Abstract

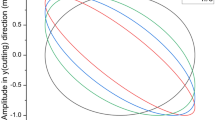

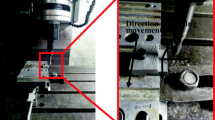

The SiC particle-reinforced aluminum matrix composites (MMCs) possess a low machinability due to their evident hardness difference. The underlying cutting mechanism is investigated in ultrasonic vibration cutting (UVC) of SiC/Al by finite element analysis, underlining its dependence on employed vibration parameters. Simulated results indicate that the high frequency in the x- and y-direction ultrasonic vibration leads to the reducing time-averaged cutting force and cutting temperature at the tool tip. Nevertheless, the large amplitude in the unidirectional ultrasonic vibration results in a reduce of the time-averaged cutting force and an increase of the time-averaged cutting temperature. It is also found that the maximal cutting temperature located at the tool tip shows a similar trend to the time-averaged cutting temperature with variation of ultrasonic vibration parameters. Corresponding experiments of UVC and conventional machining using the identical machining and material parameters to the FE simulations are also conducted to validate the present finite element model.

Similar content being viewed by others

Availability of data and materials

The data and materials that support the findings of this study are available from the corresponding author upon reasonable request.

References

Dabade UA, Joshi SS, Balasubramaniam R, Bhanuprasad VV (2007) Surface finish and integrity of machined surfaces on Al/SiCp composites. J Mater Process Technol 192:166–174

Sahin Y (2003) Preparation and some properties of SiC particle reinforced aluminium alloy composites. Mater Des 24(8):671–679

Teng X, Chen W, Huo D, Shyha I, Lin C (2018) Comparison of cutting mechanism when machining micro and nano- particles reinforced SiC/Al metal matrix composites. Compos Struct 203(11):636–647

Wang Y, Liao W, Yang K, Chen W, Liu T (2018) Investigation on cutting mechanism of SiCp/Al composites in precision turning. Adv Manuf Technol 100:963–972

Kishawy HA, Ghandehariun A, Hussein HM, Umer U (2016) On tool-workpiece interactions during machining metal matrix composites: investigation of the effect of cutting speed. Int J Adv Manuf Technol 84(9):2423–2435

Liu J, Cheng K, Ding H, Chen S, Zhao L (2017) Simulation study of the influence of cutting speed and tool-particle interaction location on surface formation mechanism in micromachining SiCp/Al composites. P I Mech Eng C-J Mec 232(11):1–13

Ghandehariun A, Kishawy HA, Umer U, Hussein HM (2016) Analysis of tool-particle interactions during cutting process of metal matrix composites. Int J Adv Manuf Technol 82:143–152

Umer U, Kishawy H, Ghandehariun A, Xie L, Al-Ahmari A (2017) On modeling tool performance while machining aluminum-based metal matrix composites. Int J Adv Manuf Tech 104(8):1–12

Xiong H, Dz B, Ge S (2020) Review on current situation and development trend for ultrasonic vibration cutting technology. Mater Today 1–12

Yang Z, Zhu L, Zhang G, Ni C, Lin B (2020) Review of ultrasonic vibration-assisted machining in advanced materials. Int J Tool Manu 156:103594

Zhang J, Zhang J, Cui T, Hao Z, Zahrani AA (2017) Sculpturing of single crystal silicon microstructures by elliptical vibration cutting. J Manuf Process 29:389–398

Zhang J, Suzuki N, Wang Y, Shamoto E (2014) Fundamental investigation of ultra-precision ductile machining of tungsten carbide by applying elliptical vibration cutting with single crystal diamond. J Mater Proces Tech 214:2644–2659

Wang J, Fang F, Yan G, Guo Y (2019) Study on diamond cutting of ion implanted tungsten carbide with and without ultrasonic vibration. Nanomanufacturing and Metrology 2:177–185

Nestler A, Schubert A (2014) Surface properties in ultrasonic vibration assisted turning of particle reinforced aluminium matrix composites. Procedia CIRP 13:125–130

Luo H, Wang Y, Zhang P (2020) Effect of cutting and vibration parameters on the cutting performance of 7075–T651 aluminum alloy by ultrasonic vibration. Int J Adv Manuf Tech 107(7):1–14

Pei L, Wu H (2019) Effect of ultrasonic vibration on ultraprecision diamond turning of Ti6Al4V. Int J Adv Manuf Technol 103:433–440

Nath C, Rahman M (2008) Effect of machining parameters in ultrasonic vibration cutting. Int J Mach Tool Manuf 48:965–974

Peng Z, Zhang D, Zhang X (2020) Chatter stability and precision during high-speed ultrasonic vibration cutting of a thin-walled titanium cylinder. Chinese J Aeronaut 1486:1–15

Lu Z, Zhang D, Zhang X, Peng Z (2020) Effects of high-pressure coolant on cutting performance of high-speed ultrasonic vibration cutting titanium alloy. J Mater Process Technol 279:116584

Guo B, Zhao Q (2017) Ultrasonic vibration assisted grinding of hard and brittle linear micro-structured surfaces. Precis Eng 48:98–106

Dai H, Du H, Chen J, Chen G (2019) Influence of elliptical vibration on the behavior of silicon during nanocutting. Int J Adv Manuf Technol 102:3597–3612

Mohammad L, Javad A (2021) Finite element simulation of ultrasonic-assisted machining: a review. Int J Adv Manuf Tech 116(3):1–20

Bai W, Sun R, Leopold J, Silberschmidt VV (2017) Microstructural evolution of Ti6Al4V in ultrasonically assisted cutting: numerical modelling and experimental analysis. Ultrasonics 78:70–82

He Y, Zou P, Zhu W, Ehmann KF (2017) Ultrasonic elliptical vibration cutting of hard materials: simulation and experimental study. Int J Adv Manuf Technol 91(1–4):363–374

Lotfi M, Amini S (2018) FE simulation of linear and elliptical ultrasonic vibrations in turning of Inconel 718. Proc Inst Mech Eng Part E: J Process Mech Eng 232(4):438–448

Lotfi M, Amini S (2017) Experimental and numerical study of ultrasonically-assisted drilling. Ultrasonics 75:185–193

Paktinat H, Amini S (2017) Ultrasonic assistance in drilling: FEM analysis and experimental approaches. Int J Adv Manuf Tech 92(5–8):2653–2665

Ying N, Feng J, Bo Z (2020) A novel 3D finite element simulation method for longitudinal-torsional ultrasonic-assisted milling. Int J Adv Manuf Technol 106(1–2):385–400

Chen W, Zheng L, Teng X, Yang K, Huo D (2019) Finite element simulation and experimental investigation on cutting mechanism in vibration-assisted micro-milling

Lotfi M, Amini S, Aghaei M (2018) 3D FEM simulation of tool wear in ultrasonic assisted rotary turning. Ultrasonics 88:106

Lotfi M, Amini S, Aghaei M (2018) Tool wear modeling in rotary turning modified by ultrasonic vibration. Simul Model Pract Theory 87:226–238

Zhang J, Han L, Zhang J, Liu H, Yan Y, Sun T (2019) Brittle-to-ductile transition in elliptical vibration-assisted diamond cutting of reaction-bonded silicon carbide. J Manuf Process 45:670–681

Han L, Zhang J, Chen J, Zhang J, Liu H, Yan Y, Sun T (2020) Influence of vibration parameters on ultrasonic elliptical vibration cutting of reaction-bonded silicon carbide. Int J Adv Manuf Tech 107(10):1–12

Ducobu F, Rivière-Lorphèvre E, Filippi E (2017) On the importance of the choice of the parameters of the Johnson-cook constitutive model and their influence on the results of a ti6al4v orthogonal cutting model. Int J Mech Sci 122:143–155

Tursun G, Weber U, Soppa E, Schmauder S (2006) The influence of transition phases on the damage behaviour of an Al/10vol.% SiC composite. Comp Mater Sci 37(1–2):119–133

Camamho PP, Davila CG (2002) Mixed-mode decohesion finite elements for the simulation of delamination in composite materials, NASA/TM-2002–211737

Canal LP, Segurado J, Llorca J (2009) Failure surface of epoxy-modified fiber-reinforced composites under transverse tension and out-of-plane shear. Int J Solids Struct 46(11):2265–2274

Dandekar CR (2010) Multi-scale modeling and laser-assisted machining of metal matrix composites. Dissertation, Purdue University

Tao ZH (2002) Friction analysis and modelling in metal cutting processes at elevated temperatures. Dissertation, University of Pittsburgh

Funding

This study was supported by the National Natural Science Foundation of China (Grant No. 51675144), and the Natural Science Foundation of Heilongjiang Province (Grant No. LH2020E064). national natural science foundation of china,No. 51675144,Xiaoyan Teng,Heilongjiang Provincial Science and Technology Department,No.LH2020E064,Xiaoyan Teng

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethics approval

Complied with ethical standards.

Consent to participate and consent to publish

All authors agree to contribute and publish the article.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jiang, X., Xiao, D. & Teng, X. Influence of vibration parameters on ultrasonic vibration cutting micro-particles reinforced SiC/Al metal matrix composites. Int J Adv Manuf Technol 119, 6057–6071 (2022). https://doi.org/10.1007/s00170-021-08525-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-08525-x