Abstract

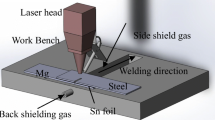

A three-dimensional numerical model for thermal-fluid-metallurgical coupling was established to inspect the effect from a stable longitudinal magnetic field on molten pool of magnesium/aluminum laser welding. Magnetic field-assisted laser welding platform was built to test the morphology and spectrum of the metal vapor/plasma. The scanning electron microscope (SEM) and energy dispersive spectrometry (EDS) were used to determine the morphology and element distribution of molten pool cross section. Simulation results showed that temperature gradient of molten pool was reduced, heat distribution became uniform, and keyhole area was enlarged. In addition, the flow velocity of molten pool was increased, the vorticity of molten pool was improved, and the flow region of liquid metal was enlarged. Experimental results showed that penetration of molten pool was deeper, the shape of welding pool tended to be symmetrical, and the density of Al element distribution in welding pool was increased by magnetic field. Thus, heat and mass transfer in welding pool was promoted due to the application of magnetic field, the elements exchange and the convection of liquid metal were accelerated, and the distribution of Mg-Al compounds should be dispersed under the agitation of Lorentz force. It is predicted that the distribution of Mg-Al compounds in magnesium/aluminum laser welding would be positively affected by magnetic field, which was beneficial to control the weld quality. Hence, numerical results and experimental verification shared good consistency.

Similar content being viewed by others

References

Liu LM, Wang HY, Zhang ZD (2007) The analysis of laser weld bonding of Al alloy to Mg alloy. Scr Mater 56:473–476. https://doi.org/10.1016/j.scriptamat.2006.11.034

Liu LM, Wang HY (2009) The effect of the adhesive on the microcracks in the laser welded bonding Mg to Al joint. Mater Sci Eng A 507:22–28. https://doi.org/10.1016/j.msea.2008.11.061

Chang WS, Rajesh SR, Chun CK, Kim HJ (2011) Microstructure and mechanical properties of hybrid laser-friction stir welding between AA6061-T6 Al alloy and AZ31 Mg alloy. J Mater Sci Technol 27:199–204. https://doi.org/10.1016/S1005-0302(11)60049-2

Gao M, Mei S, Li X, Zeng X (2012) Characterization and formation mechanism of laser-welded Mg and Al alloys using Ti interlayer. Scr Mater 67:193–196. https://doi.org/10.1016/j.scriptamat.2012.04.015

Tse H, Man H, Yue T (1999) Effect of magnetic field on plasma control during CO2 laser welding. Opt Laser Technol 31:363–368. https://doi.org/10.1016/S0030-3992(99)00080-8

Chen R, Jiang P, Shao X, Mi G, Wang C (2018) Enhancement of fatigue resistance for 316L welds produced by magnetic field assisted laser-MIG hybrid welding. J Mater Process Technol 254:114–123. https://doi.org/10.1016/j.jmatprotec.2017.11.030

Yan F, Wang X, Chai F, Ma H, Tian L, Du X, Wang C, Wang W (2019) Improvement of microstructure and performance for steel/Al welds produced by magnetic field assisted laser welding. Opt Laser Technol 113:164–170. https://doi.org/10.1016/j.optlastec.2018.12.030

Chen X, Luo M, Hu R, Li R, Liang L, Pang S (2019) Thermo-electromagnetic effect on weld microstructure in magnetically assisted laser welding of austenite steel. J Manuf Process 41:111–118. https://doi.org/10.1016/j.jmapro.2019.03.033

Qi Y, Chen G, Deng S, Zhou D (2019) Periodic root humps in thick-plate laser welding using steady electromagnetic force. J Mater Process Technol 273:116247. https://doi.org/10.1016/j.jmatprotec.2019.05.028

Zhu Z, Ma X, Wang C, Mi G (2020) Altering morphological, crystalline and compositional features in 316 L laser-MIG weldments with an external magnetic field. Mater Des 196:109156. https://doi.org/10.1016/j.matdes.2020.109156

Xu L, Tang X, Zhang R, Lu F, Cui H (2021) Weld bead characteristics for full-penetration laser welding of aluminum alloy under electromagnetic field support. J Mater Process Technol 288:116896. https://doi.org/10.1016/j.jmatprotec.2020.116896

Üstündağ Ö, Bakir N, Gumenyuk A, Rethmeier M (2021) Influence of oscillating magnetic field on the keyhole stability in deep penetration laser beam welding. Opt Laser Technol 135:106715. https://doi.org/10.1016/j.optlastec.2020.106715

Li J, Liu Y, Kang K, Sun Q, Jin P, Liu Y, Cai C, Sun Q (2021) A novel approach to regulate energy allocation and melt flow in narrow gap laser welding with electromagnetic assisted wire wobbling. J Mater Process Technol 289:116909. https://doi.org/10.1016/j.jmatprotec.2020.116909

Cao L, Zhou Q, Liu H, Li J, Wang S (2020) Mechanism investigation of the influence of the magnetic field on the molten pool behavior during laser welding of aluminum alloy. Int J Heat Mass Transf 162:120390. https://doi.org/10.1016/j.ijheatmasstransfer.2020.120390

Liu F, Tan C, Wu L, Gong X, Chen B, Song X, Zhao H, Wang G (2020) Influence of waveforms on Laser-MIG hybrid welding characteristics of 5052 aluminum alloy assisted by magnetic field. Opt Laser Technol 132:106508. https://doi.org/10.1016/j.optlastec.2020.106508

Chen R, Kong HJ, Luan JH, Wang AD, Jiang P, Liu CT (2020) Effect of external applied magnetic field on microstructures and mechanical properties of laser welding joint of medium-Mn nanostructured steel. Mater Sci Eng A 792:139787. https://doi.org/10.1016/j.msea.2020.139787

Gatzen M, Tang Z (2010) CFD-based model for melt flow in laser beam welding of aluminium with coaxial magnetic field. Phys Procedia 5:317–326

Bachmann M, Avilov V, Gumenyuk A, Rethmeier M (2013) About the influence of a steady magnetic field on weld pool dynamics in partial penetration high power laser beam welding of thick aluminium parts. Int J Heat Mass Transf 60:309–321. https://doi.org/10.1016/j.ijheatmasstransfer.2013.01.015

Bachmann M, Avilov V, Gumenyuk A, Rethmeier M (2016) Numerical assessment and experimental verification of the influence of the Hartmann effect in laser beam welding processes by steady magnetic fields. Int J Therm Sci 101:24–34. https://doi.org/10.1016/j.ijthermalsci.2015.10.030

Rong Y, Huang Y, Xu J, Zheng H, Zhang G (2017) Numerical simulation and experiment analysis of angular distortion and residual stress in hybrid laser-magnetic welding. J Mater Process Technol 245:270–277. https://doi.org/10.1016/j.jmatprotec.2017.02.031

Chen J, Wei Y, Zhan X, Gu C, Zhao X (2018) Thermoelectric currents and thermoelectric-magnetic effects in full-penetration laser beam welding of aluminum alloy with magnetic field support. Int J Heat Mass Transf 127:332–344. https://doi.org/10.1016/j.ijheatmasstransfer.2018.08.004

Fuhrich T, Berger P, Hügel H (2001) Marangoni effect in laser deep penetration welding of steel. J Laser Appl 13:178–186. https://doi.org/10.2351/1.1404412

Mills KC, Keene BJ, Brooks RF, Shirali A (1998) Marangoni effects in welding. Philos Trans R Soc A Math Phys Eng Sci 356:911–925. https://doi.org/10.1098/rsta.1998.0196

Zhang X, Zhao Z, Mi G, Wang C, Li R, Hu X (2017) Effect of external longitudinal magnetic field on arc plasma characteristics and droplet transfer during laser-MIG hybrid welding. Int J Adv Manuf Technol 92:2185–2195. https://doi.org/10.1007/s00170-017-0293-2

Wang Z, Oliveira JP, Zeng Z, Bu X, Peng B, Shao X (2019) Laser beam oscillating welding of 5A06 aluminum alloys: microstructure, porosity and mechanical properties. Opt Laser Technol 111:58–65. https://doi.org/10.1016/j.optlastec.2018.09.036

Wang H, Xu Y, Zheng H, Zhou W, Ren N, Ren X, Li T (2019) Monitoring and analysis of millisecond laser drilling process and performance with and without longitudinal magnetic assistance and/or assist gas. J Manuf Process 48:297–312. https://doi.org/10.1016/j.jmapro.2019.10.015

Huang L, Liu P, Zhu S, Hua X, Dong S (2020) Experimental research on formation mechanism of porosity in magnetic field assisted laser welding of steel. J Manuf Process 50:596–602. https://doi.org/10.1016/j.jmapro.2020.01.007

Availability of data and material

All data generated or analyzed during this study are included in the manuscript.

Code availability

Not applicable.

Funding

The authors received financial support from the National Key Research and Development Project of China (No. 2018YFB1107905) and the National Natural Science Foundation of China (51674112).

Author information

Authors and Affiliations

Contributions

Jiafu Zhou: Data curation, writing-original draft, software, visualization, investigation

Dianwu Zhou: Conceptualization, methodology, writing-review and editing

Jinshui Liu: Supervision

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable. The article involves no studies on humans.

Consent for publication

Not applicable. The article involves no studies on humans.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhou, J., Zhou, D. & Liu, J. Numerical and experimental investigation of magnesium/aluminum laser welding with magnetic field. Int J Adv Manuf Technol 116, 545–559 (2021). https://doi.org/10.1007/s00170-021-07483-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07483-8