Abstract

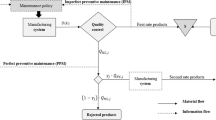

This paper presents a study on a hybrid manufacturing and remanufacturing system that degrades according to its production rate. The system consists of two failures and repairs prone machines that produce a single type of product. Both machines degrade according to their production rates, which affects their availability and the quality of the products. The main objective of this study is to develop optimal joint manufacturing, remanufacturing, maintenance and quality control policies for a deteriorating production system. A stochastic dynamic programming approach is used to develop the Hamilton–Jacobi–Bellman (HJB)-type optimality conditions. Subsequently, we used the numerical methods to solve its obtained HJB equations in order to determine the optimal manufacturing and remanufacturing thresholds, the optimal fractions of products to be controlled and the optimal conditions to start preventive maintenance operations. To illustrate this work, we have simulated a numerical example of a hybrid production line (manufacturing/remanufacturing). The obtained results allowed us to develop simultaneously a critical threshold production policy, a sampling inspection policy and an opportunistic maintenance policy. Next, we performed a sensitivity analysis of our models to show their robustness. Finally, we compared our policy with policies adapted from the literature. This comparison allowed us to highlight the gains generated by the proposed control policies.

Similar content being viewed by others

Data availability

Data related to this work will be provided upon request.

Code availability

Developed code related to this work is provided on the github repository: github.com/patrick438-cell.

References

Delpla V, Kenne JP, Hof LA (2021) Circular manufacturing 4.0: towards internet of things embedded closed-loop supply chains. Int J Adv Manuf Technol

Ouaret S, Kenne JP, Gharbi A (2018) Stochastic optimal control of random quality deteriorating hybrid manufacturing/remanufacturing systems. J Manuf Syst 49:172–185

Huang YS, Chen MW, Fang CC (2013) A study of the optimal production strategy for hybrid production systems. Int J Prod Res 51(19):5853–5865

Hajej Z, Rezg N, Gharbi A (2021) Joint production preventive maintenance and dynamic inspection for a degrading manufacturing system. Int J Adv Manuf Technol 112(1–2):221–239

Kenne JP, Gharbi A (2004) Stohastic optimal production control problem with corrective maintenance. Comput Ind Eng 46(4):865–875

Roux O, Duvivier D, Quesnel G, Ramat E (2013) Optimization of preventive maintenance through a combined maintenance-production simulation model. Int J Prod Econ 143(1):3–12

Chouikhi H, Khatab A, Rezg N (2011) A maintenance policy for a production system under environment constraints. Proceedings of International Conference on Industrial Engineering and Systems Management (Iesm'2011): Innovative Approaches and Technologies for Networked Manufacturing Enterprises Management 1060–1069

Nodem FID, Kenné J-P, Gharbi A (2010) Preventive maintenance and replacement policies for deteriorating manufacturing systems. IFAC Proc Vol 43(3):98–103

Kouedeu AF, Kenné JP, Dejax P, Songmene V, Polotski V (2015) Production and maintenance planning for a failure-prone deteriorating manufacturing system: a hierarchical control approach. Int J Adv Manuf Technol 76(9–12):1607–1619

Kim J, Gershwin SB (2005) Integrated quality and quantity modeling of a production line. OR Spectrum 27(2–3):287–314

Kim JY, Gershwin SB (2008) Analysis of long flow lines with quality and operational failures. IIE Trans 40(3):284–296

Colledani M, Tolio T (2011) Integrated analysis of quality and production logistics performance in manufacturing lines. Int J Prod Res 49(2):485–518

Rached M, Bahroun Z, Campagne JP (2015) Assessing the value of information sharing and its impact on the performance of the various partners in supply chains. Comput Ind Eng 88:237–253

Mehdi R, Nidhal R, Anis C (2010) Integrated maintenance and control policy based on quality control. Comput Ind Eng 58(3):443–451

Colledani M, Tolio T (2012) Integrated quality, production logistics and maintenance analysis of multi-stage asynchronous manufacturing systems with degrading machines. CIRP Ann Manuf Technol 61(1):455–458

Nourelfath M, Nahas N, Ben-Daya M (2016) Integrated preventive maintenance and production decisions for imperfect processes. Reliab Eng Syst Saf 148:21–31

Foteinopoulos P, Esnault V, Komineas G, Papacharalampopoulos A, Stavropoulos P (2020) Cement-based additive manufacturing: experimental investigation of process quality. Int J Adv Manuf Technol 106:4815–4826. https://doi.org/10.1007/s00170-020-04978-8

Alexios P, Konstantinos T, Kyriakos S, Panagiotis S (2020) Deep quality assessment of a solar reflector based on synthetic data: Detecting surficial defects from manufacturing and use phase, sensing technology and data interpretation in machine diagnosis and systems condition monitoring. Sensors 20(19):5481

Robotis A, Boyaci T, Verter V (2012) Investing in reusability of products of uncertain remanufacturing cost: The role of inspection capabilities. Int J Prod Econ 140(1):385–395

Rivera-Gomez H, Gharbi A, Kenne JP (2013) Joint production and major maintenance planning policy of a manufacturing system with deteriorating quality. Int J Prod Econ 146(2):575–587

Mohammadi B, Taleizadeh AA, Noorossana R, Samimi H (2015) Optimizing integrated manufacturing and products inspection policy for deteriorating manufacturing system with imperfect inspection. J Manuf Syst 37:299–315

Bouslah B, Gharbi A, Pellerin R (2016) Integrated production, sampling quality control and maintenance of deteriorating production systems with AOQL constraint. Omega-Int J Manag Sci 61:110–126

Rivera-Gomez H, Gharbi A, Kenné JP, Montaño-Arango O, Corona-Armenta JR (2020) Joint optimization of production and maintenance strategies considering a dynamic sampling strategy for a deteriorating system. Comput Ind Eng 140

Ait-El-Cadi A, Gharbi A, Dhouib K, Artiba A (2021) Integrated production, maintenance and quality control policy for unreliable manufacturing systems under dynamic inspection. Int J Prod Econ 236

Yoo SH, Kim D, Park MS (2012) Inventory models for imperfect production and inspection processes with various inspection options under one-time and continuous improvement investment. Comput Oper Res 39(9):2001–2015

Kenne JP, Dejax P, Gharbi A (2012) Production planning of a hybrid manufacturing-remanufacturing system under uncertainty within a closed-loop supply chain. Int J Prod Econ 135(1):81–93

Ouaret S, Polotski V, Kenné JP, Gharbi A (2013) Optimal production control of hybrid manufacturing/remanufacturing failure-prone systems under diffusion-type demand. Appl Math 4(3):10

Kouedeu AF, Kenné JP, Dejax P, Songmene V, Polotski V (2014) Production planning of a failure-prone manufacturing/remanufacturing system with production-dependent failure rates. Appl Math 5(10):1557–1572

Ouaret S, Kenne JP, Gharbi A (2018) Production and replacement policies for a deteriorating manufacturing system under random demand and quality. Eur J Oper Res 264(2):623–636

Polotski V, Kenne JP, Gharbi A (2019) Optimal production and corrective maintenance in a failure-prone manufacturing system under variable demand. Flex Serv Manuf J 31(4):894–925

Kenne JP, Gharbi A (1999) Experimental design in production and maintenance control problem of a single machine, single product manufacturing system. Int J Prod Res 37(3):621–637

Dellagi S, Rezg N, Gharbi A (2010) Optimal maintenance/production policy for a manufacturing system subjected to random failure and calling upon several subcontractors. Int J Manag Sci Eng Manag 5(4):261–267

Ayed S, Sofiene D, Nidhal R (2012) Joint optimisation of maintenance and production policies considering random demand and variable production rate. Int J Prod Res 50(23):6870–6885

Tarek A, Hajej Z, Rezg N (2016) Production and maintenance optimization for multi-machines under degradation constraint. Ifac Papersonline 49(31):149–154

Kang KC, Subramaniam V (2018) Joint control of dynamic maintenance and production in a failure-prone manufacturing system subjected to deterioration. Comput Ind Eng 119:309–320

He Y, Liu F, Cui J, Han X, Zhao Y, Chen Z, Zhou D, Zhang A (2019) Reliability-oriented design of integrated model of preventive maintenance and quality control policy with time-between-events control chart. Comput Ind Eng 129:228–238

Paraschos PD, Koulinas GK, Koulouriotis DE (2020) Reinforcement learning for combined production-maintenance and quality control of a manufacturing system with deterioration failures. J Manuf Syst 56:470–483

Cheng G, Li L (2020) Joint optimization of production, quality control and maintenance for serial-parallel multistage production systems. Reliab Eng Syst Saf 204

Hlioui R, Gharbi A, Hajji A (2015) Replenishment, production and quality control strategies in three-stage supply chain. Int J Prod Econ 166:90–102

Acknowledgements

The authors would like to acknowledge the financial support of the Natural Sciences and Engineering Research Council of Canada (NSERC) under the Discovery Grant (RGPIN-2018-05292 and RGPIN 2019-05973).

Funding

This work was supported by the Natural Sciences and Engineering Research Council of Canada (NSERC).

Author information

Authors and Affiliations

Contributions

Patrick Megoze Pongha contributed to writing—original draft, conceptualization, methodology, software, and investigation. Guy-Richard Kibouka performed writing—review and editing, and investigation. Jean-Pierre Kenné was involved in supervision, writing—review and editing, conceptualization, methodology, and funding acquisition. Lucas A. Hof contributed to supervision, writing—review and editing, conceptualization, methodology, investigation, project administration, and funding acquisition.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix A

The solution of Eq. (28) by the analytical method is very complex [8]. Therefore, we will use the numerical method of Kushner. Therefore, an approximation of the derivative of the value function by a finite difference is defined by the following Eq. (36).

By injecting the last equation in Hamilton–Jacobi–Bellman (HJB) and developing, we obtain:

Isolating all ϑ (x, α) members in the left-hand member, we have:

Hence:

Now we have:

Mode 1

Both machines are in operation. The rejection rate of the main machine is \(\beta\), and the control fraction is \({f}_{1}\).

With: \({\Omega }_{h}^{1}=\left|{q}_{11}\right|+\frac{\left|\dot{x}\right|}{h}\) \({\mathrm{P}}_{x}^{+}\left(1\right)=\left\{\begin{array}{lc}\frac{\dot{x}}{h{\Omega }_{h}^{1}} & if\;\dot{x}>0\\ 0 & if\;not\end{array}\right.\)

Mode 2

Only the main machine M1 is in operation. The rejection rate of the main machine is \(\beta\), and the control fraction is \({f}_{2}.\)

With: \({\Omega }_{h}^{1}=\left|{q}_{11}\right|+\frac{\left|\dot{x}\right|}{h}\) \({\mathrm{P}}_{x}^{+}\left(1\right)=\left\{\begin{array}{lc}\frac{\dot{x}}{h{\Omega }_{h}^{1}} & if\;\dot{x}>0\\ 0 & if\;not\end{array}\right.\)

Mode 3

Only the second M2 machine is in operation. No fraction to control in this case.

with: \({\Omega }_{h}^{3}=\left|{q}_{33}\right|+\frac{\left|\dot{x}\right|}{h}\)

Mode 4: Both machines are out of order.

with

and

Appendix B

Rights and permissions

About this article

Cite this article

Megoze Pongha, P., Kibouka, GR., Kenné, JP. et al. Production, maintenance and quality inspection planning of a hybrid manufacturing/remanufacturing system under production rate-dependent deterioration. Int J Adv Manuf Technol 121, 1289–1314 (2022). https://doi.org/10.1007/s00170-022-09078-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-09078-3