Abstract

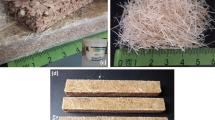

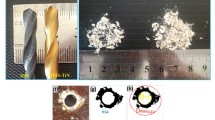

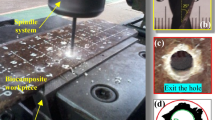

The present study examined the effects of drilling parameters such as spindle speed (N), feed rate (f), diameter of the tools (d) and drill geometry such as twist drills (HSS-TiN) and brad and spur drills (BSD) used on delamination damage in a biosandwich structure consisting of an epoxy matrix reinforced with bidirectional jute fibres and cork (JFCE). Response surface methodology (RSM) and artificial neural networks (ANNs) were exploited to evaluate the influence and interaction of the cutting parameters on the delamination factor (Fd) at the output during drilling. In addition, several optimization methods, such as desirability-based RSM, the genetic algorithm (GA) and the fmincon function, were applied to validate the optimal combination of cutting parameters (f, N and d) in the structures studied in biosandwiches during this research. According to the experimental results, severe damage was indeed observed with the BSD tool (Fd = 1.684) compared to the HSS-TiN tool (Fd = 1.555) for the same cutting conditions. To obtain the minimum Fd, the optimum conditions obtained by GA were respectively 1397.54 rev/min, 51.162 mm/min and 5.981 mm for HSS-TiN for f, N and d.

Similar content being viewed by others

Data availability

Not applicable.

References

Manaia JP, Manaia AT, Rodriges L (2019) Industrial hemp fibers: an overview. Fibers 7(12):106. https://doi.org/10.3390/fib7120106

Koronis G, Silva A, Fontul M (2013) Green composites: a review of adequate materials for automotive applications. Compos Part B Eng 44:120–127. https://doi.org/10.1016/j.compositesb.2012.07.004

Shahzad A (2011) Hemp fiber and its composites – a review. J Compos Mater 46:973–986. https://doi.org/10.1177/0021998311413623

Baley C, Le Duigou A, Bourmaud A, Davies P (2012) Influence of drying on the mechanical behaviour of flax fibres and their unidirectional composites. Compos Part A Appl Sci Manuf 43:1226–1233. https://doi.org/10.1016/j.compositesa.2012.03.005

Le Duigou A, Baley C (2014) Coupled micromechanical analysis and life cycle assessment as an integrated tool for natural fibre composites development. J Clean Prod 83:61–69. https://doi.org/10.1016/j.jclepro.2014.07.027

Diabor E, Funkenbusch P, Kaufmann EE (2019) Characterization of cassava fiber of different genotypes as a potential reinforcement biomaterial for possible tissue engineering composite scaffold application. Fibers Polym 20:217–228. https://doi.org/10.1007/s12221-019-8702-9

Faruk O, Bledzki AK, Fink HP, Sain M (2012) Biocomposites reinforced with natural fibers: 2000-2010. Prog Polym Sci 37:1552–1596. https://doi.org/10.1016/j.progpolymsci.2012.04.003

Amroune S, Belaadi A, Bourchak M, Makhlouf A, Satha H (2020) Statistical and experimental analysis of the mechanical properties of flax fibers. J Nat Fibers. https://doi.org/10.1080/15440478.2020.1775751

Zhou Y, Fan M, Chen L (2016) Interface and bonding mechanisms of plant fibre composites: An overview. 101:31–45. https://doi.org/10.1016/j.compositesb.2016.06.055

Rajmohan T, Vinayagamoorthy R, Mohan K (2019) Review on effect machining parameters on performance of natural fibre–reinforced composites (NFRCs). J Thermoplast Compos Mater 32:1282–1302. https://doi.org/10.1177/0892705718796541

Dutta S, Kim NK, Das R, Bhattacharyya D (2019) Effects of sample orientation on the fire reaction properties of natural fibre composites. Compos Part B Eng 157:195–206. https://doi.org/10.1016/j.compositesb.2018.08.118

Cherief M, Belaadi A, Bouakba M, Bourchak M, Meddour I (2020) Behaviour of lignocellulosic fibre-reinforced cellular core under low-velocity impact loading: Taguchi method. Int J Adv Manuf Technol. 108:223–233. https://doi.org/10.1007/s00170-020-05393-9

Boumaaza M, Belaadi A, Bourchak M (2020) The effect of alkaline treatment on mechanical performance of natural fibers-reinforced plaster: optimization using RSM. J Nat Fibers. https://doi.org/10.1080/15440478.2020.1724236

Jaouadi M, M’sahli S, Sakli F (2009) Optimization and characterization of pulp extracted from the Agave americana L. fibers. Text Res J 79:110–120. https://doi.org/10.1177/0040517508090781

Bedjaoui A, Belaadi A, Amroune S, Madi B (2019) Impact of surface treatment of flax fibers on tensile mechanical properties accompanied by a statistical study. Int J Integr Eng 6:10–17

Belaadi A, Amroune S, Bourchak M (2019) Effect of eco-friendly chemical sodium bicarbonate treatment on the mechanical properties of flax fibres: Weibull statistics. Int J Adv Manuf Technol. 106:1753–1774. https://doi.org/10.1007/s00170-019-04628-8

Benzannache N, Belaadi A, Boumaaza M, Bourchak M (2021) Improving the mechanical performance of biocomposite plaster/Washingtonian filifira fibres using the RSM method. J Build Eng 33:101840. https://doi.org/10.1016/j.jobe.2020.101840

Weng B, Cheng D, Guo Y, Zhai S, Wang C, Xu R, Guo J, Lv Y, Shi L, Chen Y (2020) Properties of Natural Luffa Vine as potential reinforcement for biomass composites. Ind Crops Prod 155:112840. https://doi.org/10.1016/j.indcrop.2020.112840

Engineering M, Ramzan M, Karim A, et al (2020) Sodium carbonate treatment of fibres to improve mechanical and water absorption characteristics of short bamboo natural fibres reinforced polyester composite. Plast Rubber Compos 49:425–433. https://doi.org/10.1080/14658011.2020.1768336

Malik K, Ahmad F, Gunister E (2021) Drilling performance of natural fiber reinforced polymer composites: a review. J Nat Fibers. https://doi.org/10.1080/15440478.2020.1870624

Belaadi A, Laouici H, Bourchak M (2020) Mechanical and drilling performance of short jute fibre-reinforced polymer biocomposites: statistical approach. Int J Adv Manuf Technol 106:106–2006. https://doi.org/10.1007/s00170-019-04761-4

Belaadi A, Boumaaza M, Amroune S, Bourchak M (2020) Mechanical characterization and optimization of delamination factor in drilling bidirectional jute fibre-reinforced polymer biocomposites. Int J Adv Manuf Technol. 111:2073–2094. https://doi.org/10.1007/s00170-020-06217-6

Rao YS, Mohan NS, Shetty N, Shivamurthy B (2019) Drilling and structural property study of multi-layered fiber and fabric reinforced polymer composite - a review. Mater Manuf Process 34:1549–1579. https://doi.org/10.1080/10426914.2019.1686522

Zhang H, Zhu P, Liu Z, Qi S, Zhu Y (2020) Research on prediction method of mechanical properties of open-hole laminated plain woven CFRP composites considering drilling-induced delamination damage. Mech Adv Mater Struct 0:1–16. https://doi.org/10.1080/15376494.2020.1745969

Feito N, Díaz-Álvarez J, López-Puente J, Miguelez MH (2018) Experimental and numerical analysis of step drill bit performance when drilling woven CFRPs. Compos Struct 184:1147–1155. https://doi.org/10.1016/j.compstruct.2017.10.061

Fernández-Pérez J, Cantero JL, Díaz-Álvarez J, Miguélez MH (2017) Influence of cutting parameters on tool wear and hole quality in composite aerospace components drilling. Compos Struct 178:157–161. https://doi.org/10.1016/j.compstruct.2017.06.043

Feito N, Diaz-Álvarez J, López-Puente J, Miguelez MH (2016) Numerical analysis of the influence of tool wear and special cutting geometry when drilling woven CFRPs. Compos Struct 138:285–294. https://doi.org/10.1016/j.compstruct.2015.11.065

Feito N, Diaz-Álvarez A, Cantero JL, Rodríguez-Millán M, Miguélez H (2016) Experimental analysis of special tool geometries when drilling woven and multidirectional CFRPs. J Reinf Plast Compos 35:33–55. https://doi.org/10.1177/0731684415612931

Díaz-Álvarez J, Olmedo A, Santiuste C, Miguélez MH (2014) Theoretical estimation of thermal effects in drilling of woven carbon fiber composite. Materials (Basel) 7:4442–4454. https://doi.org/10.3390/ma7064442

Díaz-Álvarez A, Rodríguez-Millán M, Díaz-Álvarez J, Miguélez MH (2018) Experimental analysis of drilling induced damage in aramid composites. Compos Struct 202:1136–1144. https://doi.org/10.1016/j.compstruct.2018.05.068

Bayraktar Ş, Turgut Y (2020) Determination of delamination in drilling of carbon fiber reinforced carbon matrix composites/Al 6013-T651 stacks. Measurement 154:107493. https://doi.org/10.1016/j.measurement.2020.107493

Chaitanya S, Singh I (2018) Ecofriendly treatment of aloe vera fibers for PLA based green composites. Int J Precis Eng Manuf - Green Technol. 5:143–150. https://doi.org/10.1007/s40684-018-0015-8

De Olveira LÁ, Dos Santos JC, Panzera TH et al (2018) Investigations on short coir fibre-reinforced composites via full factorial design. Polym Polym Compos 26:391–399. https://doi.org/10.1177/0967391118806144

Bajpai PK, Debnath K, Singh I (2015) Hole making in natural polylactic acid laminates: an experimental investigation. J Thermoplast Compos Mater 30:1–17. https://doi.org/10.1177/0892705715575094

Debnath K, Sisodia M, Kumar A, Singh I (2016) Damage-free hole making in fiber-reinforced composites: an innovative tool design approach. Mater Manuf Process 31:1400–1408. https://doi.org/10.1080/10426914.2016.1140191

Debnath K, Singh I, Dvivedi A (2014) Drilling characteristics of sisal fiber-reinforced epoxy and polypropylene composites. Mater Manuf Process 29:1401–1409. https://doi.org/10.1080/10426914.2014.941870

Debnath K, Singh I, Dvivedi A (2017) On the analysis of force during secondary processing of natural fiber-reinforced composite laminates. Polym Compos 38:164–174. https://doi.org/10.1002/pc.23572

Chaudhary V, Gohil PP (2016) Investigations on drilling of bidirectional cotton polyester composite. Mater Manuf Process 31:960–968. https://doi.org/10.1080/10426914.2015.1059444

Venkateshwaran N, ElayaPerumal A (2013) Hole quality evaluation of natural fiber composite using image analysis technique. J Reinf Plast Compos 32:1188–1197. https://doi.org/10.1177/0731684413486847

Athijayamani A, Thiruchitrambalam M, Natarajan U, Pazhanivel B (2010) Influence of alkali-treated fibers on the mechanical properties and machinability of roselle and sisal fiber hybrid polyester composite. Polym Compos 31:723–731. https://doi.org/10.1002/pc.20853

Ramesh M, Sri Ananda Atreya T, Aswin US et al (2014) Processing and mechanical property evaluation of banana fiber reinforced polymer composites. Procedia Eng 97:563–572. https://doi.org/10.1016/j.proeng.2014.12.284

Ismail SO, Dhakal HN, Dimla E, Beaugrand J, Popov I (2016) Effects of drilling parameters and aspect ratios on delamination and surface roughness of lignocellulosic HFRP composite laminates. J Appl Polym Sci 133. https://doi.org/10.1002/app.42879

Abilash N, Sivapragash M (2016) Optimizing the delamination failure in bamboo fiber reinforced polyester composite. J King Saud Univ - Eng Sci 28:92–102. https://doi.org/10.1016/j.jksues.2013.09.004

Azuan SAS, Juraidi JM, Muhamad WMW (2012) Evaluation of delamination in drilling rice husk reinforced polyester composites. Appl Mech Mater 232:106–110. https://doi.org/10.4028/www.scientific.net/AMM.232.106

Díaz-Álvarez A, Díaz-Álvarez J, Santiuste C, Miguélez MH (2019) Experimental and numerical analysis of the influence of drill point angle when drilling biocomposites. Compos Struct 209:700–709. https://doi.org/10.1016/j.compstruct.2018.11.018

Babu GD, Babu KS, Gowd BUM (2012) Effects of drilling parameters on delamination of hemp fiber reinforced composites. Int J Mech Eng Res Dev 2:1–8

Azuan SAS (2013) Effects of drilling parameters on delamination of coconut meat husk reinforced polyester composites. Adv Environ Biol 7:1097–1100. https://doi.org/10.1007/978-3-642-38345-8_6

Roy Choudhury M, Srinivas MS, Debnath K (2018) Experimental investigations on drilling of lignocellulosic fiber reinforced composite laminates. J Manuf Process 34:51–61. https://doi.org/10.1016/j.jmapro.2018.05.032

Aravindh S, Umanath K (2015) Delamination in drilling of natural fibre reinforced polymer composites produced by Compression moulding. In: Advances in Materials and Manufacturing. Trans Tech Publications 766-767:796–800. https://doi.org/10.4028/www.scientific.net/AMM.766-767.796

Sridharan V, Muthukrishnan N (2013) Optimization of machinability of polyester/modified jute fabric composite using grey relational analysis (GRA). Procedia Eng 64:1003–1012. https://doi.org/10.1016/j.proeng.2013.09.177

Sridharan V, Raja T, Muthukrishnan N (2016) Study of the effect of matrix, fibre treatment and graphene on delamination by drilling jute/epoxy nanohybrid composite. Arab J Sci Eng 41:10–14. https://doi.org/10.1007/s13369-015-2005-2

Yallew TB, Kumar P, Singh I (2015) A study about hole making in woven jute fabric-reinforced polymer composites. Proc IMechE Part L J Mater Des Appl 230:888–898. https://doi.org/10.1177/1464420715587750

Monteiro SN, Terrones LAH, D’Almeida JRM (2008) Mechanical performance of coir fiber/polyester composites. Polym Test 27:591–595. https://doi.org/10.1016/j.polymertesting.2008.03.003

Jayabal S, Natarajan U (2011) Drilling analysis of coir – fibre-reinforced polyester composites. Bull Mater Sci 34:1563–1567. https://doi.org/10.1007/s12034-011-0359-y

Bajpai PK, Singh I (2013) Drilling behavior of sisal fiber-reinforced polypropylene composite laminates. J Reinf Plast Compos 32:1569–1576. https://doi.org/10.1177/0731684413492866

Durão LMP, Gonçalves DJS, Tavares JMRS, de Albuquerque VHC, Panzera TH, Silva LJ, Vieira AA, Baptista APM (2013) Drilling delamination outcomes on glass and sisal reinforced plastics. Mater Sci Forum 730–732:301–306. https://doi.org/10.4028/www.scientific.net/MSF.730-732.301

Chen W-C (1997) Some experimental investigations in the drilling of carbon fiber-reinforced plastic (CFRP) composite laminates. Int J Mach Tools Manuf 37:1097–1108. https://doi.org/10.1016/S0890-6955(96)00095-8

Anand G, Alagumurthi N, Palanikumar K, Venkateshwaran N, Elansezhain R (2018) Influence of drilling process parameters on hybrid vinyl ester composite. Mater Manuf Process 33:1299–1305. https://doi.org/10.1080/10426914.2018.1453161

Chandramohan D, Marimuthu K (2011) Drilling of natural fiber particle reinforced polymer composite material. Int J Adv Eng Res Stud I:134–145

Mercy JL, Sivashankari P, Sangeetha M, Kavitha KR, Prakash S (2020) Genetic optimization of machining parameters affecting thrust force during drilling of pineapple fiber composite plates – an experimental approach. J Nat Fibers. https://doi.org/10.1080/15440478.2020.1788484

M N, Upadhya R, Sehgal S, et al (2020) Mechanical and drilling process characterisation of herringbone sisal fabric reinforced vinyl ester sandwich composites. Adv Mater Process Technol. https://doi.org/10.1080/2374068X.2020.1855963

Machado CM, Silva D, Vidal C, Soares B, Teixeira JP (2021) A new approach to assess delamination in drilling carbon fibre-reinforced epoxy composite materials. Int J Adv Manuf Technol. 112:3389–3398. https://doi.org/10.1007/s00170-021-06636-z

Davim JP, Rubio JC, Abrao AM (2007) A novel approach based on digital image analysis to evaluate the delamination factor after drilling composite laminates. Compos Sci Technol 67:1939–1945. https://doi.org/10.1016/j.compscitech.2006.10.009

Majumder A (2010) Comparison of ANN with RSM in predicting surface roughness with respect to process parameters in Nd: YAG laser drilling. Int J Eng Sci Technol 2:5175–5186

Karnik SR, Gaitonde VN, Davim JP (2008) A comparative study of the ANN and RSM modeling approaches for predicting burr size in drilling. Int J Adv Manuf Technol 38:868–883

Benardos PG, Vosniakos G-C (2003) Predicting surface roughness in machining: a review. Int J Mach Tools Manuf 43:833–844. https://doi.org/10.1016/S0890-6955(03)00059-2

Rezghi Maleki H, Hamedi M, Kubouchi M, Arao Y (2019) Experimental study on drilling of jute fiber reinforced polymer composites. J Compos Mater 53:283–295

Ramesh M, Palanikumar K, Reddy KH (2014) Experimental investigation and analysis of machining characteristics in drilling hybrid glass-sisal-jute fiber reinforced polymer composites. In: 5th international & 26th all india manufacturing technology, design and research conference AIMTDR

Vinayagamoorthy R, Rajeswari N, Karthikeyan S (2015) Investigations of damages during drilling of natural sandwich composites. In: Applied Mechanics and Materials. Trans Tech Publ 766-767:812–817. https://doi.org/10.4028/www.scientific.net/AMM.766-767.812

Vinayagamoorthy R, Rajeswari N, Sivanarasimha S, Balasubramanian K (2015) Fuzzy based optimization of thrust force and torque during drilling of natural hybrid composites. In: Applied Mechanics and Materials. Trans Tech Publ 787:265–269. https://doi.org/10.4028/www.scientific.net/AMM.787.265

Ramnath BV, Sharavanan S, Jeykrishnan J (2017) Optimization of process parameters in drilling of fibre hybrid composite using Taguchi and grey relational analysis. In: IOP Conference Series: Materials Science and Engineering. IOP Publishing 183:12003. https://doi.org/10.1088/1757-899X/183/1/012003

Vinayagamoorthy R (2017) Parametric optimization studies on drilling of sandwich composites using the Box–Behnken design. Mater Manuf Process 32:645–653. https://doi.org/10.1080/10426914.2016.1232811

Pailoor S, Murthy HNN, Sreenivasa TN (2021) Drilling of in-line compression molded jute/polypropylene composites. J Nat Fibers 18:91–104. https://doi.org/10.1080/15440478.2019.1612309

Çelik YH, Alp MS (2020) Determination of milling performance of jute and flax fiber reinforced composites. J Nat Fibers 00:1–15. https://doi.org/10.1080/15440478.2020.1764435

Acknowledgments

The authors gratefully acknowledge (la Direction Générale de la Recherche Scientifique et du Développement Technologique, Algérie) DGRSDT for their support in this work.

Funding

The authors declare no funding information.

Author information

Authors and Affiliations

Contributions

Zohir Tabet: Conceptualization, Investigation, Methodology, Writing—review and editing. Ahmed Belaadi: Conceptualization, Investigation, Methodology, Supervision, Writing—review and editing. Messaouda Boumaaza: Conceptualization, Investigation, Writing—review and editing. Mostefa Bourchak: Investigation, Writing—review and editing.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Ethics approval

The work contains no libellous or unlawful statements, does not infringe on the rights of others, or contains material or instructions that might cause harm or injury.

Consent to participate

The authors consent to participate.

Consent for publication

The authors consent to publish.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Tabet, Z., Belaadi, A., Boumaaza, M. et al. Drilling of a bidirectional jute fibre and cork-reinforced polymer biosandwich structure: ANN and RSM approaches for modelling and optimization. Int J Adv Manuf Technol 117, 3819–3839 (2021). https://doi.org/10.1007/s00170-021-07679-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07679-y