Abstract

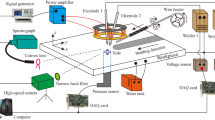

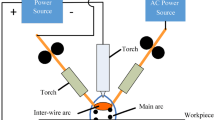

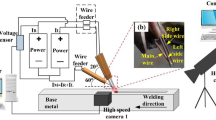

In this paper, a self-designed cusp external magnetic field (EMF) was employed to assist the two-electrode TIG (T-TIG), and its common conductive channel characteristics were aimed to optimize the energy distribution of T-TIG. The influences of the cusp EMF on arc morphology, arc plasma information, and arc pressure of T-TIG were respectively analyzed based on a high-speed camera, spectrograph, and pressure sensor. The results showed that the cusp EMF could compress T-TIG in the direction parallel to the array of two electrodes of T-TIG, and thus, a common conductive channel with stronger brightness and higher stiffness was obtained. Besides, by applied cusp EMF, the electron temperature and electron density of the common conductive channel of T-TIG were increased, and in the radial, the distributions of electron temperature and electron density of T-TIG were more concentrated. Under the condition of welding current of 40 A + 40 A, the electron density on the central axis of T-TIG could be increased by 16% by applied cusp EMF with a 30 A excitation current. In addition, the enhanced common conductive channel characteristics of T-TIG by the cusp EMF caused the arc pressure on the central axis of T-TIG to be increased by 14%, which was beneficial to improve the weld penetration.

Similar content being viewed by others

Data availability

All the data have been presented in the manuscript.

References

Kobayashi K, Yamada M, Fujishima K, Iijima T, Ushio M (2004) Development of high efficiency twin-arc TIG welding method. IIW Doc XII:1669-1701

Leng X, Zhang G, Wu L (2006) Experimental study on improving welding efficiency of twin electrode TIG welding method. Sci Technol Weld Join 11:550–554

Leng X, Zhang G, Wu L (2006) The characteristic of twin-electrode TIG coupling arc pressure. J Phys D Appl Phys 39:1120–1126

Wu D, Huang J, Kong L, Hua X, Wang M (2020) Coupled mechanisms of arc, weld pool and weld microstructures in high speed tandem TIG welding. Int J Heat Mass Transf 154:119641

Ogino Y, Hirata Y, Nomura K (2011) Numerical analysis of the heat source characteristics of a two-electrode TIG arc. J Phys D Appl Phys 44:215202

Ogino Y, Hirata Y, Kawata J, Nomura K (2013) Numerical analysis of arc plasma and weld pool formation by a tandem TIG arc. Weld World 57:411–423

Wang X, Luo Y, Wu G, Chi L, Fan D (2018) Numerical simulation of metal vapour behavior in double electrodes TIG welding. Plasma Chem Plasma Process 38:1095–1114

Wang X, Fan D, Huang J, Huang Y (2014) A unified model of coupled arc plasma and weld pool for double electrodes TIG welding. J Phys D Appl Phys 47:275202

Tsai NS, Eagar TW (1985) Distribution of the heat and current fluxes in gas tungsten arcs. Metall Trans B 16:841–846

Wu H, Chang Y, Lu L, Bai J (2017) Review on magnetically controlled arc welding process. Int J Adv Manuf Technol 91:4263–4273

Wang J, Sun Q, Feng J, Wang S, Zhao H (2017) Characteristics of welding and arc pressure in TIG narrow gap welding using novel magnetic arc oscillation. Int J Adv Manuf Technol 90:413–420

Sun Q, Wang J, Cai C, Li Q, Feng J (2016) Optimization of magnetic arc oscillation system by using double magnetic pole to TIG narrow gap welding. Int J Adv Manuf Technol 86:761–767

Yin X, Gou J, Zhang J, Sun J (2012) Numerical study of arc plasmas and weld pools for GTAW with applied axial magnetic fields. J Phys D Appl Phys 45:285203

Xiao L, Fan D, Huang J (2018) Tungsten cathode-arc plasma-weld pool interaction in the magnetically rotated or deflected gas tungsten arc welding configuration. J Manuf Process 32:127–137

Liu S, Liu Z, Zhao X, Fan X (2020) Influence of cusp magnetic field configuration on K-TIG welding arc penetration behavior. J Manuf Process 53:229–237

Liu Z, Chen S, Yuan X, Zuo A, Zhang T, Luo Z (2018) Magnetic-enhanced keyhole TIG welding process. Int J Adv Manuf Technol 99:275–285

Wang L, Chen J, Wu C, Luan S (2020) Numerical analysis of arc and droplet behaviors in gas metal arc welding with external compound magnetic field. J Mater Process Technol 282:116638

Chen J, Zhang Y, Wu C, Padhy GK (2019) Suppression of undercut defects in high-speed GMAW through a compound magnetic field. J Mater Process Technol 274:116288

Liu L, Chen M, Li C (2013) Effect of electric arc on laser keyhole behavior based on direct observation during low power pulsed laser–arc hybrid welding process. Opt Lasers Eng 51:1153–1160

Chen M, Xin L, Zhou Q, He L, Wu F (2018) Effect of laser pulse on alternative current arc discharge during laser-arc hybrid welding of magnesium alloy. Opt Lasers Eng 100:208–215

Kumar A, DebRoy T (2003) Calculation of three-dimensional electromagnetic force field during arc welding. J Appl Phys 94:1267–1277

Qi B, Yang M, Cong B, Liu F (2013) The effect of arc behavior on weld geometry by high-frequency pulse GTAW process with 0Cr18Ni9Ti stainless steel. Int J Adv Manuf Technol 66:1545–1553

Lin ML, Eagar TW (1986) Pressures produced by gas tungsten arcs. Metall Trans B 17:601–607

Lago F, Gonzalez JJ, Freton P, Gleizes A (2004) A numerical modelling of an electric arc and its interaction with the anode: Part I. The two-dimensional model. J Phys D Appl Phys 37:883–897

Ueyama T, Ohnawa T, Tanaka M, Nakata K (2007) Occurrence of arc interaction in tandem pulsed gas metal arc welding. Sci Technol Weld Join 12:523–529

Maecker H (1955) Plasmastromungen in lichtbogen infolge eigenmagnetischer compression. Z Phys 141:198–216

Ando K, Hasegawa M (1985) The phenomenon of welding arc. China Machine Press, Beijing in Chinese

Funding

This work was supported by the National Key Research and Development Program of China(2018YFB1107900), and the National Natural Science Foundation of China (No. U1960111).

Author information

Authors and Affiliations

Contributions

Yanli Zhu: methodology, writing-original draft, formal analysis.

Xinkun Xu: supervision, validation.

Runtao Liu: conceptualization.

Liming Liu: conceptualization, writing-review and editing, funding acquisition.

Corresponding author

Ethics declarations

Ethics approval

The paper follows the guidelines of the Committee on Publication Ethics(COPE).

Consent to participate

The authors declare that they all consent to participate this research.

Consent for publication

The authors declare that they all consent to publish the manuscript.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhu, Y., Xu, X., Liu, R. et al. Magnetic-enhanced common conductive channel characteristics of two-electrode TIG. Int J Adv Manuf Technol 116, 3217–3229 (2021). https://doi.org/10.1007/s00170-021-07674-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07674-3