Abstract

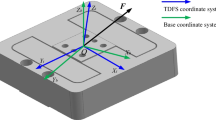

The posture adjustment mechanism (PAM) for large components of aircraft is composed of several numerical control positioners (NCPs). This paper proposes a self-calibration method of positioner to guarantee the accuracy of posture alignment. Firstly, the redundant axis of the PAM is controlled by force feedback to obtain additional joint trajectory information, and the ball joint center (BJC) position is calculated by the spatial circle fitting method. Secondly, the coordinates of the BJC in the base coordinate system and the positioner coordinate system are registered to obtain the position and posture parameters between the positioners. Thirdly, the main factors affecting the calibration accuracy are studied, and the uncertainty of positioner calibration is analyzed by Monte Carlo simulation. Finally, a simulated posture adjustment system of large components is built, and two methods are used to calibrate the positioner. The posture adjustment experiment results show that compared with the conventional calibration method, the proposed calibration method can improve the posture alignment accuracy and significantly reduce the interaction force between the positioners.

Similar content being viewed by others

Availability of data and material

All data generated or analyzed during this study are included in this published article.

References

Mei Z, Maropoulos PG (2014) Review of the application of flexible, measurement-assisted assembly technology in aircraft manufacturing. Proc Inst Mech Eng Part B J Eng Manuf 228(10):1185–1197. https://doi.org/10.1177/0954405413517387

Wu D, Du F (2018) A new method of precise orientation adjustment based on matrix similarity for large-scale component. Assem Autom 38(2):207–215. https://doi.org/10.1108/AA-01-2017-010

Li Y, Zhang L, Wang Y (2017) An optimal method of posture adjustment in aircraft fuselage joining assembly with engineering constraints. Chin J Aeronaut 30(6):2016–2023. https://doi.org/10.1016/j.cja.2017.05.006

Webb P, Eastwood S, Jayaweera N, Chen Y (2005) Automated aerostructure assembly. Ind Robot 32(5):383–387. https://doi.org/10.1108/01439910510614646

Jayaweera N, Webb P (2007) Automated assembly of fuselage skin panels. Assem Autom 27(4):343–355. https://doi.org/10.1108/01445150710827122

Zhang B, Yao B, Ke Y (2009) A novel posture alignment system for aircraft wing assembly. J Zhejiang Univ Sci A 10:1624–1630. https://doi.org/10.1631/jzus.A0820777

Tang W, Li Y, Yu J, Zhang J, Sun Y (2013) A posture evaluation method for aircraft wing based on a simple measurement system. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture 227(4):627–630. https://doi.org/10.1177/0954405412474248

Deng Z, Li S, Huang X (2018) Uncertainties evaluation of coordinate transformation parameters in the large-scale measurement for aircraft assembly. Sens Rev 38(4):542–550. https://doi.org/10.1108/SR-08-2017-0150

Peng G, Ji M, Xue Y, Sun Y (2021) Development of a novel integrated automated assembly system for large volume components in outdoor environment. Measurement 168. https://doi.org/10.1016/j.measurement.2020.108294

Eastwood SJ, Webb P, McKeown C (2003) The use of the TI2 manufacturing system on a double-curvature aerospace panel. Proc Inst Mech Eng Part B J Eng Manuf 217(6):849–855. https://doi.org/10.1243/09544050360673224

Edmondson N, Redford A (2002) Generic flexible assembly system design. Assem Autom 22(2):139–152. https://doi.org/10.1108/01445150210423189

Liu H, Zhu W, Dong H, Ke Y (2019) An adaptive ball-head positioning visual servoing method for aircraft digital assembly. Assem Autom 39(2):287–296. https://doi.org/10.1108/AA-05-2018-066

Chu W, Huang X, Li S, Lou P (2021) A ball head positioning method based on hybrid force-position control. Proc Inst Mech Eng Part I J Syst Control Eng 235(8):1433–1444. https://doi.org/10.1177/0959651820987903

Williams G, Chalupa E, Rahhal S (2000) Automated positioning and alignment systems. SAE Technical Paper 2000–01–3014. https://doi.org/10.4271/2000-01-3014

Zhang H, Yang D, Yang K, Guo L, Tan J (2014) Posture alignment and finishing system for aircraft wing. Appl Mech Mater 644–650:4956–4959. https://doi.org/10.4028/www.scientific.net/AMM.644-650.4956

Walker L, Freeman R, Marcus S (1991) Analysis of motion and internal loading of objects grasped by multiple cooperating manipulators. Int J Robot Res 10(4):396–409. https://doi.org/10.1177/027836499101000408

Suryohadiprojo H (1990) Study of the error correction procedure in robot calibration. Proc IEEE Int Conf Robot Autom 291–296. https://doi.org/10.1109/ROBOT.1990.125989

Veitschegger W, Wu C (1988) Robot calibration and compensation. IEEE J Robot Autom 4(6):643–656. https://doi.org/10.1109/56.9302

Gang C, Tong L, Ming C, Xuan J, Xu S (2014) Review on kinematics calibration technology of serial robots. Int J Precis Eng Manuf 15:1759–1774. https://doi.org/10.1007/s12541-014-0528-1

Li S, Chen L, Huang X, Fang W (2012) A measuring tool for sphere hinge center position of follow-up positioner. CN102313516A (CN Patent)

Chen L, Huang X, Ma Z, Li S (2016) Kinematic calibration of asymmetricly actuated 6-DOF 3-PPPS parallel mechanism. Trans Nanjing Univ Aeronaut Astronaut 33(3):294–300. https://doi.org/10.16356/j.1005-1120.2016.03.294

Deng Z, Huang X, Li S, Xing H (2019) On-line calibration and uncertainties evaluation of spherical joint positions on large aircraft component for zero-clearance posture alignment. Robot Comput Integr Manuf 56:38–54. https://doi.org/10.1016/j.rcim.2018.07.016

Zhu Y, Huang X, Fang W, Li S (2010) Trajectory planning algorithm based on quaternion for 6-DOF aircraft wing automatic position and pose adjustment method. Chin J Aeronaut 23(6):707–714. https://doi.org/10.1016/S1000-9361(09)60273-9

Chakarov D (2004) Study of the antagonistic stiffness of parallel manipulators with actuation redundancy. Mech Mach Theory 39(6):583–601. https://doi.org/10.1016/j.mechmachtheory.2003.12.001

Lee S, Lee J, Yi B, Kim S, Kwak Y (2005) Optimization and experimental verification for the antagonistic stiffness in redundantly actuated mechanisms: a five-bar example. Mechatronics 15(2):213–238. https://doi.org/10.1016/j.mechatronics.2004.07.008

Chu W, Huang X, Li S (2021) A calibration method of redundant actuated parallel mechanism for posture adjustment. Ind Robot 48(4):494–509. https://doi.org/10.1108/IR-11-2020-0251

Roth Z, Mooring B, Ravani B (1987) An overview of robot calibration. IEEE J Robot Autom 3(5):377–385. https://doi.org/10.1016/j.mechatronics.2004.07.008

Zhang D, Maropoulos P, Hill M (2006) Random uncertainty propagation in estimates of sphere parameters from coordinate measurements. Int J Mach Tools Manuf 46(12–13):1362–1368. https://doi.org/10.1016/j.ijmachtools.2005.10.008

Alici G, Shirinzadeh B (2005) A systematic technique to estimate positioning errors for robot accuracy improvement using laser interferometry based sensing. Mech Mach Theory 40(8):879–906. https://doi.org/10.1016/j.mechmachtheory.2004.12.012

Hervé J (1999) The Lie group of rigid body displacements, a fundamental tool for mechanism design. Mech Mach Theory 34(5):719–730. https://doi.org/10.1016/S0094-114X(98)00051-2

Arun K, Huang T, Blostein S (1987) Least-squares fitting of two 3-D point sets. IEEE Trans Pattern Anal Mach Intell 9(5):698–700. https://doi.org/10.1109/TPAMI.1987.4767965

Horn BKP (1988) Closed-form solution of absolute orientation using unit quaternions. J Opt Soc Am A 4(4):629–642. https://doi.org/10.1364/JOSAA.4.000629

Handschin JE (1970) Monte Carlo techniques for prediction and filtering of non-linear stochastic processes. Automatica 6(4):555–563. https://doi.org/10.1016/0005-1098(70)90010-5

Chu W, Huang X, Li S (2020) Cabin posture adjustment method based on redundant constrained parallel mechanism. Assem Autom 40(3):377–386. https://doi.org/10.1108/AA-07-2019-0140

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Consent to participate

Not applicable.

Consent for publication

All the authors listed approved the publication of the manuscript.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chu, W., Huang, X. Self-calibration method of NC positioner for posture adjustment. Int J Adv Manuf Technol 119, 7669–7683 (2022). https://doi.org/10.1007/s00170-021-08514-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-08514-0