Abstract

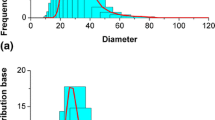

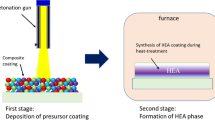

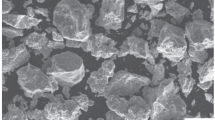

The feasibility study of elaboration of metal composite coatings by detonation spray using the blends of iron, nickel, copper, cobalt, and aluminum powders was performed using different spray modes. The numerical simulation of particle parameters showed that the particles formed the coating in solid, semi-molten, or molten state depending on the spraying modes, particle material, and particle size. It was shown that successful formation of the coating containing all powder mixture components could be achieved in case of proper optimization of spraying parameters. Obtained Fe-Co-Ni, Fe-Co-Ni-Cu, and Fe-Co-Ni-Cu-Al coatings had the uniform lamellae structure. However, the composition of the coatings differed from the initial powder mixture composition due to different deposition efficiencies of the powders. It was also found the mutual influence of blend components on bonding. In particular, the deposition efficiency of iron particles was probably affected by copper.

Similar content being viewed by others

Data availability

The authors declare that all data supporting the findings of this study are available within the article. No supplementary data are available.

Code availability

The LIH code used for simulation is not available for free downloading. The demands should be addressed to Vladimir Yu. Ulianitsky (ulianv@mail.ru).

Change history

30 July 2021

Springer Nature’s version of this paper was updated to present the correct author name Ahmad Ostovari Moghaddam.

References

Fauchais PL, Heberlein JVR, Boulos MI (2014) Thermal spray fundamentals: from powder to part. Springer, pp 1–1566

Pawlowski L (2008) The science and engineering of thermal spray coatings: second edition, pp 1–626. https://doi.org/10.1002/9780470754085

Shabani A, Nahvi SM, Raeissi K (2021) Effect of heat treatment on structure and oxidation resistance of flame-sprayed Ni-20 wt.% Al on carbon steel. J Therm Spray Technol 30:739–753. https://doi.org/10.1007/s11666-021-01158-2

Nikbakht R, Assadi H, Jodoin B (2021) Intermetallic phase evolution of cold-sprayed Ni-Ti composite coatings: influence of as-sprayed chemical composition. J Therm Spray Technol 30:119–130. https://doi.org/10.1007/s11666-020-01112-8

Li X, Wang Q, Niu W, Mao X (2020) Microstructure and mechanical properties of Al-Ni deposits with cold spraying by heat treatment. Xiyou Jinshu/Chin J Rare Met 44(11):1153–1162. https://doi.org/10.13373/j.cnki.cjrm.XY19080014

Wang H-T, Li C-J, Ji G-C, Yang G-J (2012) Annealing effect on the intermetallic compound formation of cold sprayed Fe/Al. J Therm Spray Technol 21(3-4):571–577. https://doi.org/10.1007/s11666-011-9722-1

Chen Y, Liang X, Wei S, Liu Y, Xu B (2009) Heat treatment induced intermetallic phase transition of arc-sprayed coating prepared by the wires combination of aluminum-cathode and steel-anode. Appl Surf Sci 255(19):8299–8304. https://doi.org/10.1016/j.apsusc.2009.05.142

Grosdidier T, Liao HL, Morniroli J-P, Coddet C (2005) Spray forming thick nanostructured and microstructured FeAl deposits. Intermetallics 13(6):596–607

Grosdidier T, Tidu A, Liao H-L (2001) Nanocrystalline Fe-40Al coating processed by thermal spraying of milled powder. Scr Mater 44(3):387–393. https://doi.org/10.1016/S1359-6462(00)00611-4

Blackford JR, Buckley RA, Jones H, Sellars CM, Mccartney DG, Horlock AJ (1998) Spray deposition of an iron aluminide. J Mater Sci 33(17):4417–4421. https://doi.org/10.1023/A:1004424913511

Hashemi SM, Enayati MH, Fathi MH (2009) Plasma spray coatings of Ni-Al-SiC composite. J Therm Spray Technol 18:284–291. https://doi.org/10.1007/s11666-009-9296-3

Ostovari Moghaddam A, Shaburova NA, Samodurova MN, Abdollahzadeh A, Trofimov EA (2021) Additive manufacturing of high entropy alloys: a practical review. J Mater Sci Technol 77:131–162. Cited 5 times. https://doi.org/10.1016/j.jmst.2020.11.029

Ulianitsky VY, Dudina DV, Shtertser AA, Smurov I (2019) Computer-controlled detonation spraying: flexible control of the coating chemistry and microstructure. Metals 9(12):1244. https://doi.org/10.3390/met9121244

Ulianitsky V, Shtertser A, Zlobin S, Smurov I (2011) Computer-controlled detonation spraying: from process fundamentals toward advanced applications. J Therm Spray Technol 20(4):791–801. https://doi.org/10.1007/s11666-011-9649-6

Dudina DV, Batraev IS, Ulianitsky VY, Bulina NV, Korchagin MA, Lomovsky OI (2015) Detonation spraying of Ti-Al intermetallics: phase and microstructure development of the coatings. Mater Manuf Process 30(6):724–729. https://doi.org/10.1080/10426914.2014.984221

Subramani P, Padgelwar N, Shetty S, Pandit A, Sreenivasulu V, Arivazhagan N, Duoli WU, Manikandan M (2019) Hot corrosion studies on detonation-gun-sprayed NiCrAlY and 80Ni–20Cr coatings on alloy X22CrMoV12-1 at 600 °C. Trans Indian Inst Metals 72(6):1639–1642. https://doi.org/10.1007/s12666-019-01567-6

Cui S, Zhai H, Li W, Fan X, Li X, Ning W, Xiong D (2020) Microstructure and corrosion resistance of Fe-based amorphous coating prepared by detonation spray. Surf Coat Technol 399:126096. https://doi.org/10.1016/j.surfcoat.2020.126096

Singh PK, Mishra SB (2020) Studies on solid particle erosion behaviour of D-Gun sprayed WC-Co, Stellite 6 and Stellite 21 coatings on SAE213-T12 boiler steel at 400 °C temperature. Surf Coat Technol 385:125353. https://doi.org/10.1016/j.surfcoat.2020.125353

Cui Y, Wang C, Tang Z (2021) Erosion resistance improvement of polymer matrix composites by detonation-sprayed multilayered coatings. J Therm Spray Technol 30(1-2):394–404. https://doi.org/10.1007/s11666-020-01120-8

Arunnellaiappan T, Baskaran S, Arun S, Prithivirajan R (2021) Corrosion behaviour of detonation gun sprayed cermet coatings on AA5083. Surf Eng 37(2):263–270. https://doi.org/10.1080/02670844.2020.1807096

Rakhadilov B, Buitkenov D, Sagdoldina Z, Seitov B, Kurbanbekov S, Adilkanova M (2021) Structural features and tribological properties of detonation gun sprayed Ti–Si–C coating. Coatings 11(2):141, pp. 1-13. https://doi.org/10.3390/coatings11020141

Sova A, Pervushin D, Smurov I (2010) Development of multimaterial coatings by cold spray and gas detonation spraying. Surf Coat Technol 205(4):1108–1114. https://doi.org/10.1016/j.surfcoat.2010.07.092

Gavrilenko T, Nikolaev Y, Ulianitsky V, Kim M, Hong J (1998) In: Coddet C (ed) Computational code for detonation spraying process, thermal spray: meeting the challenges of the 21st century. ASM International, Nice, pp 1475–1483

Gavrilenko T, Nikolaev Y (2007) Calculation of detonation gas spraying, combust. Explos Shock Waves 43(6):724–731

Yu UV, Dudina DV, Batraev IS, Kovalenko AI, Bulina NV, Bokhonov BB (2015) Detonation spraying of titanium and formation of coatings with spraying atmosphere-dependent phase composition. Surf Coat Technol 261:174–180

Dudina DV, Batraev IS, Ulianitsky VY, Korchagin MA (2014) Possibilities of the computer-controlled detonation spraying method: a chemistry viewpoint. Ceram Int 40(2):3253–3260

Sova A, Maestracci R, Jeandin M, Bertrand P, Smurov I (2017) Kinetics of composite coating formation process in cold spray: modelling and experimental validation. Surf Coat Technol 318:309–314. https://doi.org/10.1016/j.surfcoat.2016.06.084

Funding

This work was supported by the Russian Science Foundation (project No. 20-19-00304).

Author information

Authors and Affiliations

Contributions

Vladimir Ulianitsky: Conceptualization, numerical simulation, methodology, formal analysis, supervision

Denis Rybin: Experimental investigation, numerical simulation, methodology, formal analysis

Alexey Sova: Methodology, formal analysis, writing - original draft

Ahmad Ostovari Moghaddam: Experimental investigation, formal analysis

Evgeny Trofimov: Experimental investigation, formal analysis

Maria Doubeskaia: Methodology, formal analysis

Marina Samodurova: Methodology, supervision

Corresponding author

Ethics declarations

Ethics approval

Not applicable

Consent to participate

Not applicable

Consent for publication

Not applicable

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ulianitsky, V.Y., Rybin, D.K., Sova, A. et al. Formation of metal composites by detonation spray of powder mixtures. Int J Adv Manuf Technol 117, 81–95 (2021). https://doi.org/10.1007/s00170-021-07743-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07743-7