Abstract

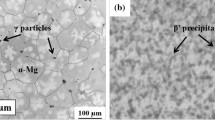

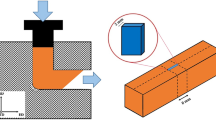

Based on the crack phenomena observed in an actual cogging experiment of the new as-cast GH4151 alloy, the mechanism of crack generation and propagation during cogging was studied by scanning electron microscopy (SEM) and electron backscatter diffraction (EBSD). The results reveal that there were massive and spherical precipitates at the original grain boundary, large-scale holes at the edge of the precipitates and other areas, tiny pores near the grain boundary, and secondary microcracks along the grain boundary. These phenomena all promoted the generation and propagation of cracks. The fracture surface of the crack was determined as intergranular fracture, and local cleavage fracture was found to occur at the grain intersection. Moreover, the strain energy concentration at the grain boundary was evident, and the deformation of billets was found to primarily depend on grain boundary slip and grain rotation.

Similar content being viewed by others

Availability of data and materials

The data, materials, and related pictures in this article are true and available.

References

Li XX, Jia CL, Jiang ZH, Zhang Y, Lv SM (2020) Investigation of solidification behavior in a new high alloy Ni-based superalloy. JOM 72:4139–4147. https://doi.org/10.1007/s11837-020-04346-7

Jia CL, Zhang FL, Wei K, Lv SM (2019) Effective solution treatment can result in improved creep performance of superalloys [J]. J Alloys Compd 770:166–174. https://doi.org/10.1016/j.jallcom.2018.08.089

Li XX, Jia CL, Zhang Y, Lv SM, Jiang ZH (2020) Incipient melting phase and its dissolution kinetics for a new superalloy. T Nonferr Metal Soc 30(8):2107–2118. https://doi.org/10.1016/S1003-6326(20)65364-X

Li XX, Jia CL, Zhang Y, Lv SM, Jiang ZH (2020) Segregation and homogenization for a new nickel-based superalloy. Vacuum 177:109379. https://doi.org/10.1016/j.vacuum.2020.109379

Li XX, Jia CL, Zhang Y, Lv SM, Jiang ZH (2020) Cracking mechanism in as-cast GH4151 superalloy ingot with high γ′; phase content. T Nonferr Metal Soc 30(10):2020,2697–2020,2708. https://doi.org/10.1016/S1003-6326(20)65413-9

Lv SM, Jia CL, He XB, Wan ZP, Li XX, Qu XH (2019) Superplastic deformation and dynamic recrystallization of a novel disc superalloy GH4151. Materials (Basel, Switzerland) 12(22):3667. https://doi.org/10.3390/ma12223667

Lv SM, Chen JB, He XB, Jia CL, Wei K, Qu XH (2020) Investigation on sub-solvus recrystallization mechanisms in an advanced γ-γ ' nickel-based superalloy GH4151. Materials (Basel, Switzerland) 13(20):4553. https://doi.org/10.3390/ma13204553

Allwood JM, Tekkaya AE, Stanistreet TF (2005) The development of ring rolling technology. Steel Res Int 76(2-3):111–120. https://doi.org/10.1002/srin.200505981

Na YS, Yeom JT, Park NK, Lee JY (2003) Prediction of microstructure evolution during high temperature blade forging of a Ni−Fe based superalloy, Alloy 718. Met Mater Int 9:15–19. https://doi.org/10.1007/BF03027224

Chan KS (2014) Time-dependent crack growth thresholds of Ni-base superalloys. Metall Mater Trans A 45:3454–3466. https://doi.org/10.1007/s11661-014-2271-8

Floreen S, Davidson JM (1983) The effects of b and zr on the creep and fatigue crack growth behavior of a Ni-base superalloy. Metall Mater Trans A 14:895–901. https://doi.org/10.1007/BF02644294

Hwang SK, Lee HN, Yoon BH (1989) Mechanism of cyclic softening and fracture of an Ni-base γ′-Strengthened alloy under low-cycle fatigue. Metall Mater Trans A 20:2793–2801. https://doi.org/10.1007/BF02670171

Suzuki A, Gigliotti MFX, Hazel BT, Konitzer DG, Pollock TM (2010) Crack progression during sustained-peak low-cycle fatigue in single-crystal Ni-base superalloy René N5. Metall Mater Trans A 41:947–956. https://doi.org/10.1007/s11661-009-0169-7

Kim SH, Kim C, Cha JH, Jang C, Yoo YS (2019) Effect of minor alloying elements on the oxidation behavior of Ni-base alloys in a high-temperature steam environment. Oxid Met 92:505–523. https://doi.org/10.1007/s11085-019-09940-y

Deng DY, Eriksson R, Peng RL, Moverare J (2020) On the dwell-fatigue crack propagation behavior of a high-strength Ni-base superalloy manufactured by selective laser melting. Metall Mater Trans A 51:962–972. https://doi.org/10.1007/s11661-019-05548-8

Chu ZK, Yu JJ, Sun XF, Guan HR, Hu ZQ (2009) High-temperature creep deformation and fracture behavior of a directionally solidified Ni-base superalloy DZ951. Metall Mater Trans A 40:2927–2937. https://doi.org/10.1007/s11661-009-0001-4

Xie G, Wang L, Zhang J, Lou LH (2008) Influence of recrystallization on the high-temperature properties of a directionally solidified Ni-base superalloy. Metall Mater Trans A 39:206–210. https://doi.org/10.1007/s11661-007-9387-z

Sharghi-Moshtaghi R, Kahn H, Ge YD, Gu XT, Martin FJ, Natishan PM, Rayne RJ, Michal GM, Ernst F, Heuer AH (2010) Low-temperature carburization of the Ni-base superalloy IN718: improvements in surface hardness and crevice corrosion resistance. Metall Mater Trans A 41:2022–2032. https://doi.org/10.1007/s11661-010-0299-y

Zhao Z, Zhang F, Dong C, Yang X, Chen B (2020) Initiation and early-stage growth of internal fatigue cracking under very-high-cycle fatigue regime at high temperature. Metall Mater Trans A 51:1575–1592. https://doi.org/10.1007/s11661-020-05633-3

Chen K, Rui SY, Wang F, Dong JX, Yao ZH (2019) Microstructure and homogenization process of as-cast GH4169D alloy for novel turbine disk. Int J Miner Metall Mater 26:889–900. https://doi.org/10.1007/s12613-019-1802-0

Borouni A, Kermanpur A (2020) Effect of Ta/W ratio on microstructural features and segregation patterns of the single crystal PWA1483 Ni-based superalloy. J Mater Eng Perform 29:7567–7586. https://doi.org/10.1007/s11665-020-05189-8

He LZ, Zheng Q, Sun XF, Hou GC, Guan HR, Hu ZQ (2005) M23C6 precipitation behavior in a Ni-base superalloy M963. J Mater Sci 40:2959–2964. https://doi.org/10.1007/s10853-005-2418-5

Murata Y, Suga K, Yukawa N (1986) Effect of transition elements on the properties of MC carbides in IN-100 nickel-based superalloy. J Mater Sci 21:3653–3660. https://doi.org/10.1007/BF02403016

Nathal MV, Ebert LJ (1985) The influence of cobalt, tantalum, and tungsten on the elevated temperature mechanical properties of single crystal nickel-base superalloys. Metall Mater Trans A 16:1863–1870. https://doi.org/10.1007/BF02670373

Ravindran C, Chaturvedi MC (1975) Effect of aluminum addition on the precipitation behavior of a Co-Ni-Cr base superalloy containing Nb. Metall Mater Trans A 6:213–217. https://doi.org/10.1007/BF02673690

Jia Z, Gao ZX, Ji JJ (2020) A mechanism for the evolution of hot compression cracking in Inconel 625 alloy ingot with respect to grain growth. Adv Eng Mater 22:1901445. https://doi.org/10.1002/adem.201901445

Funding

Zhi Jia would like to gratefully acknowledge the support of the Open Project of Science and Technology on Advanced High Temperature Structural Materials Laboratory (No. 6142903200206), Science Foundation for Distinguished Young Scholars of Gansu Province (No. 18JR3RA134), and Lanzhou University of Technology Support Plan for Excellent Young Scholars (No. CGZH001).

Author information

Authors and Affiliations

Contributions

All the authors participated in and agreed to publish this article, and provided a lot of help in the process of writing this article.

Corresponding author

Ethics declarations

Ethical approval

The submitted article is original by the authors, and has not been published in any form or language in other places. The data are obtained through reasonable and rigorous experimental methods, and there is no fabrication, forgery, or plagiarism of other people’s data.

Consent to participate

Consent

Consent for publication

Consent

Conflict of interest

All authors have read and approved this version of the article, and due care has been taken to ensure the integrity of the work. No part of this paper has been published or submitted elsewhere. The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jia, Z., Wei, B., Jia, C. et al. The mechanism of crack generation and propagation in the new casting alloy GH4151 during cogging. Int J Adv Manuf Technol 116, 2455–2465 (2021). https://doi.org/10.1007/s00170-021-07609-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07609-y