Abstract

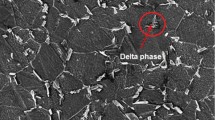

In this work, novel DPS/MWCNT composites were synthesized through filling multi-walled carbon nanotubes (MWCNTs) with dialkyl pentasulfide (DPS) using a wet-chemical method. A nanofluid that use the DPS/MWCNT composites as additives was then developed for achieving a high-performance turning. The performance of the developed nanofluid including dispersion stability, heat transfer capacity, and wettability was evaluated using thermophysical analytical methods. The machining performance of the DPS/MWCNT composites nanofluid was systematically investigated in the turning of AISI 52100 alloy steel, using a commercial emulsion coolant as a benchmark. The lubrication mechanism of the nanofluid involved in the turning process was reveal with the aid of X-ray photoelectron spectroscopy (XPS). The results showed that DPS was successfully filled into MWCNTs with a filling rate of around 25.7%. The nanofluid had an excellent dispersion performance and produced respective 105.0% and 23.6% improvements in the heat transfer and wetting performance, in comparison to a base fluid. During turning, the composites suspended in the nanofluid acted as microbearings to reduce the friction of sliding, while the DPS filled in the MWCNTs was released under pressure to generate a complex lubricating film at the tool-chip interface, leading to a low resistance to cutting. This thus resulted in 15% and 25% reductions in the cutting force and temperature as well as 16% and 22% improvements in the surface roughness and tool life, in comparison to a conventional turning.

Similar content being viewed by others

Data availability

Not applicable.

References

Choi SUS, Eastman JA (1995) Enhancing thermal conductivity of fluids with nanoparticles. ASME International Mechanical EngineeringCongress & Exposition, San Francisco, Expo 66:99–105

Jung SN, Pil-Ho L (2011) Experimental characterization of micro-drilling process using nanofluid minimum quantity lubrication. Int J Mach Tool Manu 51:649–652

Lee PH, Nam TS, Li C, Lee SW (2010) Experiment study on meso-scale milling process using nanofluid minimum quantity lubrication and compressed chilly air. Trans Korean Soc Mech Eng 34:1493–1498

Su Y, Gong L, Li B, Liu Z, Chen D (2016) Performance evaluation of nanofluid MQL with vegetable based oil and ester oil as base fluids in turning. Int J Adv Manuf Technol 83:2083–2089

Roy S, Ghosh A (2013) High speed turning of AISI 4140 steel using nanofluid through twin jet SQL system. In: Proceedings of the ASME 2013 International Manufacturing Science and Engineering Conference, Wisconsin, Madison, June 10-14

Zhang YB, Li CH (2015) Experimental evaluation of the lubrication performance of MoS2/CNT nano fluid for minimal quantity lubrication in Ni-based alloy grinding. Int J Mach Tool Manu 99:19–33

Marcon A, Melkote S, Kalaitzidou K, Debra D (2010) An experimental evaluation of graphite nanoplatelet based lubricant in micro-milling. CIRP Ann Manuf Technol 59:141–144

Heireddin B, Gao H, Liang H (2016) Roles of nanoparticles in oil lubrication. Tribol Int 102:88–98

Sharma P, Sidhu BS, Sharma J (2015) Investigation of effects of nanofluids on turning of AISI D2 steel using minimum quantity lubrication. J Clean Prod 108:72–79

Rao SN, Satyanarayana DB, Venkatasubbaiah DK (2011) Experimental estimation of tool wear and cutting temperatures in MQL using cutting fluids with CNT inclusion. Int J Eng Sci 4:2928–2931

Öndin O, Kıvak T, Sarıkaya M, Yıldırım ÇV (2020) Investigation of the influence of MWCNTs mixed nanofluid on the machinability characteristics of PH 13-8 Mo stainless steel. Tribol Int 148:106323

Iijima S (1991) Helical microtubes of graphitic carbon. Nature 354:56–58

Wang P, Zhang D (2018) Effect of molecular structure on dispersion of carbon nanotubes by natural organic matter surrogates. China Environ Sci 38:3429–3436

Yuba RP, Li WZ (2018) Synthesis, properties, and applications of carbon nanotubes filled with foreign materials: a review. Mater Today Phys 7:7–34

Wang GJ, Qu ZH (2006) Modification of carbon nanotubes by chemical reaction. Prog Chem 18:1305–1312

Dujardin E, Ebbesen TW, Hiura H, Tanigaki K (1994) Capillarity and wetting of carbon nanotubes. Science 265:1850–1852

Kumar PG, Renuka M, Velraj R (2018) Thermal and electrical conductivity enhancement of solar glycol-water mixture containing MWCNTs. Fullerenes, Nanotubes, Carbon Nanostruct 26:871–879

Guan JJ, Wang J, Lv T, Xue XF (2019) Dispersion stability and enhanced heat transfer of cutting use nanofluids prepared by composite of carbon nanotubes and Dialkyl pentasulfide. Mater Res Express 8:085633

Nurettin S, Muammer K (2018) Stabilization of the aqueous dispersion of carbon nanotubes using different approaches. Therm Sci Eng Prog 8:411–417

Bikash CB, Chetana DS, Sudarsan Ghosha P, Venkateswara R (2017) Spread ability studies of metal working fluids on tool surface and its impact on minimum amount cooling and lubrication turning. J Mater Process Technol 244:1–16

Xu J, Yamda K, Sekiya K (2017) Study of comparing cutting force signal features for dry, air cooling and minimum quantity lubrication (MQL) drilling. J Adv Mech Des Syst 11:16–00537

Xia J, Li BZ, Zhang XP (2014) The effects of minimum quantity lubrication (MQL) on machining force, temperature, and residual stress. Int J Precis Eng Manuf 15:2443–2451

Prabhu S, Vinayagam BK (2012) AFM investigation in grinding process with nanofluids using taguchi analysis. Int J Adv Manuf Technol 60:149–160

Thakur A, Manna A, Samir S (2020) Experimental investigation of nanofluids in minimum quantity lubrication during turning of EN-24 steel. P I Mech Eng J-J Eng 234:712–729

Lv T, Huang SQ, Hu XD, Feng BHXXF (2019) Study on Aerosol Characteristics of Electrostatic Minimum Quantity Lubrication and Its Turning Performance. J Mech Eng 55:129–138

Turgay K, Murat S, Çağrı VY, Şenol Ş (2020) Study on turning performance of PVD TiN coated Al2O3+TiCN ceramic tool under cutting fluid reinforced by nano-sized solid particles. J Manuf Process 56:522–539

Khaleduzzaman SS, Mahbubul IM, Shahrul IM, Saidur R (2013) Effect of particle concentration, temperature and surfactant on surface tension of nanofluids. Int Commun Heat Mass Transfer 49:110–114

Guan JJ, Liu DL, Wang Y, Feng BH, Xu XF (2020) Tribological properties of nanofluid prepared by composite of carbon nanotube and oleic acid. Tribology 40:290–299

Guan JJ, Wang J, Ding YP, Lv T, Xu XF (2019) Dispersion stability and enhanced heat transfer of cutting use nanofluids prepared by composite of carbon nanotubes and Dialkyl pentasulfide. Mater Res Express 6:085633

Dosbaeva GK, El Hakim MA, Shalaby MA (2015) Cutting temperature effect on PCBN and CVD coated carbide tools in hard turning of D2 tool steel. Int J Refract Met Hard Mater 50:1–8

Briggs D (1998) Surface Analysis of Polymers by XPS and Static SIMS. Cambridge University Press, London

Rashi G, Amzad K, Om PK (2020) Fatty acid-derived ionic liquids as renewable lubricant additives: effect of chain length and unsaturation. J Mol Liq 301:112322

Yi HL, Wu H, Zeng XQ, Ren TH (2006) X-ray absorption near-edge structure spectroscopy of tribochemical/thermal films generated from serial alkyl polysulfides. Acta Phys Sin 22:1473

Yu B, Liu ZL, Ma CB, Sun JJ, Liu WM, Zhou F (2015) Ionic liquid modified multi-walled carbon nanotubes as lubricant additive. Tribol Int 81:38–42

Şenol Ş, Turgay K (2019) Performances of different eco-friendly nanofluid lubricants in the milling of Inconel X-750 superalloy. Tribol Int 137:180–192

Çağrı VY, Murat S, Turgay K, Şenol Ş (2019) The effect of addition of hBN nanoparticles to nanofluid-MQL on tool wear patterns, tool life, roughness and temperature in turning of Ni-based Inconel 625. Tribol Int 134:443–456

Funding

This research was financially supported by the Youth Science Foundation Program of Natural Science Foundation of China (NSFC 51805345) and Youth Science Foundation Program of Natural Science Foundation of Jiangsu Province (BK20170373).

Author information

Authors and Affiliations

Contributions

All the authors contributed significantly to the work with the order provided.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Guan, J., Ding, Y., Gao, C. et al. Experimental study on turning performance of a novel nanofluid prepared by composites of MWCNTs. Int J Adv Manuf Technol 116, 2373–2385 (2021). https://doi.org/10.1007/s00170-021-07554-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07554-w