloys. Int J HydroG Energy 22(2):205–212. https://doi.org/10.1016/S0360-3199(96)00156-5

Hatt O, Larsson H, Giuliani F, Crawforth P, Wynne B, Jackson M (2016) Predicting chemical wear in machining titanium alloys via a novel low cost diffusion couple method. Procedia CIRP 45:219–222. https://doi.org/10.1016/j.procir.2016.01.196

Hartung PD, Kramer BM, von Turkovich BF (1982) Tool wear in titanium machining. CIRP Ann 31(1):75–80. https://doi.org/10.1016/S0007-8506(07)63272-7

Hatt O, Crawforth P, Jackson M (2017) On the mechanism of tool crater wear during titanium alloy machining. Wear 374–375:15–20. https://doi.org/10.1016/j.wear.2016.12.036

Ramirez C, Idhil Ismail A, Gendarme C, Dehmas M, Aeby-Gautier E, Poulachon G, Rossi F (2017) Understanding the diffusion wear mechanisms of WC-10%Co carbide tools during dry machining of titanium alloys. Wear 390–391:61–70. https://doi.org/10.1016/j.wear.2017.07.003

Jianxin D, Yousheng L, Wenlong S (2008) Diffusion wear in dry cutting of Ti–6Al–4V with WC/Co carbide tools. Wear 265(11):1776–1783. https://doi.org/10.1016/j.wear.2008.04.024

Acknowledgements

This work is sponsored by the National Natural Science Foundation of China (No. 52075251).

Funding

This work is sponsored by the National Natural Science Foundation of China (No. 52075251).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation was performed by Hui Tian and Jia Yin. Experiment design was performed by Yifan Jiang with the guidance from Hui Tian, Jia Yin, and Yinfei Yang. Experiment work, data collection, and analysis were performed by Yifan Jiang with the guidance from Liang Li and Guolong Zhao. The first draft of the manuscript was written by Yifan Jiang, and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Conflicts of interest/competing interests

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jiang, Y., Tian, H., Yin, J. et al. Investigation on the machinability of metastable β titanium alloy M28. Int J Adv Manuf Technol 121, 2135–2148 (2022). https://doi.org/10.1007/s00170-022-09423-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-09423-6