Abstract

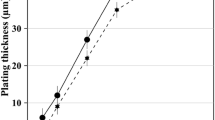

The improvement of working life is the main purpose of this paper to evaluate the mechanical properties of the electroless Ni–P coatings of radial micro journal bearings. The study was carried out using different plating parameter combinations, namely, pH values of the plating solution (6, 7, and 8), deposition time (10, 20, and 30 min), and bath temperature (60, 80, and 95 °C). The structure, surface morphology, hardness, and wear resistance of the electroless Ni–P coatings were measured and analyzed. The optimum combination of plating parameters for minimum wear is a pH value of 8, deposition time of 30 min, and bath temperature of 95 °C. When the Ni–P film is annealed at 400 °C, the hardness, wear and surface roughness can get the best values of 960 HV, 0.1 mg, and 0.177 μm, respectively, and this is because the Ni–P coating has changed from an amorphous phase to a crystalline composite phase (Ni + Ni3P) structure. However, as the annealing temperature continues to increase; the hardness, wear, and surface roughness begin to deteriorate. The coherent relationship of the crystalline composite phase is broken, the grains of the Ni–P coating will grow, and the tensile stress of the Ni–P coating will increase.

Similar content being viewed by others

Data availability

All necessary data is shown in the figures and tables within the document. The raw data can be made available upon request.

Code availability

Not applicable.

References

Mallory GO, Hajdu JB (1990) Electroless coating: fundamentals and applications. American Electroplaters and Surface Finishers Society

Goldenstein AW, Rostoker W, Schossberger F (1957) Structure of chemically deposited nickel. J Electrochem Soc 104(2):104–110

Gutzeit G (1981) On the mechanism of electroless coating II: One mechanism for different reductants plating. J Appl Electrochem 11(3):395–400

Park SH, Lee DN (1988) A study on the microstructure and phase transformation of electroless nickel deposits. Mater Sci 23(5):1643–1654

Jones RH, Danielson MJ, Bear DR (1986) Role of segregated P and S in intergranular stress corrosion cracking of Ni. Materials for Energy Systems 8(2):185–196

Bai CN, Liang AM, Cao ZY, Qiang L, Zhang JY (2018) Achieving a high adhesion and excellent wear resistance diamond-like carbon film coated on NBR rubber by Ar plasma pretreatment. Diam Relat Mater 89:84–93

Hsu RC, Huang CH, Yu MS (2018) Mechanical and fatigue properties of electro-less Ni-P coating on brass substrates by plasma-etched pretreatment. Int J Fatigue 112:63–69

Czagány M, Baumli P, Kaptay G (2017) The influence of the phosphorous content and heat treatment on the nano-micro-structure, thickness and micro-hardness of electroless Ni-P coatings on steel. Appl Surf Sci 423:160–169

Umapathi D, Devaraju A, Rathinasuriyan C, Raji A (2020) Mechanical and tribological properties of electroless nickel phosphorous and nickel phosphorous-titanium nitride coating. Mater Today: Proc 22(3):1038–1042

Salicio-Paz A, Dalmau A, Grande H, Iriarte A, Sort J, Pellicer E, Fornell J, García-Lecina E (2020) Impact of the multilayer approach on the tribocorrosion behaviour of nanocrystalline electroless nickel coatings obtained by different plating modes. Wear 456–457:203384

Tima R, Mahboubi F (2021) Ability of plasma nitriding to improve tribological behavior of medium and high boron electroless nickel coatings. Tribol Int 156:106822

Allen RM, Vander Sande JB (1982) The structure of electroless Ni-P films as a function of composition. Scripta Metallurgica 16(10):1161–1164

Huang HC, Chung ST, Pan SJ, Tsai WT, Lin CS (2010) Microstructure evolution and hardening mechanisms of Ni-P electrodeposits. Surf Coat Technol 205:2097–2103

Acknowledgements

The authors gratefully acknowledge the support of the Ministry of Science and Technology of the Republic of China, through Grant nos. MOST 109-2221-E-262-003.

Funding

The authors appreciate the financial support of the Ministry of Science and Technology of the Republic of China (MOST 109–2221-E-262–003).

Author information

Authors and Affiliations

Contributions

JinYi Kao: conceptualization, experimentation, characterization, validation, analysis, writing-original draft.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Consent to participate

Not applicable.

Consent to publish

Not applicable.

Conflict of interest

The author declares no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kao, JY. Improvement in the working life of a micro journal bearings with an electroless Ni–P coating. Int J Adv Manuf Technol 119, 7487–7502 (2022). https://doi.org/10.1007/s00170-022-08699-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-08699-y