Abstract

JIS SUS 304L stainless steel was joined by a combination welding process of plasma arc welding and gas tungsten arc welding (PAW+GTAW). Then pre-strain treatment on 304L welded joint of 9 % was carried out using uniaxial quasi-static tensile at room temperature. Effect of strain on microstructure evolution in joint was analyzed by field emission scanning electron microscope (FESEM) and on mechanical properties was also studied. The results indicated that the pre-strain rate of 304L joint showed inhomogeneity including 3 % in the weld metal and 13 % in the heat-affected zone (HAZ), which induced martensitic transformation occurring in HAZ. Tensile strength of the joint increased from 700 MPa as welded to 804 MPa after pre-strain treatment at room temperature, and it reached 1700 MPa from 1480 MPa as welded at low temperature of −196 °C. Impact energy in the HAZ was the least among the whole 304L weld, but it was still 94 J at −196 °C after pre-strain. The fracture morphology showed large numbered of cleavage steps with elongated parabolic dimples.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

JIS SUS 304L austenitic stainless steel is widely used for pressure vessel at low temperature due to its good comprehensive mechanical properties and excellent corrosion resistance. The permissible stress of 304L steel is usually designed to use by its yield strength considering current safety factor. Therefore, the thickness of pressure vessel is designed to be large in some heavy equipment owing to its low ratio of yield strength to tensile strength, which leads to high cost of manufacturing, transportation, and waste of materials. The yield strength of JIS SUS 304L steel can be significantly improved by pre-strain treatment to make it partially plastic deformed on the premise that the original mechanical properties of 304L steel are not greatly affected [1,2,3]. The thickness of pressure vessels designed by new yield strength after pre-strain can be reduced by 20–30 %, which is favorable to save materials and reduce costs and energy consumption in transportation [4].

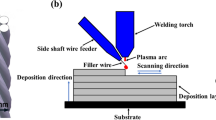

Welding is the key technology in manufacturing austenitic stainless steel pressure vessel. Submerged arc welding (SAW), gas tungsten arc weld (GTAW), and laser deposited with wire are commonly used in the manufacture of medium and heavy stainless steel pressure vessels [5,6,7]. The HAZ in joint is wide due to the larger welding heat input by SAW, which makes the performance in the HAZ reduced greatly after pre-strain [8]. GTAW has a major application in the some important joints because of its high welding quality [9]. However, more applications have been limited by its low productivity on joining thick pressure vessels. Plasma arc welding (PAW), which is a kind of fusion welding process with keyhole, is effective in joining JIS SUS 304L steel with a thickness of 8–12 mm due to its high energy density [10, 11]. Undercut and corrosion sometimes occur in the weldment because there is no filler metal during PAW. So research on the combination of PAW and GTAW (PAW+GTAW) has been conducted to weld JIS SUS 304L, and a good formation and excellent mechanical properties in joint were obtained [12]. In addition, PAW+GTAW process has some advantages including energy concentration and high welding efficiency compared with single PAW and GTAW.

Pre-strain treatment has also an effect on microstructure and mechanical properties in JIS SUS 304L steel joint. Effect of strain rate on microstructural properties in JIS SUS 304L joint by PAW with a thickness of 8 mm has been studied, and it indicated that a number of dislocations and deformation twins were increasing with hardening stress and α′-martensite (α′-M) occurred in the joint [13, 14]. There was some dislocation with high density in the fusion zone and a lot of α′-M with twins in base metal. Impact energy of the welded joint at low temperature still met the requirement of national standard, and the fracture morphology showed ductile fracture with dimple after pre-strain treatment [15].

In this paper, JIS SUS 304L steel with a thickness of 12 mm was welded by PAW+GTAW, and then pre-strain treatment of 9 % was conducted on the whole joint including weld metal and base metal. Effect of pre-strain on microstructure characteristics in 304L joint was studied to investigate tensile strength and impact energy at −196°C.

2 Experimental design

In this work, JIS SUS 304L austenitic stainless steel with a thickness of 12 mm supplied by Shanxi Taigang Stainless Steel Corp. was used as the base metal for butt-welding by PAW+GTAW. Two plates, each measuring 250mm×150mm, were machined with perfectly square edges and then thoroughly degreased with acetone in preparation for the butt-welding process. 308LSi-type consumable with a diameter of 1.0 mm supplied by Tianjin Bridge Welding Materials Corp. was used for GTAW process. The chemical compositions of JIS SUS 304L base metal and 308LSi-type consumable are listed in Table 1.

Before welding, two plates were provided with a 60° V-type groove by a blunt edge of 7 mm. The first weld layer was obtained by PAW process using EWM-422 PAW machine of German IDA. Cover welding was carried out by GTAW after the completion of penetration welding by PAW. The wire feeding speed was 2.8 m/min, and the pure argon was adopted with a flow rate of 18 l/min. Table 2 summarizes the welding parameters employed in the present study, including the current, voltage, welding speed, and plasma gas. The porosity of the weldment was examined radio graphically, and the acceptable specimens were then prepared for metallographic observations and further study.

High pressure water jet was used to cut some samples in such a way that they contained portions of the base metal (BM), the heat-affected zone (HAZ), and the FZ for metallographic observation, pre-strain treatment, and mechanical test along the direction perpendicular to the weld metal. The surface of specimen with a length of 300mm were then carefully finished to assure a close contact during quasi-static tension pre-strain of 9 % using a hydraulic extensometer (WE-600A) at room temperature, as shown in Fig. 1. The original gauge length of specimen before pre-strain is 200mm, and the total strain was 9 %. The loading rate was 0.1 kN/s and the strain rate was 3×10−4/s.

V-notch impact test samples with dimensions of 55 mm × 10 mm × 10 mm were extracted transverse to each weld. The locations notched are at the weld metal (WM), the heat-affected zone (HAZ), and base metal (BM) shown in Fig.2. The fractured joint samples are presented in Fig.2c. Tensile strength and impact toughness were tested at 25 °C and −196 °C in the liquid nitrogen according to the ISO148-1. The microstructure of the joint was analyzed by XJP-6A metallographic microscope and thermal field emission scanning electron microscope (SU-70).

The microstructure of the weldment specimens were observed using XJP-6A optical microscopy and thermal field emission scanning electron microscope (SU-70). Prior to observation, the mounted specimens were grounded with a grit sequence 180–1200 mesh abrasive paper, polished with a micro-cloth using a 0.3 μm alumina slurry, and then etched in a solution of one part HNO3, one part HCl, and one part H2O for approximately 3min.

V-notch impact test samples with dimensions of 55 mm × 10 mm × 10 mm were extracted transverse to each weld according to the ISO148-1. The locations notched were at the weld metal (WM), the heat-affected zone (HAZ), and base metal (BM), shown in Figure 2. Tensile strength was tested at room temperature of 25 °C and at low temperature of −196 °C in the liquid nitrogen. The tensile strength of the weldment was determined using an Instron tensile test machine. Samples for Charpy V-notch impact test were put into the thermos cup, and liquid nitrogen was slowly poured to be at least 45 mm higher than the height of the samples. When the temperature of the samples dropped to −196 °C, it was kept for not less than 20 min. Then samples were quickly placed between the two supports in JB-W300YZ instrument supplied by Jinan Hengda Huifeng Testing Instrument Corp. It should be completed within 5 s to avoid the influence of the temperature rise of the samples on the test results. For both tensile and impact testing, three specimens were tested for each condition, and the average values were calculated as final results. Finally, fracture morphology was observed using a JEOL JSM840 scanning electron microscope operating at 15kV.

3 Results and discussion

3.1 Joint morphology and strain feature

Figure 3 shows the morphology of JIS SUS 304L stainless steel joint obtained by PAW+GTAW process. It is found that the front GTAW weld ripple is smooth and neat and the weld pool height is uniform. There is a good fusion between both base metal and weld metal. An excellent back shaping is also got by PAW single weld with the effect of keyhole, and the back bead is penetrated fully with a good appearance. Fig.3 b shows the cross-section feature of PAW+GTAW joint. The internal quality of the weld metal is uniform with deep penetration characteristics of PAW bead and a complete metallurgic combination between GTAW and PAW weld bead. It can also be seen that the high cooling rate associated with the PAW process results in an arrow HAZ.

A sample with a total length of 300 mm including weld metal and base metal was prepared for pre-strain treatment and the total strain was 9 % at an original gauge length of 200mm. The surface of specimen was marked by line at an equal distance of 10 mm, as shown in Fig.4a. After pre-strain treatment, the distance between the every two original marked lines was measured, and the result is shown in Fig.4b. Strain percentage varies in different location of the whole 304L joint including BM, WM, and HAZ. It suggests that ability to resist strain deformation is different due to the various microstructures in BM, WM, and HAZ although the total average strain is 9 %.

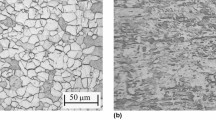

The strain percentage in the weld metal (WM) has a minimum value of about 3 %, and it has a peak value of 13 % in HAZ. It is mainly related to the microstructure characteristics with different crystal lattice. Fig.5 a shows microstructure in 304L joint got by PAW+GTAW. It can be obviously seen that there is a large number of delta ferrite (δ-F) with body-centered cubic (bcc) crystal structure in WM and austenite (A) with face-centered cubic (fcc) crystal structure in HAZ as welded. And there is a mixture of δ-F with A in FZ between WM and HAZ. Both weldment consist of a columnar dendritic structure with a vertical fusion line. These features indicate that the substructure growth takes place along the direction of the maximum temperature gradient.

The strain condition is known to exert a significant influence on the dislocation substructure and density [16]. There is less δ-F slip systems in bcc crystal structure, which makes it easier to stack dislocations and increase deformation resistance [17]. Therefore, a lot of δ-F is still in WM after the pre-strain of only 3 %. The larger deformation in HAZ is attributed to the weakening of austenitic grain boundary experiencing pre-strain treatment, as shown in Fig.5b. Meanwhile, there are more slip systems in austenitic fcc system, and martensite shearing occurs in grains, which makes stress concentration relaxed and reduces slip resistance. So deformation is conducive in different orientations of austenite. These results indicate that the generation of dislocations in the HAZ provides a greater strengthening effect than that in the weld metal.

3.2 Microstructure evolution

Figure 6 shows the microstructure comparison of 304L steel joint as welded and after pre-strain treatment, respectively. The distribution of δ-F in GTAW weld metal is relatively concentrated and the large part is skeletal δ-F with some interfacial characteristics such as migrating grain boundary (MGB), solidified grain boundary (SGB), and solidified subgrain boundary (SSGB), as shown in Fig.6a. The skeletal δ-F provides a greater resistance to plastic flow during pre-strain treatment. The microstructure in WM by GTAW becomes fine and dense with decreasing ferrite lath gap along the deformation, refer Fig.6b. The interfacial characteristics with SGB are not obvious, and the structure of δ-F is slender and irregular. The fine δ-F introduces an increased number of dislocation sources, which act as barriers to the mobile dislocations [16].

Fig.6 c shows the microstructure in PAW bead as weld, and it is mainly composed of A and δ-F. Temperature in molten pool is high, and the temperature gradient is large under the action of high energy plasma arc. Therefore, A is generated by eutectic reaction of ferrite cell boundary and dendrite boundary. The distribution of A and δ-F in the weld metal by plasma arc is not uniform, and orientation of A is obvious. This is because the phase transformation from reaction in Fe-Ni system to eutectic reaction in Fe-Cr-Ni system is greatly affected by the diffusion of solute atoms in the front of solid-liquid interface.

Fig. 6 d shows the microstructure characteristic in the weld metal for PAW after pre-strain treatment. It is found that the grain in WM has been elongated along the deformation direction. The epitaxial grain growth leads to the transformation from cellular dendrite to columnar grain, and there are fewer dense non-uniform shear deformation bands after pre-strain. Some studies [13, 16] have shown the effect of different strain rates on the microstructure transformation of 304 stainless steel; it is revealed that these fine spacing shear bands are the product of changing the microstructure of austenitic stainless steel in the process of pre-strain, and the dislocation in the weld metal is prone to pile up. In the present study, it is assumed that the difference between the closely packed lattice planes in the δ-F and those in the A does not represent the source of micro-shear band formation and martensitic nucleation. Consequently, there are fewer formations of martensite and micro-shear bands in the WM.

Some inhomogeneity of microstructure is shown in narrow HAZ with the welding thermal cycling shown in Fig.7a. The grain size of HAZ is large, and grain growth occurs near the high temperature zone due to the concentrated energy by plasma arc. The current high-resolution lattice image displays that presence of dislocation is limited to the A structures shown in Fig.7b. There is also a small amount of δ-F that can be observed in the HAZ, and there is a trend of extending from the FZ to the HAZ along the direction of large temperature gradient. The δ-F in the HAZ has no liquid-solid phase transformation but only solid phase transformation.

Fig.7 c shows that there are α′-martensite (α′-M) formations and micro-shear bands in the HAZ after pre-strain. The formation of micro-shear bands and α′-M appears to be influenced by the high density dislocation in A grain. The stacking fault energy of A is low, which provides the driving force for martensitic transformation [18]. The lath martensitic are parallel or cross distributed in A grains, as shown in Fig.7d. The α′-M with different orientation overlaps within the A and an increased volume of martensitic transformation causes a corresponding reduction of A, which not only influences the motion of the dislocations, but also reduces the number of twin formations. Meanwhile, more stacking faults in A promote the accumulation of solute atoms at the stacking faults to increase the resistance of deformation dislocation expansion resulting in a work hardening effect [15]. The deformation dislocation, micro-shear band, and their intersection location will become the preferential nucleation area of martensitic transformation [16]. The original grains in the HAZ are elongated, and the grains are broken with the grain boundaries disappeared after pre-strain. A similar observation was also reported by Lee et al [19], who stated that dense deformation slip bands and finer lath martensite were found in the grains under the larger pre-strain.

The formation of martensite depends on stacking fault energy. With the increase of stacking fault energy, stacking fault overlap becomes more and more irregular to make martensite nucleation difficult [20]. Fig.8 schematically shows α′-M formation in A during pre-strain treatment. It is noted that the origin of α′-M is dislocation, and then occurrence of dislocation increment is found in the deformed microstructure under the condition of pre-strain (refer Fig.8b). When more and more dislocations are produced, the different dislocations will meet and merge each other (refer Fig.8c). The dynamic mechanical behavior at a specific strain can be associated with the work-hardening stress, which in turn is related to the dislocation density. At this time, some stacking faults form, and they are parallel in A grain, which provides driving force to α′-M formation (refer Fig.8d). It suggests that the stacking faults act as precursor to the deformation-induced formation of α′-M at larger pre-strain of 13 % in the HAZ. Meanwhile, some dislocations and even stacking faults with different orientation occur, and they slip to form lath martensite with deformation (refer Fig.8e). Finally, the lath martensite with network is shown in A grain, refer Fig.8f.

The microstructure evolutions in the HAZ of 304L joint reveal that the α′-M structures and micro-shear bands are both formed in the A grain experiencing pre-strain by 13 %. This is attributed to the motion of different orientation dislocation under the condition of deformation. It is also noted that the larger deformation is in the joint, the finer lath martensite can be formed.

3.3 Effect on mechanical properties

The present microstructural observations provide insights into the evolution of the dislocation slip and martensite transformation after pre-strain. However, it is also desirable to study the effect of pre-strain on mechanical properties of weld in order to better understand the characteristics of the 304L steel joint by PAW+GTAW under high pre-strain deformation. Fig.9 depicts that tensile strength is greatly different between the joint as welded (AW) and that after pre-strain (AS). It is also noted that there is a significant effect of pre-strain on tensile strength and fracture location of JIS SUS304L weld at both room temperature 25 °C and low temperature of −196 °C.

It can be seen that the tensile strength of JIS SUS304L weld AW is 700 MPa and the fracture occurs in the HAZ at 25 °C. The tensile strength increases to 804 MPa after pre-strain. This suggests that joint has a work hardening effect of 104 MPa induced by strain, and it is more apparent at −196 °C. The tensile strength increases from 1480 MPa AW to 1700 MPa AS, and the fracture occurs in the base metal (refer Fig.9b). It is related to transformation of α′-M with high hardness phase at high pre-strain of 13 % in the HAZ. Meanwhile, there are in a large number of dislocations and twins in the A grains. Compared to 304L steel joint AW fracturing in HAZ, deformation in the weld metal and base metal is smaller, and fracture AS occurs in above regions.

In addition, the dislocation accumulation and increment in A grain may form cellular structure, and the deformation twins produced in the process of pre-strain can also induce work hardening effect, which improves the strength of JIS SUS304L weldment. There is obvious necking phenomenon in the tensile fracture at 25 °C, as shown in Fig.10a. However the fracture at low temperature of −196 °C is relatively flat, and the martensitic transformation structure shows greater brittleness, as shown in Fig.10b. The tensile fracture morphology at −196 °C is obvious brittle feature with much more cleavage step pattern.

Fig.11 shows the impact energy of 304L weld at low temperature (−196 °C). It is noted that the impact energy in BM, the HAZ, and WM decreases after pre-strain treatment. Especially, the impact energy in the HAZ reduces from 116 in welded to 94 J. This can be explained by the microstructure characteristics after pre-strain. There are a lot of ferrite in the WM which can limit the sharp decreasing of ductility and impact energy. The grain boundary can prevent the dislocation from slipping resulted to higher impact energy than that in the HAZ, while the less impact energy in the HAZ is mainly due to the formation of deformed martensite with high strength, high hardness, and low toughness. The crystal distortion and dislocation density increase in A grain after pre-strain with work hardening effect, which leads to the decrease of impact energy at −196 °C. These deformed lath martensite and dislocations accumulate at grain boundaries resulting in stress concentration and reduction of impact energy. The fracture morphology with more deep cleavages is also shown in Fig.11b compared to that in as welded state.

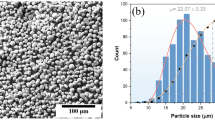

Figure 12 shows the representative impact fracture morphology of the specimens both notched at the weld metal (WM) and the heat-affected zone (HAZ) under the condition of as welded and after pre-strain. As shown in Fig. 12 a and b, most of fracture pattern is dimple zone in the WM as welded and there are fewer tearing with elongated dimple shown in the WM after pre-straining. The stress-fracture regions in as welded state are covered with ~5 μm and ~50 μm diameter dimples. The small-dimple area in the specimen as welded shows deep holes, and the corresponding impact energy is up to 122 J. A comparison of the fracture surfaces of the specimens pre-strained shows that the area of dimple is less with more obvious tearing feature than that in as welded specimens. The diameter of the large dimples increased with decreasing small-dimple area. The pre-straining conducted in 304L weld has decreased the average size of the dimples in WM.

Fig.12 c shows the fracture morphology of impact-tested specimens in the HAZ as welded. It is a mixture of dimples and few quasi-cleavages, which reflects an interaction between the cleavage cracks and grains that suffered plastic deformation [21]. Dimple fracture is a known kind of ductile fracture which occurs during high energy absorption process. However, quasi-cleavage is a kind of brittle fracture. It can be concluded that the fracture in as welded state exhibits a mixed-mode of brittle and ductile rupture. Large numbers of cleavage steps occur in the impact fracture surface for specimens after pre-strained as shown in Fig.12d. In comparison to Fig. 12c, the cleavage area is found to be larger, which indicated an identical brittle fracture feature with less toughness after pre-strain. This is distributed in the true strain treated by 13 % in the HAZ. There are a lot of microdefects such as dislocations in the grain caused by martensite sheared in the HAZ after pre-strain, which leads to the stress concentration and the formation of micro-cracks in the process of impact loading. Subsequently, the micro-cracks accelerate the crack growth, and they are unfavorable to the impact energy.

4 Conclusion

In the present work, the effects of pre-strain on the microstructure evolution, tensile properties, and impact energy at a low temperature of −196 °Cof JIS SUS304L stainless steel weld were investigated using pre-strained specimens containing the weld metal, the heat-affected zone, and base metal, which were achieved by PAW+GTAW process. The conclusions can be summarized as follows:

-

(1)

The deformation percentage of JIS SUS304L joint shows inhomogeneity at an average pre-strain of 9 %. The deformation of the weld metal is only 3 %, and it is 13 % in the heat-affected zone.

-

(2)

The skeletal delta ferrite in the weld metal for GTAW covering layer becomes fine and dense with decreasing ferrite lath gap along the deformation, and crystal orientation of austenite in PAW backing layer is elongated along the deformation direction after pre-strain.

-

(3)

There are martensite formations and micro-shear bands occurring in the HAZ after pre-strain, and the finer lath martensite is cross distributed in A under the larger strain of 13 %.

-

(4)

The origin of α′-M transformation in the HAZ is dislocation, and then occurrence of dislocation increment is found in the deformed microstructure. Subsequently, stacking faults act as a precursor to the deformation-induced formation of α′-M experiencing pre-train, and some stacking faults with different orientation occur, and they slip to form lath martensite with lager deformation.

-

(5)

There is a significant effect of strain on tensile strength. The tensile strength of JIS SUS304L steel weld as welded is 700 MPa, and it increases to 804 MPa after pre-strain at room temperature. Meanwhile, work hardening effect is more apparent at −196 °C, and the tensile strength increases from 1480 to 1700 MPa in specimen after pre-straining.

-

(6)

The impact energy at −196 °C in base metal, the heat-affected zone, and weld metal decreases after pre-strain treatment, especially the impact energy in the HAZ sharply reduces from 116 to 94 J. Correspondingly, a mixed mode of brittle and ductile rupture in as welded state is also changed into large numbered cleavage steps after pre-straining.

References

Farias F, Alvarez-Armas I, Armas AF (2020) On the strain-induced martensitic transformation process of the commercial AISI 304 stainless steel during cyclic loading. Int J Fatigue 140:1–8. https://doi.org/10.1016/j.ijfatigue.2020.105809

Follansbee PS, Gross DJ, Minichiello J, Rodriguez R (2011) A lower-bound temperature and strain-rate dependent strength model for AISI 304 SS. J Press Vess-T ASME 133(5):113–120. https://doi.org/10.1115/PVP2011-57399

Kinoshita K (2015) Influence of tensile stress on permeability properties of type 304 stainless steel. J Appl Phys 117(17):713–716. https://doi.org/10.1063/1.4913819

Lee YH, Wu KL, Jhou JH, Tsai YH, Yan BH (2013) Two-dimensional vibration-assisted magnetic abrasive finishing of stainless steel SUS304. Int J Adv Manuf Technol 69:2723–2733. https://doi.org/10.1007/s00170-013-5242-0

Chi K, Maclean MS, McPherson NA, Baker TN (2007) Single sided single pass submerged arc welding of austenitic stainless steel. Mater Sci Technol 23(9):1039–1048. https://doi.org/10.1179/174328407X161277

Ravisankar A, Velaga SK, Rajput G, Venugopal S (2014) Influence of welding speed and power on residual stress during gas tungsten arc welding (GTAW) of thin sections with constant heat input: a study using numerical simulation and experimental validation. J Manuf Process 16(2):200–211. https://doi.org/10.1016/j.jmapro.2013.11.002

Su JZ, Xiao MZ, Zhang ZJ, Ye ZP, J X, Yang YC (2017) Microstructural morphology and evolution of austenite stainless steel deposited using pulsed laser and wire. Int J Adv Manuf Technol 93:3357–3370. https://doi.org/10.1007/s00170-017-0625-2

Wang BM, Chen T, Xu T, He H (2013) Influence of welding technology on strain strengthening properties of austenitic stainless steel welded joints. Press Vess Tech 30(4):29–33. https://doi.org/10.3969/j.issn.1001-4837.2013.04.006

Kang N, Singh J, Kulkarni AK (2003) Gravitational effects on the gas tungsten arc welds of 304 stainless steels. Mater Manuf Process 18(4):549–561. https://doi.org/10.1081/AMP-120022496

Harish TM, Jerome S, Yadukrishna B, Kumar RS, Suresh CM, Ramesh K (2019) Assessment of microstructure and mechanical properties of keyhole plasma arc welded similar butt joint of AISI 304H austenitic stainless steel. Mater Res Expr 6(11):1–12. https://doi.org/10.1088/2053-1591/ab4e04

Mahrle A, Rose S, Schnick M, Beyer E, Füssel U (2013) Stabilisation of plasma welding arcs by low power laser beams. Sci Technol Weld Join 18(4):323–328. https://doi.org/10.1179/1362171813Y.0000000109

Liu K, Li YJ, Wang J (2016) Microstructure and low-temperature mechanical properties of 304 stainless steel joints by PAW+GTAW combined welding. J Mater Eng Perform 25(10):4561–4573. https://doi.org/10.1007/s11665-016-2288-9

Lee WS, Lin CF, Cheng CW, Lin CF (2004) The effects of strain rate and welding current mode on the dynamic impact behavior of plasma-arc-welded 304L stainless steel weldments. Metall Mater Trans A 35(5):1501–1515. https://doi.org/10.1007/s11661-004-0258-6

Mostafa M, Mostafa K (2018) Influence of strain state on the kinetics of martensitic transformation induced plasticity (TRIP) in AISI 304 stainless steel. Steel Res Int 89(3):359–365. https://doi.org/10.1002/srin.201700359

Lee WS, Lin CF, Liu CY, Cheng CW (2007) Effects of strain rate and welding current mode on microstructural properties of SUS 304L PAW welds. J Mater Process Technol 183(2/3):183–193. https://doi.org/10.1016/j.jmatprotec.2006.10.008

Talonen J, Hanninen H (2007) Formation of shear bands and strain-induced martensite during plastic deformation of metastable austenitic stainless steels. Acta Mater 55(18):6108–6118. https://doi.org/10.1016/j.actamat.2007.07.015

Moallemi M, Kermanpur A, Najafizadeh A, Rezaee A, Samaei Baghbadorani H, Dastranjy Nezhadfar P (2016) Deformation-induced martensitic transformation in a 201 austenitic steel: the synergy of stacking fault energy and chemical driving force. Mater Sci Eng A 653:147–152. https://doi.org/10.1016/j.msea.2015.12.006

Kaoumi D, Liu JL (2018) Deformation induced martensitic transformation in stainless steels:in-situ vs. ex-situ transmission electron microscopy characterization. Mater Sci Eng A 715:73–82. https://doi.org/10.1016/j.msea.2017.12.036

Lee WS, Lin CF (2002) Effects of prestrain and strain rate on the dynamic deformation characteristics of 304L stainless steel. Part II-Microstructural study. Mater Sci Technol 18(8):877–884. https://doi.org/10.1179/026708302225004720

Yeddu HK, Lookman T, Saxena A (2013) Strain-induced martensite transformation in stainless steels: a three-dimensional phase-field study. Acta Mater 61(18):6972–6982. https://doi.org/10.1016/j.actamat.2013.08.011

Tang LQ, Qian CF, Wang ZB, Li HF (2015) Experimental study of the strain-strengthening effect on the mixed mode notch-crack fatigue propagation in austenitic stainless steel 06Cr19Ni10. Eng Fract Mech 134:54–60. https://doi.org/10.1016/j.engfracmech.2014.12.003

Acknowledgements

The authors gratefully acknowledge the financial support provided to this study by the National Nature Science Foundation of China (Grant No.52075295) and the Nature Science Foundation of Shandong Province (Grant No.ZR2019MEE117 & Grant No.2019JZZY010366).

Availability of data and materials

The data and materials used and/or analyzed during the current study are included in this article, and they are available from the corresponding author on reasonable request.

Funding

This work was supported by the National Nature Science Foundation of China (Grant No.52075295) and the Nature Science Foundation of Shandong Province (Grant No.ZR2019MEE117 & Grant No.2019JZZY010366).

Author information

Authors and Affiliations

Contributions

All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval

The submitted work is original and has not been published elsewhere in any form or language. The manuscript is not submitted to more than one journal for simultaneous consideration.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

Not applicable.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Juan, W., Yajiang, L., Qi, W. et al. Strain effect on microstructural properties of SUS 304L joint by PAW+GTAW. Int J Adv Manuf Technol 117, 1233–1242 (2021). https://doi.org/10.1007/s00170-021-07800-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07800-1