Abstract

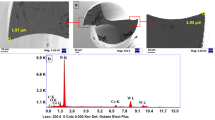

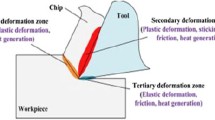

Owing to the increasing demand in ultra-precision machining of biocompatible materials, the demand to improve the performance of cutting processes and tools becomes progressively important. To increase the performance of the micro-tools leading to longer tool life and better surface finish, applications of solid lubricant coatings are necessary. Diamond-like carbon (DLC) coatings have been successfully used in many conventional cutting tools. In this study, the performance of the DLC coating in tungsten carbide micro-mills will be evaluated during the ultra-precision machining of a biocompatible material, namely, tantalum (99%). Experiments were carried out on the sliding pin-on-disk test and micro-machining both coated and uncoated. As expected, the DLC film deposited reduces both the friction coefficient and the wear. The results of the tests showed that the coated tools have less wear, evidenced by the distance 130% greater than the uncoated tools. Consequently, it also induces a reduction in the specific cutting forces (kS) and critical chip thickness. Thus, a better accuracy and surface finish on tantalum biocompatible parts can be reached.

Similar content being viewed by others

References

Lauro CH, Ribeiro-Filho S, Brandão L, Davim J (2016) Analysis of behaviour biocompatible titanium alloy (Ti-6Al-7Nb) in the micro-cutting. Measurement 93:529–540. https://doi.org/10.1016/j.measurement.2016.07.059

Ng CK, Melkote SN, Rahman M, Kumar AS (2006) Experimental study of micro- and nano-scale cutting of aluminum 7075–T6. Int J Mach Tools Manuf 46:929–936. https://doi.org/10.1016/j.ijmachtools.2005.08.004

Câmara M, Rubio JC, Abrao A, Davim J (2012) State of the art on micromilling of materials, a review. J Mater Sci Technol 28(8):673–685. https://doi.org/10.1016/S1005-0302(12)60115-7

Balázs BZ, Takács M (2020. (in-press)) Experimental investigation and optimisation of the micro-milling process of hardened hot-work tool steel. Int J Adv Manuf Technol. https://doi.org/10.1007/s00170-020-04991-x.

Câmara M, Abrão A, Campos Rubio J, Godoy GC, Cordeiro B (2016) Determination of the critical undeformed chip thickness in micromilling by means of the acoustic emission signal. Precis Eng 46:377–382. https://doi.org/10.1016/j.precisioneng.2016.06.007

Son SM, Lim HS, Ahn JH (2015) Effects of the friction coefficient on the minimum cutting thickness in micro cutting. Int J Mach Tools Manuf 45(4-5):529–535. https://doi.org/10.1016/j.ijmachtools.2004.09.001

Liu Z, Shi Z, Wan Y (2013) Definition and determination of the minimum uncut chip thickness of microcutting. Int J Adv Manuf Technol 69(5-8):1219–1232. https://doi.org/10.1007/s00170-013-5109-4

Aramcharoen A, Mativenga PT (2009) Size effect and tool geometry in micromilling of tool steel. Precis Eng 33:402–407. https://doi.org/10.1016/j.precisioneng.2008.11.002

Fassi I, Shipley D (2017) Micro-Manufacturing Technologies and Their Applications: A Theoretical and Practical Guide. Part of the Springer Tracts in Mechanical Engineering book series (STME). Springer International Publishing, Switzerland. https://doi.org/10.1007/978-3-319-39651-4

Kim Y, Kim E-P, Noh J-W, Lee SH, Kwon Y-S, Ohc IS (2015) Fabrication and mechanical properties of powder metallurgy tantalum prepared by hot isostatic pressing. Int J Refract Met Hard Mater 48:211–216. https://doi.org/10.1016/j.ijrmhm.2014.09.012

Marinelli G, Martina F, Ganguly S, Williams S (2019) Microstructure, hardness and mechanical properties of two different unalloyed tantalum wires deposited via wire + arc additive manufacture. Int J Refract Met Hard Mater 83:104974. https://doi.org/10.1016/j.ijrmhm.2019.10497

Levin ZS, Wang X, Kaynak M, Karaman I, Hartwig KT (2019) Strength and ductility of powder consolidated ultrafine-grain tantalum. Int J Refract Met Hard Mater 80:73–84. https://doi.org/10.1016/j.ijrmhm.2018.12.017

Guasca Gonzalez AG, Leite WO, Mata Cabrera F, Santos AJ, Campos Rubio JC (2020) Micro-machining of a bio-compatible material for prosthesis production: 99.9% purity tantalum. Dyna 95:81–86. https://doi.org/10.6036/9158

Wu T, Cheng K (2013) Micro-milling performance assessment of diamond-like carbon coatings on a micro-end mill. Proceed Instit Mechan Eng Part J; J Eng Tribol 227(9):1038–1046. https://doi.org/10.1177/1350650112474123

Aramcharoen A, Mativenga PT, Yang S, Cooke KE, Teer DG (2008) Evaluation and selection of hard coatings for micro-milling of hardened tool steel. Int J Mach Tools Manuf 48(14):1578–1584. https://doi.org/10.1016/j.ijmachtools.2008.05.011

Imbeni V, Martini C, Lanzoni E, Poli G, Hutchings IM (2001) Tribological behaviour of multi-layered PVD nitride coatings. Wear 251:997–1002. https://doi.org/10.1016/S0043-1648(01)00706-2

Yuan W, Li L, Lee W et al (2018) Fabrication of microlens array and its application: a review. Chin J Mech Eng 31:16. https://doi.org/10.1186/s10033-018-0204-y

Baker PA, Thompson RG, Catledge SA (2016) A wear simulation study of nanostructured CVD diamond-on-diamond articulation involving concave/convex mating surfaces. J Coat Technol Res 13:385–393. https://doi.org/10.1007/s11998-015-9738-4

Kou Z, Wan Y, Cai Y, Liang X, Liu Z (2015) Burr Controlling in micro-milling with supporting material method. Proc Manuf V1:501–511. https://doi.org/10.1016/j.promfg.2015.09.015

Kou Z, Wan Y, Cai Y, Liang X, Liu Z (2015) Deformation control in micro-milling of thin-walled structures. Int J Adv Manuf Technol 81:967–974. https://doi.org/10.1007/s00170-015-7258-0

Kalpakjian S, Schimd SR (2014) Manufacturing engineering and technology, 7th edn. Prentice Hall, New Jersey ISBN 9789810694067

Aramcharoen A, Mativenga PT (2009) Size effect and tool geometry in micromilling of tool steel. Precis Eng 36:402–407. https://doi.org/10.1016/j.precisioneng.2008.11.002

ASTM (2005) G99-05, Standard test method for wear testing with a pin-on-disk apparatus. ASTM International, West Conshohocken. https://doi.org/10.1520/G0099-05

Wang C, Guo B, Shan D, Bai X (2013) Tribological behaviors of DLC film deposited on female die used in strip drawing. J Mater Process Technol 213(3):323–329. https://doi.org/10.1016/j.jmatprotec.2012.10.011

Saavides N, Bell TJ (1993) Hardness and elastic modulus of diamond -like carbon films. Thin Solid Films 228:289–292. https://doi.org/10.1016/0040-6090(93)90618-Y

ASTM C1624-05 (2015) Standard test method for adhesion strength and mechanical failure modes of ceramic coatings by quantitative single point scratch testing. ASTM International, West Conshohocken. https://doi.org/10.1520/C1624-05R15

Ribeiro RA (2006) Tribological and biomimetics study of potential bone joint repair materials. Ph D Thesis. Texas A&M University, College Station

Wang ZY, Rajurkar KP, Fan J, Petrescu G (2002) Cryogenic machining of tantalum. J Manuf Process 4(2):122–127. https://doi.org/10.1016/S1526-6125(02)70138-2

Availability of data and materials

The authors confirm that the data supporting the findings of this study are available within the article.

Funding

This work was partly financed by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (CAPES)–Finance Code 001, and the Organization of American States (OEA), which are the suppliers of the Ph. D. scholarship. Also, it must be acknowledged the financial support of the CNPq and FAPEMIG. Likewise, the authors would like to thank the ATI Specialty Alloys Components for providing the tantalum piece.

Author information

Authors and Affiliations

Contributions

Professor Juan Carlos Campos Rubio is the leader of the research team. David Jonhson Barcelos performed the film thickness experiments, the Raman scattering spectroscopy, and the scratch test, and Marcelo Araújo Câmara helped to analyze the data. Andrés Guasca González performed the pin-on-disk test and micro-milling test, and Juan Carlos Campos Rubio helped to analyze the data. Wanderson Leite and Francisco Mata wrote, edited, and reviewed the paper.

Corresponding author

Ethics declarations

Ethical approval

All authors have previously approved this paper and judged that there is no ethical infringement.

Consent to participate and publish

All authors would like to declare that they have approved their participation and consent about the publication in this journal.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Campos Rubio, J.C., Guasca González, A.G., Barcelos, D.J. et al. Tribological analysis and performance of a DLC coating on tungsten carbide micro-tools to use at tantalum precision machining. Int J Adv Manuf Technol 116, 719–732 (2021). https://doi.org/10.1007/s00170-021-07371-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07371-1