Abstract

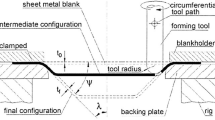

Based on a self-design comprehensive experimental platform, the experimental investigation on electropulse-assisted incremental forming (EAIF) was carried out. By means of the response surface methodology, the interactive influence rules and significances of different processing parameters on formability of AZ31B sheet metal were investigated. The experimental results show that, compared to other processing parameters, the electropulse parameters are the most significant factor, and with the increase of electropulse parameters, the forming limit of sheet metal increases obviously. In addition, an interaction effect was found between the electropulse parameters and the feed rate/tool diameter, as well as between the feed rate and the step size. Through the comprehensive optimization and analysis, there was an optimal formability for sheet metal when the electropulse parameters, feed rate, step size, and tool diameter were set in 80 V/400 Hz, 800 mm/min, 0.2 mm, and 8 mm, respectively. The research on strain state shows that the linear loading mode of rectangular pyramid presents the plane strain state, while the circular loading mode in cone model presents a tendency of biaxial stretch, and the ultimate strain has reached 150%. Benefitting from the electro-plastic effect, the high-energy electropulse can promote the dynamic recrystallization and restrain the crack growth in materials, so compared with the conventional incremental forming, the EAIF under optimal processing condition can greatly improve the forming limit of AZ31B sheet metal.

Similar content being viewed by others

Data availability

The datasets used or analyzed during the current study are available from the corresponding author on reasonable request.

Code availability

Not applicable.

References

Xu TC, Yang Y, Peng XD, Song JF, Pan FS (2019) Overview of advancement and development trend on magnesium alloy. J Magnes Alloy 7(3):536–544. https://doi.org/10.1016/j.jma.2019.08.001

Li XB, Li F, Li XW (2018) Effect of different temperatures on deformation characteristics of AZ31 magnesium alloy by continuous variable cross-section direct extrusion. Int J Adv Manuf Technol 95:4623–4628. https://doi.org/10.1007/s00170-017-1557-6

Lee JU, Kim YJ, Kim SH, Lee JH, Kim MS, Choi SH, Moon BG, Kim YM, Park SH (2019) Texture tailoring and bendability improvement of rolled AZ31 alloy using 10–12 twinning: The effect of precompression levels. J Magnes Alloy 7(4):648–660. https://doi.org/10.1016/j.jma.2019.09.002

Dimitrov NK, Liu YC, Horstemeyer MF (2020) Electroplasticity: A review of mechanisms in electro-mechanical coupling of ductile metals. Mech Adv Mater Struct:1–12. https://doi.org/10.1080/15376494.2020.1789925

Ghiotti A, Bruschi S, Simonetto E, Gennari C, Calliari I, Bariani P (2018) Electroplastic effect on AA1050 aluminium alloy formability. CIRP Annu Manuf Technol 67(1):289–292. https://doi.org/10.1016/j.cirp.2018.04.054

Konovalov S, Komissarova I, Ivanov Y, Gromov V, Kosinovc D (2019) Structural and phase changes under electropulse treatment of fatigue-loaded titanium alloy VT1-0. JMR&T 8(1):1300–1307. https://doi.org/10.1016/j.jmrt.2018.09.008

Xu H, Liu XB, Zhang D, Zhang XF (2019) Minimizing serrated flow in Al-Mg alloys by electroplasticity. J Mater Sci Technol 35(6):1108–1112. https://doi.org/10.1016/j.jmst.2018.12.007

Ao DW, Chu XR, Yang Y, Lin SX, Gao J (2018) Effect of electropulsing on springback during V-bending of Ti-6Al-4V titanium alloy sheet. Int J Adv Manuf Technol 96:3197–3207. https://doi.org/10.1007/s00170-018-1654-1

Kuang J, Low TSE, Niezgoda SR, Li X, Geng Y, Luo AA, Tang GY (2016) Abnormal texture development in magnesium alloy Mg–3Al–1Zn during large strain electroplastic rolling: Effect of pulsed electric current. Int J Plast 87:86–99. https://doi.org/10.1016/j.ijplas.2016.09.004

Li XP, Li XH, Ye YD, Zhang RK, Kure Chu SZ, Tang GY (2019) Deformation mechanisms and recrystallization behavior of Mg-3Al-1Zn and Mg-1Gd alloys deformed by electroplastic-asymmetric rolling. Mater Sci Eng A 742:722–733. https://doi.org/10.1016/j.msea.2018.09.041

Xie HY, Wang Q, Liu K, Peng F, Dong XH, Wang JF (2015) Investigation of influence of direct-current pulses on springback during V-bending of AZ31B magnesium alloy sheet. J Mater Process Technol 219:321–327. https://doi.org/10.1016/j.jmatprotec.2014.12.011

Chu XRWL, Lin SX, Yue ZM, Gao J (2018) Experimental Investigation on Formability of AZ31B Magnesium Alloy V-Bending Under Pulse Current. Acta Metall Sin (Engl) 31(12):1249–1257. https://doi.org/10.1007/s40195-018-0734-4

Bao WK, Chu XR, Lin SX, Gao J (2017) Electro-plastic effect on tensile deformation behaviour and microstructural mechanism of AZ31B alloy. Mater Sci Technol 33(7):836–845. https://doi.org/10.1080/02670836.2016.1242272

Li YL, Chen XX, Liu ZB, Sun J, Li FY, Li JF, Zhao GQ (2017) A review on the recent development of incremental sheet-forming process. Int J Adv Manuf Technol 92(5–8):2439–2462. https://doi.org/10.1007/s00170-017-0251-z

Al Ghamd KA, Hussain G (2019) Bulging in incremental sheet forming of cold bonded multi-layered Cu clad sheet: Influence of forming conditions and bending. Trans Nonferrous Metal Soc China 29(1):112–122. https://doi.org/10.1016/S1003-6326(18)64920-9

Leonhardt A, Kurz G, Victoria Hernández J, Kräusel V, Landgrebe D, Letzig D (2018) Experimental study on incremental sheet forming of magnesium alloy AZ31 with hot air heating. Proce Manuf 15:1192–1199. https://doi.org/10.1016/j.promfg.2018.07.369

Zhang S, Tang GH, Wang WQ, Jiang XK (2020) Evaluation and optimization on the formability of an AZ31B Mg alloy during warm incremental sheet forming assisted with oil bath heating. Measurement 157:107673. https://doi.org/10.1016/j.measurement.2020.107673

Hino R, Kawabata K (2014) Yoshida F (2014) Incremental Forming with Local Heating by Laser Irradiation for Magnesium Alloy Sheet. Proc Eng 81:2330–2335. https://doi.org/10.1016/j.proeng.2014.10.329

Palumbo G, Cusanno A, Garcia Romeu ML, Bagudanch I, Contessi Negrini N, Villa T, Farè S (2019) Single Point Incremental Forming and Electrospinning to produce biodegradable magnesium (AZ31) biomedical prostheses coated with porous PCL. Mater Today Proc 7:394–401. https://doi.org/10.1016/j.matpr.2018.11.101

Bao WK, Chu XR, Lin SX, Gao J (2015) Experimental investigation on formability and microstructure of AZ31B alloy in electropulse-assisted incremental forming. Mater Des 87:632–639. https://doi.org/10.1016/j.matdes.2015.08.072

Hussain G, Gao L (2007) A novel method to test the thinning limits of sheet metals in negative incremental forming. Int J Mach Tool Manuf 47(3–4):419–435. https://doi.org/10.1016/j.ijmachtools.2006.06.015

Li YL, Lu HB, Daniel WJT, Meehan PA (2015) Investigation and optimization of deformation energy and geometric accuracy in the incremental sheet forming process using response surface methodology. Int J Adv Manuf Technol 79(9–12):2041–2055. https://doi.org/10.1007/s00170-015-6986-5

Liu Y, Li F, Shi WY, Li XW, Fang WB (2019) Multi-objective optimization method for magnetic media pre-bulging process parameters of spherical bottom cylindrical parts based on response surface. Results Phys 14:102487. https://doi.org/10.1016/j.rinp.2019.102487

Ji YH, Park JJ (2008) Formability of magnesium AZ31 sheet in the incremental forming at warm temperature. J Mater Process Technol 201:354–358. https://doi.org/10.1016/j.jmatprotec.2007.11.206

Fang Y, Lu B, Chen J, Xu DK, Ou H (2014) Analytical and experimental investigations on deformation mechanism and fracture behavior in single point incremental forming. J Mater Process Technol 214:1503–1515. https://doi.org/10.1016/j.jmatprotec.2014.02.019

Deng J, Lin YC, Li SS, Chen J, Ding Y (2013) Hot tensile deformation and fracture behaviors of AZ31 magnesium alloy. Mater Des 49:209–219. https://doi.org/10.1016/j.matdes.2013.01.023

Liao HM, Tang GY, Jiang YB, Xu Q, Sun SD, Liu J (2011) Effect of thermo-electropulsing rolling on mechanical properties and microstructure of AZ31 magnesium alloy. Mater Sci Eng A 529:138–142. https://doi.org/10.1016/j.msea.2011.09.007

Funding

The authors would like to acknowledge the financial support from Natural Science Foundations of Shandong Province under Grant no. ZR2019BEE060, ZR2019MEE008 and ZR2020ME001.

Author information

Authors and Affiliations

Contributions

Wenke Bao: Main processing experiment, the conception and design of the study, original manuscript preparation. Jun Gao: Reviewing and supervising the final version. Xingrong Chu: Editing and revising of the manuscript. Junbo Liu: Measurement experiments and analysis. Wenqing Wei: Software analysis and data processing. Haijian Ma: Microscopic experiments and analysis.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

The authors have declared their consent to participate in this work.

Consent for publication

The authors have declared their consent to publish this work.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bao, W., Gao, J., Chu, X. et al. Process optimization and mechanism analysis on electropulse-assisted incremental forming of AZ31B magnesium alloy sheet. Int J Adv Manuf Technol 119, 329–342 (2022). https://doi.org/10.1007/s00170-021-08214-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-08214-9