Abstract

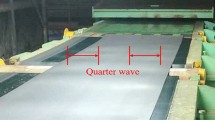

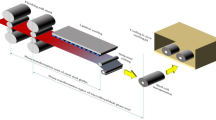

The quarter-wave defect seriously affected the quality of cold rolling products, especially in DP980 dual-phase steel production. The study is the first attempt to use a material model with transverse mechanical properties difference to explore the generation mechanism of DP980 cold rolling quarter-wave. The piecewise function was used to establish a new deformation resistance model of the strip. By this model, the mechanical property can be described in an arbitrary position. A 6-high Universal Crown Control Mill (UCM Mill) implicit FEM model, coupled with the new deformation resistance model was used to complete the research. Analysis based on the simulation results found that the thickness difference between simulation and measure data could be affected by the accuracy of the material model. Based on the multi-stand simulation results, a “local thickness drop” defect was found at 120 mm from the edge of the S3 stand. Through further research of three paths in the elastic–plastic deformation zone of stand S3, it is found that the yield strength (YS) growth rate at 120 mm away from the strip edge is much higher than other locations, which promotes the generation of high-order bending on the work roll surface and lead to the quarter-wave.

Similar content being viewed by others

Availability of data and material

The authors confirm that the data and material supporting the findings of this work are available within the article.

References

Tang D, Jiang HT, Mi ZL, Zhao AM (2010) Research and development history of cold rolled steel for automobile and its current applications situation and development trend at home [J]. Angang Technology 1

Yang G, Xia QX, Qiu ZW, Ye FY (2012) Applications of high strength steel in automobile and the research status of stamping forming properties [J]. Modern Manufacturing Engineering 7

Hance BM (2018) Advanced high-strength steel (AHSS) performance level definitions and targets SAE International. Journal of Materials and Manufacturing 11(4)505−516. https://doi.org/10.4271/2018-01-0629

Lesch C, Kwiaton N, Klose FB (2017) Advanced high strength steels (AHSS) for automotive applications− tailored properties by smart microstructural adjustments. Steel Res Int 88(10):1700210. https://doi.org/10.1002/srin.201700210

Liu XH, Shi X, Li SQ, Wang GD (2007) FEM analysis of rolling pressure along strip width in cold rolling process. J Iron Steel Res Int 14(5):22−26. https://doi.org/10.1016/S1006-706X(07)60068-5

Linghu K, Jiang ZY, Zhao JW, Li F, Wei DB, Xu JZ, Zhang XM, Zhao XM (2014) 3D FEM analysis of strip shape during multi-pass rolling in a 6-high CVC cold rolling mill. Int J Adv Manuf Technol 74(9–12)1733–1745. https://doi.org/10.1007/s00170-014-6069-z

Ma X, Ma JY, Feng ZL, Cui LH, Yang Y, Li YT, Zhang J, Ding YD, LI JP (2012) Finite element simulation of Biting Process of cold rolling strip for 6-high mill. In Materials Science Forum. Trans Tech Publications Ltd 704:203–209. https://doi.org/10.1016/j.jmapro.2018.07.008

Wang QL, Sun J, Li X, Liu YM, Wang PF, Zhang DH (2017a) Numerical and experimental analysis of strip cross-directional control and flatness prediction for UCM cold rolling mill. J Manuf Process 34:637–649. https://doi.org/10.1002/srin.201700454

Wang QL, Li X, Hu YJ, Sun J, Zhang DH (2017b) Numerical analysis of intermediate roll shifting–induced rigidity characteristics of UCM cold rolling mill. Steel Res Int 89(5):1700454 https://doi.org/10.1002/srin.201700454

Moazeni B, Salimi M (2015) Investigations on relations between shape defects and thickness profile variations in thin flat rolling. Int J Adv Manuf Tech 77(5–8):1315–1331. https://doi.org/10.1007/s00170-014-6544-6

Wang XC, Yang Q, He HN, Sun YZ, Xu D, Liu Y (2020) Effect of work roll shifting control on edge drop for 6-hi tandem cold mills based on finite element method model. Int J Adv Manuf Technol 10(5–6):249–2511. https://doi.org/10.1007/s00170-020-05160-w

Kainz AJ, Widder ME, Zeman K (2013) Enhanced strip-roll coupling concepts for the numerical simulation of flat hot rolling. Acta Mech 224(5)957–983. https://doi.org/10.1007/s00707-012-0795-9

Abdelkhalek S, Montmitonnet P, Potier-Ferry M, Zahrouni H, Legrand N, Buessler P (2010) Strip flatness modelling including buckling phenomena during thin strip cold rolling. Ironmaking Steelmaking 37(4):290–297. https://doi.org/10.1179/030192310X12646889255708

Lee JK, Kang KB, Lee KJ, Lee PJ, Lee JD (1998) Modelling of the microstructure and the mechanical property variation across the transverse direction of hot rolled steels and the effect of edge shielding. ISIJ Int 38(7):752–758. https://doi.org/10.2355/isijinternational.38.752

Poliak EI, Pottore NS, Skolly RM, Umlauf WP, Brannbacka JC (2009) Thermomechanical processing of advanced high strength steels in production hot strip rolling. la metallurgia italiana. https://doi.org/10.2320/matertrans.MRP2008389

Kaputkina LM, Marmulev AV, Poliak EI, Herman G (2013) Effect of coil cooling conditions on microstructural and mechanical properties uniformity of flat hot rolled. AHSS Met Sci Heat Treat 54(11):628–632. https://doi.org/10.1007/s11041-013-9561-4

Jacolot R, Huin D, Marmulev A, Mathey E (2014) Hot rolled coil property heterogeneities due to coil cooling: impact and prediction. In Key Engineering Materials. Trans Tech Publications Ltd 622:919–928. https://doi.org/10.4028/www.scientific.net/KEM.622-623.919

Ilmola J, Pohjonen A, Koskenniska S, Seppälä O, Leinonen O, Jokisaari J, Pyykkönen J, Larkiola J (2021) Coupled heat transfer and phase transformations of dual-phase steel in coil cooling. Materials Today Communications 26:101973. https://doi.org/10.1016/j.mtcomm.2020.101973

Funding

This work was financially supported by the National Natural Science Foundation of China (Grant No.52004029).

Author information

Authors and Affiliations

Contributions

Luzhen Chen analyzed the simulation and experimental data, completed the draft; Wenquan Sun provide the simulation idea, organized experiment; Anrui He instructed the revision of the draft; Chao Liu helped to verify the accuracy of the FEM model; Yi Qiang provided constructive suggestions on experiments.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

This work is approved by all authors for publication.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chen, L., Sun, W., He, A. et al. Study on quarter-wave generation mechanism in DP980 steel during cold rolling. Int J Adv Manuf Technol 120, 313–327 (2022). https://doi.org/10.1007/s00170-021-08395-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-08395-3