Abstract

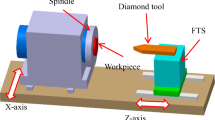

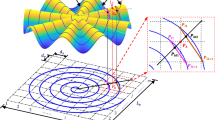

Fast tool servo and slow slide servo-based diamond turning are very important and widely used machining methods for freeform surfaces. In diamond turning of freeform surfaces, the research on tool path generation and machined surface topography prediction is generally for diamond turning processes using zero rake angle tools. But diamond turning with non-zero rake angle tools is also of great importance, for which very little research has been done on tool path planning and surface topography modeling. Therefore, based on coordinate transformations, this paper develops a new tool path generation method and discusses the tool geometry parameter selection for diamond turning utilizing non-zero rake angle tools. In addition, a new surface topography prediction model based on the actual position and orientation of the tool cutting edge is constructed for the machined surface. The machining experiments of a typical freeform surface are conducted based on the calculated tool paths and necessary critical tool geometry parameters. The measured results validate the developed tool path generation and tool geometry selection methods, and the constructed surface topography model.

Similar content being viewed by others

Data availability

All data and materials generated or analyzed during this study are included in the article.

Code availability

Not applicable.

Abbreviations

- γ :

-

Rake angle of the tool

- α :

-

Clearance angle of the tool

- θ i :

-

Included angle of the tool

- R t :

-

Nose radius of the tool

- ρt (t), φt (t), xt (t), yt (t), zt (t):

-

Polar radius, polar angle, X, Y, and Z coordinates of the tool tip point Pt in diamond turning using non-zero rake angle tools

- ρc (t), φc (t), xc (t), yc (t), zc (t):

-

Polar radius, polar angle, X, Y, and Z coordinates of the tool nose center Pc in diamond turning using non-zero rake angle tools

- R 0 :

-

Distance from the tool initial position to the center of the workpiece

- f r :

-

Feed rate of the tool along the negative X direction

- ω s :

-

Workpiece rotating angular velocity

- γ P :

-

A projection angle used to indicate the projection position of the tool nose center

- R x, R z :

-

Homogeneous rotation matrices around the X and Z directions

- T z :

-

Homogeneous translation matrix along the Z direction

- z tan :

-

Z coordinates of point Ptan

- α tan :

-

Angle between the X direction and the tangent line between the tool cutting edge and the intersection curve at point Ptan

- k tan :

-

Slope of the tangent line to the intersection curve at point Ptan

- z sur (t):

-

Z coordinates of point Psur at time t

- z′, z″:

-

The first and second partial derivatives with respect to ρ at point Pcur of the intersection curve in the cutting edge normal plane or tool rake plane

- γ cur :

-

Calculated negative angle between the Z direction and the tangent line of the intersection curve at point Psur in the cutting edge normal plane when z′ > 0

- γ critical :

-

Critical rake angle

- α cur :

-

Calculated clearance angle between the negative Y′ direction and the tangent line of the intersection curve at point Psur in the cutting edge normal plane when z′ < 0

- α critical :

-

Critical clearance angle

- R cur :

-

Curvature radius at point Psur of the intersection curve in the XOZ plane when z″ > 0

- R critical :

-

Critical nose radius

- θ cur :

-

Calculated included angle, double the angle between the Z direction and the tangent line at point Ptan of the intersection curve in the XOZ plane

- θ critical :

-

Critical included angle

- x s, y s :

-

X and Y coordinates of the sampling point Ps in the topography calculation

- z sz :

-

Cutting edge profile height corresponding to the sampling point Ps when a zero rake angle tool is used

- z cz :

-

Z coordinates of the tool nose arc center Pcz in the OXYZ coordinate system when a zero rake angle tool is used

- xtz, ytz, ztz:

-

X, Y, and Z coordinates of the tool tip point Ptz in the OXYZ coordinate system when a zero rake angle tool is used

- l :

-

Distance from the sampling point Ps to the O0Z0 direction

- z sn :

-

Cutting edge profile height corresponding to the sampling point Ps when a non-zero rake angle tool is used

- z cn :

-

Z coordinates of the tool nose arc center Pcn in the OXYZ coordinate system when a non-zero rake angle tool is used

- x tn, y tn, z tn :

-

X, Y, and Z coordinates of the tool tip point Ptn in the OXYZ coordinate system when a non-zero rake angle tool is used

- d :

-

Perpendicular distance from the sampling point Ps to the O0X0 direction

- zs,m, zs,m+1:

-

Cutting edge profile heights at the sampling point Ps in the m-th and the m+1-th revolutions, respectively

- z s :

-

Surface topography height after machining at the sampling point Ps

- A :

-

Amplitude of the sinusoidal wavy surface

- λ :

-

Wavelength of the sinusoidal wavy surface

- A x, A y :

-

Amplitudes of the sinusoidal grid surface

- λ x, λ y :

-

Wavelengths of the sinusoidal grid surface

- D w :

-

Workpiece diameter

- D c :

-

Depth of cut

- R s :

-

Spindle rotation speed

References

Patterson SR, Magrab EB (1985) Design and testing of a fast tool servo for diamond turning. Precis Eng 7(3):123–128. https://doi.org/10.1016/0141-6359(85)90030-3

Kim H-S, Lee K-I, Lee K-M, Bang Y-B (2009) Fabrication of free-form surfaces using a long-stroke fast tool servo and corrective figuring with on-machine measurement. Int J Mach Tool Manu 49(12-13):991–997. https://doi.org/10.1016/j.ijmachtools.2009.06.011

Yi AY, Li L (2005) Design and fabrication of a microlens array by use of a slow tool servo. Opt Lett 30(13):1707–1709. https://doi.org/10.1364/OL.30.001707

Yin ZQ, Dai YF, Li SY, Guan CL, Tie GP (2011) Fabrication of off-axis aspheric surfaces using a slow tool servo. Int J Mach Tool Manu 51(5):404–410. https://doi.org/10.1016/j.ijmachtools.2011.01.008

Fang FZ, Zhang XD, Weckenmann A, Zhang GX, Evans C (2013) Manufacturing and measurement of freeform optics. Cirp Ann-Manuf Technol 62(2):823–846. https://doi.org/10.1016/j.cirp.2013.05.003

Fang FZ, Zhang XD, Hu XT (2008) Cylindrical coordinate machining of optical freeform surfaces. Opt Express 16(10):7323–7329. https://doi.org/10.1364/OE.16.007323

Yu DP, Wong YS, Hong GS (2011) Optimal selection of machining parameters for fast tool servo diamond turning. Int J Adv Manuf Technol 57(1-4):85–99. https://doi.org/10.1007/s00170-011-3280-z

Li Z, Fang F, Chen J, Zhang X (2017) Machining approach of freeform optics on infrared materials via ultra-precision turning. Opt Express 25(3):2051–2062. https://doi.org/10.1364/OE.25.002051

Mukaida M, Yan J (2017) Ductile machining of single-crystal silicon for microlens arrays by ultraprecision diamond turning using a slow tool servo. Int J Mach Tool Manu 115:2–14. https://doi.org/10.1016/j.ijmachtools.2016.11.004

Mukaida M, Yan J (2017) Fabrication of hexagonal microlens arrays on single-crystal silicon using the tool-servo driven segment turning method. Micromachines 8(11). https://doi.org/10.3390/mi8110323

Zhang XD, Fang FZ, Wang HB, Wei GS, Hu XT (2009) Ultra-precision machining of sinusoidal surfaces using the cylindrical coordinate method. J Micromech Microeng 19(5):054004. https://doi.org/10.1088/0960-1317/19/5/054004

Zhang XD, Fang FZ, Wu QQ, Liu XL, Gao HM (2013) Coordinate transformation machining of off-axis aspheric mirrors. Int J Adv Manuf Technol 67(9-12):2217–2224. https://doi.org/10.1007/s00170-012-4642-x

Gong H, Wang Y, Song L, Fang FZ (2015) Spiral tool path generation for diamond turning optical freeform surfaces of quasi-revolution. Comput Aided Des 59:15–22. https://doi.org/10.1016/j.cad.2014.08.001

Tian F, Yin Z, Li S (2015) Fast tool servo diamond turning of optical freeform surfaces for rear-view mirrors. Int J Adv Manuf Technol 80(9-12):1759–1765. https://doi.org/10.1007/s00170-015-7152-9

Yu DP, Gan SW, Wong YS, Hong GS, Rahman M, Yao J (2012) Optimized tool path generation for fast tool servo diamond turning of micro-structured surfaces. Int J Adv Manuf Technol 63(9-12):1137–1152. https://doi.org/10.1007/s00170-012-3964-z

Yu DP, Hong GS, Wong YS (2012) Profile error compensation in fast tool servo diamond turning of micro-structured surfaces. Int J Mach Tool Manu 52(1):13–23. https://doi.org/10.1016/j.ijmachtools.2011.08.010

Neo DWK, Kumar AS, Rahman M (2014) A novel surface analytical model for cutting linearization error in fast tool/slow slide servo diamond turning. Precis Eng-J Int Soc Precis Eng Nanotechnol 38(4):849–860. https://doi.org/10.1016/j.precisioneng.2014.05.002

Kong LB, Cheung CF (2012) Modeling and characterization of surface generation in fast tool servo machining of microlens arrays. Comput Ind Eng 63(4):957–970. https://doi.org/10.1016/j.cie.2012.06.007

Gong H, Fang FZ, Hu XT (2012) Accurate spiral tool path generation of ultraprecision three-axis turning for non-zero rake angle using symbolic computation. Int J Adv Manuf Technol 58(9-12):841–847. https://doi.org/10.1007/s00170-011-3433-0

Zhou X, Zuo C, Liu Q, Lin J (2016) Surface generation of freeform surfaces in diamond turning by applying double-frequency elliptical vibration cutting. Int J Mach Tool Manu 104:45–57

Zong WJ, Huang YH, Zhang YL, Sun T (2014) Conservation law of surface roughness in single point diamond turning. Int J Mach Tool Manu 84:58–63. https://doi.org/10.1016/j.ijmachtools.2014.04.006

Kishawy HA, Elbestawi MA (1999) Effects of process parameters on material side flow during hard turning. Int J Mach Tool Manu 39(7):1017–1030. https://doi.org/10.1016/S0890-6955(98)00084-4

Funding

This work was supported by the State Administration of Science, Technology and Industry for National Defense, PRC (grant number WDZC2020JJ020); the National Natural Science Foundation of China (grant numbers U19A20104, U1601203); the Scientific and Technological Development Program of Jilin Province (grant numbers 20190302020GX, 20180101321JC, 20190302099GX); the Industrial Technology of Research and Development of Jilin Province (grant number 2019C037-3); and the Education Department of Jilin Province (grant numbers JJKH20200955KJ, JJKH20200960KJ). In addition, Chengming Zuo would like to express sincere gratitude to Dr. Mingxing Chen, Dr. Yingnan Kan, and Dr. Yuxin Sun.

Author information

Authors and Affiliations

Contributions

GM, XZ, and QL conceived the idea of the study; CZ performed the research and wrote the initial draft of the paper; QL, SJ, XZ, and PX contributed to the experiments; YZ, XZ, and GY contributed to analyzing the results and finalizing this paper.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

All the authors agree with the participation.

Consent for publication

All the authors agree with the publication.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix 1

In the following transformation processes, the tool and the workpiece shown in Fig. 2 are taken as a whole rigid body. Rotate the freeform surface and the tool by −φt (t) around the Z direction, and the rotation matrix can be expressed as below:

Based on Eq. (1), the coordinates of point Pt can be written as (xt (t), yt (t), zc (t)-Rt cos(γ)). Translate the surface and the tool from point Pt to the XOY plane along the negative Z direction, and the translation matrix can be expressed as below:

The transformed surface and tool are shown in Fig. 18a. Rotate the freeform surface and the tool by −γ around the X direction, and the rotation matrix can be expressed as below:

The transformed surface and tool are shown in Fig. 18b. Translate the surface and the tool from the XOY plane to the height of the original point Pt along the Z direction, and the translation matrix can be expressed as below:

The surface and the tool after the transformations are shown in Fig. 19, in which the tool rake plane is perpendicular to the XOY plane. Based on the geometric relationship between point Pt, point Ptan, and point Pc, the Z coordinates of point Pt can be obtained as

where ztan is the Z coordinates of point Ptan, and αtan is the angle between the X direction and the tangent line between the tool cutting edge and the intersection curve at point Ptan.

The coordinates of the transformed freeform surface can be calculated through a series of homogeneous coordinate transformations:

where (x, y, z) and (x1, y1, z1) are the freeform surface coordinates before and after the coordinate transformations, respectively.

The transformed freeform surface can be expressed as

The equation above can be further transformed to the cylindrical coordinates:

The surface can be written as F (ρ, θ, z) = 0, and the intersection curve generated by the tool rake plane and the freeform surface at time t can be obtained as

The first derivative of the intersection curve can be calculated as

Appendix 2

Rotate the freeform surface shown in Fig. 3 by −φt (t) around the Z direction, and the rotation matrix can be expressed as below:

Translate the surface from the surface point Psur to the XOY plane along the negative Z direction, and the translation matrix can be expressed as below:

Rotate the freeform surface by −γ around the X direction, and the rotation matrix can be expressed as below:

Translate the surface from the XOY plane to point Psur along the Z direction, and the translation matrix can be expressed as below:

The surface after the transformations is shown in Fig. 20. The coordinates of the transformed freeform surface can be calculated through a series of homogeneous coordinate transformations:

where (x, y, z) and (x1, y1, z1) are the freeform surface coordinates before and after the coordinate transformations, respectively.

The transformed freeform surface can be expressed as

The equation above can be further written in cylindrical coordinates:

The surface can be written as F (ρ, θ, z) = 0, and the intersection curve generated by the XOZ plane and the freeform surface at time t shown in Fig. 20b can be calculated as

The first derivative of the intersection curve can be calculated as

The second derivative of the intersection curve can be calculated as

Rights and permissions

About this article

Cite this article

Zuo, C., Meng, G., Zhou, X. et al. Diamond turning of freeform surfaces using non-zero rake angle tools. Int J Adv Manuf Technol 118, 2265–2284 (2022). https://doi.org/10.1007/s00170-021-07890-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07890-x