Abstract

Nowadays, end customers require personalized products to match their specific needs. Thus, production systems must be extremely flexible. Companies typically exploit assembly lines to manufacture produces in great volumes. The development of assembly lines distinguished by mixed or multi models increases their flexibility concerning the number of product variants able to be manufactured. However, few scientific contributions deal with customizable products, i.e., produces which can be designed and ordered requiring or not a large set of available accessories.

This manuscript proposes an original two-step procedure to deal with the multi-manned assembly lines for customized product manufacturing. The first step of the procedure groups the accessories together in clusters according to a specific similarity index. The accessories belonging to a cluster are typically requested together by customers and necessitate a significant mounting time. Thus, this procedure aims to split accessories belonging to the same cluster to different assembly operators avoiding their overloads.

The second procedure step consists of an innovative optimization model which defines tasks and accessory assignment to operators. Furthermore, the developed model defines the activity time schedule in compliance with the task precedencies maximizing the operator workload balance. An industrial case study is adopted to test and validate the proposed procedure. The obtained results suggest superior balancing of such assembly lines, with an average worker utilization rate greater than 90%. Furthermore, in the worst case scenario in terms of customer accessories requirement, just 4 line operators out of 16 are distinguished by a maximum workload greater than the cycle time.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Manufacturing production evolved over the years since its origin. Indeed, different paradigms characterized the history of manufacturing since the industrial revolution. The “craft production” was arisen with the first industrial revolution in the eighteenth century and was supplanted by the “mass production,” i.e., the paradigm born in the Piquette factory of Detroit to produce the Ford Model T at the beginning of 1900 [1]. Such latter paradigm leverages for the first time the assembly line (AL), i.e., a product flow-oriented production system (Hu Jack 2013). The mass production paradigm allowed companies to provide identical final goods cheaply. Indeed, the adopted ALs ensured a dramatically productivity increase due to both the component standardization and work activities optimization [2]. The availability of cheap products that could be purchased by previously excluded segments of the population ensured the emergence of novel markets. Such circumstances allowed the success of the mass production paradigm which held sway until 1980 [3, 4]. A growing portion of consumers looked for products that better match their personal requirements, even at a higher cost [5]. Thus, the “one-size-fits-all” products that aimed to minimize the production cost did not meet the consumer expectations. Thus, the 1980s mass production was no longer a suitable production paradigm. The stiff ALs which allowed a huge productivity increase during the previous years do not have the required flexibility to manufacture the customized products required by the market.

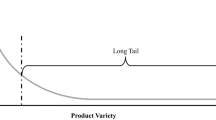

Such circumstances forced companies to develop a high variety of products, giving rise to the “mass customization” paradigm [6]. Mass customization means that customers can define the product specification by choosing the available accessories. An accessory modifies the functional or aesthetic product attributes and is typically related to a physical component [7]. Furthermore, the number of product variants provided by companies increased considerably over time. For instance, in the automotive industry, the number of accessories available to customers is tremendously raised in the last decades, i.e., leading up to 1032 available variants for a single model for traditional compact cars [8, 9].

As result, such environment forces production systems to be more flexible. Therefore, for highly customized products, companies focus on assembly to order approach [10]. The firms that implement such approach define which features the final product can satisfy and then develop the needed components to achieve the selected features [11]. Thus, the customers can design the final product by equipping it with the components that ensure the fulfilment of their needs or preferences.

In light of the aforementioned aspects, several industrial companies leverage ALs to manufacture customizable products. Indeed, the aim is to preserve the line productivity which distinguishes the manufacturing of identical products even for those ones dedicated to customizable products. A proper design of such production systems is crucial to achieve the abovementioned goals. The balancing of customizable product ALs must consider both temporal and spatial aspects. Indeed, the workload should be similar between the line operators and the components must physically fit in the available area even in the presence of accessories. Furthermore, a customize production of large size produces, e.g., cars and machineries, typically requires the coordination of several operators within the same workstation of an AL. In fact, multiple operators are traditionally involved in the simultaneous performance of assembly tasks on the same workpiece and in the same workstation. Thus, the assembly tasks scheduling over the line cycle time must define the temporal workloads of every single operator within the same workstation at every time to ensure the task technological precedencies.

Considering the aforedescribed scenario, this paper proposes an original procedure to efficiently and effectively solve the problem of balancing ALs distinguished by highly customized product to be manufactured. The novelty of this research is a unique two-step approach which enables to tackle such complex scenario. In particular, the first step aims at defining clusters of accessories often required together by end-customers leveraging the details of the received orders. These clusters represent valuable input data for the AL balancing mathematical model proposed as a second step of the procedure to decrease the problem complexity and therefore obtaining a feasible and good solution in a limited amount of time. Indeed, the aim of this research is to offer a suitable solution procedure in particular for those real industrial case studies often distinguished by hundreds of mounting tasks and other practical constraints, as more than one operators working simultaneously in the same station on the same product.

This paper is organized as follows. Section 2 outlines the current state of the art of the AL systems deepening on the customizable products. Section 3 presents the AL balancing problem (ALBP) for customised product qualitatively. Section 4 describes the management of product accessory in compliance with the customer requirements. Section 5 presents the mathematical model developed to optimise the previously described problem. Section 6 describes a real industrial case study related to big agricultural machine assembly exploited to test and validate the proposed procedure. The achieved results are presented and discussed in Sect. 7, while the conclusions and advices for further research development are proposed in the last Sect. 8.

2 Literature review

The industrial production focuses on assembly systems since the mass production paradigm outbreak. Scientific research developed throughout the years different ways to represent the AL production systems and several methodologies have been proposed to achieve the workload balancing between the workstations. The increasing number of product variants requested by the market imposes to focus the scientific effort on mixed or multi-model ALs. A multi-model line performs at least two different product types requiring set-up operations; thus, end produces are mounted in batches [12]. A mixed-model line manufactures a family of similar products that share some tasks with each other and are distinguished by different end-produced variants (e.g., accessories). Such lines do not require any set-up operations between the mounting of different product variants,thus, the lot size can be considered equal to one [13, 14]. The mixed model lines also allow the assembly of products that can be equipped with multiple accessories to define several end product variants. However, these variants are not able to adequately and fully represent the customizations requested by end customers necessary to define a personalized and unique version of the required product [15].

Assembly product customization can be classified into two main typologies. Accessory is a product feature that may or may not be required by the end customers, as the parking assistant system of a car. On the other hand, an option represents a feature always included in the final product. Indeed, the customers have to choose one alternative of each option [16]. For instance, the car alloy wheels must typically be chosen between several alternatives which include different designs and sizes, but strictly one selection has to be picked.

Traditional research typically faces the mixed-model ALBP as a simple ALBP by creating a joint precedence graph [17]. Such chart represents the precedence graph for the assembly tasks of a virtual average model which results from the overlay of all the precedence graphs of the different product variants mounted by the AL. Since the number of product accessories experienced a tremendous increment in the latest years, the definition of the joint precedence graph is extremely challenging [18]. Indeed, the number of all possible combinations of product customizations represents an enormous variety [19]. Considering such circumstances, it is recommendable to reduce the problem size by considering how often each accessory is required by end-customers [20].

The opportunity to customize the products increases the risk of overload occurrence since the accessories require an extra assembly time. Mixed-model ALBPs aim to define task assignment avoiding overloads. Furthermore, the models developed in the literature typically exploit the joint precedence graph and the average task execution time as input data [21]. However, a task assignment so obtained cannot avoid overloads whether several products which require numerous accessories follow each other, especially if assigned to the same workstation. On the other hand, significant idle times arise when the line assembly several products are characterized by low assembly time [22]. The product sequencing faces the overload issue in a short-time perspective. The first problem formulation proposed by the literature imposes that each workstation performs no more than one accessory [23].

A further relevant area of research which tackles such problem category is defined as customized product manufacturing. Several mathematical models have been proposed to define the optimal task to machine assignment considering the required product personalizations [24]. Some of these also consider the dynamic evolution of the manufacturing systems over time trying to minimize the idle time of the employed resources [25]. Further contributions propose very promising two-step approaches to split the definition of the accessory clustering from the scheduling of these to manufacturing machines (Kamrani and Smadi, 2012). Unfortunately, very few researches have been developed so far to translate these concepts into production systems organized in ALs. Lu et al. [26] suggest a qualitative framework to model the dynamic variability of large assembly systems for highly customized products. As far as the authors’ knowledge, Otto and Li [27] is the unique contribution which proposes a mathematical formulation to tackle the problem of assembling customized products with a particular focus on the scheduling of the product sequence to the line but not on the balancing of the mounting activities to the different operators and stations thus resulting in possible overloads of the employed resources.

Indeed, despite the huge number of product variants, customer requests typically have several common accessories. Such circumstance allows to reduce the overloads if proper leveraged. In fact, it is possible to cluster the product variants requested by customers according to the accessories which have to be assembled. Thus, both the task assignment and the product sequencing may depend on the product clusters reducing the operator’s overloads (Solnon et al. 2005).

Furthermore, most tasks and accessories involve the assembly of physical components that occupy a specific volume and dimensions (length, width, and height). Some of these require a negligible space and are typically placed in trolleys without considering the occupied space, e.g., commercial components such as screws or seals [28]. On the other hand, several components occupy a considerable volume and must be placed in the storage area along the AL. Indeed, each workstation has a dedicated storage area to stock the components which must be mounted in such workstation [29].

The constraints concerning the components fitting in the storage area influence the optimal workload balance solutions, especially for large-sized products (Fattahi et. al, 2011). Indeed, a balanced solution can be infeasible if several large components must be stored in the same workstation due to the task assignment and they cannot be fitted in the storage area. Furthermore, customized production enables the customers to choose between several accessories which require the assembly of different components [30]. The tasks to station assignment must ensure the components fitting within the dedicated workstation storage area whatever the accessory combination requested by the customers is.

Moreover, the assembly of large components can involve two or more operators due to handling difficulties, i.e., the crankcases assembly to cover moving mechanical components. If two or more operators belong to the same workstation, the production system is classified as a multi-manned AL [31]. The task and accessory assignment as well the material feeding is more challenging in such ALs compared to the single-operator ones. Indeed, the activity coordination of the different operators must be adequately managed [32, 33]. Such requirement imposes the task scheduling even within the same station to define the start and the end times of each task execution.

As far as the authors’ knowledge, no contribution in the scientific literature, in particular in the field of customized product manufacturing, seems to combine all the aforementioned features in a unique mathematical model to provide a valuable help in the ALBP and activity scheduling. Therefore, this paper presents a two-step procedure to efficiently and effectively solve problems distinguished by the simultaneous presence of all these features:

-

customized products to be assembled, defined by the unique combination of accessories to be mounted requested by the end customer

-

consideration of the space required in every station to store the components needed by the assembly tasks, also the ones to mount the accessories

-

possibility to have more than one operator per station, therefore resulting in a multi-manned AL, in particular for large-sized products

-

balancing of the assembly activities between the operators, in particular, considering the different frequencies of the several accessories to be mounted

The procedure’s first step is represented by an original clustering algorithm necessary to define the sets of accessories distinguished by similar characteristics, as assembly duration, and often requested together by end customers. The second step is defined by a novel integer linear programming model (ILP) to solve such complex ALBP for customized product manufacturing leveraging between the multiple input data the accessory clusters. This model guarantees a suitable balance of the workload between the operators of the AL considering the task time scheduling and the constraints related to the available area near the workstations for component storage.

3 The problem of customized product assembly line

This paper deals with the assembly of customizable product performed on multi-manned ALs considering component storage at station level and accessory request by end customers. The main feature which distinguishes customized product ALs from traditional ones is represented by the impact that product accessories have on AL balancing. Indeed, traditional ALs are distinguished by a set of tasks which have to be executed each cycle time, e.g., every product needs all of them to be completed. On the contrary, the produced accessories which distinguish customized product AL require the related mounting tasks only for those orders for which the end customers select them. In particular, for every customized product to be manufactured on the AL, a subset of accessories is selected by the customer; therefore, it is needed to be mounted on the line. This subset differs from client to client resulting in a different operator workload every cycle time, since they may or may not execute the assembly task related to a product accessory depending on the customer requirement.

This manuscript presents an original two-step procedure which leads to assembly task assignment to line operators maximizing the workload balance between them while considering the relevant and interconnected features which distinguish such complex problem. The first procedure step involves the product customization management. Indeed, a proper produce accessory management is crucial to prevent unexpected overloads of workers and guarantee a proper workload balance. This step exploits the list of customer orders to define which accessories are typically requested together, thus usually mounted on the same product. Indeed, this step leads to define clusters of accessories based on specific similarity conditions. The ultimate goal is to assig to different operators the accessories belonging to the same cluster, e.g., usually mounted on the same product, to prevent overloads in the AL. Table 1 presents an example of a possible order list. This table shows which customers require (✓ symbol) which accessory and which no (- symbol). Therefore, Table 1 points out the accessories typically requested together by the customers. For instance, in the example presented below, every customer order which requires the accessory A10014 also requires the accessory A10080 and vice versa.

The second step of the proposed procedure includes a novel integer linear programming (ILP) model which assigns the traditional mounting tasks as well as the product accessories to the operators ensuring a proper workload balance between them. Furthermore, such AL management requires several expedients due to the product customization as well as the simultaneous presence of several operators in the same workstation. Indeed, a customized production requires the assembly of a predefined number of tasks and a variable number of accessories, which can be chosen by every single customer. Moreover, this research considers the assembly of tasks and accessories both in terms of time required for mounting activities and for the station storage area needed for component feeding.

In particular, the following assumptions are considered in the modelling of the aforedescribed customized product AL:

-

traditional tasks and product accessories are distinguished by known values for the following:

-

deterministic execution time

-

mounting frequency (i.e., percentage of customer orders which requires a certain accessory)

-

dimensions of the required components

-

number of needed operators to carry out the related assembly activities

-

-

line operators are equally skilled, e.g., every task or accessory can be assembled by whatever operator requiring the same mounting time

-

number of operators per station can vary within a upper limit

-

paced line with constant cycle time

The features which distinguish customized product ALs from traditional ones also have a significant impact on the two-step procedure proposed to solve such complex ALBPs. Indeed, an optimal workload balancing along customized product ALs must consider how often the operators have to perform assembly tasks related to the accessories assigned to them. Thus, the proposed procedure leverages the order list with the specification of all the accessories requested by each single customer. This enables to define the accessory mounting frequency, i.e., how frequently accessories are requested together by the same customers. Furthermore, assembly operators might face overload in their activities if a product requires the assembly of several accessories. For instance, if several low-frequency accessories are assigned to an operator, his average workload can be moderate. Nevertheless, if one specific final product ordered by a single customer requires the assembly of all such accessories, it probably causes an overload in assembly activities. Figure 1 presents an example of the workload of an operator which assemble three different customer orders distinguished by the same set of traditional tasks (letter T) but a varying set of accessories (letter A), resulting in a potential unbalance.

Finally, the latest feature of the considered multi-manned customized product AL deals with the need of assembly activity scheduling. Indeed, compared with traditional ALBPs, task and accessory assignment to operators does not guarantee the respect of technological precedence. Indeed, since two or more workers belong to the same station, every task and accessory has to be scheduled, i.e., define the time instant when its execution starts and finishes during the cycle time. The developed ILP model also defines the scheduling of mounting, thus allowing the fulfilment of the technical precedencies even for the tasks and accessories assigned to different operators who belong to the same workstation.

The next two sections present the two steps of the developed procedure which leads to solve the customized product ALBP. Section 4 describes the accessory clustering which avoids operator overloads. Section 5 presents the developed ILP model which defines both the task and accessory assignment to operators as well as the scheduling of all the assembly activities.

4 Accessory clustering

This section presents the first step of the developed procedure which aims to manage the accessory clustering. Such accessories have to be assembled only if a customer requires them. Thus, the operator workload varies according to the customer requests. This workload should be as smooth as possible to avoid production delays, stressful working conditions, and the improper presence of pieces along the AL. The developed procedure groups the accessories in clusters. A cluster is a collection of accessories which share common features. The proposed procedure suggests to compute high similarity between the pairs of accessories which are typically requested together by the customers. Thus, the clusters contain accessories which usually have to be assembled for the same product. This circumstance could lead to an overload if the accessories belonging to the same cluster are assigned to the same operator. Therefore, a proper AL balance should leverage these clusters favoring the assignment of accessories belonging to the same cluster to different operators.

The procedure for accessory clustering starts by calculating the similarity index Sij of all the accessory pairs (i,j) as a value between 0 and 1. Sij involves multiple parameters to consider both customers accessory preferences and average workload due to accessory pairs assembly activities. Sij computation requires customer orders as well accessory mounting time as input data. Indeed, Sij (Eq. (1)) considers both how often customers require accessories i and j together and the average mounting time parameter (MTij) of the accessory pair (Eq. (2)). Sij tends to 1 for the pairs of accessories typically requested together by customers and which represent a great average workload for the operators. Indeed, the parameter aijo is equal to 1 if both accessories i and j are requested by customer order o and 0 otherwise. On the other hand, bijo value is 1 only if customer order o requires strictly one accessory between i and j, while pijo is equal to 1 when neither i nor j is requested by the customer. Furthermore, MTij, which ranges between 0 and 1, considers both the accessory mounting time (ti and tj) and frequency (fi and fj) to compute the average workload faced by the operator who has to assemble both the accessories i and j. MTij is equal to 1 only for the pairs of accessories which require the highest average workload, e.g., high mounting time and frequency. Finally, Eq. (3) defines the accessory mounting frequency (fi). The involved binary parameter qio is equal to 1 if the customer order o requires the accessory i, 0 otherwise.

Once Sij is computed, the proposed procedure leverages a hierarchical algorithm to group the accessories in clusters in sequential steps. Every step consists in merging 2 elements or previously formed clusters into a new cluster. Furthermore, the algorithm proceeds with the subsequent merging favoring the joining between the pairs with the highest Sij. In particular, the UPGMA hierarchical algorithm is adopted to define Sij [34,35,36,37,38,39,40,41,42,43,44]. The algorithm repeats such step until all the accessories are grouped into a single cluster. This procedure allows drawing a dendrogram, i.e., a rooted tree which highlights every clustering resulting from the hierarchical algorithm. Figure 2 presents a dendrogram example with the vertical axis expressing the similarity index. Every accessory or cluster joining is performed for decreasing similarity values as suggested by the hierarchical algorithm. The accessory clustering results from the dendrogram cut. For instance, Fig. 2 displays the rooted tree cut, i.e., the red line, at the similarity value of 0.7. Such dendrogram cutting leads to group the accessories in 2 clusters. The first one includes the accessories A10031, A10032, and A10033, while the second contains A10034 and A10035.

The output of this procedure step, i.e., the accessory clustering, represents an input for the later workload balance step. The cluster information is summarized through four data sets. The parameter eic identifies the accessories belonging to clusters (Eq. (4)). Equation 5 defines the cluster cardinality |c|. Each cluster is distinguished by the average mounting time (TAc) and the average mounting frequency (FAc), Eqs. (6), and (7), respectively.

Finally, Fig. 3 outlines the proposed procedure for accessory clustering. Customer order analysis enables to define the required input and consequently the computation of MTij and Sij. Thus, leveraging the hierarchical algorithm a dendrogram is defined, which cut-off defines the accessory clusters. Finally, several data, as eic, FAc, and TAc, are obtained by the clusters and become input for the next step of the procedure, i.e., workload balance.

The next section presents the integer linear programming model which leads to the optimal operator workload balance in the customized production AL. In order to achieve such objective, the accessories belonging to the same cluster should be assigned to different operators to avoid peaks in worker workload for those customer orders which require them simultaneously.

5 ILP model

This section presents the second step of the developed procedure to tackle the ALBP of customized products. This step consists in a novel integer linear programming (ILP) model which aims to balance the workload between the operators of the AL while minimizing the total number of operators involved. The ILP model achieves the aforementioned objectives guaranteeing the production pace that meets the market requests and in compliance with the technical constraints of the assembly process. Furthermore, the model considers the spatial constraints to ensure the components fitting in the storage area of the different workstations. Finally, the proposed ILP model also considers the outputs of the accessory clustering procedure. Indeed, several constraints limit the number of accessories that could be assigned to an operator if belonging to the same cluster.

Concerning the ILP model definition, the index i identifies both tasks and accessories. The developed model differentiates between these two categories through the usage of fi and eic parameters. fi is equal to 1 if i is a task; otherwise, the value is less than 1 since it represents how often the customers require that accessory i. eic is equal to 0 for tasks since they are not involved in the clustering phase, whereas its value is equal to 1 if the accessory i belongs to the cluster c and 0 otherwise, since it represents the belonging of accessories to clusters. The ILP model leverages the binary variable xikwm to assign and schedule the tasks and accessories. xikwm is equal to 1 if the operator w who belongs to the workstation k starts to perform the assembly of task/accessory i at time instant m. On the other hand, the integer variable yk represents the number of operators assigned to workstation k. A complete list of all the ILP model indices, parameters, and variables, along with their description, is proposed in the Nomenclature section of this manuscript.

Focusing on the model objective function (Eq. (8)), it minimizes the maximum operator workload of the entire AL dealing both with tasks and accessories. Indeed, their mounting time is multiplied by their frequency, which is less than 1 if i is an accessory. Thereby, the computed workload measures the average operator workload. The effective workload value could be lower or higher, depending on the accessories required by the customer. Thus, Eq. (8) also maximizes the smoothness of the operator’s average workload. Equation 9 guarantees all the tasks and accessory execution by whatsoever workstation and operator, within the cycle time. Equation 10 prevents the execution of 2 or more tasks/accessories at the same time whereas Eq. (11) ensures compliance with the technical precedencies, both for tasks and accessories. The multiplied factor \(k\bullet CT\), where k is the workstation index and CT represents the cycle time, ensures the adherence to these precedencies if tasks/accessories i and j are assigned to different workstations. On the other hand, the parameter m allows the fulfilment of temporal precedencies for pairs (i,j) assembled in the same workstation, no matter which operator the tasks/accessories are assigned to. Indeed, in such circumstances, the task/accessory scheduling is crucial. Indeed, i must be completely assembled before another operator starts the mounting of j. Thus, ti ensures that the mounting of j can start only when the assembly of i is already finished.

A further set of equations deals with the fulfilment of the AL cycle time. Equation 12 limits the average workload, i.e., considering the accessory mounting frequency, of all the operators to CT. On the contrary, the effective operator workload can be lower or higher than the average one according to customer requests. Indeed, a product equipped with all the available accessories requires more time to be assembled than the average workload. Equation 13 ensures the fulfilment of CT adjusted by a factor g which is major than 1 for such circumstances. This equation allows overloads as long as they are restricted by a g factor. Furthermore, such constraint does not imply a continuous overload. Indeed, each overload is necessarily balanced by previous or subsequent idle times to fulfil Eq. (12). On the contrary, Eq. (14) adds a time component to the workload compared to Eq. (12). Such component represents the average time required for the assembly of an accessory which belongs to cluster c. Moreover, this added time occurs only if an operator has to assemble a number of accessories belonging to cluster c which exceeds nmc (Eq. (23)). nmc results from the equal division of the accessories belonging to cluster c between operators. Thus, if an operator has to assemble more than nmc accessories of the same cluster, it could result to an overload if a product requires them simultaneously. Such aspect is also tackled by Eq. (15). Indeed, this constraint prevents an over-allocation of accessories belonging to the same cluster to an operator. The number of accessories belonging to the same cluster which are assigned to an operator must be less than nmc adjusted by \({\upvarepsilon }_{\mathrm{c}}\) factor. \({\upvarepsilon }_{\mathrm{c}}\) gives more flexibility to the ILP model. Indeed, without this factor, the ALBP could be infeasible according to the considered case study. Equation 16 limits the maximum number of operators involved in the entire AL, while Eq. (17) assures a proper operators splitting between the different workstations. Equation 18 guarantees that only the involved operator can assemble the considered tasks or accessories. The next two constraints face the spatial aspects related to tasks and accessories physical dimensions. Equation 19 assures that the sum of the component length of tasks and accessories assigned to the same workstation must be less than the length of the storage area. On the other hand, the components/accessories cannot be transversely placed side by side compared to the AL layout (Eq. (20)). Finally, \({\mathrm{x}}_{\mathrm{ikwm}}\) variable has to be binary (Eq. (21)) and yk must be greater or equal to 0 (Eq. (22)).

Subject to:

Where

The ILP model output consists in the variables yk and xikwm values. yk represents the number of operators which has to be involved in each workstation k. xikwm denotes the task and accessory assignment, i.e., which operator has to assemble them, in which workstation and time frame. Indeed, xikwm also defines the task and accessory time scheduling through the index m. This variable is worth 1 only for the value of m which corresponds to the mounting start instant of the task/accessory. Therefore, this model provides the optimal solution considering both assignment and scheduling requirements. Such solution can be used as a workplan for the operators since it also considers the accessory mounting time and frequency. According to proposed equations, the presented ILP model includes \(K(1+I\cdot W\cdot CT)\) variables, whereas an upper bound to the constraint number is \(1+I\left(1+I\right)+K\left(3+I\right)+2K\cdot W(1+C+CT(0.5+I))\) occurring for the worst theoretical precedence graph distinguished by I tasks/accessories.

The next section presents the case study leveraged to test and validate the proposed accessory clustering algorithm and ILP model for ALB. Such case study consists of an AL which manufactures self-propelled machinery for agricultural use.

6 Case study

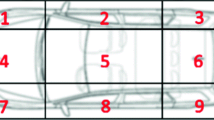

An industrial case study involving a European manufacturer of farm tractors is adopted to test and validate the proposed accessory clustering algorithm and ILP model for ALB (Fig. 4). The considered manufacturer proposes to its customers several product configurations. Indeed, every product can be highly customized by choosing multiple accessories.

The considered manufacturing system employs a multi-manned AL with 10 workstations due to facility layout constraints. The areas for component storage at each workstation are organized as Table 2 presents, specifying both the storage area length and depth. Furthermore, Fig. 5 proposes the layout of the considered AL, highlighting the workstations (in yellow) and the related storage areas (in red). Finally, the blue boxes represent the trolleys to store small and general-purpose components.

Concerning further case study information, cycle time is equal to 115 min (6900 s) to assure the productivity requested by the market. Table 3 presents task and accessory data presenting the number of assembly operations, the average total duration, the maximum total duration, average assembly duration for the tasks/accessories, and the average assembly frequency for accessories. In particular, this manufacturing process is distinguished by 105 tasks and 12 accessories.

Considering the presented data, the lower bound of the AL operators is equal to 15 due to a cycle time of 115 min and an average manufacturing product time equal to 1662.7 min.

Table 4 summarizes the relevant information referring to each task and accessory as assembly duration, assembly frequency, length, and depth of components to be assembled. Component size is equal to 0 if the related task/accessory involves the mounting of a small size component of negligible storage area occupancy. Detailed information for each task and accessory, both in terms of duration and frequency, are presented in Appendix 1, 2. Tables 9 and 10.

The aforementioned tasks and accessories have to be assembled in compliance with the technical precedencies. Such constraints are summarized through the precedence graph in Fig. 6. The presented graph adequately represents the complexity of real industrial ALBPs. Indeed, it is possible to notice that multiple tasks can be executed as first in the AL, and a significant number of tasks do not lead to further subsequent ones, e.g., they represent the final task of a portion of the precedence graph. Moreover, the proposed graph is distinguished by a relevant number of precedence constraints, which significantly increase the complexity of the targeted ALBP. Appendix 2 presents in detail all the precedence constraints for each pair of tasks/accessories.

Furthermore, in compliance with the working habits of the considered manufacturing system, parameter g is assumed equal to 1.15, corresponding to a maximum of 15% overload over the succeeding cycle times. Finally, \({\upvarepsilon }_{\mathrm{c}}\) is assumed equal to 1, since the number of accessories is lower than the operator’s number. The next section presents the results related to this case study considering the accessory clustering as well as the task and accessory assignment to operators and workstations.

7 Results and discussion

This section presents the manuscript results regarding both the accessory clustering and the AL balancing for the considered industrial case study. The clustering procedure exploits the customer order list and it leads to the accessory clustering definition. The proposed procedure leverages the UPGMA hierarchical algorithm to define the accessories dendrogram presented in Fig. 7. In particular, this figure presents the list of the accessories and their grouping into succeeding clusters distinguished by decreasing values of similarity index. The cutting value of 0.33 is adopted to define the final accessory clustering which leads to group the accessories in 4 clusters. This value has been chosen according to the case study features, as a proper trade-off between the cluster numerousness and the similarity of the belonging accessories. Indeed, higher cutting values would enable to assign to the same operator accessories which are likely to be requested by the same customer order, thus leading to an overload of the involved worker. On the contrary, cutting values lower than the one selected may force the assignment of certain cluster of accessories not to the same operator despite they are not often requested together by customer orders, thus leading to an AL unbalancing.

The accessory clusters enable to determine the parameter eic which is equal to 1 if the accessory i belongs to cluster c. Table 5 presents its values.

The definition of cluster enable to evaluate the clusters main information (Table 6), i.e., the data which are the input for ILP model, as number of accessories belonging to clusters, the average mounting duration, and the average mounting frequency of accessories belonging to the cluster.

Such cluster information along with eic represent the output of the accessory clustering algorithm and they are the inputs for ILP model, whose results are presented in the following.

Table 7 lists the tasks (in black) and the accessories (in red) assignment to the AL operators of the 10 workstations. The first row defines the operator’s ID, which is identified by the belonging workstation number. The letters A and B identify the operators within the same station. Thus, letter B is included only in workstations which involve two operators. The following rows present the tasks and the accessory IDs in the execution sequence planned for the operators. The proposed task and accessory sequences ensure the compliance with all ILP constraints.

The task and accessory execution determines the operator workload. Figure 8 presents the average operator workload, considering the different frequencies of the mounted accessories. Each graph bar represents how long the related operator has to work on average during the cycle time. The blue bars define the assembly time due to task mounting, which is always required. On the other hand, the red bars represent the average workload due to accessory mounting. Indeed, not all the operators have to assemble accessories. On average, the operator workload is equal to 6226 s, corresponding to an average time saturation greater than 90%, providing an excellent solution for the considered ALBP distinguished by a great efficiency in the workforce usage.

The aforementioned average workload considers the accessory mounting time weighted on the corresponding mounting frequency. Thus, the operator workload is greater if a product requires the assembly of all the available accessories. Table 8 presents the maximum operator workload, which corresponds to the workload considering the accessory mounting frequency equal to 1. The presented values have to be lower than the cycle time factor g, i.e., 6900∙1.15 = 7935 s, which is fulfilled by every operator of the considered case study.

A further crucial aspect of the proposed research concerns the component stocking in the storage areas along the AL. Indeed, each workstation has its own specific storage area, even if it involves two operators which should share it. Figure 9 presents the storage area saturation providing a comparison between the available and the required space in all the workstations. Furthermore, the area required by the components is determined by both tasks and accessories. Indeed, the accessory components need their storage area even if their mounting frequency is extremely low to ensure the availability of the related components when needed to be assembled for the customer orders requiring the related accessories. The case study results suggest how the storage area belonging to the first workstation is much larger than the one of the others. Indeed, the first tasks consist of the chassis and axles mounting, i.e., components which are large in size. The average storage area saturation is greater than 85%, which is a significant achievement. Furthermore, some areas reach their maximum saturation, i.e., 100%.

8 Conclusion and further research

This paper proposes an innovative procedure to balance ALs dedicated to customized products. The current market trends impose the companies to provide a wide range of product variants to their customers. The typical approach consists in the development of accessories which can be chosen or not by the customers to make the product suit with their own specific requests. Thus, the product assembly involves both task mounting, which is always performed, and accessories assembled if required by the customers.

The procedure presented in this manuscript to tackle such complex problem is composed of two succeeding steps. The first one deals with the accessory clustering. The clusters involve accessories which are typically requested together by customers and whose assembly requires a significant amount of time. A specific similarity index is developed to consider the aforementioned features leading to define a dendrogram and the related cut-off to cluster together with the accessories in the most appropriate sets.

The second procedure step, e.g., an original ILP model, leverages the cluster data to avoid operator overloads. Two or more accessories typically requested together by customers should be assigned to different AL operators to avoid their overload. Thus, the proposed ILP model aims to split the accessories belonging to the same cluster assigning them to different operators. This model defines task and accessory assignment to operators according to the technical precedencies as well as spatial and time constraints. Furthermore, it also provides task and accessory schedules over the cycle time for each operator, defining the assembly start time for all the mounting activities. The model objective function ensures sharing the overall workload properly between all the operators.

The overall procedure is tested and validated leveraging an industrial case study involving a farm tractor producer. The results suggest that the adoption of this procedure ensures an average operator usage rate greater than 90% avoiding structural overloads for them with a very efficient utilization of the workstation areas for component storage.

Further research should focus deeply on the product customization, for instance, proposing a one-step procedure that includes the accessory features directly in an optimization model with novel constraints. Moreover, an additional but relevant industry trend is related to customer requests which often change continuously. Thus, the product accessories may also change very often. For this reason, an evolution of the proposed ILP model could be considered to rebalance the AL considering the occurred modifications to the manufacturing system of interest.

Availability of data and material

All data generated or analyzed during this study are included in this published article.

Code availability

Not applicable.

Change history

20 July 2022

Missing Open Access funding information has been added in the Funding Note.

Abbreviations

- i, j = 1:

-

... I task or accessory

- k = 1:

-

... K assembly workstation

- w = 1:

-

... W workstation operator

- m = 1:

-

... CT time

- c = 1:

-

... C Cluster

- o = 1:

-

... O customer order

- ti :

-

assembly time of task/accessory i-th [s]

- fi :

-

order frequency of task/accessory i-th [ ]

- li :

-

physical length of task/component i-th [cm]

- di :

-

physical depth of task/component i-th [cm]

- TAc :

-

average assembly time of cluster c [s]

- FAc :

-

average order frequency of cluster c-th [ ]

- CT:

-

cycle time [s]

- MTij :

-

average mounting time parameter for accessories i-th and j-th [ ]

- lkk :

-

storage area length of workstation k-th [cm]

- dkk :

-

storage area depth of workstation k-th [cm]

- WM:

-

maximum number of operator belonging to the line

- g:

-

corrective parameter for cycle time

- nmc :

-

max theoretic number of accessories belong to cluster c-th, allocable to an operator

- \(\varepsilon_c\) :

-

corrective parameter for the allocable accessories belonging to cluster c-th.

- \(a_{ij}^o\) :

-

\(\left\{\begin{array}{l}1,\;\mathrm{if}\;\mathrm{order}\;\mathrm o\;\mathrm{requires}\;\mathrm{both}\;\mathrm{accessories}\;\mathrm i\;\mathrm{and}\;\mathrm j\\0,\;\mathrm{otherwise}\end{array}\right.\)

- \(b_{ij}^o\) :

-

\(\left\{\begin{array}{l}1,\;\mathrm{if}\;\mathrm{order}\;\mathrm o\;\mathrm{requires}\;\mathrm{only}\;1\;\mathrm{accessory}\;\mathrm{between}\;\mathrm i\;\mathrm{and}\;\mathrm j\\0,\;\mathrm{otherwise}\end{array}\right.\)

References

Jovane F, Koren Y, Boer CR (2003) Present and future of flexible automation: towards new paradigms. CIRP Ann 52(2):543–560

Wilson JM, McKinlay A (2010) Rethinking the assembly line: organisation, performance and productivity in Ford Motor Company, c. 1908–27. Bus Hist 52(5):760–778

Pine BJ (1991) Paradigm shift--from mass production to mass customization. Doctoral dissertation, Massachusetts Institute of Technology

Scott AJ (1988) Flexible production systems and regional development. Int J Urban Reg Res 12(2):171–186

Cohen Y, Naseraldin H, Chaudhuri A, Pilati F (2019) Assembly systems in Industry 4.0 era: a road map to understand Assembly 4.0. Int J Adv Manuf Syst 105(9):4037–4054

Dimitris M, Sophia F, Nikoletta B, Pietro P (2018) Product-service system (PSS) complexity metrics within mass customization and Industry 4.0 environment. Int J Adv Manuf Syst 97(1–4):91–103

Bortolini M, Faccio M, Gamberi M, Pilati F (2017) Multi-objective assembly line balancing considering component picking and ergonomic risk. Comput Ind Eng 112:348–367

Bortolini M, Ferrari E, Gamberi M, Pilati F, Faccio M (2017a) Assembly system design in the Industry 4.0 era: a general framework. IFAC-PapersOnLine 50(1):5700–5705

Meyr H (2009) Supply chain planning in the German automotive industry. In Supply Chain Planning. Springer, Berlin, Heidelberg, pp 1–23

Manavizadeh N, Rabbani M, Radmehr F (2015) A new multi-objective approach in order to balancing and sequencing U-shaped mixed model assembly line problem: a proposed heuristic algorithm. Int J Adv Manuf 79(1–4):415–425

Wang X, Wang Y, Tao F, Liu A (2021) New paradigm of data-driven smart customisation through digital twin. J Manuf Syst 58:270–280

Cevikcan E (2016) An optimization methodology for multi model walking-worker assembly systems: an application from busbar energy distribution systems. Assembly Automation

Kumar A, Pattanaik LN, Agrawal R (2019) Optimal sequence planning for multi-model reconfigurable assembly systems. Int J Adv Manuf 100(5–8):1719–1730

Saif U, Guan Z, Liu W, Wang B, Zhang C (2014) Multi-objective artificial bee colony algorithm for simultaneous sequencing and balancing of mixed model assembly line. Int J Adv Manuf 75(9–12):1809–1827

ElMaraghy H, Schuh G, ElMaraghy W, Piller F, Schönsleben P, Tseng M, Bernard A (2013) Product variety management Cirp Annals 62(2):629–652

Scholl A, Becker C (2006) State-of-the-art exact and heuristic solution procedures for simple assembly line balancing. Eur J Oper Res 168(3):666–693

van Zante-de Fokkert JI, de Kok TG (1997) The mixed and multi model line balancing problem: a comparison. Eur J Oper Res 100(3):399–412

Röder A, Tibken B (2006) A methodology for modeling inter-company supply chains and for evaluating a method of integrated product and process documentation. Eur J Oper Res 169(3):1010–1029

Boysen N, Fliedner M, Scholl A (2007) A classification of assembly line balancing problems. Eur J Oper Res 183(2):674–693

Boysen N, Fliedner M, Scholl A (2008) Assembly line balancing: which model to use when? Int J Prod Econ 111(2):509–528

Håkansson J, Skoog E, Eriksson KM, K. M. (2008) A review of assembly line balancing and sequencing including line layouts. Chalmers Technical University, Gothenburg, Sweden, In PLANs forsknings-och tillämpningskonferens

Uddin MK, Lastra JLM (2011) Assembly line balancing and sequencing. Assembly Line–Theory and Practice 13–36

Parello BD, Kabat WC, Wos L (1986) Job-shop scheduling using automated reasoning: a case study of the car sequencing problem. J Autom Reason 2(1986):1–42

Sabioni RC, Daaboul J, Le Duigou J (2021) An integrated approach to optimize the configuration of mass-customized products and reconfigurable manufacturing systems. Int J Adv Manuf 115:141–163

Weng W, Fujimura S (2012) Control methods for dynamic time-based manufacturing under customized product lead times. Eur J Oper Res 218(1):86–96

Lu RF, Petersen TD, Storch RL (2007) Modeling customized product configuration in large assembly manufacturing with supply-chain considerations. Int J Flex Manuf Syst 19(4):685–712

Otto A, Li X (2020) Product sequencing in multiple-piece-flow assembly lines. Omega 91:102055

Medbo L (2003) Assembly work execution and materials kit functionality in parallel flow assembly systems. Int J Ind Ergon 31(4):263–281

Faccio M, Cohen Y, Kilic HS, Durmusoglu MB (2015) Advances in assembly line parts feeding policies: a literature review. Assembly Automation

Zhou BH, Shen CY (2018) Multi-objective optimization of material delivery for mixed model assembly lines with energy consideration. J Clean Prod 192:293–305

Roshani A, Nezami FG (2017) Mixed-model multi-manned assembly line balancing problem: a mathematical model and a simulated annealing approach. Assembly Automation

Ferrari E, Faccio M, Gamberi M, Margelli S, Pilati F (2019) Multi-manned assembly line synchronization with compatible mounting positions, equipment sharing and workers cooperation. IFAC-PapersOnLine 52(13):1502–1507

Pilati F, Ferrari E, Gamberi M, Margelli S (2021) Multi-manned assembly line balancing: workforce synchronization for big data sets through simulated annealing. Appl Sci 11(6):2523

Murtagh F, Contreras P (2012) Algorithms for hierarchical clustering: an overview. Wiley Interdisciplinary Reviews: Data Mining and Knowledge Discovery 2(1):86–97

Amen M (2006) Cost-oriented assembly line balancing: model formulations, solution difficulty, upper and lower bounds. Eur J Oper Res 168(3):747–770

Esmaeilbeigi R, Naderi B, Charkhgard P (2015) The type E simple assembly line balancing problem: a mixed integer linear programming formulation. Comput Oper Res 64:168–177

Fattahi P, Roshani A, Roshani A (2011) A mathematical model and ant colony algorithm for multi-manned assembly line balancing problem. Int J Adv Manuf 53(1–4):363–378

Gualtieri L, Rauch E, Vidoni R (2021) Methodology for the definition of the optimal assembly cycle and calculation of the optimized assembly cycle time in human-robot collaborative assembly. Int J Adv Manuf 113(7):2369–2384

Hu SJ (2013) Evolving paradigms of manufacturing: from mass production to mass customization and personalization. Procedia Cirp 7:3–8

Kamrani A, Smadi H, Salhieh SM (2012) Two phase methodology for customized product design and manufacturing. J Manuf Technol Manag 23(3):370–401

Rosa C, Silva FJG, Ferreira LP, Campilho RDSG (2017) SMED methodology: the reduction of setup times for Steel Wire-Rope assembly lines in the automotive industry. Procedia Manufacturing 13:1034–1042

Salveson ME (1955) The assembly line balancing problem. J Ind Eng Int 6(3):18–25

Selvaraj P, Radhakrishnan P, Adithan M (2009) An integrated approach to design for manufacturing and assembly based on reduction of product development time and cost. Int J Adv Manuf 42(1–2):13–29

Solnon C, Nguyen A, Artigues C (2008) The car sequencing problem: overview of state-of-the-art methods and industrial case-study of the ROADEF, pp 912–927

Funding

Open access funding provided by Università degli Studi di Trento within the CRUI-CARE Agreement.

Author information

Authors and Affiliations

Contributions

Francesco Pilati: methodology, investigation, conceptualization, writing; Giovanni Lelli: formal analysis, validation, data curation, writing; Alberto Regattieri: resources, conceptualization, review, and editing; Emilio Ferrari: supervision.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix 1

Appendix 2

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Pilati, F., Lelli, G., Regattieri, A. et al. Assembly line balancing and activity scheduling for customised products manufacturing. Int J Adv Manuf Technol 120, 3925–3946 (2022). https://doi.org/10.1007/s00170-022-08953-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-08953-3