Abstract

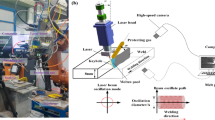

The welding solidification crack is a common welding defect occurring in the narrow gap laser welded high-strength steel joint, which poses a detrimental effect in reducing the weld quality. However, the relationship between the weld geometric characteristics and the metallurgical characteristics with the solidification crack of the narrow gap laser weld is still unclear. In this study, a 20-mm-thick 10Ni5CrMoV high-strength steel with a root gap of 3 mm and groove angle of 1º was used to analyze the single-pass welding process of narrow gap laser welding using high-frequency beam oscillation. The correlation between the weld form factor and the welding solidification crack was discussed, alongside with the clarification on the influence of the welding process parameter on the welding solidification crack, the aim of which was to analyze the causes for the formation of welding solidification crack and explore the effective ways to suppress it. The results showed that the influence of welding process parameters on welding solidification crack could be attributed to change in the form factor of the weld and weld metal solidification crystallization characteristics. The smaller the weld form factor, the larger the area of the opposite crystal growth in the upper part of the weld cross section, and the higher the tendency toward solidification crack formation. Furthermore, the higher welding speed was also likely to have columnar grains with a larger angle of crystallization direction with the centerline. This resulted in a higher tendency of solidification crack formation. Under the test conditions used in this study, a weld form factor φ = 0.8 was considered effective for controlling welding solidification crack.

Similar content being viewed by others

Data availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also form part of an ongoing study.

Code availability

Not applicable.

References

Btuler CA, Meister RP, Randall MD (1969) Narrow gap welding. Weld J 48(2):102–108

Zhang X, Ashida E, Tarasawa S, Anma Y, Okada M, Katayama S, Mizutani M (2011) Welding of thick stainless steel plates up to 50 mm with high brightness lasers. J Laser Appl 23(2):1–7

Tommi J, Veli K (2003) High power Nd:YAG laser welding in manufacturing of vacuum vessel of fusion reactor. Fusion Eng Des 69(1–4):349–353

Zhang GW, Xiao RS (2014) Microstructure and mechanical properties of 5083 aluminum alloy joint of heavy section by ultra-narrow gap fiber laser beam welding. Chin J Lasers 41(09):108–114

Hu LH, Huang J, Li ZG, Wu YX (2009) Microstructure and properties of high power CO2 laser welded pipeline steel. Chin J Lasers 36(12):3174–3178

Li LQ, Tao W, Zhu XL (2009) Wire filling laser multilayer welding of high strength steel thick plate. Chin J Lasers 36(5):1251–1255

Wu S, Zou J, Xiao R, Zhang G (2016) Ultra-narrow-groove laser welding for heavy sections in ITER. Weld Journal 95:300–308

Ramakrishna R, Amrutha P, Rahman Rashid RA, Palanisamy S (2020) Narrow gap laser welding (NGLW) of structural steels-a technological review and future research recommendations. Int J Adv Manuf Technol 111(7–8):2277–2300

Zhao Y, Ma SC, Huang J, Wu YX (2017) Narrow-gap laser welding using filler wire of thick steel plates. Int J Adv Manuf Technol 93(5–8):2955–2962

Elmesalamy AS, Li L, Francis JA, Sezer HK (2013) Understanding the process parameter interactions in multiple-pass ultra-narrow gap laser welding of thick-section stainless steels. Int J Adv Manuf Technol 68(1–4):1–17

Xie YFS, Huang J, Wang W, Wang H, Hua XM (2017) Ultra-narrow gap laser wire filling welding forming defects of 5083 aluminum alloy thick plate. Chin J Lasers 44(03):112–118

Cao H, Lei Z, Huang RS, Meng SH, Liang XM (2019) Effects of laser swing welding parameters on porosity and weld formation of high strength steel. Welding and joining 04:39–43

Onozuka M, Alfile JP, Aubert P, Dagenais JF, Grebennikov D, Ioki K, Jones L, Koizumi K, Krylov V, Maslakowski J (2001) Manufacturing and maintenance technologies developed for a thick-wall structure of the ITER vacuum vessel. Fusion Eng Des 55(4):397–410

Huang Z, Cai Y, Mu WD, Li YZ (2018) Effects of process parameters of narrow gap laser welding with filler wire on weld formation of 9%Ni steel. Hot Working Technology 47(19):25–29

Phaoniam R, Shinozaki K, Yamamoto M, Kadoi K, Nishijima A, Yamamoto M (2014) Solidification cracking susceptibility of modified 9Cr1Mo steel weld metal during hot-wire laser welding with a narrow gap groove. Weld in the World 58(4):469–476

Gong L, Zhu L, Zhou C (2016) Effects of welding parameters on ultra-narrow gap welding hot cracking. Transactions of the China Welding Institution 37(10):93–96

Feng JC, Guo W, Francis J, Irvine N, Li L (2016) Narrow gap laser welding for potential nuclear pressure vessel manufacture. J Laser Appl 28(2):022421(1–6).

Todo M, Shinozaki K, Yamamoto M, Kadoi K, Yamamoto M, Phaonaim R, Okagaito T (2015) Hot-wire laser welding process using laser diode for large-diameter pipe with narrow gap joint. Quarterly Journal of the Japan Welding Society 33(2):107–110

Tsukamoto T, Kawanaka H, Maeda Y (2011) Laser narrow gap welding of thick carbon steels using high brightness laser with beam oscillation. In: 30th International Congress on Applications of Lasers and Electro-Optics. ICALEO 2011, Orlando, pp 141–146

Dong DS, Jia XS, Mei X (2010) Analysis for the hot cracking of thick plate of JEF-HITEN780S high strength steel in multi-layer welding simulation based on ANSYS. Heavy Casting and Forging 4:10–13

Dittrich D, Schedewy R, Brenner B, Standfuss J (2013) Laser-multi-pass-narrow gap-welding of hot crack sensitive thick aluminum plates. IWLTC 2013:225–233

Onozuka M, Ioki K, Sannazzaro G, Utin Y, Yoshimura H (2001) Design and thermal hydraulic characteristics of the ITER-FEAT vacuum vessel. Fusion Eng Des 58(11):857–861

Zhang J, Liu HF (2015) Causes of welding thermal cracks in 0Cr25Ni20 austenitic stainless steel and preventive measures. MW Metal Forming 12:49–51

Gao H, Agarwal G, Amirthalingam M, Hermans MJM (2017) Hot cracking investigation during laser welding of high-strength steels with multi-scale modelling approach. Science and Technology of Welding and Joining 23(4):287–294

Xu W, Westerbaan D, Nayak SS, Chen DL, Goodwin F, Biro E, Zhou Y (2012) Microstructure and fatigue performance of single and multiple linear fiber laser welded DP980 dual-phase steel. Mater Sci Eng 553(36):51–58

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (No. 51975137).

Author information

Authors and Affiliations

Contributions

Zhen Lei contributed to methodology, investigation, writing—original draft, and writing—review and editing. Hao Cao helped in methodology, investigation, and writing—review and editing. Xiufang Cui contributed to resources, supervision, writing—review and editing, and funding acquisition. Guo Jin and Ruisheng Huang contributed to methodology and writing—review and editing. Kaixin Xu and Bao Jiang investigated the study.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Consent to participate

Informed consent was obtained from all individual participants included in the study.

Consent for publication

The participant has consented to the submission of the case report to the journal.

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lei, Z., Cao, H., Cui, X. et al. Analysis of welding solidification crack in narrow gap laser welding of high-strength steel. Int J Adv Manuf Technol 119, 4177–4190 (2022). https://doi.org/10.1007/s00170-022-08659-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-08659-6