Abstract

Maintaining the minimum allowable distance between proximity welds has always been considered a subject of debate among design engineers, welding engineers/inspectors and fabricators/engineering contractors. The scattered nature of guidelines available in welding codes and standards for maintaining the minimum allowable distance poses a significant challenge in the welding procedure and inspection criteria development process. This is especially critical for complex welded joints on submerged sections of offshore structures, in compact layouts/branched connections of topside piping components, and on topside structural joints (depending on the complexity). This manuscript presents the findings of an experimental study that was performed by fabricating two girth welds at proximity on an S355 steel tubular section with diameter of 219.1 mm and thickness of 8.18 mm. Proximity girth welds were fabricated on S355 tubular sections at three different distances between their weld toes, 5, 10, and 15 mm, respectively, using two different welding procedures. Welding procedure qualification record (WPQR) was performed, and all prescribed mechanical tests were recorded as per NORSOK M-101, a structural steel fabrication code. Although all results from the mechanical test met the minimum specified values as defined in the NORSOK code, the research findings revealed a noticeable difference in Charpy and hardness values for proximity region between adjacent welds. Considerable changes in final microstructure morphology were observed between proximity welds due to varying thermal cycles. These observations can form the basis for the future welding procedure qualification of critical welded joints, especially for proximity welds on critical welded joints of offshore structures and welds fabricated during replacement/repair procedures in compact piping layouts.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Welding is the most widely accepted method for the joining of two structural members with or without the use of filler wire when it comes to the fabrication of steel and various advanced engineering alloys, ranging from offshore jackets, floating structures, piping and pipelines to bridges, and aircrafts [1,2,3,4,5,6]. In the past, many accidents and delays have been related to weld failures; however, this issue persists, despite the improvement in welding techniques and inspection procedures [7]. For instance, the Alexander L. Kielland offshore accommodation rig failure in the restrained geometry of its brace hydrophone support was reported to be due to insufficient fillet weld size and high residual stress, leading to an overload of welds and catastrophic fatigue cracking [8]. The recent delay of Equinor’s Johan Castberg floating production, storage and offloading (FPSO) hull for Barents Sea has been credited to faulty welds [9]. The popularity of both fixed and floating types of wind turbines cannot be ignored, as accidents due to cracks in welds are gaining attention, in contrast to the usually reported cracks in the bolts of turbines [10]. Such incidents in large structures cannot be overlooked, as the consequences due to failure leading to loss of life, climate, and property, are very high and irrevocable.

The fabrication of large structures like offshore jacket structures, onshore and offshore wind monopiles and tubular truss bridge structures often brings forward the challenge of welds coming within proximity of each other, as shown in Fig. 1. This challenge of maintaining a minimum distance between welds is often debated among designers, inspectors, and contractors who often rely on international codes and standards for recommendations [11]. A detailed assessment of these codes and practices for maintaining minimum distance criteria between welds has been performed previously by the authors in [12] where a clear lack of consensus has been found regarding maintaining a final distance that is often based on a factor of 4 or 5 times the thickness or 1 or 1.5 times the diameter. In procedures for replacing compact layouts of piping racks, unavoidable situations of placing a new weld close to an existing weld of branched connections, nozzles, etc., are often encountered, as is the case in offshore jacket critical joints, e.g., non-overlapping braces. In the case of repair or replacement procedures, international codes and standards offer no guidance on defining, either the minimum distance between welds or welding procedures for proximity welds, and such decisions are often left to stakeholders’ engineering judgment.

Detail of offshore joints [13]

DNVGL-ST-0126 code on support structures for wind turbines [14] recommends maintaining a distance between consecutive girth welds of not less than 300 mm for an outer diameter of less than 300 mm and states that “ The minimum weld distances mentioned above have been derived based on practical experience. Shorter distances may be suitable but need to be proven both with respect to impact on stress concentration factor (SCFs) as well as residual stresses”. This indicates a need to further investigate areas between proximity welds with an unqualified welding procedure qualification record (WPQR) which have experienced multiple cycles of heating and cooling and unprescribed residual stress profiles used during defect assessment procedures, as per fitness for service (FFS) codes [15, 16]. The importance of potential factors that degrade welding quality in terms of defects requires an assessment of the most vulnerable welding procedure specifications (WPSs) and imperfection factors that contribute to the majority of defective welds [17]. Pressure Vessel Research Council (PVRC) Phase 2 [18, 19] highlights the conservativeness in residual stress profiles at a distance away from welds, as per FFS codes such as BS7910, API 579 RP-1/ASME FFS-1, etc.

With this background, the aim of the current study is to qualify WPQRs for two different girth welds, placed at proximity with a minimum distance between their weld toes of 5 mm, 10 mm, and 15 mm, respectively. All necessary mechanical testing was performed in accordance with NORSOK M-101 [20], the code for structural steel fabrication, to understand changes in hardness and Charpy values at the proximity region. Lastly, detailed microstructure characterization was performed to understand the grain morphology at the proximity region due to the varying thermal cycles of two different welds. The remainder of the paper is structured as follows: Sect. 2 presents the experimental details. Thereafter, in Sect. 3, the results are presented and discussed. Subsequently, in Sect. 4, a conclusion is drawn.

2 Experimental set-up

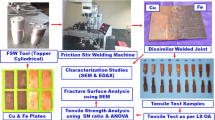

A schematic diagram of the experimental set-up is shown in Fig. 2, pictorially displaying the fabrication steps from ‘a’ to ‘c’. Structural steel grade S355G14 + N seamless pipes were selected for this experiment, with an outside diameter of 219.1 mm and a thickness of 8.18 mm. As shown in Fig. 2a–c, vee joint geometry was machine cut for welds A and B in accordance with prequalified WPS adopted from reputable industrial partners. As shown in Fig. 2b, initially, weld A was fabricated as a single weld on a pipe section and, subsequently, the vee groove for weld B was machine cut. Lastly, weld B was welded after weld A was completed, maintaining proximity distances between their weld toes of 5,mm, 10 mm, and 15 mm, respectively, as shown in Fig. 2c and summarized in Table 1.

In this study, welding parameters were maintained as per pre-qualified WPS for welds A and B, and digital weld log data was maintained during the experiments, as mentioned in Table 2. The mechanical and material composition of the tubular pipe and filler wire is also presented in Tables 3 and 4, respectively. In this study, to simulate the practical situation of weld proximity encountered during repair and replacement procedures, weld B was welded with a different welding procedure, i.e., MAG-metal core (138) semi-automatic method for root pass, as it employs a short-circuiting technique for better root penetration and FCAW (136) semi-automatic method for the remaining passes for faster production. In weld A, all passes were completely fabricated with TIG (141), a semi-automatic welding process. This demonstrates the practical situation of critical welded joints fabricated under shop conditions, by using a controlled procedure like TIG, and during on-site repair or replacement situations, welded with a faster and more mobile procedure like MAG + FCAW.

NORSOK M-101 [20] code was used for qualification of WPQR and adopted in this project catering for the Norwegian continental shelf (NCS) and offshore-welded tubular structures used in oil exploration and the processing industry. NORSOK M-101 code for WPQR is strictly valid within the limitations specified in ISO 15614–1 [21], the widely accepted code for welding qualification around the world. Welding was performed under controlled conditions after optimizing the welding parameters as mentioned in Tables 2 and 3 in line with pre-qualified WPS. Three samples from each proximity distance were finally fabricated and were subjected to mechanical tests as per NORSOK M-101 and ISO 15614–1 as detailed in Table 5.

All necessary and recommended destructive and nondestructive testing (NDT) was performed, and the general procedure and acceptance criteria for each method are summarized in Table 6, as per ISO EN15614-1 [21]. Charpy specification as per EN ISO 9016–2012 was performed; however, in the case of WPQR for proximity welds, Charpy locations shown in Fig. 3 were selected. The notch for Charpy specimens was made at locations shown in Fig. 3.

-

Notch in center of weld

-

Notch in fusion line (FL)

-

Notch in heat affected zone (HAZ), 2 mm from fusion line

-

Notch in HAZ, 5 mm from fusion line

Hence, in the case of a weld proximity distance of 5 mm, six samples and four sets of Charpy locations were extracted, as the fusion line (FL + 5 mm) was not possible due to the 5 mm proximity distance. In the proximity case of 10 and 15 mm case, a total of eight samples and four sets were extracted due to there being sufficient proximity distance.

3 Results and discussion

3.1 Visual and radiographic examination

As shown in Table 6, all mechanical destructive and NDT was performed in accordance with relevant EN standards. Visual and NDT testing of radiography was performed to 100% extent on each proximity distance sample. Due to spray mode in MAG + FCAW welding process Weld B, a wider and irregular cap weld bead was observed in contrast to a smooth weld cap bead of weld A [22], which was welded with TIG process as shown in Fig. 4. As per the acceptance criteria of ISO 10675–2016, both joints were accepted after performing radiography testing on proximity.

3.2 Hardness testing

Vickers hardness testing on each case of weld-proximity distances of 5, 10, and 15 mm was performed according to NS-EN ISO 9015–1:2011. As per indentation marks shown in Fig. 5, there was a recommended distance of 1 mm between indentations and, in HAZ ≤ 0.5 mm, between the center point of the indentation and the fusion line. The indentation marks shown in Fig. 5 can be seen clearly in macro graphs of each weld proximity case in Fig. 9a–c. As the proximity distance was the area of concern, hardness measurement points between adjacent weld toes at ‘weld cap and root level’ for 5, 10, and 15 mm proximity distances are shown in Fig. 6a, b, respectively. High hardness values were observed at the proximity distance (PD-A&B) between two weld metals (WM-A&B) and their respective adjacent HAZ-A&B, in constrast to the parent metal (PM). This proximity distance, or area known as ‘alien metal’, has experienced microstructural changes due to high restraint and successive thermal cycles of multipass welds, as noticed in [23] for proximity-welded joints K-brace joints of offshore jacket structures.

A maximum value of 210 HV was observed close to a HAZ value of 225 HV on either side for 5 mm proximity distance welds at cap level, as shown in Fig. 6a. Cold cracking chances increase if hardness values are between 350 and 400 HV. This region may be prone to cracking, as it has accumulated high stresses and chances of martensitic formation have been sustained due to successive thermal cycles of heating and cooling [23]. Similar hardness points’ profiles for weld proximity distances of 10 and 15 mm are shown in Fig. 6a, b for fair comparison. As the proximity distance is increasing, a drop in hardness values can be seen and is comparable to PM in the 10 and 15-mm cases. In case of 10-mm proximity distance, the highest value of 186 HV was observed at the proximity region and of 167 HV in the case of 15-mm distance, which is almost equivalent to parent metal value at weld cap level. It is also worth mentioning that hardness values at weld cap level in the 5-mm case are maximum in the HAZ area, in comparison to 10 and 15-mm cases.

3.3 Charpy testing

Charpy testing was performed in accordance with KV8, NS-EN ISO 148–1:2016 and ISO 9016:2012 at −20 °C. As discussed previously and shown in Fig. 3, due to the limited space for FL + 5 mm samples, only six specimens were available for 5-mm proximity distance whereas FL + 5 mm was possible for 10- and 15-mm proximity distances. Sample size was kept at 5 × 10 × 55 mm size, as the pipe thickness was 8.2 mm; hence, a conversion factor of 2/3 was applied, when calculating energy values as per code EN 15,614–2017.

Figures 7 and 8, respectively, illustrate scanning electron microscope (SEM) micrographs of fracture surface at FL + 2 mm and the Charpy energy values chart. A region compromised of a mainly dimple-like ductile fracture zone is observed, as shown in SEM micrographs in Fig. 7a, for 5-mm WP distances. However, some cleavage river-like patterns, along with dimples, are observed in Fig. 7a, indicating some regions of brittle fracture, in contrast to Fig. 7b, where dominant dimples like a ductile fracture surface are observed for the 15-mm weld proximity case. Features like the area of the ductile fracture zone of HAZ and the shear lip of HAZ can also help in determining the dominant fracture mode in HAZ [24].

As shown in Fig. 8, low energy values are noted for 5 mm weld proximity (WP). It can be observed from Fig. 8 that the least energy values of 55 J at the proximity region, i.e., weld A-FL + 2 mm, were observed for the 5-mm proximity distance, in contrast to the 10 and 15-mm cases. To draw fair comparison, FL + 2 mm Charpy values are highlighted in Fig. 8, with values of 62 J and 66 J being observed, i.e., between welds A–B for the 10 and 15-mm cases. Due to high hardness and high restraint in the 5-mm proximity case, a drop in energy values can be observed. This drop can be attributed to the high hardness values observed, as explained in Sect. 3.2, and the mixed pattern of cleavage river and dimples, leading to brittle and ductile fracture surfaces, respectively. However, microstructure graphs shown later in Sect. 3.4 also substantiates the high hardness values at proximity regions for changed morphology of grain size in the proximity region.

3.4 Macro testing

Macro examination was performed in accordance with NS-EN 17,639–2013 and was accepted as per the criteria of NS-EN ISO 5817:2014, with imperfection inside quality level B, as shown in Fig. 9a–c. In the proximity case of 5-mm between its weld toes, overlapping of the heat-affected zone cannot be observed, as shown in Fig. 9a; however, no visual changes in the proximity region (metal subjected to successive cycles of heating and cooling) were observed between proximity welds.

3.4.1 Microstructure characterization

Due to the high values in hardness and the drop in Charpy values for the 5-mm weld proximity case, there was a need to further perform microstructure characterization. Optical microstructures across the weld interface, starting from the parent metal to HAZ of weld A, then to proximity region to HAZ of weld B, were analyzed on macro specimen samples of 5-mm weld proximity, as shown in Fig. 10a–d. The microstructures at HAZ showed acceptable weld interface without any defects; however, different orientation of grains was observed in the region identified as the proximity region/alien metal i.e., between two welds, as shown in Fig. 10d.

Microhardness results at the designated location of HAZ and the proximity area between welds (PA) correspond to values of 225 HV and 210 HV, respectively, as shown in Fig. 6a, for the 5-mm proximity case. Based on this information, the microstructure in HAZ regions can be mainly composed of ferrite (50 to 80%), bainite (0 to 30%), pearlite (0 to 20%), and martensite (0 to 20%) corresponding to Vickers hardness values for steel S355 [23]; refer to Table 7 [25].

The optical images seem to confirm regions of perlite (P) and ferrite (F) in the parent metal, as shown in Fig. 10 a. Acicular ferrite (AF-large light areas) with grain boundary ferrites (GBF) can be observed in weld metal A and B. Depending on the final temperature range attained, HAZ is divided into coarse-grained HAZ (CGHAZ), fine-grained HAZ (FGHAZ), and the inter-critical HAZ (ICHAZ) [12]. In HAZ, the structure is formed upon temperature attained between Ac1 and Ac3, i.e., upper, and lower critical temperatures as shown in Fig. 10 b and d. As the proximity area/alien metal corresponds to a fine-grained structure in contrast to CGHAZ and FGHAZ, it can be identified as a region close to ICHAZ that is subjected to successive cycles of heating and cooling between Ac1 and Ac3 temperatures, i.e., 725–915 °C, with finer grain, as confirmed from thermocouple data.

It is difficult to identify the presence and quantify the fraction of martensite; however, sufficient evidence of martensite-austenite (M-A) islands has been identified in the inter-critically reheated coarse-grained heat affected zone (ICCGHAZ) undergoing partial austenization and forming austenitic-martensitic (M-A) phases, which are brittle and known as local brittle zones (LBZ) [26]. However, their presence needs further investigation by performing scanning electron microscopy (SEM) analysis which will be presented in future research.

3.5 Tensile and bend tests

Tensile tests were performed for all three weld proximity cases (5-, 10-, and 15-mm), in accordance with ISO 6892–1:2016. Table 8 summarizes the values of all tensile test data along with its fracture location. It was interesting to note that values of tensile strength for the 5-mm weld proximity case were found to be somewhat lower than in the 10- and 15-mm cases. Fracture location could not provide any conclusion, as it changed from outside of weld A or B, i.e., sufficiently far from HAZ and the proximity region. It would have been interesting if failure had occurred between welds for the 5-mm case. However, in the case of 15-mm proximity, fracture occurred between welds in one case. It can be inferred that the 15-mm distance is sufficiently far, and the fracture location can be considered close to the parent metal.

Tensile results sufficiently meet the required strength of 460–620 MPa; however, all values were found to be less than the pipe measured value of 553 MPa, as referred to in the material test certificate mentioned in Table 3. Elongation values in all cases were found to be less than 22%, indicating the high restraint and residual stresses caused by welds placed at proximity.

Bend tests were also performed as per EN ISO-5173:2010 at the designated location of root and face, as mentioned in NORSOK M-101 and EN 15,614–2017. For thickness of less than 12-mm, two samples each for face and root bend were tested. For all weld proximity samples of 5, 10, and 15-mm, testing did not reveal any one single flaw greater than 3-mm in any direction. Flaws appearing at corners of test specimen were ignored, as mentioned in EN 15,614–2017.

4 Conclusion

Welding procedure qualification record (WPQR) was performed on grade S355 tubular pipes’ girth welds with a proximity distance between their weld toes of 5, 10, and 15 mm. Welds were fabricated with two different welding processes, in accordance with the pre-qualified welding procedure specification (WPS). WPQR was performed in accordance with NORSOK M-101, which follows EN 15,614–2017 standard, and all relevant mechanical tests were performed. Based on detailed mechanical evaluation, an increase in Vickers hardness values and a drop in Charpy values for the 5-mm weld proximity case were observed. It is also pertinent to mention here that the drop in elongation values observed in tensile test data in all cases can be attributed to the high restraint and residual stresses caused by welds placed at proximity. It was also inferred from the microstructure characterization that there was the formation of an inter-critically reheated coarse-grained heat affected zone (ICCGHAZ), as verified from thermocouple data, which is prone to cracking due to the presence of austenitic-martensitic (M-A) phases which are brittle and known as local brittle zones (LBZ).

After performing welding qualification on proximity welds, mechanical results justify the need to avoid such situations, especially when the proximity distance is less than half the thickness of the joining member between adjacent weld toes i.e., 5 mm in this current study. One times the thickness and two times the thickness of the joining member, i.e., 10 mm and 15 mm also used in this current study, did not show any harmful effect, as verified by mechanical test results. The codes and standards also do not provide any recommendation for maintaining minimum proximity distances for repair and replacement welds [12]. The region identified as ‘proximity region or alien metal’ between adjacent welds requires careful defect assessment and inspection procedures in relation to the compact welded joints found in offshore jacket structures and high restraint situations developed during pipe replacement procedures in compact layouts. Detailed assessment and record keeping of previous welding process parameters and mechanical tests can help in the future qualification of new welding procedures for repair welds placed at proximity. In the future, the authors plan to measure residual stress profiles and fatigue life between proximity welds, for their detailed assessment and to provide practical recommendations to industrial partners for maintaining the minimum distance between proximity welds.

Availability of data and material

All data generated and analyzed during this research are included in this published article.

References

Norrish J (2006) 1 - An introduction to welding processes, in Advanced Welding Processes, J. Norrish, Editor, Woodhead Publishing. p 1–15

Ratnayake RMC, Brevik VA (2014) Experimental investigation of underwater stud friction stir welding parameters. Mater Manuf Processes 29(10):1219–1225. https://doi.org/10.1080/10426914.2014.930891

Oliveira JP et al (2019) Microstructure and mechanical properties of gas tungsten arc welded Cu-Al-Mn shape memory alloy rods. J Mater Process Technol 271:93–100. https://doi.org/10.1016/j.jmatprotec.2019.03.020

Oliveira JP et al (2021) Laser welding of H-phase strengthened Ni-rich NiTi-20Zr high temperature shape memory alloy. Mater Des 202:109533. https://doi.org/10.1016/j.matdes.2021.109533

Oliveira JP et al (2022) Dissimilar laser welding of a CoCrFeMnNi high entropy alloy to 316 stainless steel. Scripta Mater 206:114219. https://doi.org/10.1016/j.scriptamat.2021.114219

Shamsolhodaei A et al (2020) Controlling intermetallic compounds formation during laser welding of NiTi to 316L stainless steel. Intermetallics 116:106656. https://doi.org/10.1016/j.intermet.2019.106656

Ratnayake RM (2013) An algorithm to prioritize welding quality deterioration factors: a case study from a piping component fabrication process. Int J Qual Reliab Manag. https://doi.org/10.1108/02656711311325584

Lotsberg I (2016) Fatigue design of marine structures. Cambridge University Press, Cambridge

Link M (2021) Equinor: Several Factors Behind Faulty Welds on Johan Castberg FPSO Hull. Available from: https://www.marinelink.com/news/equinor-several-factors-behind-faulty-486965#.YH4FKi90m_8.linkedin. [Cited 2021 29/09/2021]

Talkshop TS (2014) 100m Turbine collapse: not bolts this time – weld failure in the main tower. Available from: https://tallbloke.wordpress.com/2014/12/17/100m-turbine-collapse-not-bolts-this-time-weld-failure-in-the-main-tower/. [Cited 2021 29/10/2021]

Larsson M, Larsson M, Ratnayake RM (2021) Investigation of Fatigue Strength Behaviour in Dual Weld S420 Steel Joints Fabricated at a Close Proximity. https://doi.org/10.1007/978-981-15-9121-1_27

Bhardwaj S, Ratnayake RMC (2020) Challenges due to welds fabricated at a close proximity on offshore structures, pipelines, and piping: State of the Art. In ASME 2020 39th International Conference on Ocean, Offshore and Arctic Engineering. https://doi.org/10.1115/omae2020-18586

NORSOK N-004 Standard (2021), Design of steel structures, Norway

DNVGL-ST-0126 Standard (2018), Support structures for wind turbine, DNVGL

Larsson M, Larsson M Ratnayake RM (2021) Experimental Investigation of Weld Joints Manufactured at Close Proximity in S420 Structural Steel. https://doi.org/10.1007/978-981-15-9121-1_25

Larsson M et al (2021) Experimental Residual Stress Investigation of Weld Joints Fabricated at a Close Proximity in S420 Structural Steel. https://doi.org/10.1007/978-981-15-9121-1_26

Ratnayake RM (2014) A methodology for assessing most vulnerable welding procedure specifications and imperfection factors. Int J Data Anal Tech Strateg 6:362–383. https://doi.org/10.1504/IJDATS.2014.066606

Bhardwaj S, Chandima Ratnayake RM (2020) Residual stress estimation in defect assessment procedures at weld toe and away locations on girth welds: Review of key parameters. Theor Appl Fract Mech. https://doi.org/10.1016/j.tafmec.2020.102848

Dong P et al (2014) On residual stress prescriptions for fitness for service assessment of pipe girth welds. Int J Press Vessels Pip 123–124:19–29. https://doi.org/10.1016/j.ijpvp.2014.07.006

NORSOK M-101 Standard (2011) Structural steel fabrication: Norway

BS EN 15614–1 Standard (2017) Specification and qualification of welding procedures for metallic materials — welding procedure test

Oliveira JP et al (2020) Gas tungsten arc welding of as-rolled CrMnFeCoNi high entropy alloy. Mater Des 189:108505. https://doi.org/10.1016/j.matdes.2020.108505

Acevedo C (2011) Influence of residual stresses on fatigue response of welded tubular K-joints. EPFL

Xiong Z et al (2015) The contribution of intragranular acicular ferrite microstructural constituent on impact toughness and impeding crack initiation and propagation in the heat-affected zone (HAZ) of low-carbon steels. Mater Sci Eng A. https://doi.org/10.1016/j.msea.2015.03.090

ISF Welding and Joining Institute (2004) Chapter 4-Classification of Steels, Welding of Mild Steels

Lomozik M (2000) Effect of the welding thermal cycles on the structural changes in the heat affected zone and on its properties in joints welded in low-alloy steels. Weld Int 14(11):845–850. https://doi.org/10.1080/09507110009549281

Acknowledgements

We would like to acknowledge the support of M/s Rosenberg Worley, Stavanger, Q-lab Forsand, and Jan-Tore Jakobsen, Wakshum Mekonnen, lab engineer at University of Stavanger, Norway for their support in the fabrication and testing of samples. We would also like to thank all reviewers involved in the publication process, for providing their valuable suggestions.

Funding

Open access funding provided by University Of Stavanger. The research is fully funded by the Norwegian Ministry of Education (Internal PhD project No. IN-12168). This work has been carried out as part of a PhD research project, performed at the University of Stavanger, Norway.

Author information

Authors and Affiliations

Contributions

Sachin Bhardwaj: Conceptualization, Experimentation, Investigation, Methodology, Visualization, Writing—original draft, Writing—review and editing. R.M.Chandima Ratnayake: Conceptualization, Formal analysis, Funding acquisition, Project administration, Supervision.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Bhardwaj, S., Ratnayake, R.M.C. Welding procedure qualification record (WPQR) for welds fabricated at proximity. Int J Adv Manuf Technol 120, 4477–4491 (2022). https://doi.org/10.1007/s00170-022-09022-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-09022-5