Abstract

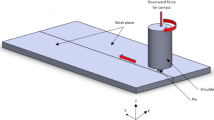

During dissimilar friction stir welding (FSW) of Al-Mg2Si metal matrix composite and AA6061 aluminum alloy, the temperature field and heat generation were investigated using a 3-dimensional computational fluid dynamics (CFD) model and FLUENT software. The simulations were conducted for rotational speeds of 720, 920, and 1120 rpm. The welding experiments were carried out to validate the simulation results. About 70% of the heat is generated at the interface between the shoulder and the workpiece. The maximum temperature is predicted on the advancing side (AS). The difference between the peak temperatures on the AS and the retreating side (RS) is about 115 K. The effect of the rotational speed on the peak temperature is significant. The temperature distribution in the cross sections is asymmetric, which originates from different material velocities on the AS and RS. The peak temperature on the RS develops under the top surface, while the peak temperature on the AS develops on the surface.

Similar content being viewed by others

Availability of data and material

The data and material that support the findings of this study are available on request.

Code availability

Not applicable.

References

Prakash P, Jha S, Lal SP (2013) A study of process parameters of friction stir welded AA6061 aluminum alloy. Int J Innov Res Sci Eng Technol 2(6):2304–2309

David S, Feng Z (2004) Friction stir welding of advanced materials: challenges. Mater Trans

Bang KS, Lee KJ, Bang HS, Bang HS (2011) Interfacial microstructure and mechanical properties of dissimilar friction stir welds between 6061–T6 aluminum and Ti-6%Al-4%V alloys. Mater Trans 52(5):974–978

Sharifitabar M, Nami H (2011) Microstructures of dissimilar friction stir welded joints between 2024–T4 aluminum alloy and Al/Mg2Si metal matrix cast composite. Compos B Eng 42(7):2004–2012

Nasiri N, Emamy M, Malekan A, Norouzi MH (2012) Microstructure and tensile properties of cast Al–15%Mg2Si composite: effects of phosphorous addition and heat treatment. Mater Sci Eng, A 556:446–453

Jahangiri A, Idris MH, Farahany S (2012) Investigation on tungsten inert gas welding of in situ Al-15 and 20 Mg2Si composites with an Al-Si filler. J Compos Mater 47(10):1283–1291

Dalkilic S, Biallas G (2006) FSW joints of an aluminium base metal matrix composite and a monolithic aluminium alloy. Proc. 6th International Symposium on Friction Stir Welding, pp 10–13

Cavaliere P (2013) Friction stir welding of Al alloys: analysis of processing parameters affecting mechanical behavior. Procedia CIRP 11:139–144

Farzadi A, Bahmani M, Haghshenas DF (2017) Optimization of operational parameters in friction stir welding of AA7075-T6 aluminum alloy using response surface method. Arab J Sci Eng 42(11):4905–4916

Kim D, Badarinarayan H, Ryu I, Kim JH, Kim Ch, Okamoto K, Wagoner RH, Chung K (2009) Numerical simulation of friction stir welding process. IntJ Mater Form 2(1):383–386

Lakshminarayanan AK, Balasubramanian V (2008) Process parameters optimization for friction stir welding of RDE-40 aluminium alloy using Taguchi technique. Trans Nonferrous Metals Soc China 18(3):548–554

Tang W, Guo X, McClure JC, Murr LE, Nunes A (1998) Heat input and temperature distribution in friction stir welding. J Mater Process Manuf Sci 7(2):163–172

Surendrababu P, Krishna A, Sirinivasa Rao C (2013) Material flow behaviour in friction stir welding process-a critical review on process parameters and modeling methodologies. Int J Emerg Technol Adv Eng 3(6):219–225

Reynolds AP, Tang W, Khandkar Z, Khan JA, Lindner K (2005) Relationships between weld parameters, hardness distribution and temperature history in alloy 7050 friction stir welds. Sci Technol Weld Join 10(2):190–199

Nandan R, Roy GG, Debroy T (2005) Numerical simulation of three-dimensional heat transfer and plastic flow during friction stir welding. Metall Mater Trans A 37(4):1247–1259

Chen G, Zhang S, Zhu Y, Yang C, Shi Q (2020) Thermo-mechanical analysis of friction stir welding: a review on recent advances. Acta Metall Sin (Engl Lett) 33(1):3–12

Chen G, Feng Z, Zhu Y, Shi Q (2016) An alternative frictional boundary condition for computational fluid dynamics simulation of friction stir welding. J Mater Eng Perform 25(9):4016–4023

Chen G, Li H, Zhang S, Dai Q, Wang X, Zhang G, Shi Q (2018) Effects of pin thread on the in-process material flow behavior during friction stir welding: a computational fluid dynamics study. Int J Mach Tools Manuf 124:12–21

Zhai M, Wu CS, Su H (2020) Influence of tool tilt angle on heat transfer and material flow in friction stir welding. J Manuf Process 59:98–112

Yang CL, Wu CS, Lv XQ (2018) Numerical analysis of mass transfer and material mixing in friction stir welding of aluminum/magnesium alloys. J Manuf Process 32:380–394

Arora A, De A, Debroy T (2011) Toward optimum friction stir welding tool shoulder diameter. Scripta Mater 64(1):9–12

Zhang S, Shi Q, Liu Q, Xie R, Zhang G, Chen G (2018) Effects of tool tilt angle on the in-process heat transfer and mass transfer during friction stir welding. Int J Heat Mass Transf 125:32–42

Chen G, Wang G, Shi Q, Zhao Y, Hao Y, Zhang S (2019) Three-dimensional thermal-mechanical analysis of retractable pin tool friction stir welding process. J Manuf Process 41:1–9

Kishore VR, Arun J, Padmanabhan R, Balasubramanian V (2015) Parametric studies of dissimilar friction stir welding using computational fluid dynamics simulation. Int J Adv Manuf Technol 80(1–4):91–98

Zhang S, Chen G, Liu Q, Li H, Zhang G, Wang G, Shi Q (2018) Numerical analysis and analytical modeling of the spatial distribution of heat flux during friction stir welding. J Manuf Process 33:245–255

Padmanaban R, Kishore VR, Balusamy V (2014) Numerical simulation of temperature distribution and material flow during friction stir welding of dissimilar aluminum alloys. Procedia Eng 97:854–863

Gotawala N, Shrivastava A (2020) Analysis of material distribution in dissimilar friction stir welded joints of Al 1050 and copper. J Manuf Process 57:725–736

Derazkola HA, Elyasi M, Hosseinzadeh M (2015) CFD modeling of friction stir welding of AA1100 aluminum alloy to A441 AISI steel butt joint. J Adv Mater Process 3(3):47–59

Yoshikawa G, Miyasaka F, Hirata Y, Katayama Y, Fuse T (2012) Development of numerical simulation model for FSW employing particle method. Sci Technol Weld Join 17(4):255–263

Nandan R, Debroy T, Bhadeshia HKDH (2008) Recent advances in friction stir welding Process, weldment structure and properties. Prog Mater Sci 53(6):980–1023

Schmidt H, Hattel J, Wert J (2004) An analytical model for the heat generation in friction stir welding. Modell Simul Mater Sci Eng 12:143–157

Wang H (2011) Numerical and artificial neural network modelling of friction stir welding. Sch Appl Sci

Totten GE, MacKenzie DS (eds) (2003) Handbook of aluminum: volume 2: alloy production and materials manufacturing, vol. 2

Nandan R, Roy GG, Lienert TJ, Debroy T (2007) Three-dimensional heat and material flow during friction stir welding of mild steel. Acta Mater 55(3):883–895

Reynolds AP, Khandkar MZH, Khan JA, Reynolds AP (2003) Prediction of temperature distribution and thermal history during friction stir welding : input torque based model. Sci Technol Weld Join 8(3):165–174

Bhattacharya TK, Das H, Jana SS, Pal TK (2017) Numerical and experimental investigation of thermal history, material flow and mechanical properties of friction stir welded aluminium alloy to DHP copper dissimilar joint. Int J Adv Manuf Technol 88(1–4):847–861

Sellars CM, Tegart WJM (1972) Hot workability. Int Metall Rev 17(1):1–24

Sheppard T, Wright DS (1979) Determination of flow stress: part 1 constitutive equation for aluminium alloys at elevated temperatures. Metals Technol 6(1):215–223

Sharghi E, Farzadi A (2018) Simulation of strain rate, material flow, and nugget shape during dissimilar friction stir welding of AA6061 aluminum alloy and Al-Mg2Si composite. J Alloy Compd 748:953–960

Hamilton C, Dymek S, Sommers A (2008) A thermal model of friction stir welding in aluminum alloys. Int J Mach Tools Manuf 48(10):1120–1130

Zhang J, Fan Z, Wang Y, Zhou B (2000) Microstructure and mechanical properties of in situ Al-Mg2Si composites. Mater Sci Technol 16(7–8):913–918

Colegrove PA, Shercliff HR (2005) 3-Dimensional CFD modelling of flow around a threaded friction stir welding tool profile. J Mater Process Technol 169(2):320–327

Farzadi A, Serajzadeh S, Kokabi AH (2008) Prediction of solidification behaviour of weld pool through modelling of heat transfer and fluid flow during gas tungsten arc welding of commercial pure aluminium. Mater Sci Technol 24(12):1427–1432

Ipekoglu G, Akcam O, Cam G (2018) Effect of plate thickness on weld speed in friction stir welding of AA6061-T6 Al-alloy plates. Paton Weld J 11–12:77–82

Farzadi A (2017) Correlation between precipitate microstructure and mechanical properties in AA7075-T6 aluminum alloy friction stir welded joints. Materialwiss Werkstofftech 48(2):151–162

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sharghi, E., Farzadi, A. Simulation of temperature distribution and heat generation during dissimilar friction stir welding of AA6061 aluminum alloy and Al-Mg2Si composite. Int J Adv Manuf Technol 118, 3147–3159 (2022). https://doi.org/10.1007/s00170-021-08175-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-08175-z